Patents

Literature

30results about How to "Extend brake life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

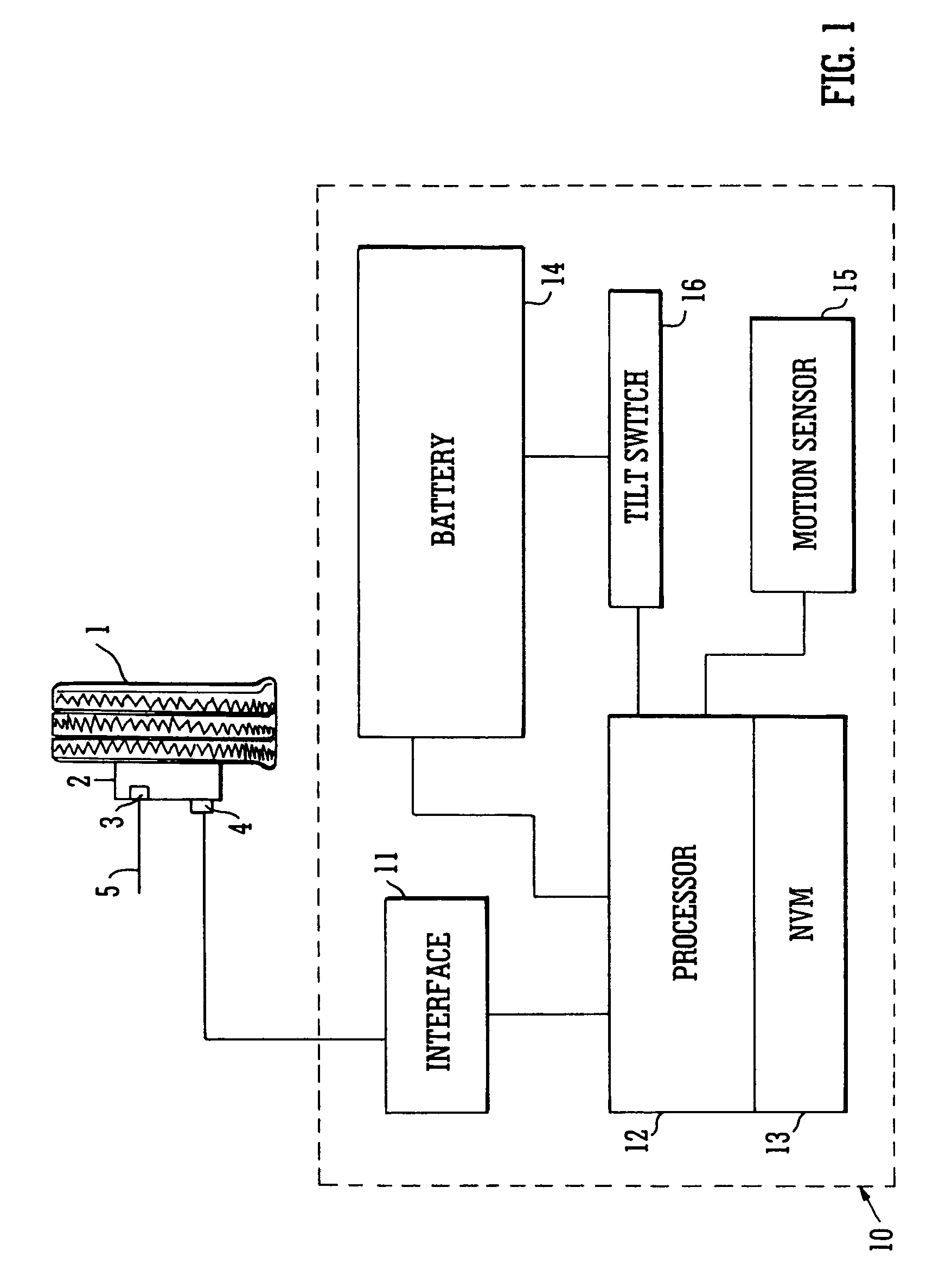

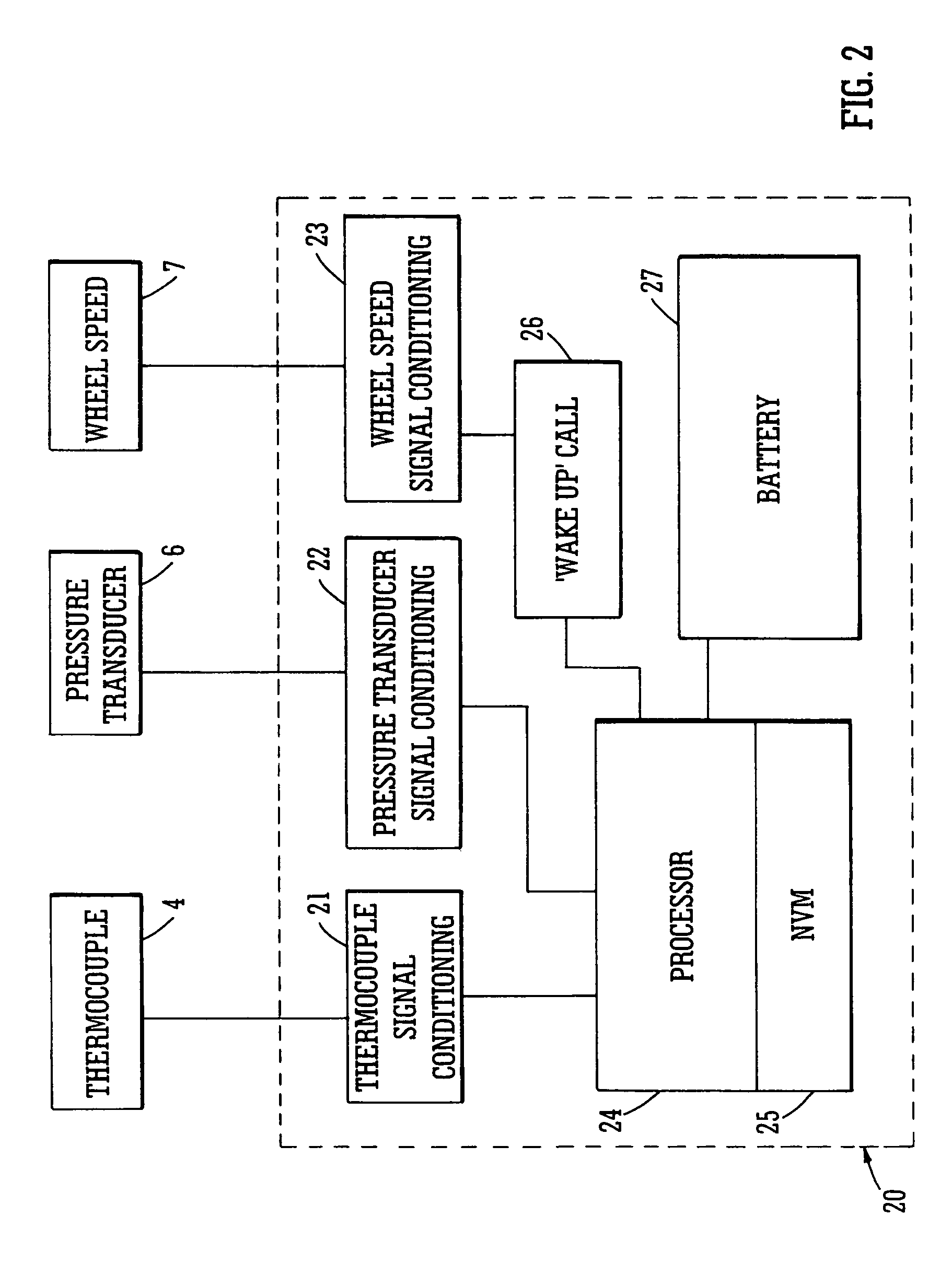

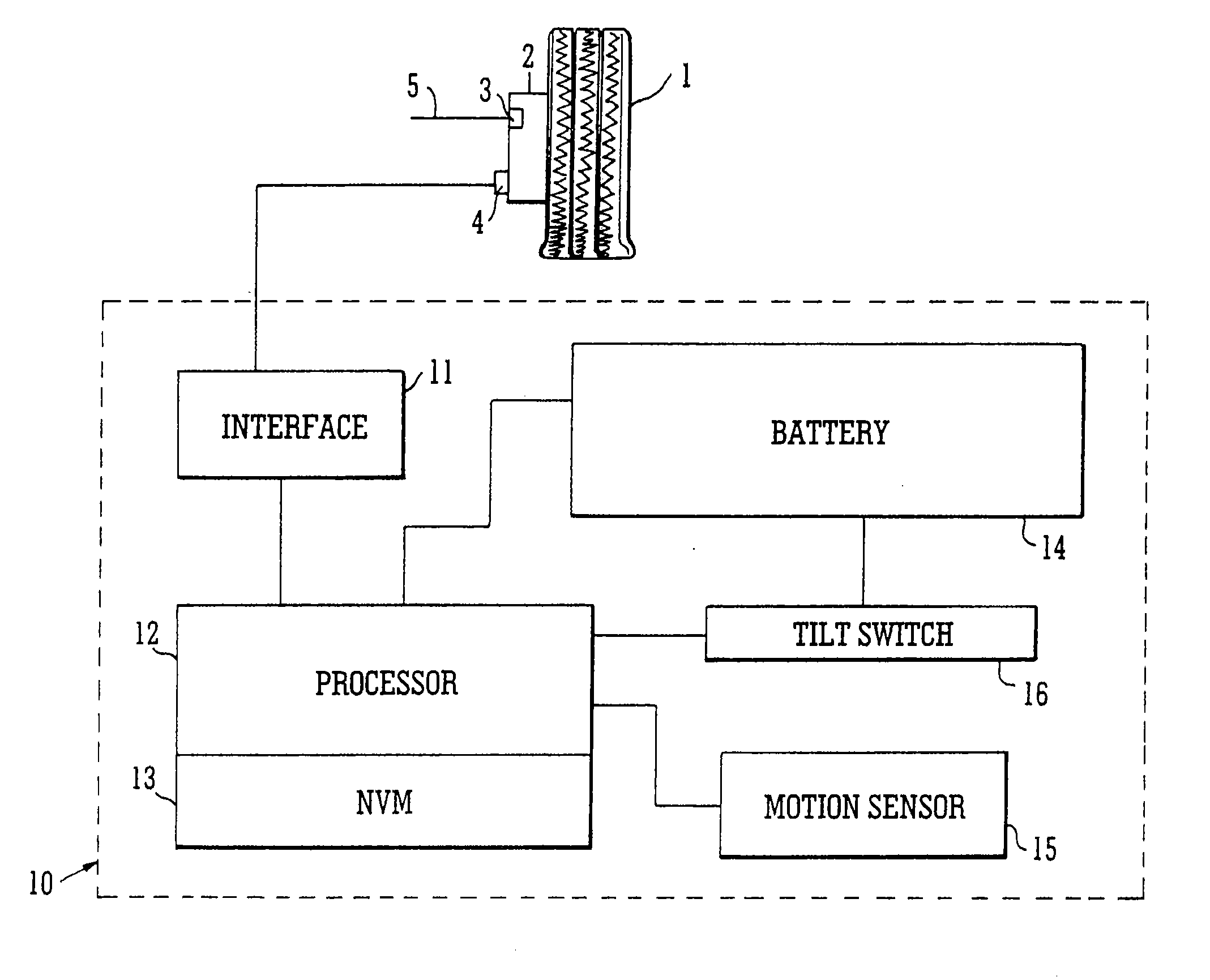

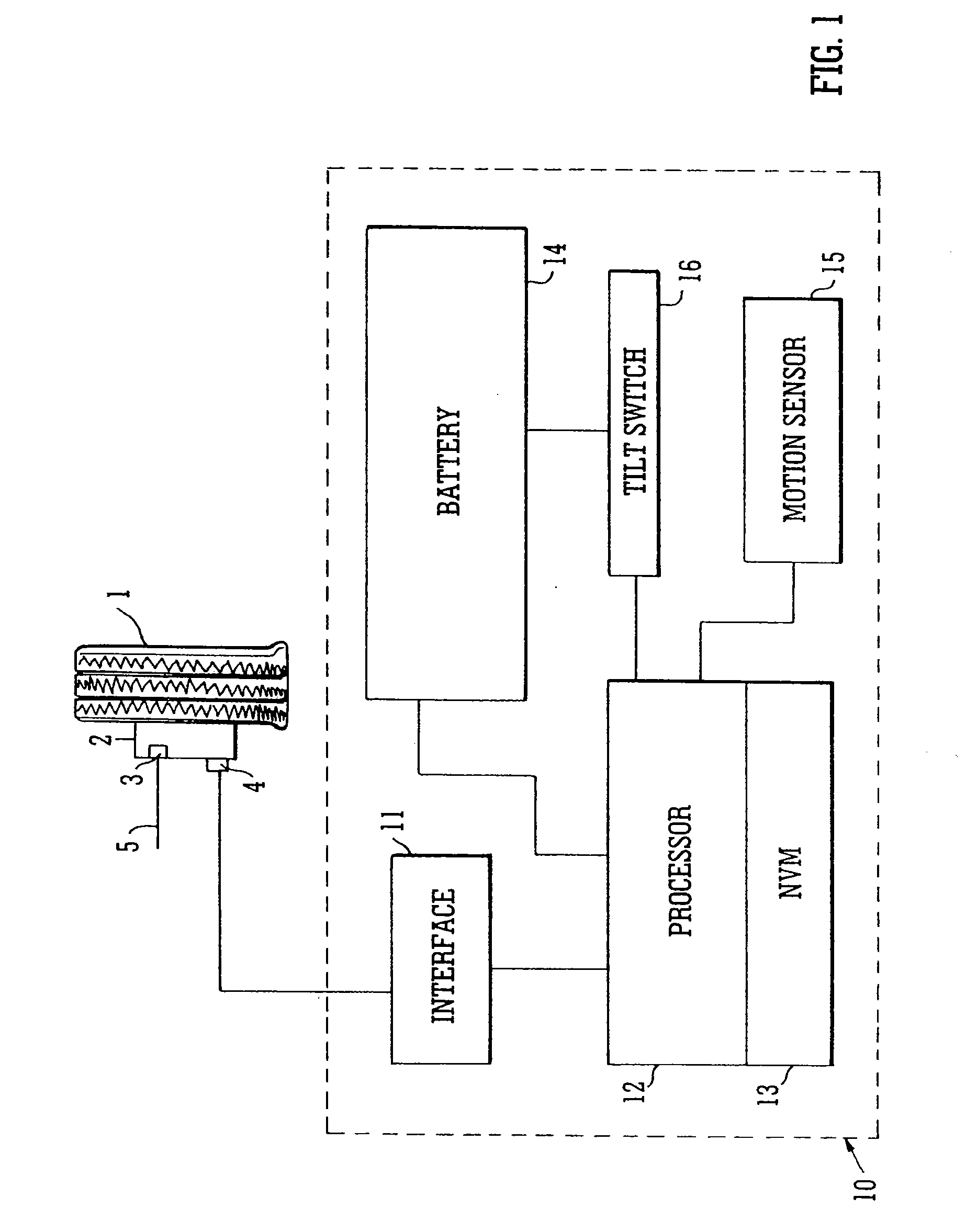

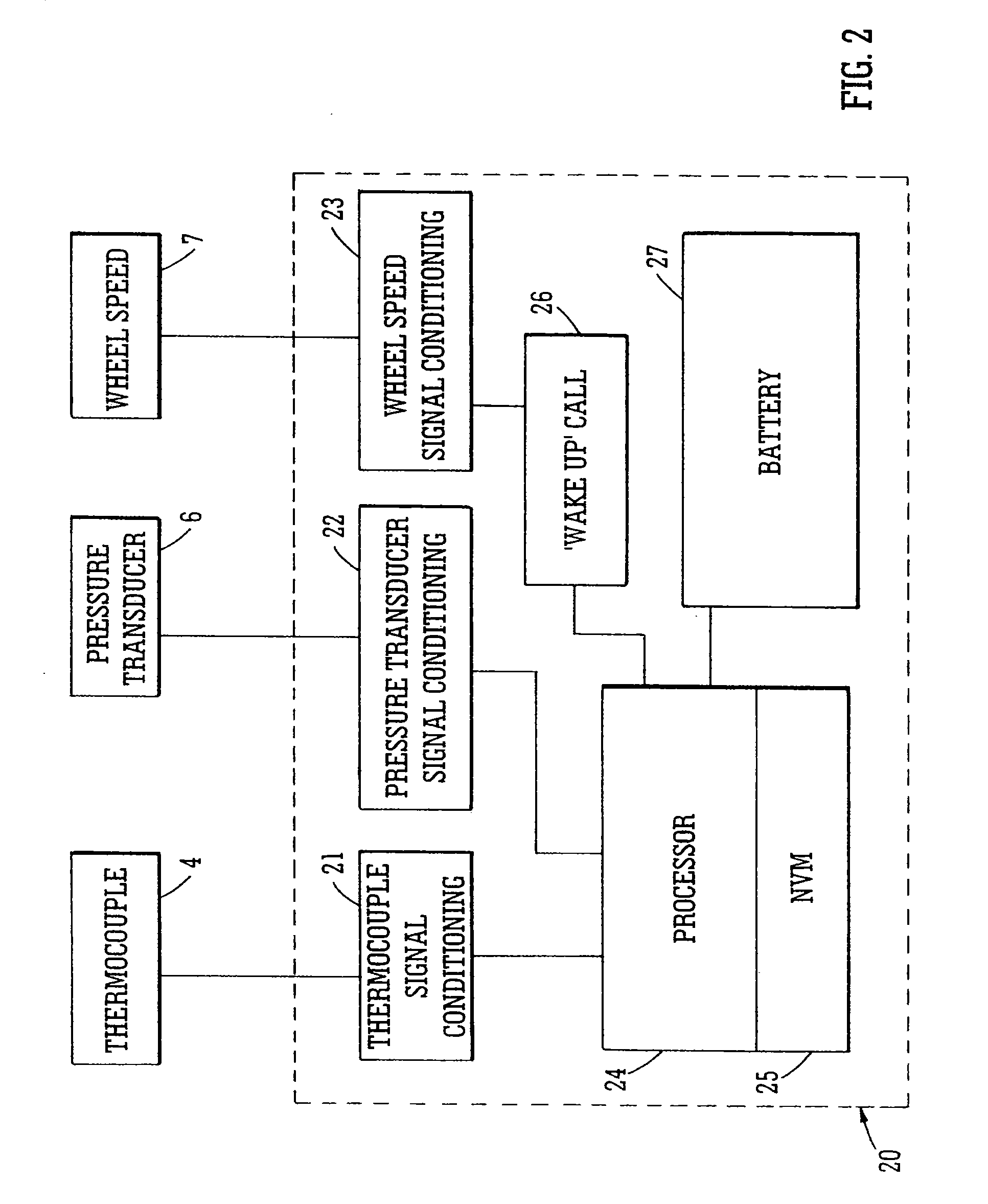

Brake condition monitoring

InactiveUS7086503B2Less-rapid decelerationBrake fluid pressure increaseFinanceAircraft braking arrangementsRelative motionBraking system

System and method for monitoring the applications of the brakes, e.g. of an aircraft to determine brake condition and operate a brake maintenance programme or charge a brake system user. It is desirable to have accurate information for determining the condition and predicting the life of carbon-carbon brake discs. This is important for safety as well as commercial reasons. The number of landings of an aircraft is often used as a determinant for such as lifetime warranties for brake discs and recommended maintenance periods. However, at least for carbon disc brakes, this may not be entirely accurate. For example such brake discs also wear during taxiing. The system and method herein includes monitoring each actuation of the brakes and making a separate record of each actuation of the brakes in which there is relative movement of the facing friction surfaces that cause wear, and from that separate record determining brake usage. The monitoring may include measuring changes and processing the signals to distinguish between those which fall below and those which are above a threshold value. Herein there is also described, a method and apparatus for monitoring a braking system comprising sensing a plurality of braking parameters having values dependent upon wear in the system and different faults of the system, and identifying and recording wear and faults based on combinations of values of said parameters.

Owner:MEGGITT AEROSPACE

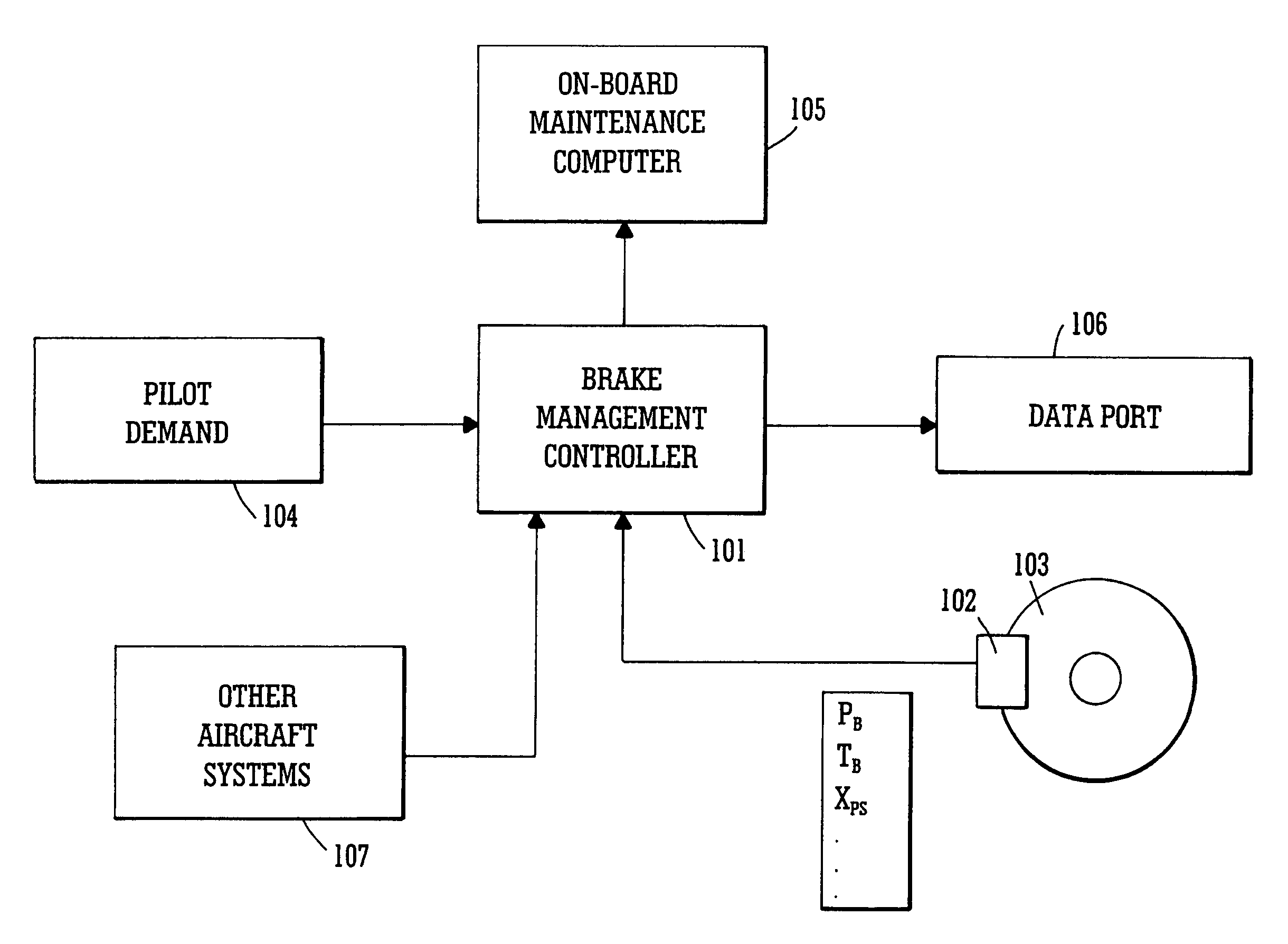

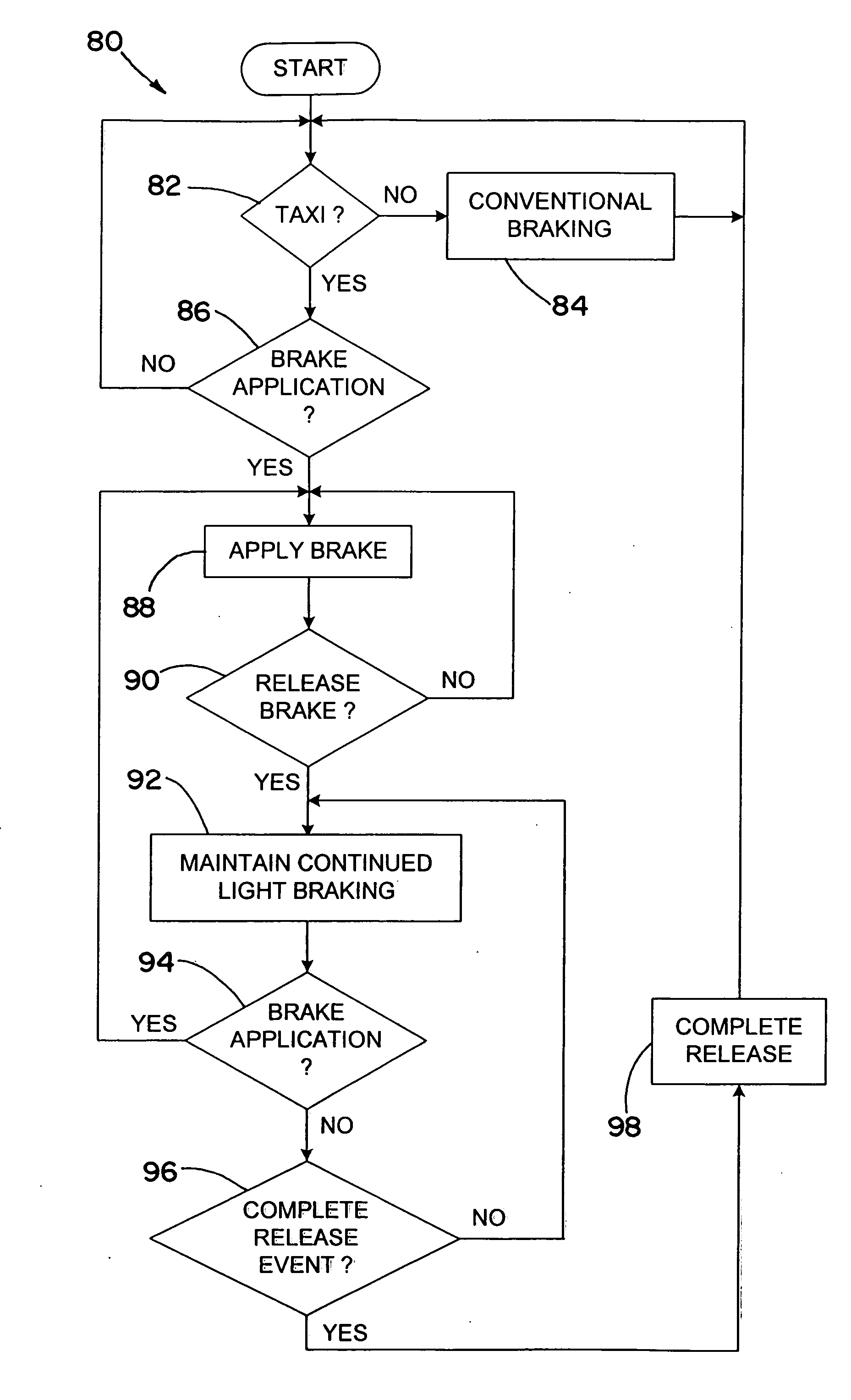

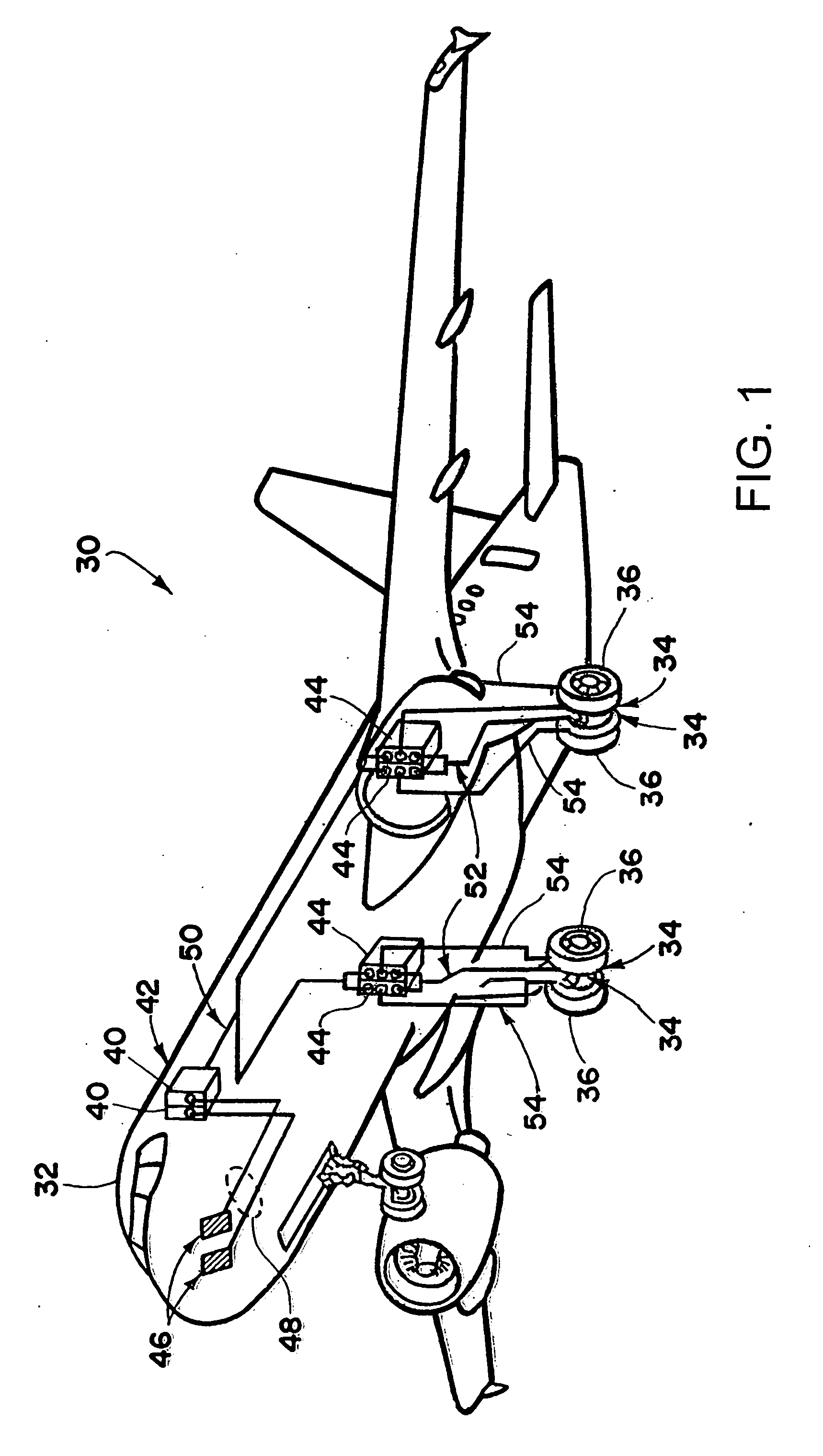

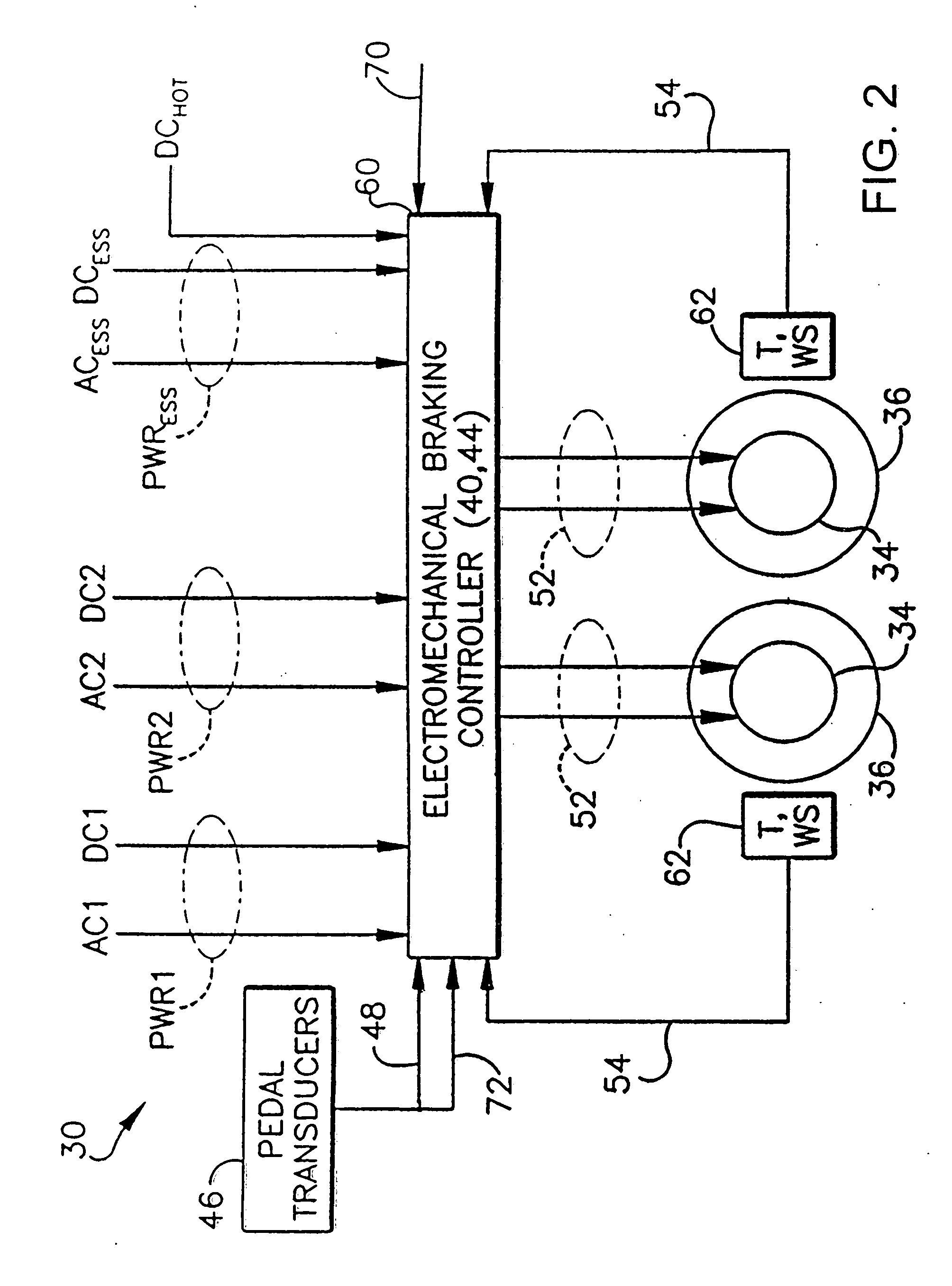

Aircraft taxi speed control system and method

InactiveUS20060226698A1Improved passenger comfortLong brake wear lifeBraking action transmissionElectrodynamic brake systemsBrake torqueElectricity

An aircraft brake control system for controlling operation of a plurality of carbon brakes is provided. Each brake includes at least one brake actuator that is responsive to an electrical drive control signal for applying squeeze force to a brake disk stack for effecting a braking torque on a wheel of a vehicle. The control system includes a controller for providing electrical drive control signals to one or more of the brake actuators in response to an input brake command signal from a pilot to effect application of squeeze force to the brake disk stack to effect a braking operation. The brake controller is configured for taxi mode operation during aircraft taxiing to provide electrical drive control signals to one or more of the brake actuators that cause some or all of the brake actuators to provide continued light braking during taxiing even when the controller is not commanded by the input brake command signal from the pilot to effect a braking operation.

Owner:THE BF GOODRICH CO

Brake condition monitoring

InactiveUS20060191751A1Accurate supplyPrecise maintenanceFinanceAircraft braking arrangementsPaymentFlight vehicle

A system and method for monitoring the usage of brake members of an aircraft braking system. The system makes a separate record of each brake actuation in which there is relative movement of the brake member's facing friction surfaces which causes wear, determines the types of brake usage and operates a pricing / payment scheme to charge for brake usage.

Owner:MEGGITT AEROSPACE

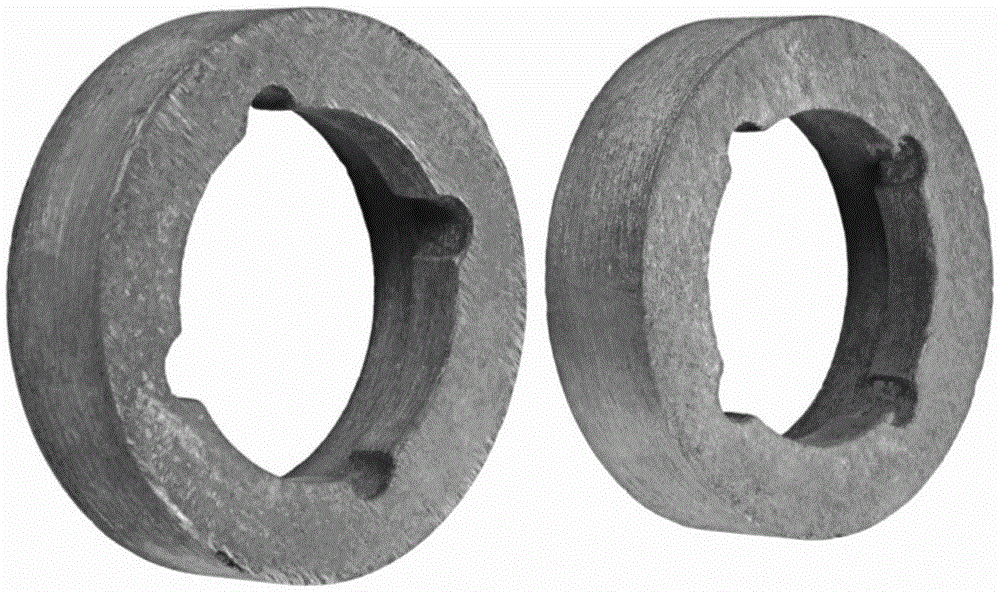

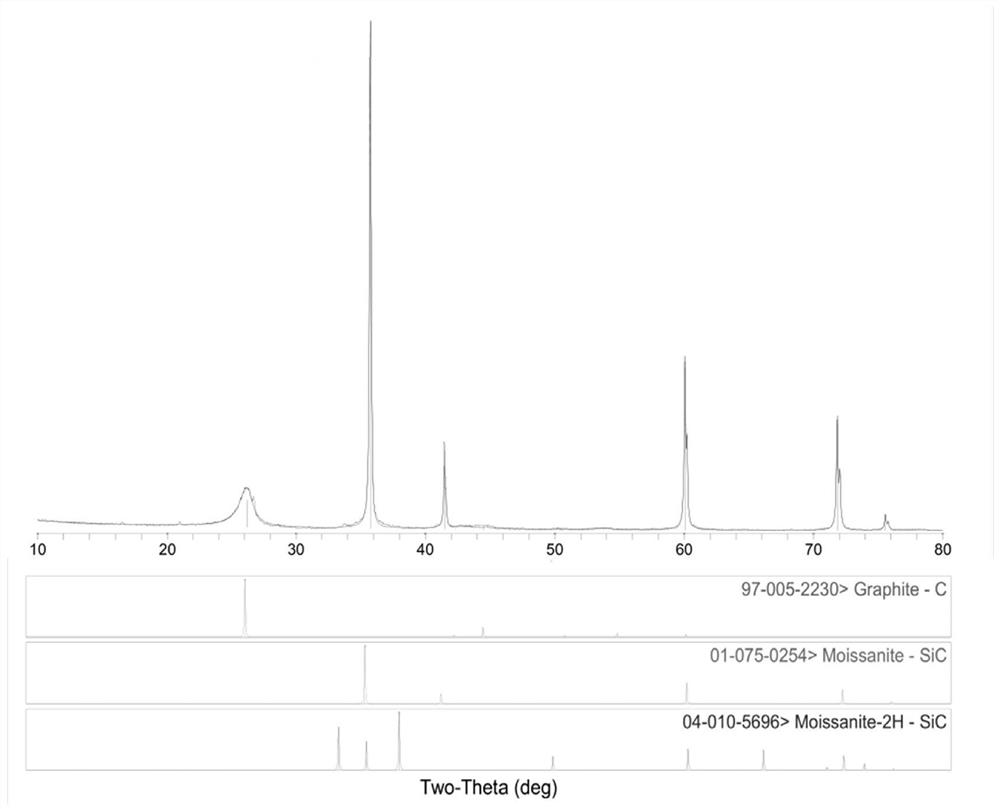

Preparation method and application of carbon/ceramic composite material

ActiveCN105565837AThere is no problem of large distribution gradientReduce wearBraking discsActuatorsCeramic compositeMetallurgy

The invention relates to a preparation method and application of a carbon / ceramic composite material, in particular to a preparation method and application of a carbon / ceramic composite material needed for braking a high-momentum delivery system. The preparation method includes: using a C / C composite material of 1.2-1.5 g / cm3 in density as a raw material; disposing the raw material in impregnation liquid I for impregnation, pyrolyzing in a protective atmosphere after impregnation, repeating impregnating-pyrolyzing operations until a carbon / ceramic composite material of 1.85-1.9 g / cm3 in density is obtained; treating the carbon / ceramic composite material obtained at high temperature until density of the carbon / ceramic composite material is lowered to 1.82-1.88 g / cm3 to obtain a pre-finished product; disposing the pre-finished product in impregnation liquid II, decomposing in a protective atmosphere after impregnation is completed, polishing after decomposing, and repeating impregnating-decomposing-polishing operations until a carbon / ceramic composite material finished product of 1.93-2.0 g / cm3 is obtained.

Owner:HUNAN BOWANG CARBON CERAMIC CO LTD

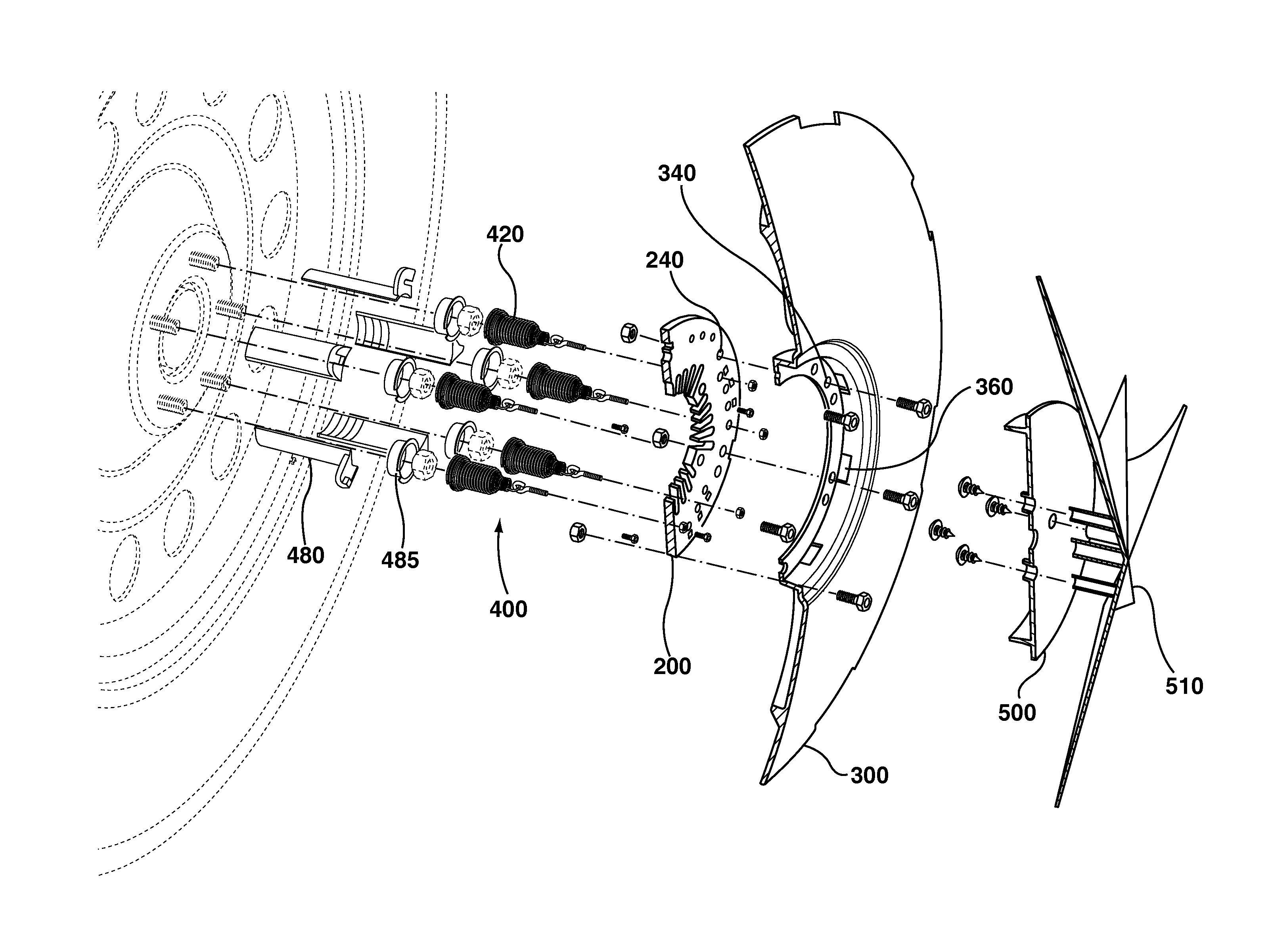

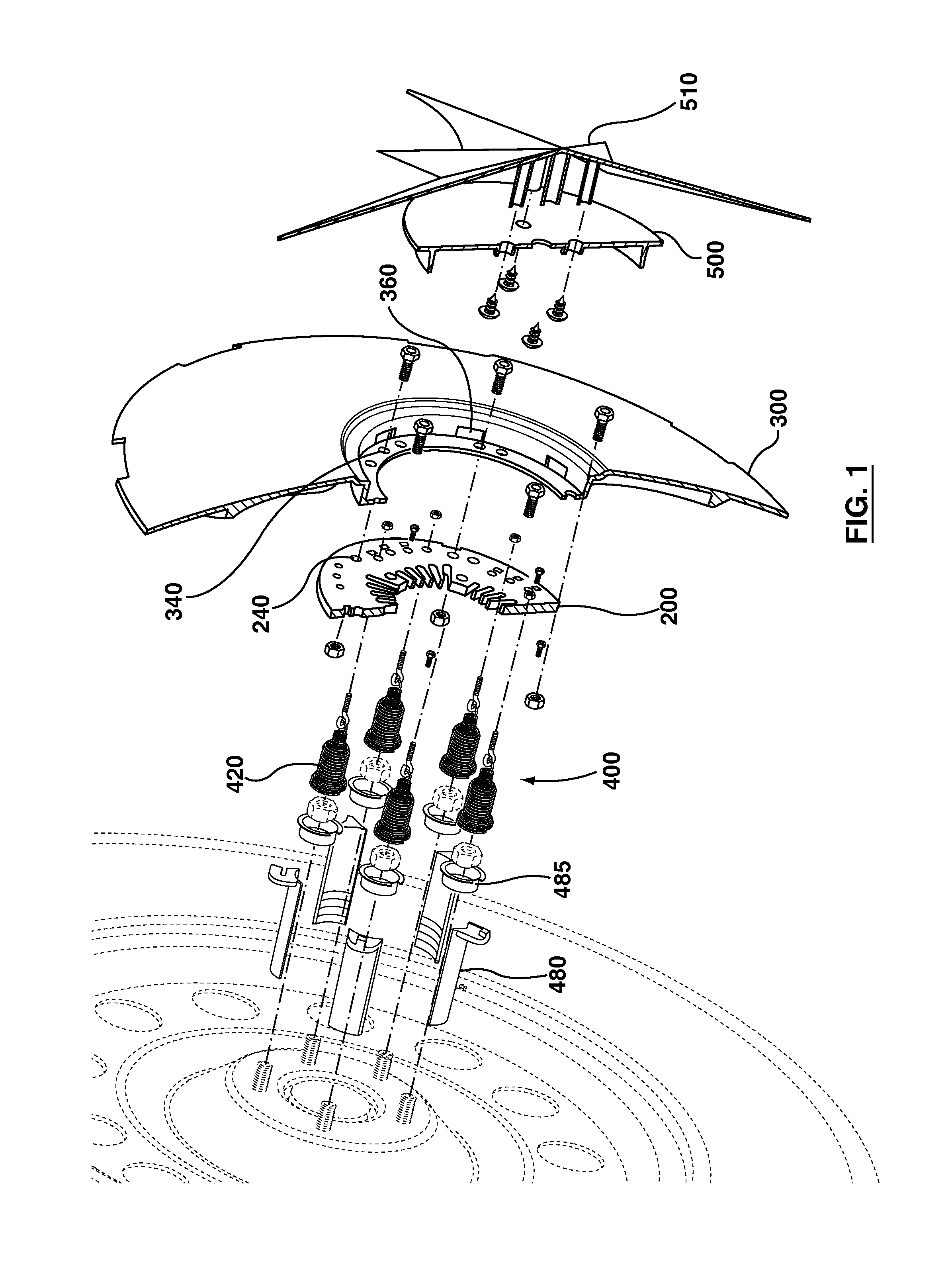

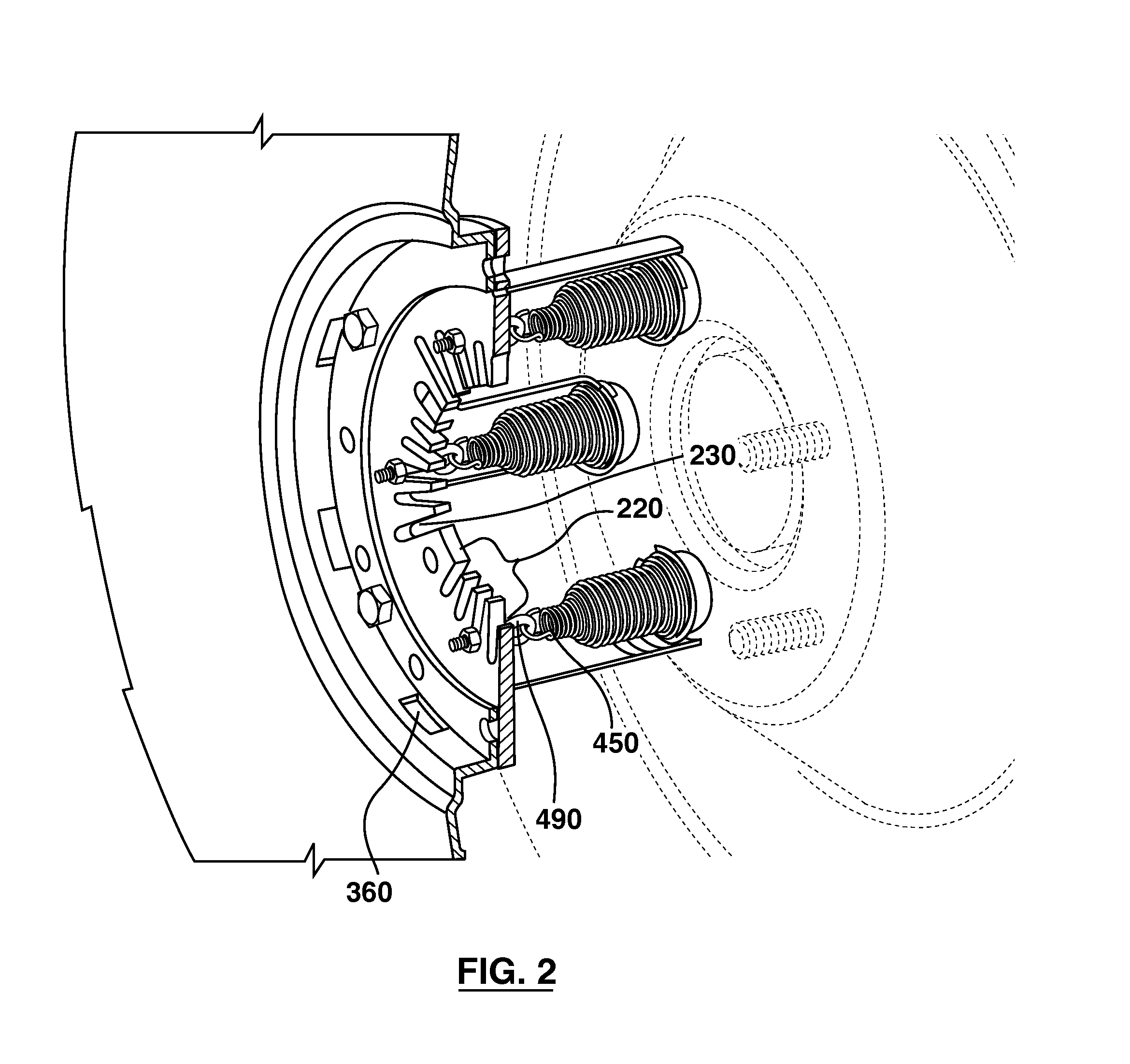

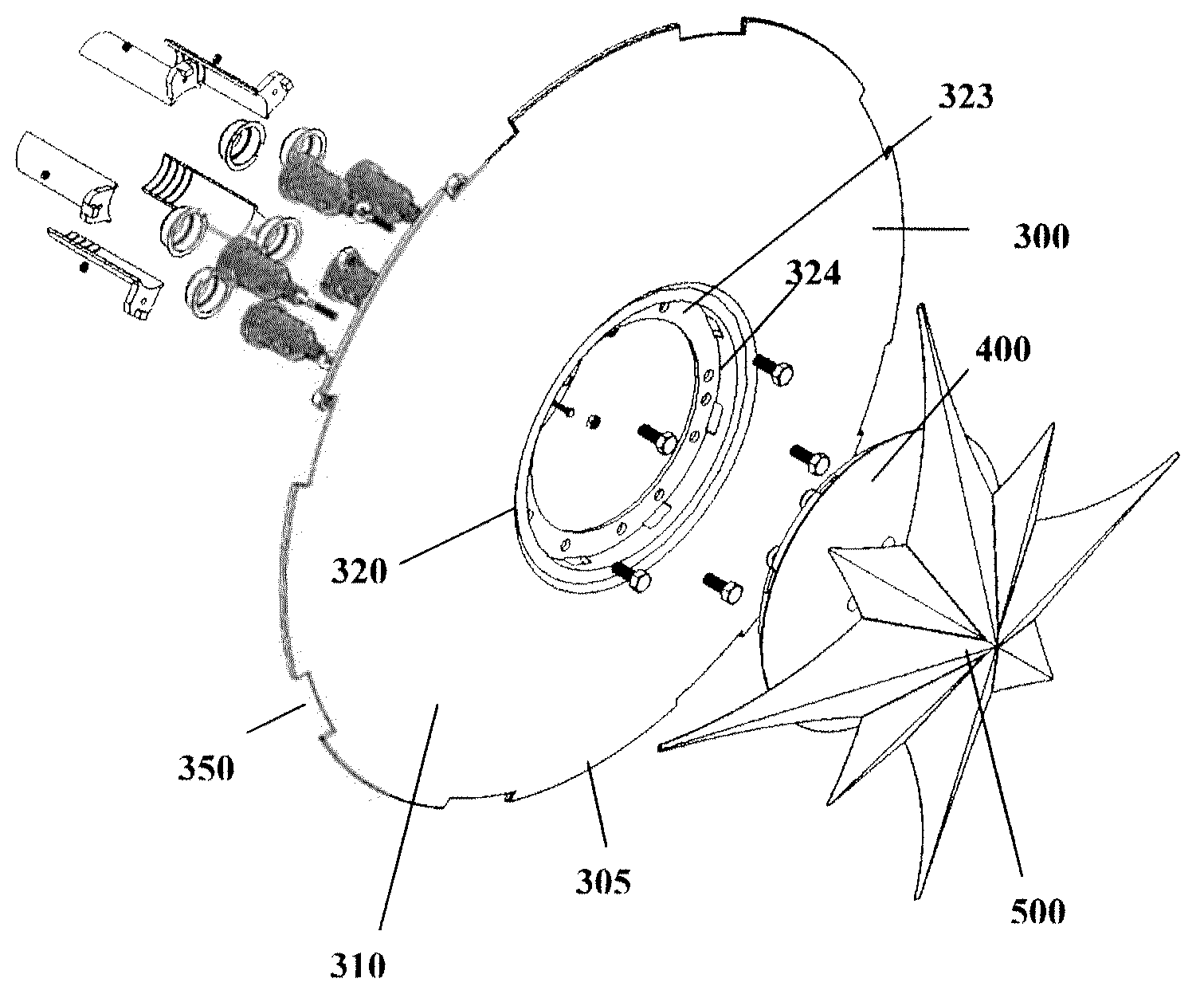

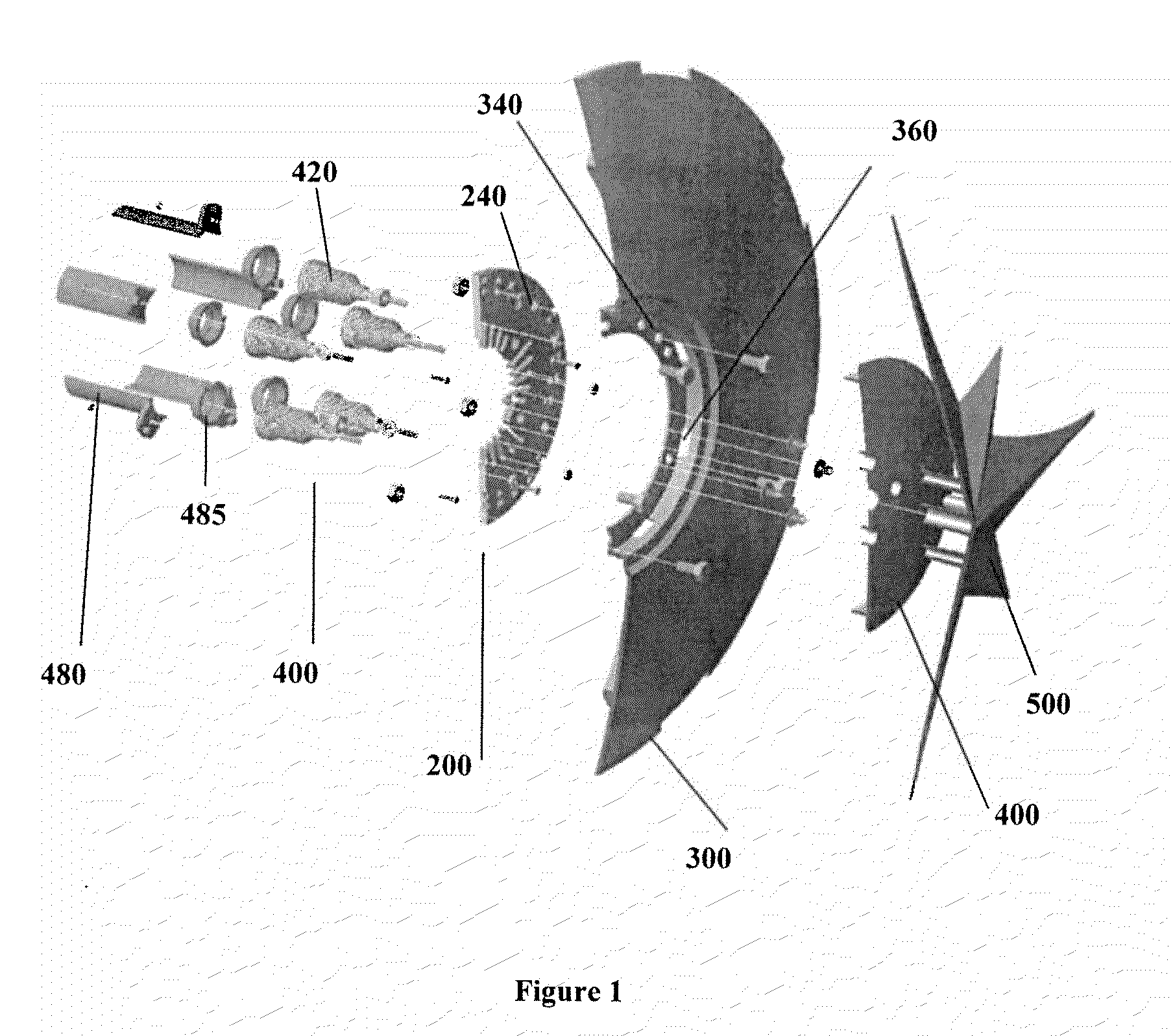

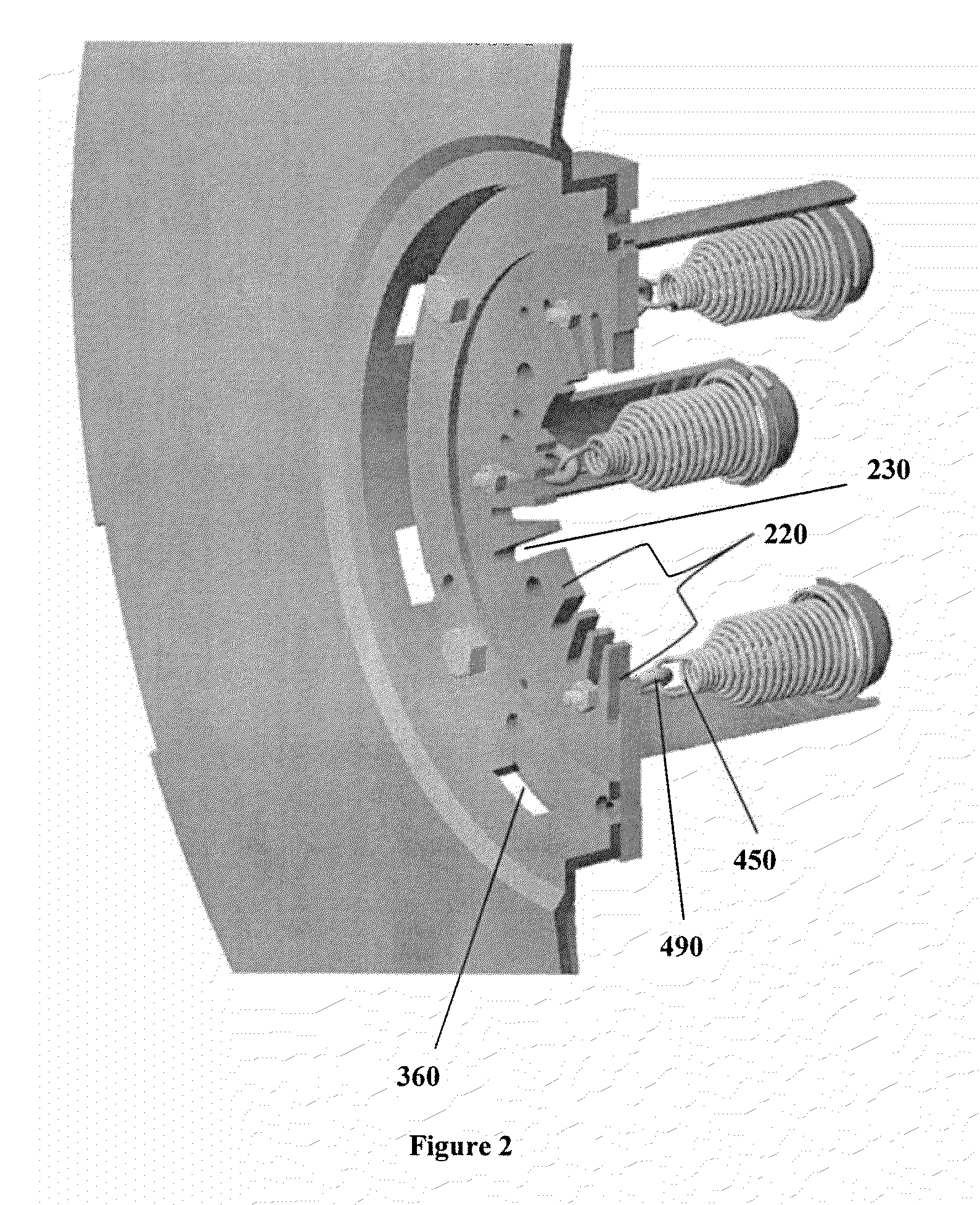

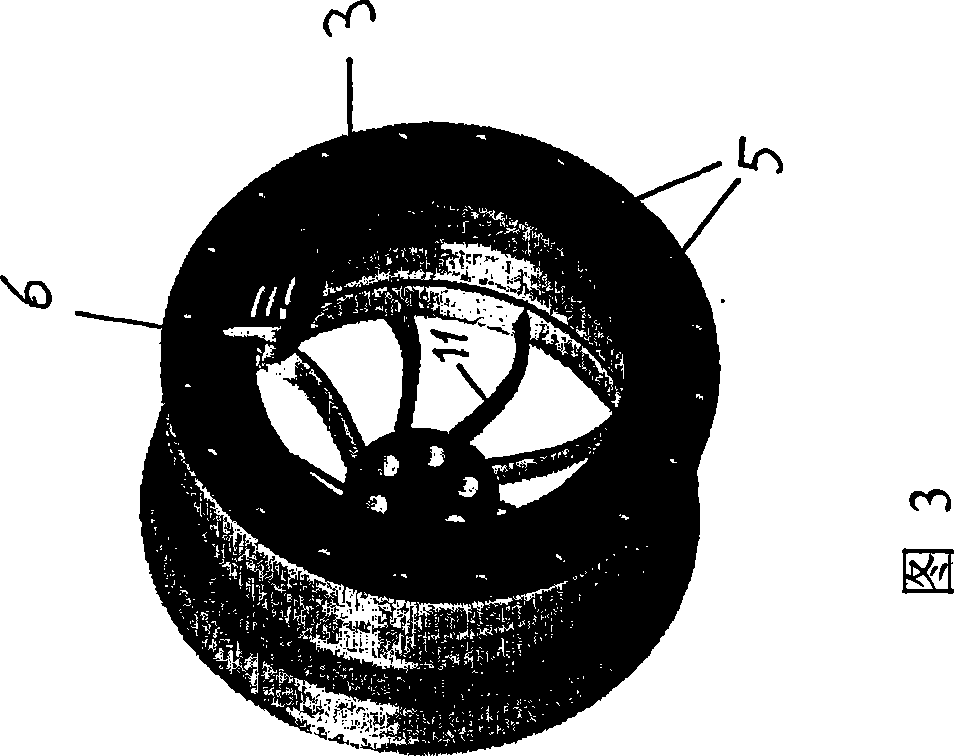

Removable wheel cover

A universal wheel cover assembly for covering a variety of different vehicle's wheels. The universal wheel cover assembly comprises: (a) a covering disc sized to cover the vehicle's wheel, (b) a universal bolt pattern plate, the universal bolt pattern plate including (i) a series of sections, each of the sections having a plurality of engagement members, wherein the sections are adapted for matching a pattern of threaded rods welded on the vehicle's axle hub used for attaching the vehicle's wheel, and (ii) a retaining system for connecting the universal bolt pattern plate to the covering disc, and (c) a spring biasing base comprising of a plurality of coil units, each coil unit for coupling one bolt in the pattern of bolts to the engagement members of the universal bolt pattern plate. The removable wheel cover assembly may be used in a variety of different vehicle tire rims and is aesthetically pleasing.

Owner:SMITH GREG

Removable wheel cover

A universal wheel cover assembly for covering a variety of different vehicle's wheels. The universal wheel cover assembly comprises: (a) a covering disc sized to cover the vehicle's wheel, (b) a universal bolt pattern plate, said universal bolt pattern plate including (i) a series of sections, each of said sections having a plurality of engagement means, wherein said sections are adapted for matching a pattern of bolts disposed on the vehicle's axel hubs used for attaching the vehicle's wheel, and (ii) a retaining system for connecting the universal bolt pattern plate to the covering disc, and (c) a spring biasing base comprising of a plurality of coil units, each coil unit for coupling one bolt in the pattern of bolts to the engagement means of the universal bolt pattern plate. The removable wheel cover assembly may be used in a variety of different vehicle tire rims and is aesthetically pleasing.

Owner:SMITH GREG

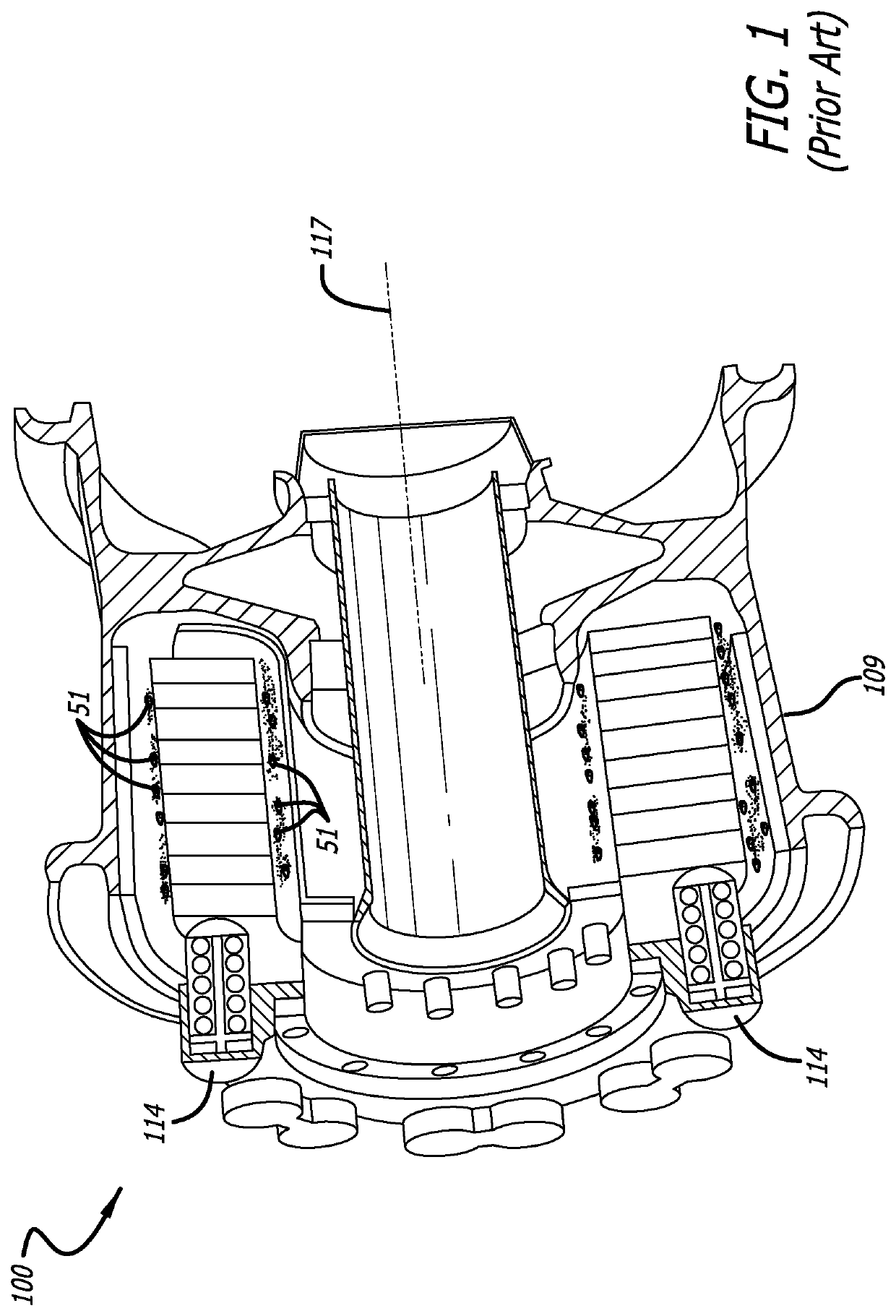

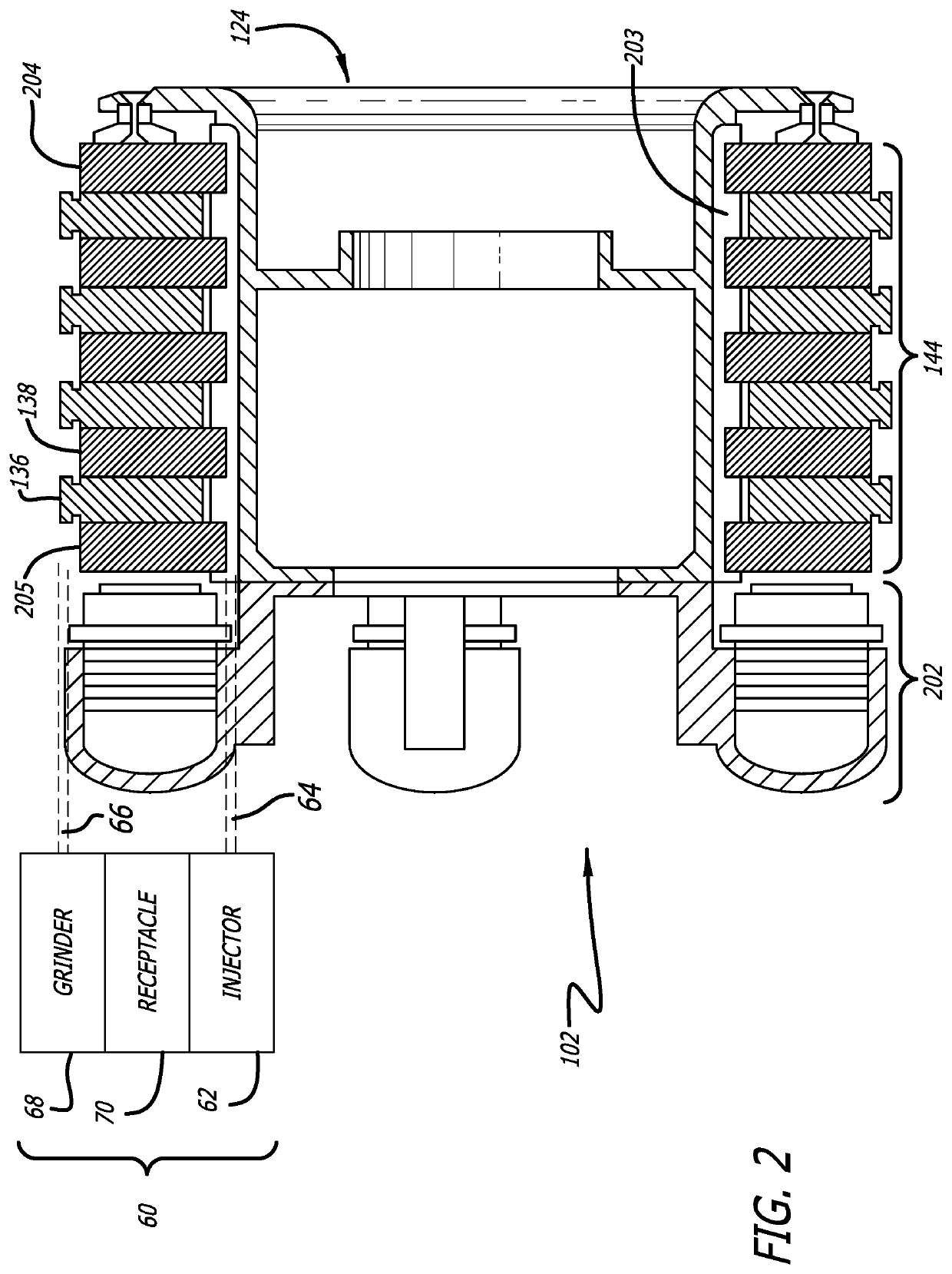

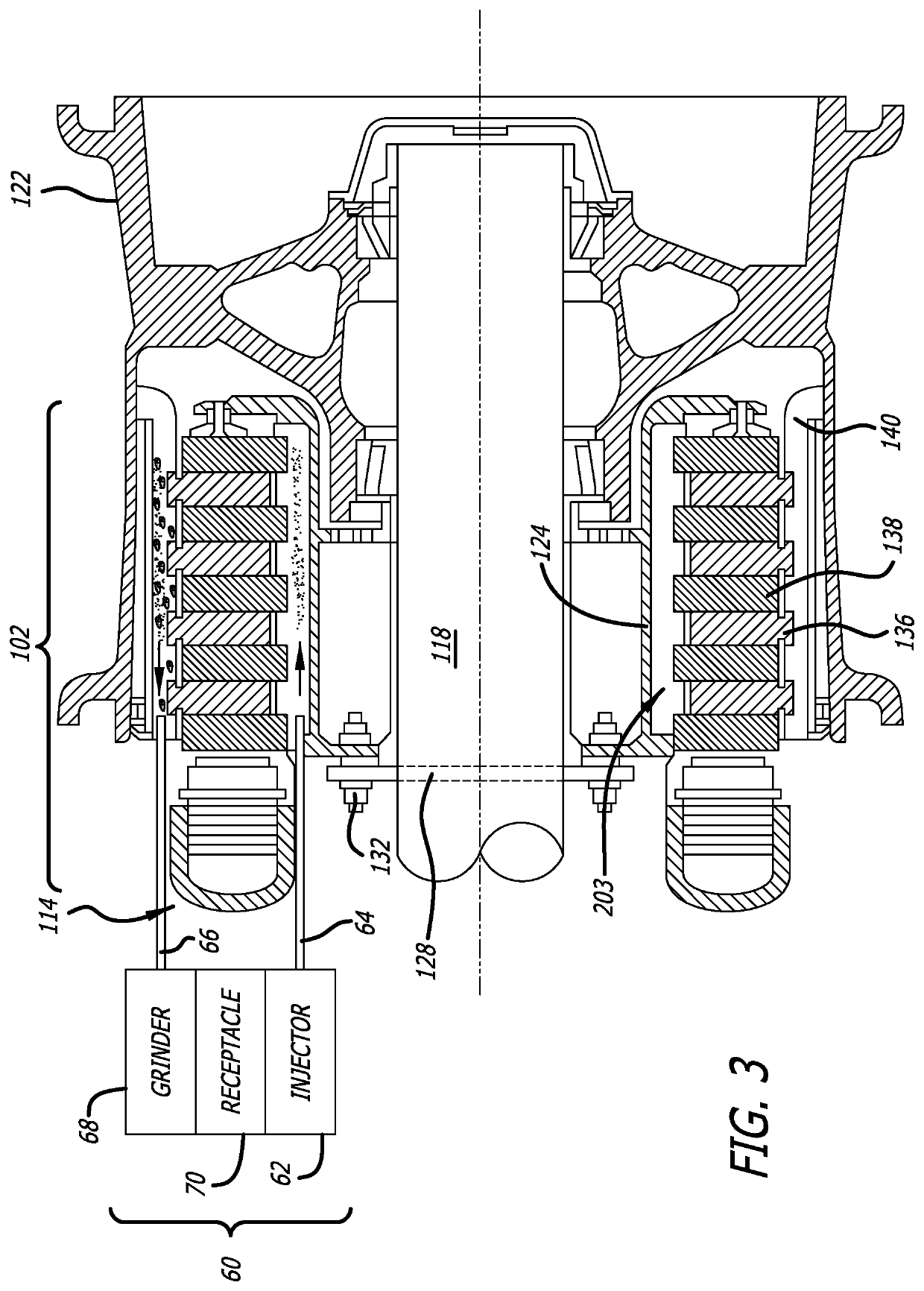

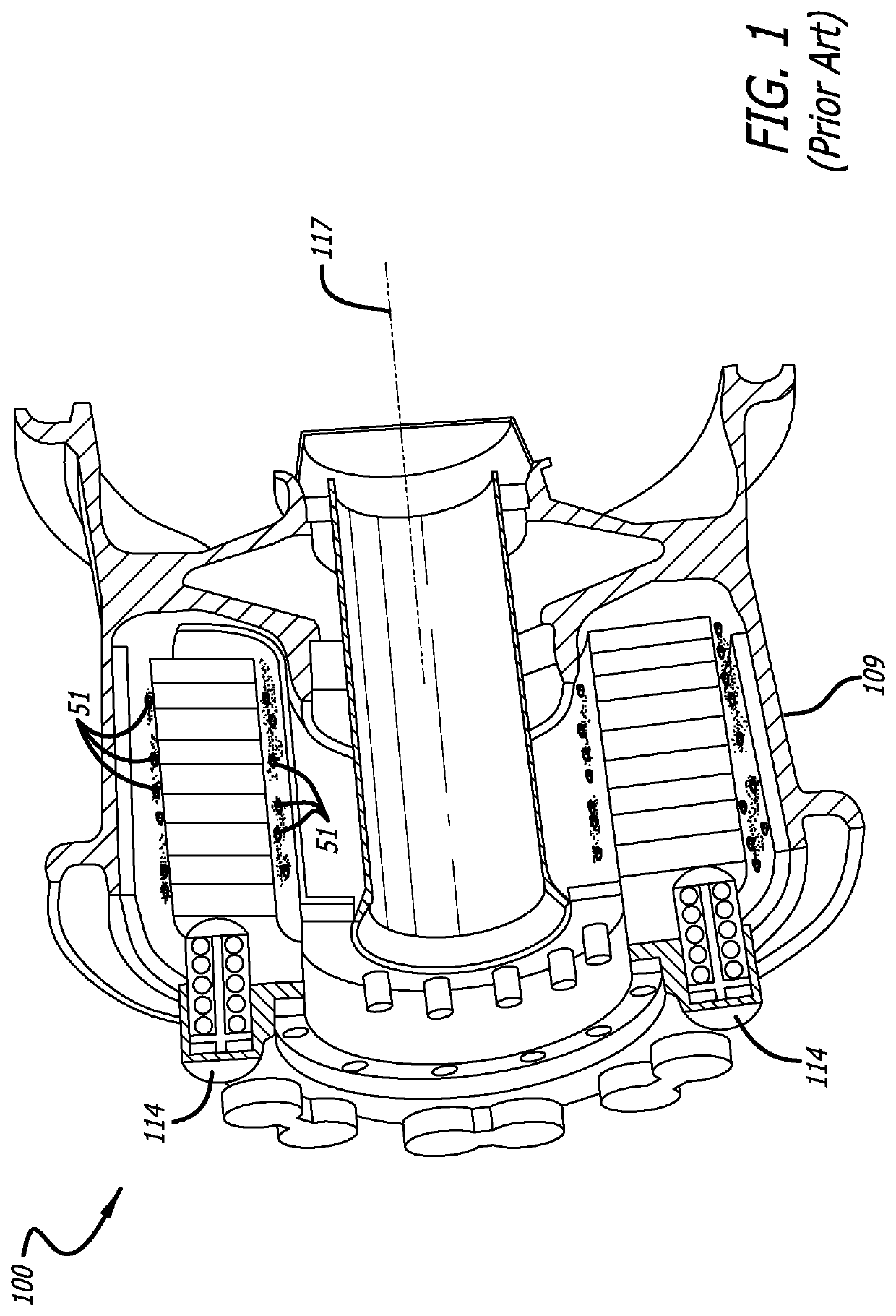

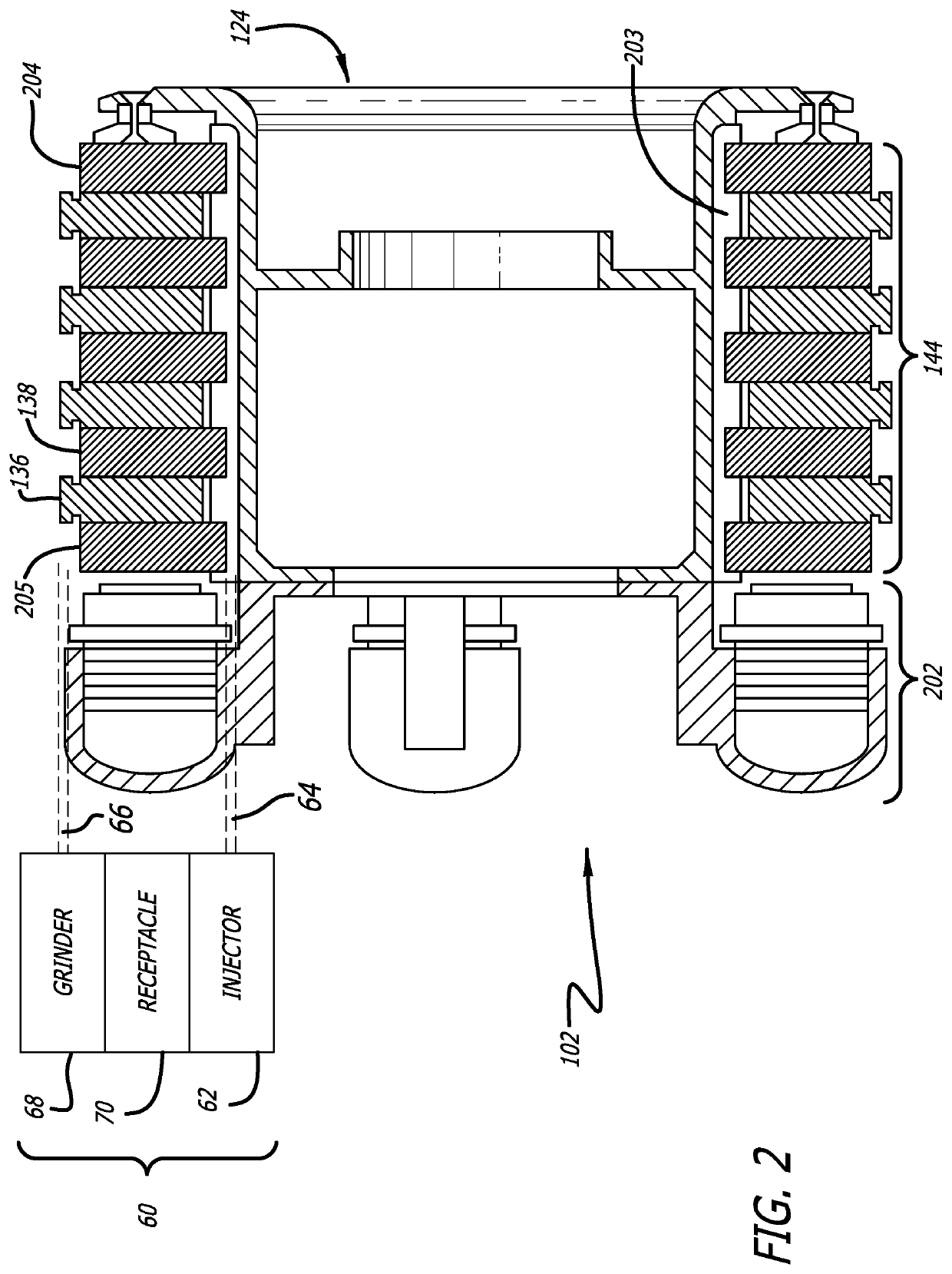

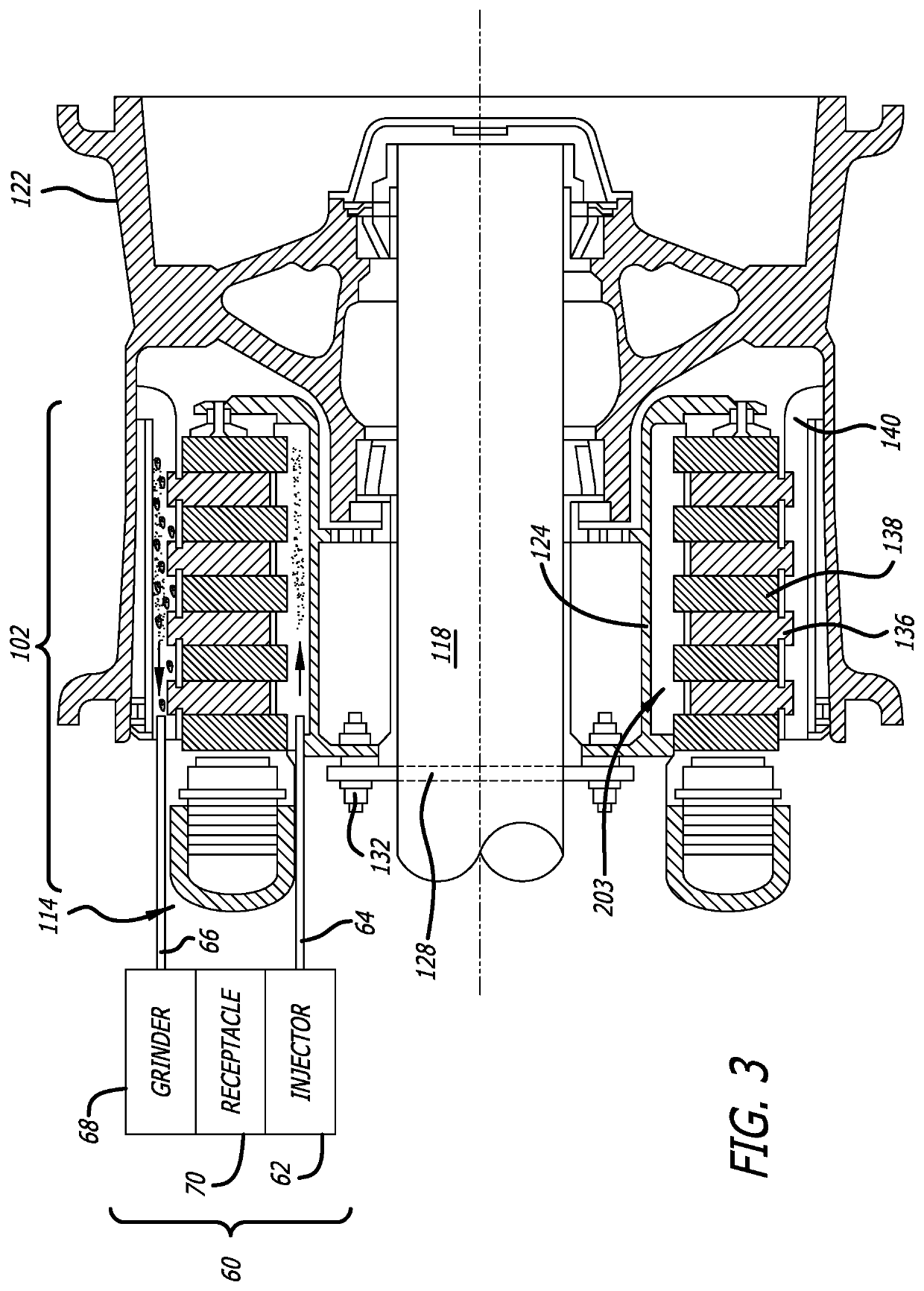

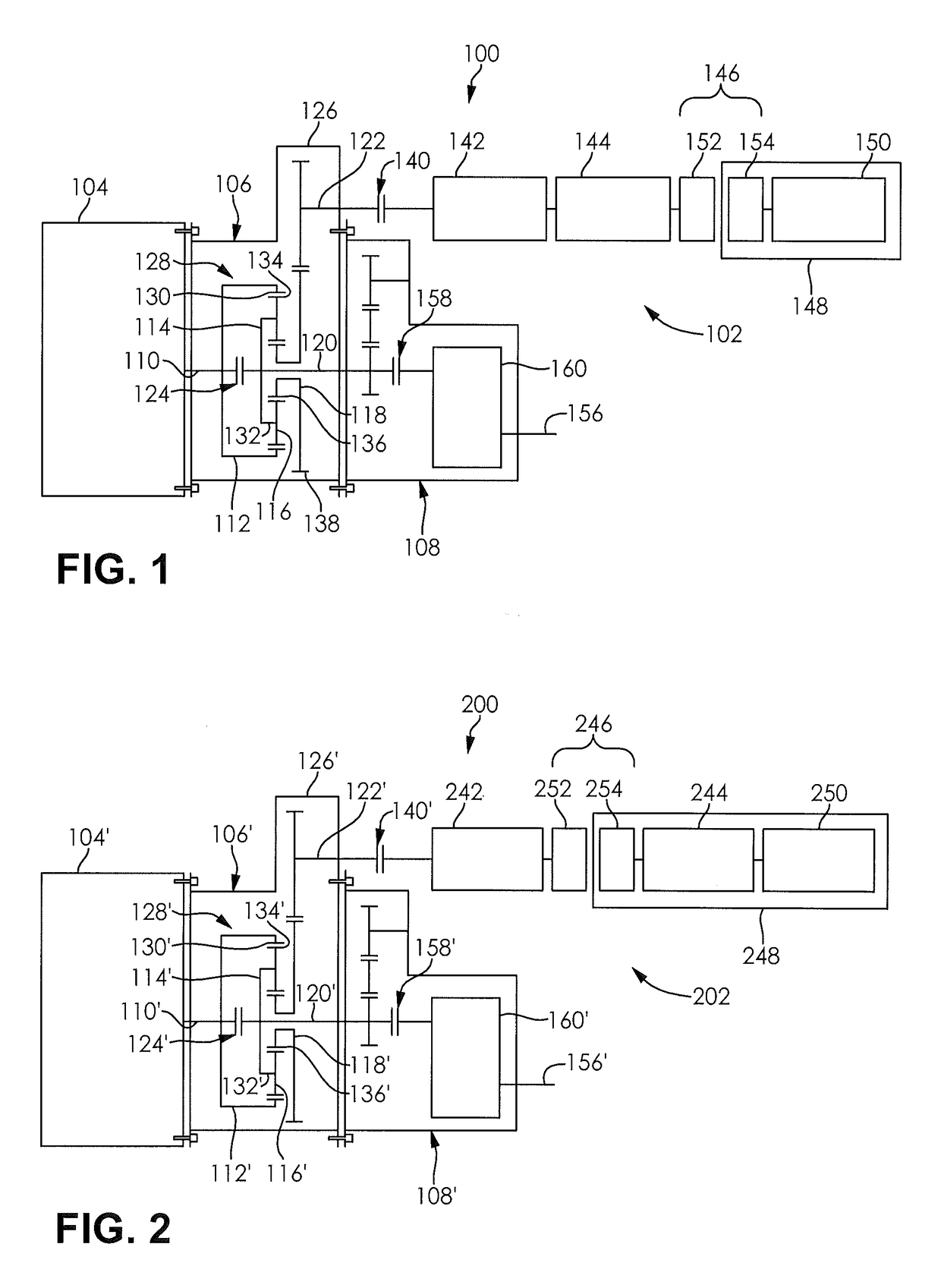

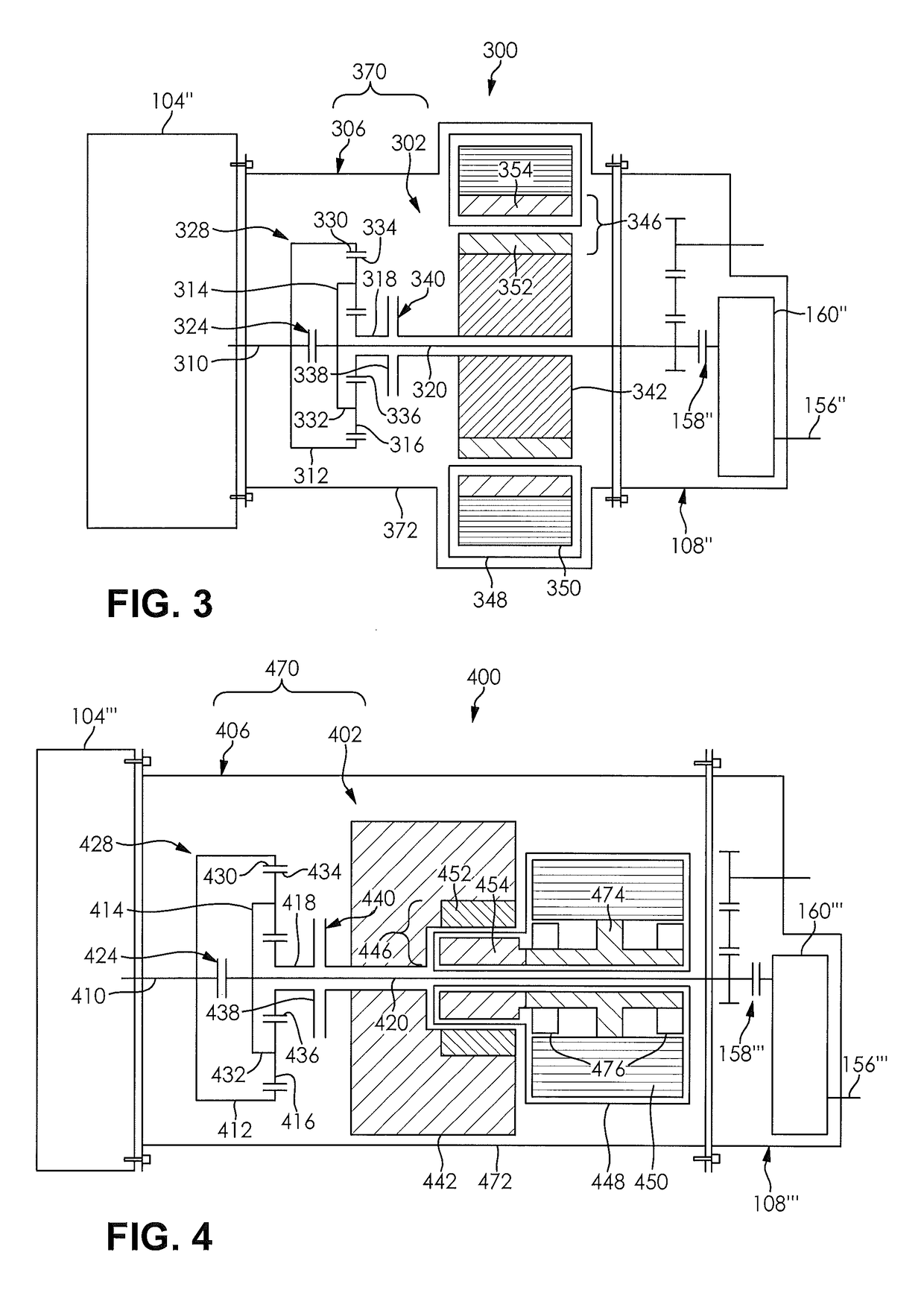

System and method for reducing aircraft brake wear

ActiveUS20200189729A1Reduced brake wearExtend brake lifeEnergy efficient operational measuresAxially engaging brakesControl theoryMechanical engineering

A system and method are provided for continuous monitoring and controlling of aircraft braking that can reduce brake wear and aircraft operating costs through the retention of carbon brake powder from the brakes or addition of carbon powder in a device mounted with respect to the brake disc stack. The use of carbon powder reduces brake wear by providing small particles between the brake discs, acting as a buffer between the brake discs when the brake stack is clamped together. Moreover, when carbon powder or small particles are used at application, such use reduces the roughness of the carbon surface and reduces the number of large particles from braking off the carbon surface, thereby reducing brake wear. Adaptive or selective braking may be used in conjunction with carbon powder to further reduce carbon brake wear.

Owner:HYDRO AIRE AEROSPACE CORP

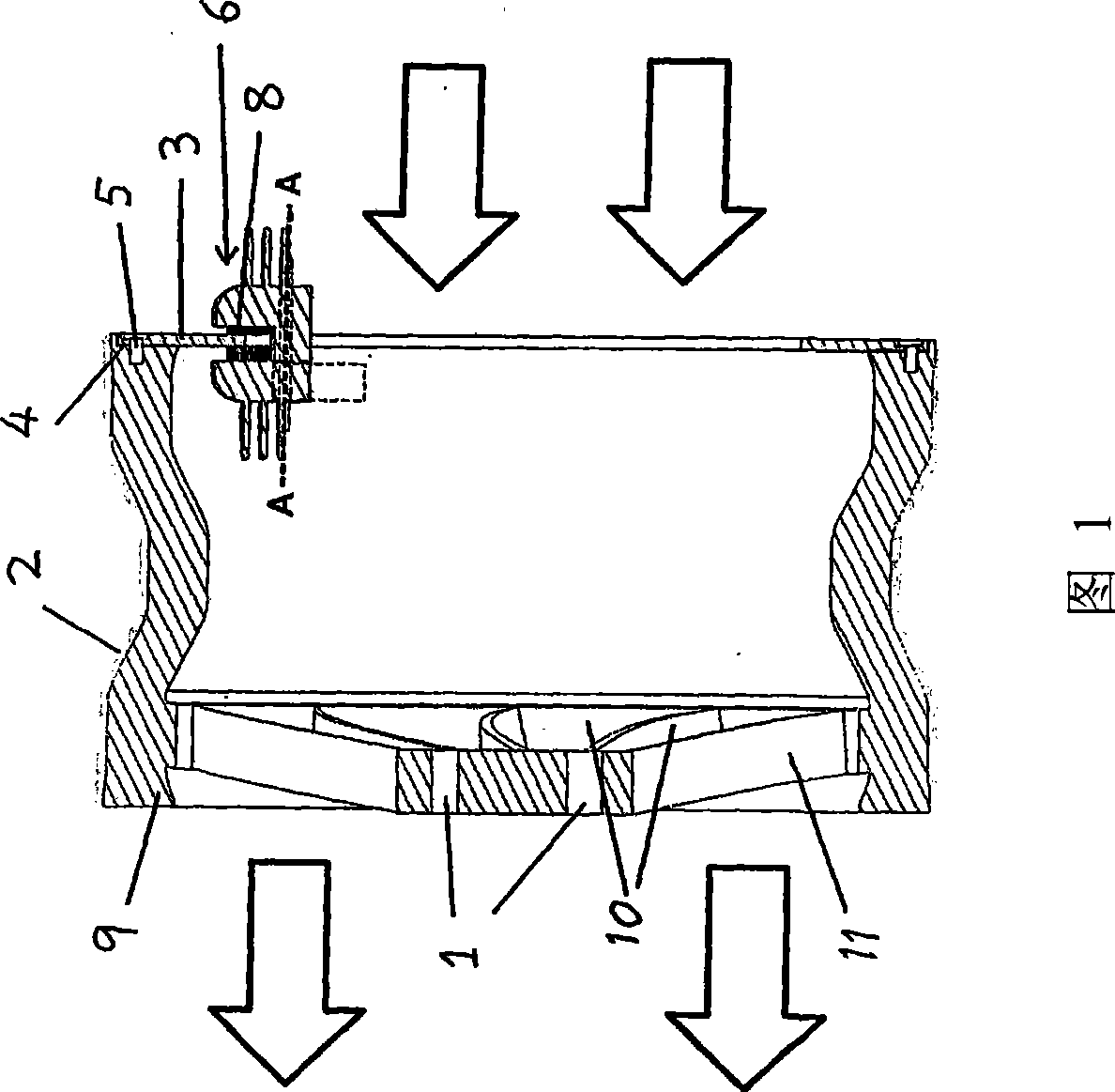

Braking systems with cooling

A braking system comprises an axle (23), a support element (22) mounted on the axle, a brake ring (3) connected to the periphery of the support element (22) and a brake calliper (21) for applying a braking force to the brake ring (3). The brake ring (3) is connected to the support element (22) in such a manner that a conductive heat flow path is provided for conducting heat from the brake ring (3) into the support element (22). There is also an airflow path passing through the support element (22) and through the region in which the brake calliper (21) is situated for transferring heat by convection from the brake ring (3) and the brake calliper (21).

Owner:威廉·爱德华·芬纳

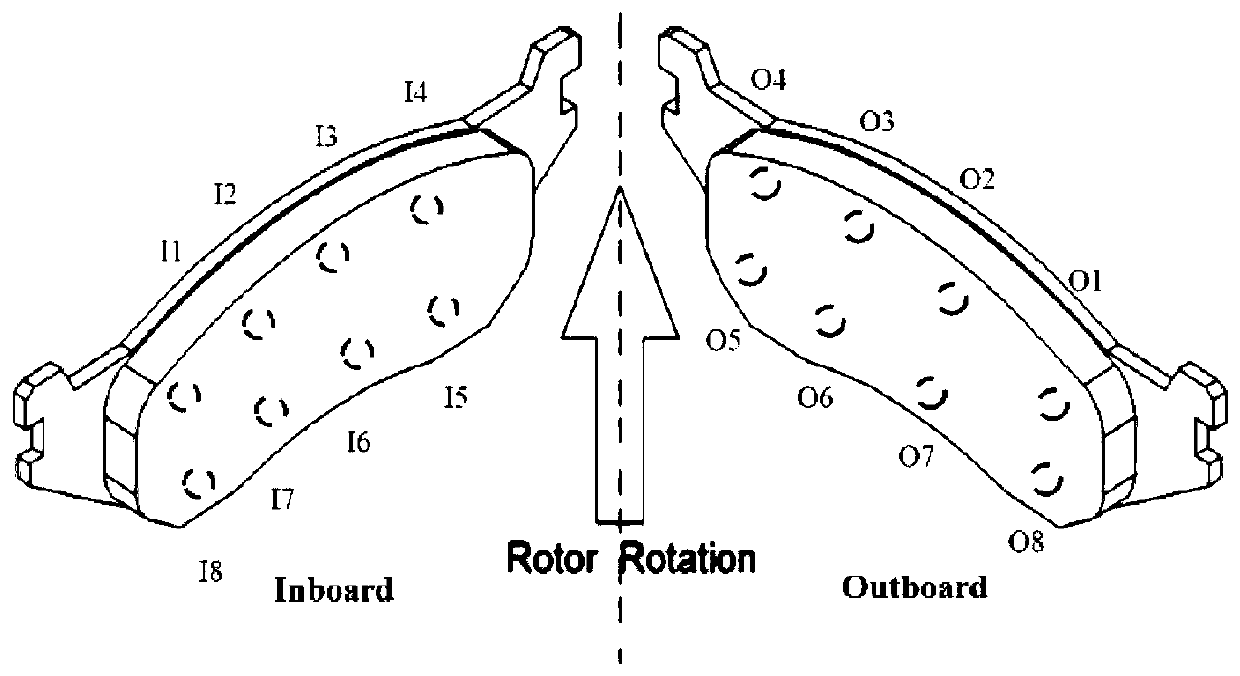

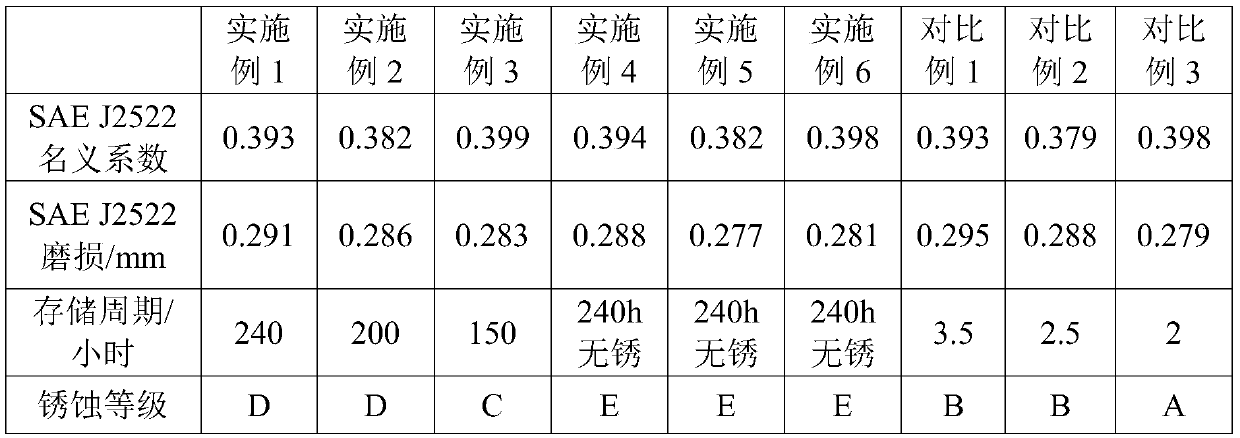

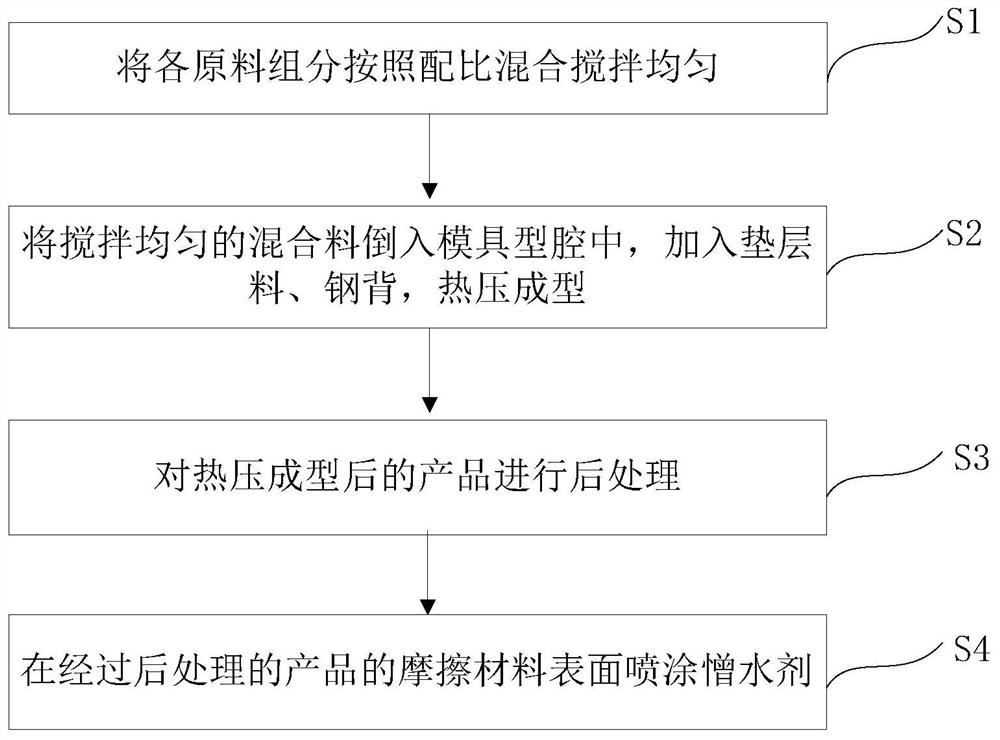

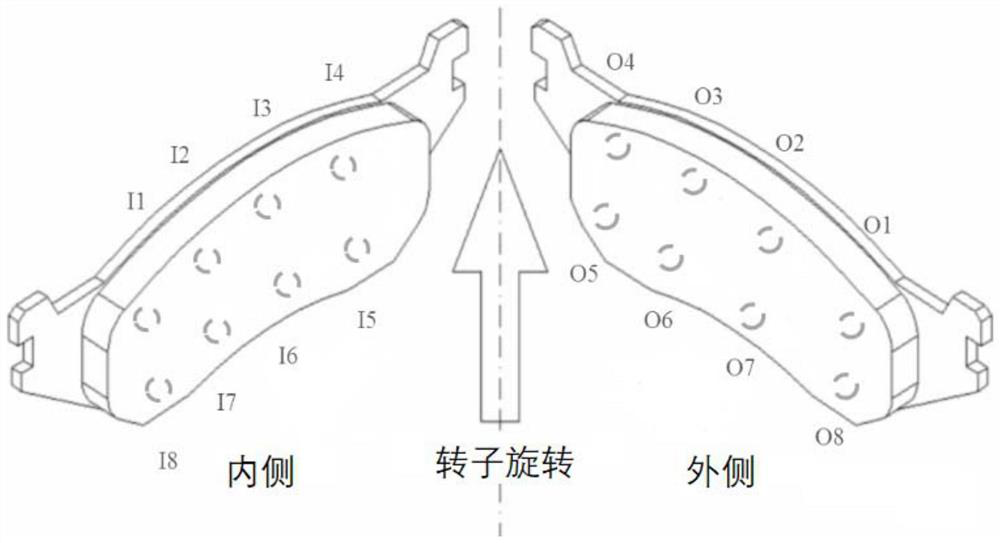

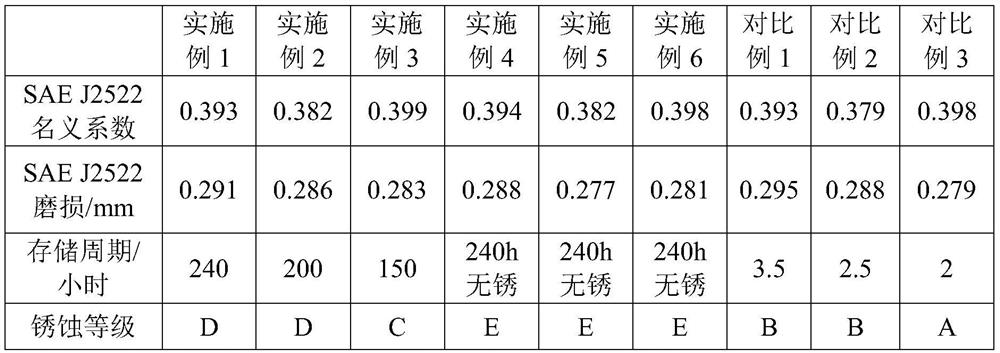

Friction material, brake pad prepared by friction material and preparation method of brake pad

ActiveCN110081107AEasy to storeImprove transportation cycleFriction liningActuatorsOxidation resistantMechanical engineering

The invention discloses a friction material, a brake pad prepared by the friction material and a preparation method of the brake pad. The preparation method of the brake pad comprises the following steps that (1) preparation of a copper-free metal friction material is performed; (2) hot-pressing molding is performed, wherein the copper-free metal friction material in the step (1) is placed in a hot-pressing mold cavity to be spread and flattened, a cushion layer material is put in the hot-pressing mold cavity to be spread and flattened, a steel backing is placed, hot-pressing molding is performed, and then demolding is performed; (3) a demolded sample undergoes heat treatment, and then is cooled to room temperature; and (4) post-treatment is performed on the sample after being treated in the step (3) to prepare the brake pad. According to the preparation method of the brake pad, the storage, transport cycle and oxidation resistance of the friction material in the brake pad can be obviously improved through rust prevention treatment.

Owner:SHANDONG GOLD PHOENIX

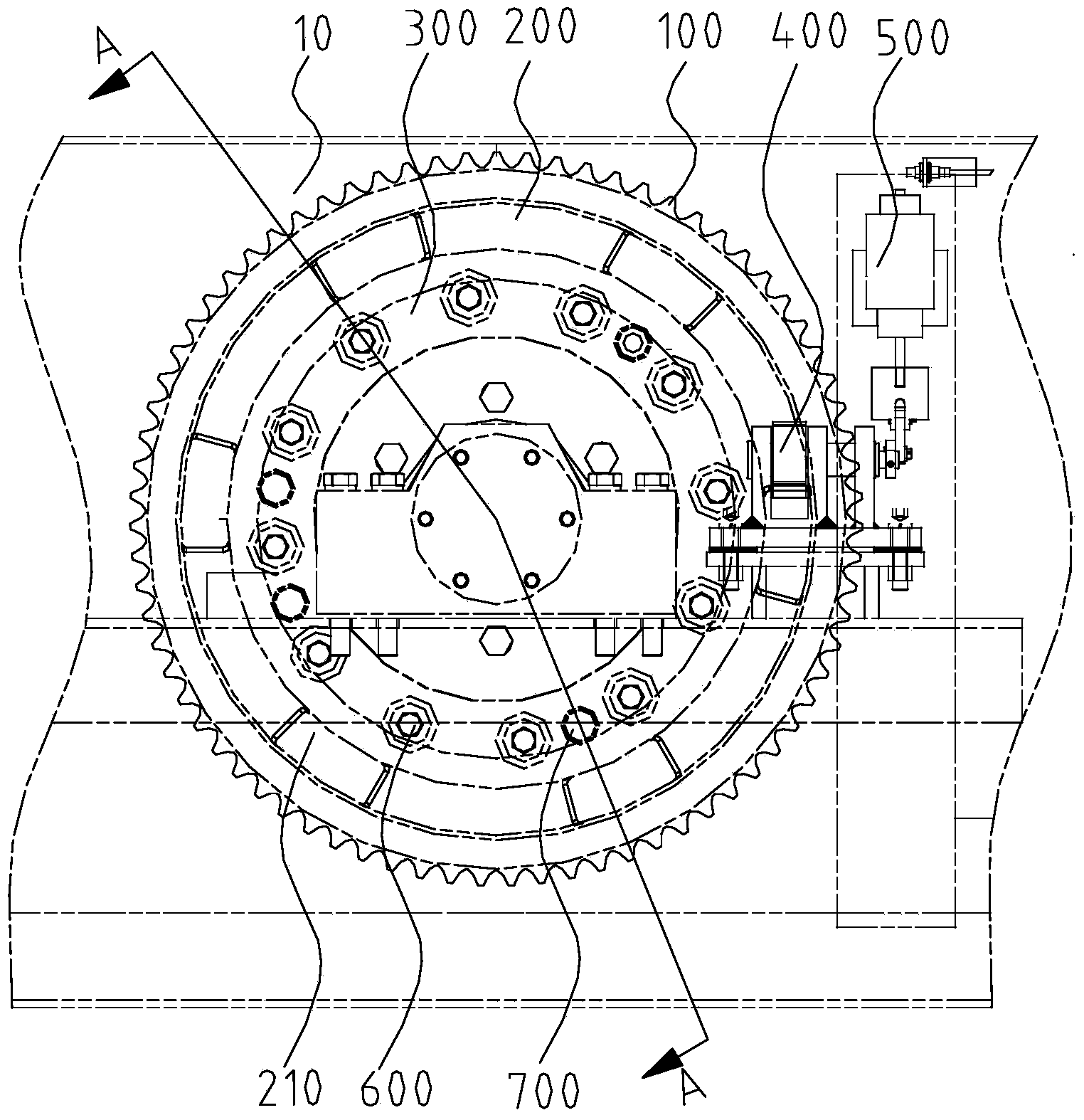

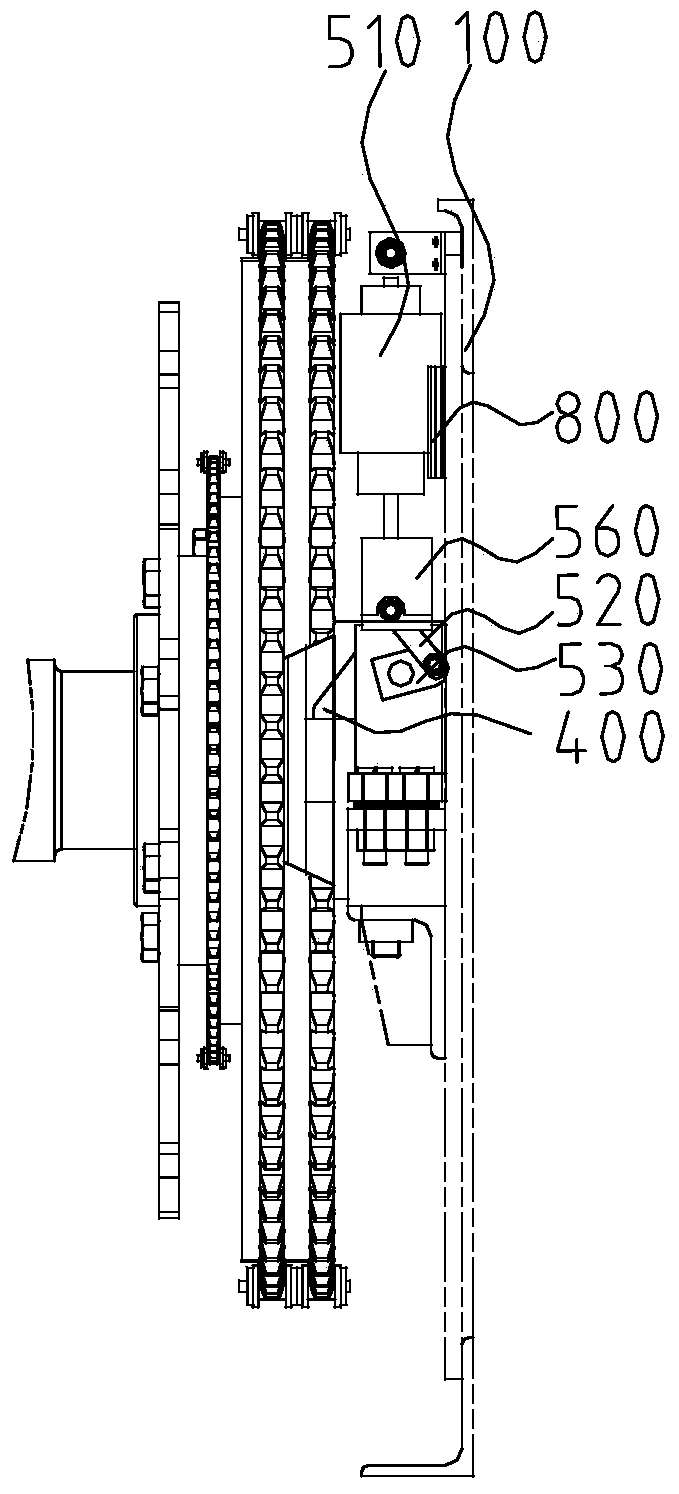

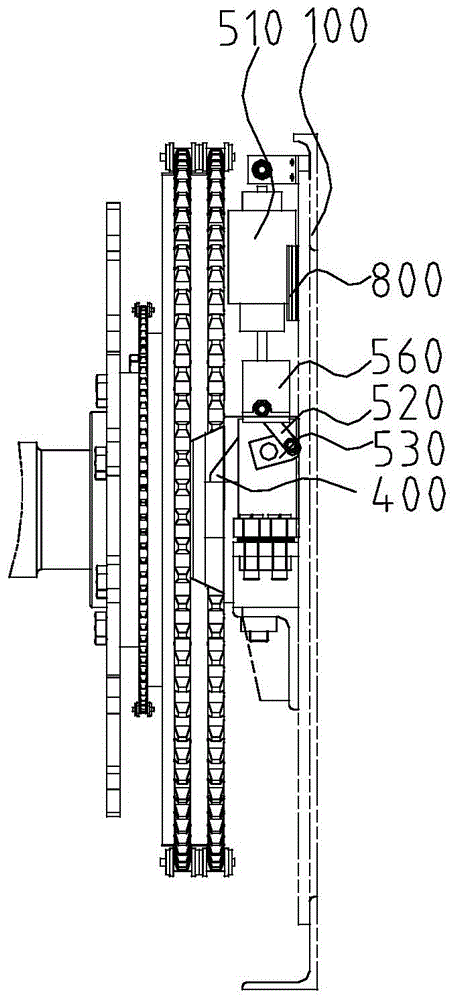

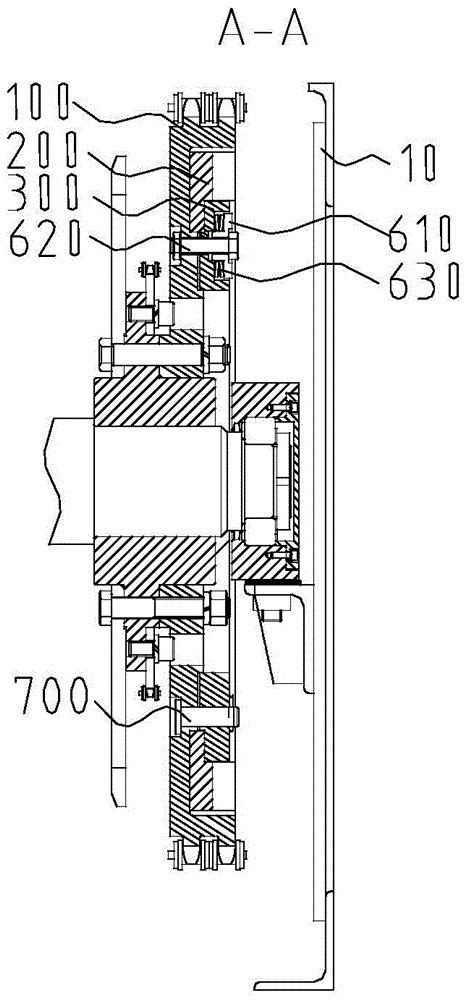

Additional brake

The invention discloses an additional brake which comprises a driving chain wheel, a brake disc, a pressing disc, a brake block and a triggering component. The brake disc is arranged between the driving chain wheel and the pressing disc which is pressed on the brake disc, and the pressing disc is connected with the driving chain wheel through a locking component. A protruding block is arranged on the brake disc. The brake block is connected with the triggering component. The brake block and the protruding block are kept in a meshing or separate state through action of the triggering component. According to the additional brake, during braking, the brake block and the protruding block are controlled to be meshed through the triggering component, so that the brake disc is kept static, the driving chain wheel and the pressing disc move relative to the brake disc respectively under the effect of inertia force, finally braking is achieved through kinetic friction force generated on a matching face, when braking is not carried out, the triggering component controls the brake disc to be separated from the protruding block, under the effect of the locking component, the driving chain wheel, the brake disc and the pressing disc operate synchronously, and the additional brake has the advantages to being simple and compact in structure, convenient to arrange and adjust, low in cost, high in assembling efficiency and the like.

Owner:HITACHI ELEVATOR GUANGZHOU ESCALATOR

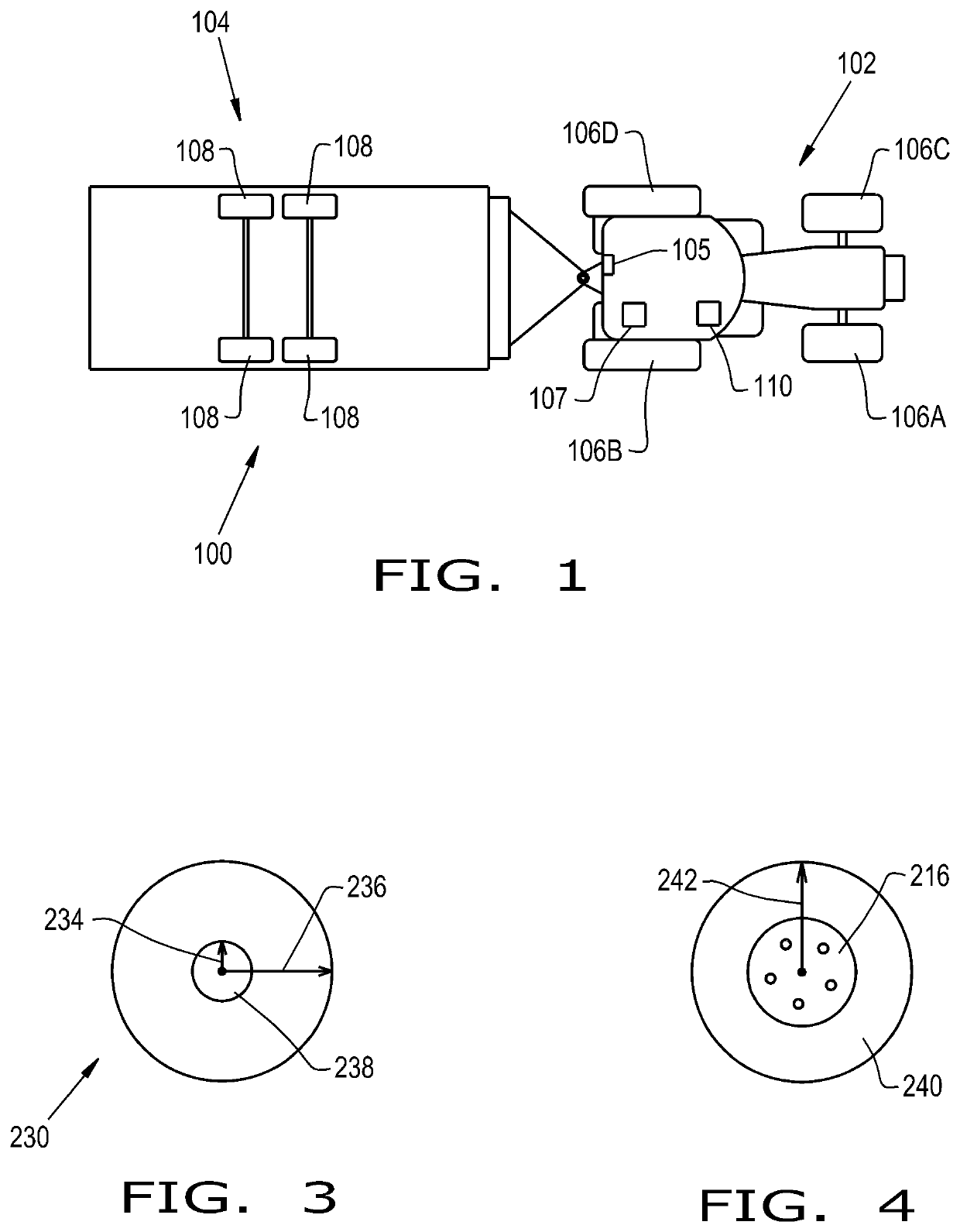

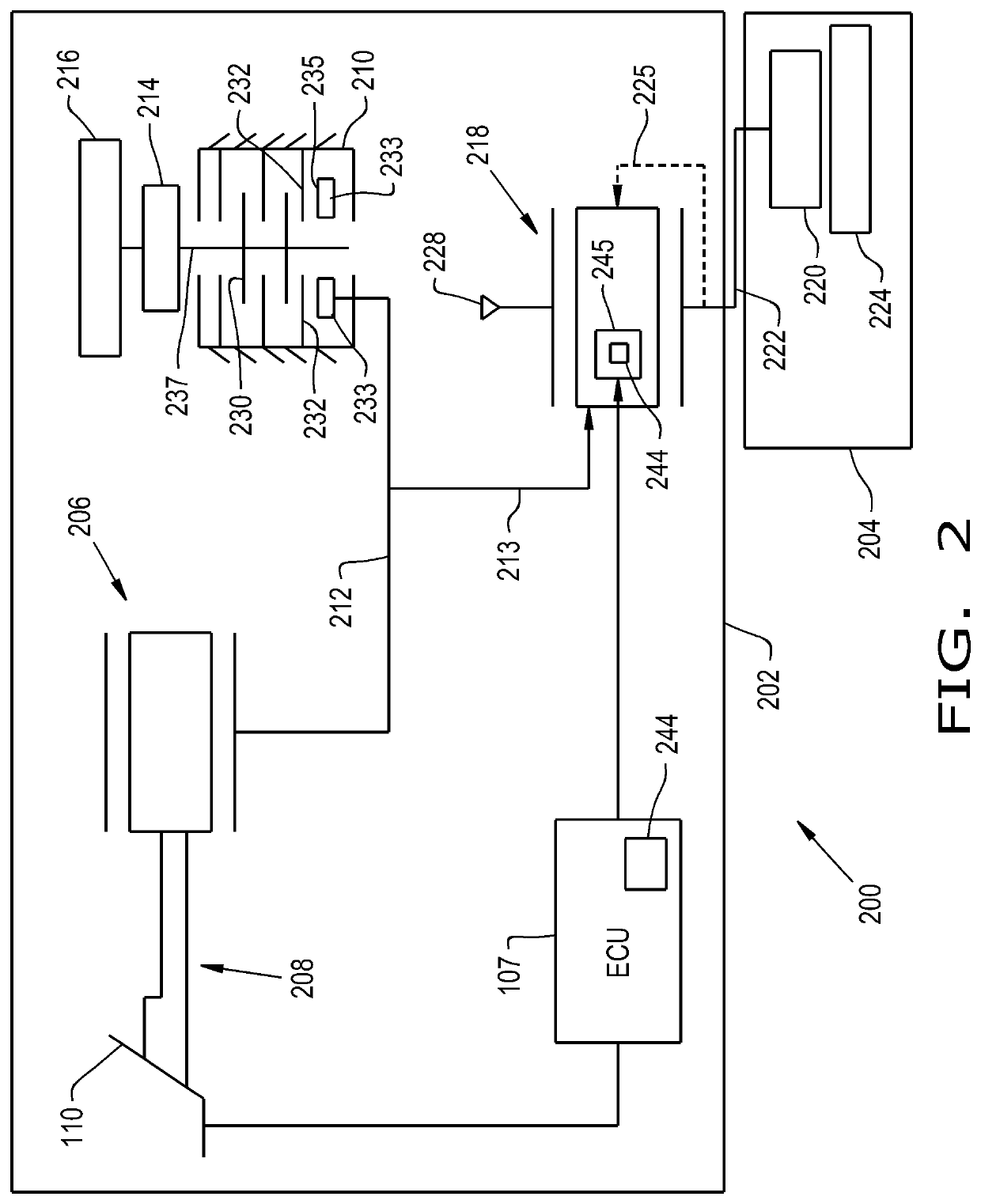

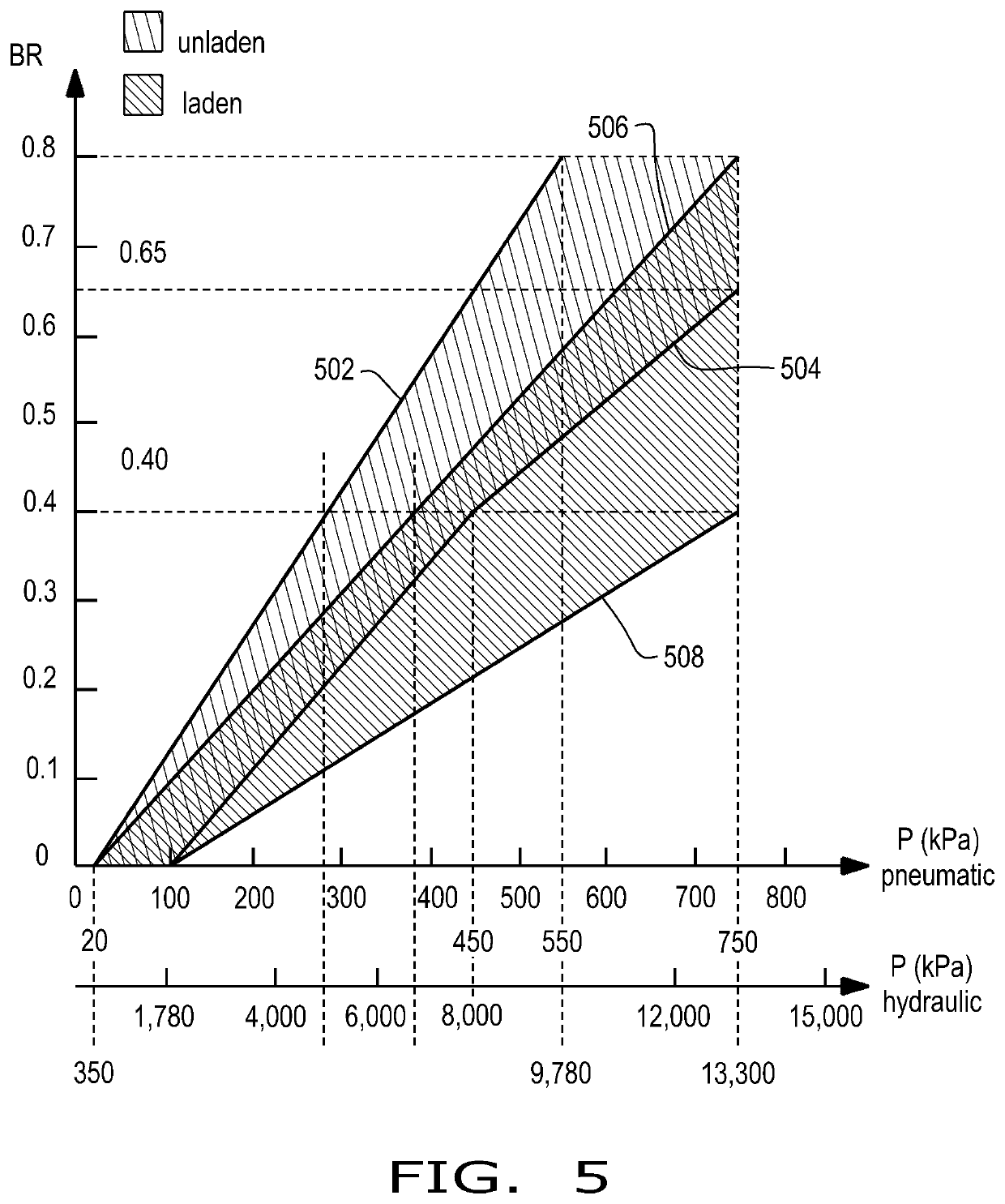

System and method for braking a tractor-trailer assembly

InactiveUS20200001841A1Reducing anti-knifingExtend brake lifeBraking element arrangementsAutomatic initiationsReduction driveControl theory

A system and method for braking a tractor-trailer assembly is provided. The method includes generating a tractor brake pressure for application to a tractor brake for braking a tractor wheel, determining a tractor brake rate based on one or more of the generated tractor brake pressure, one or more parameters of the tractor brake, one or more parameters of the tractor wheel, one or more parameters of a final drive, and a mass of the tractor, and determining a trailer brake pressure applied to a trailer brake of a trailer wheel of a trailer, based on the determined tractor brake rate.

Owner:CNH IND AMERICA LLC

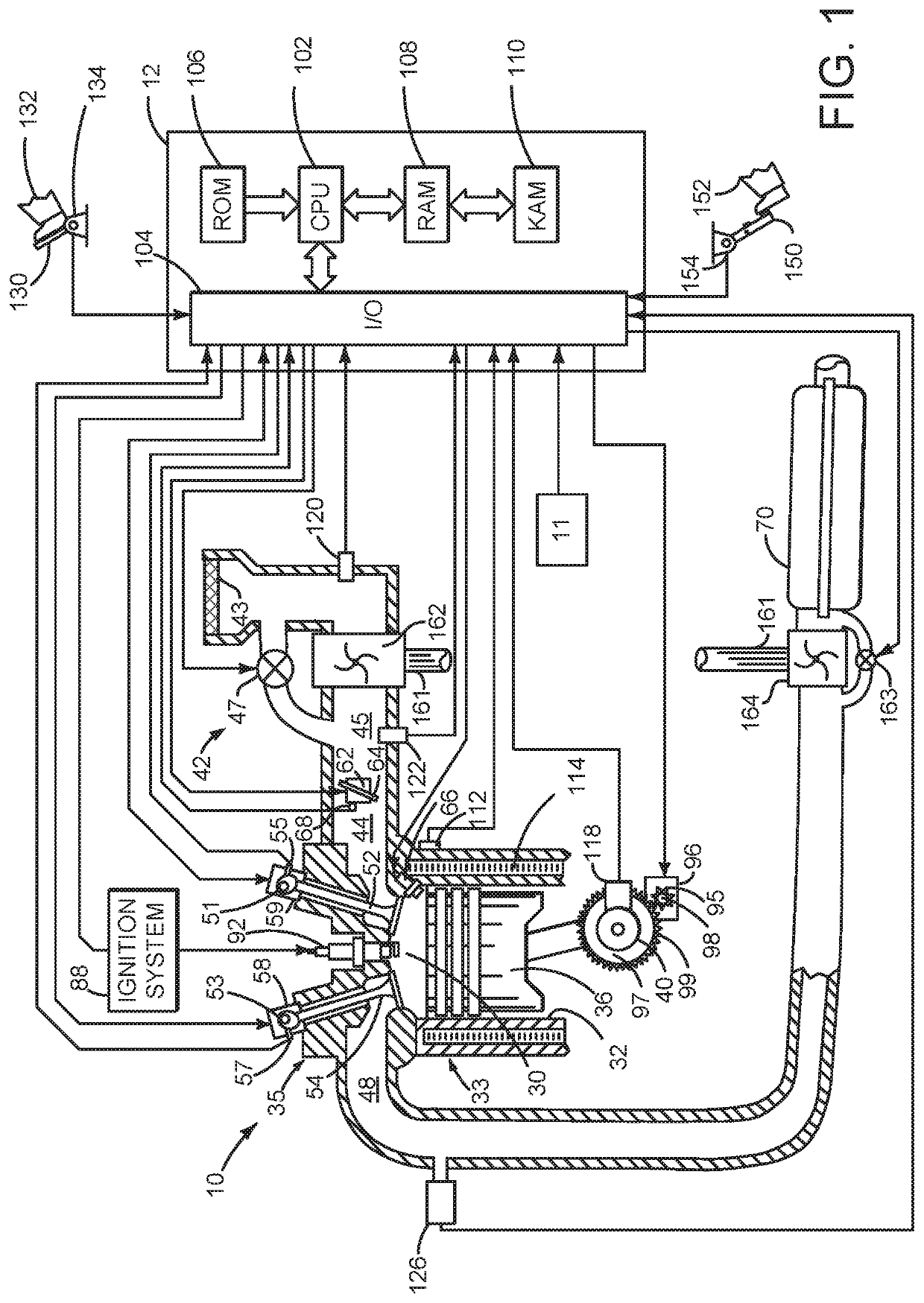

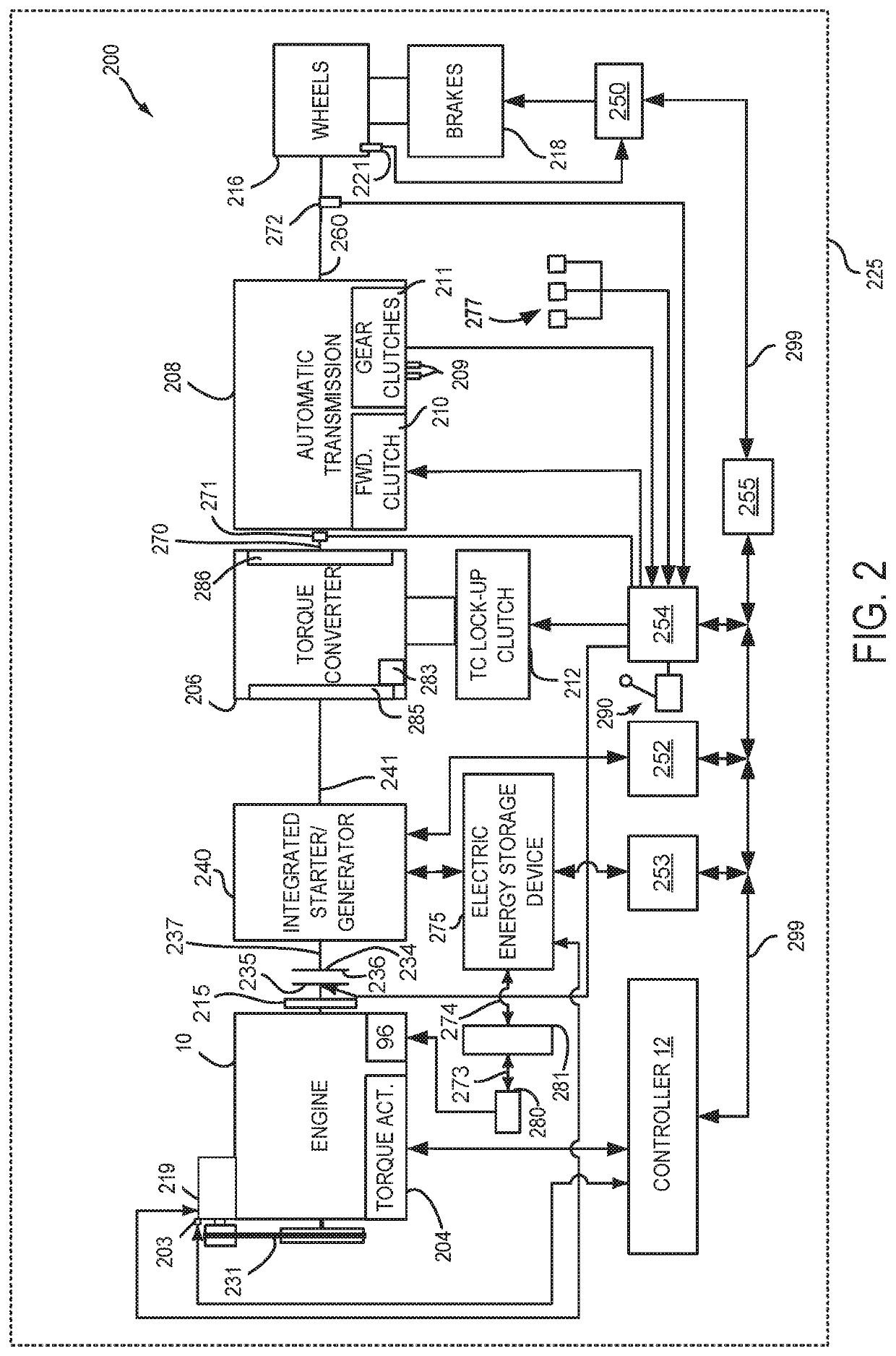

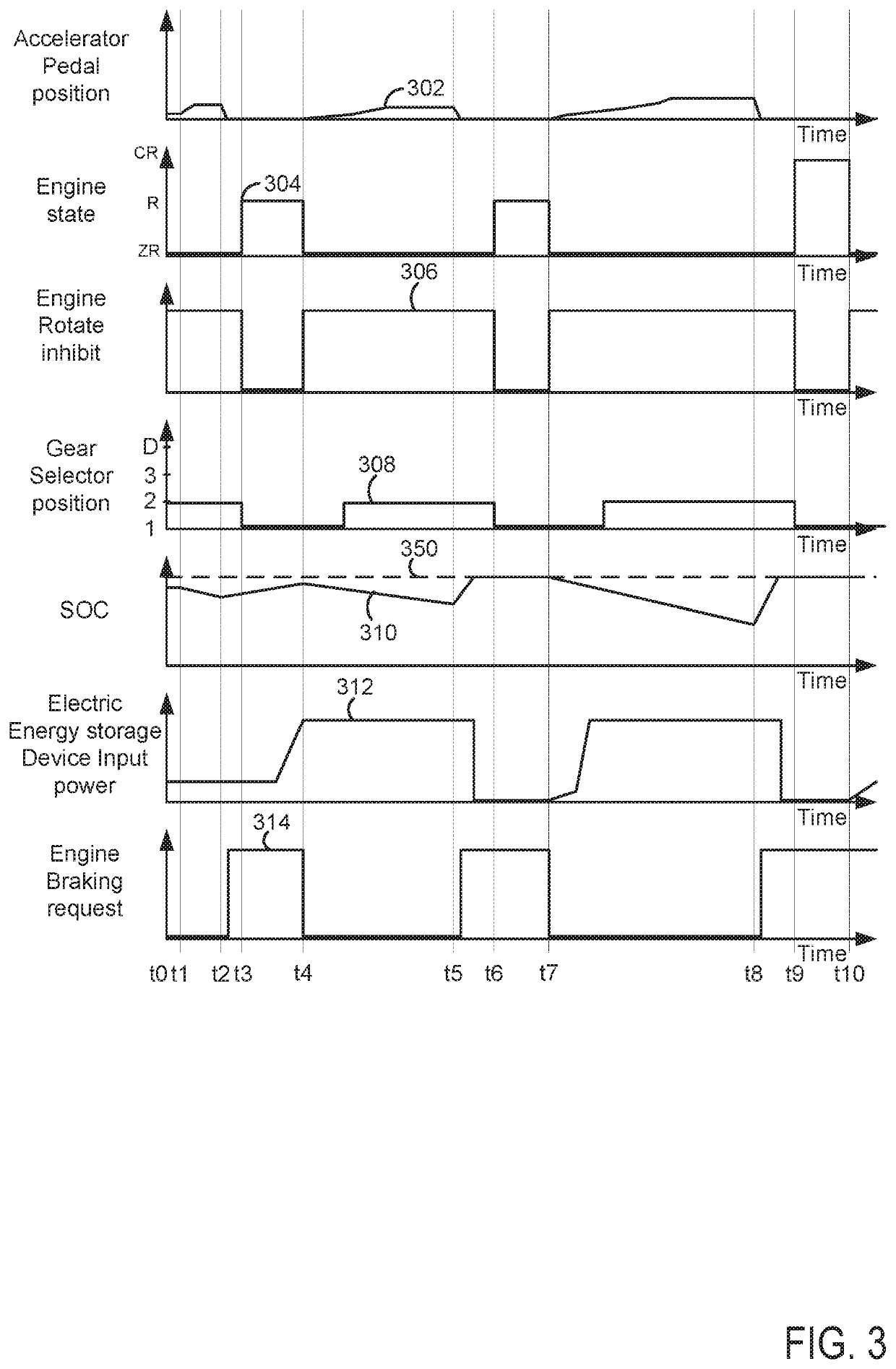

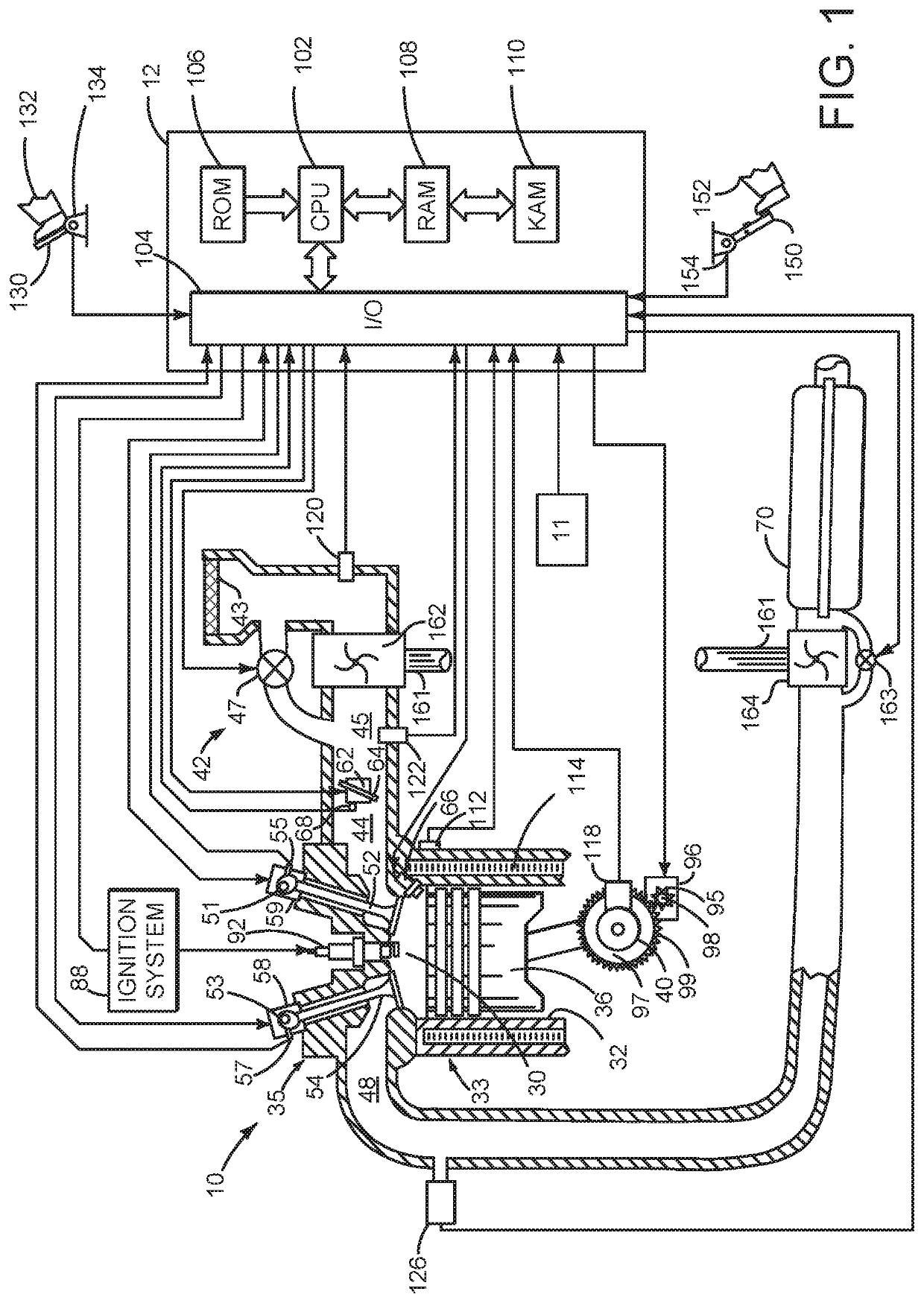

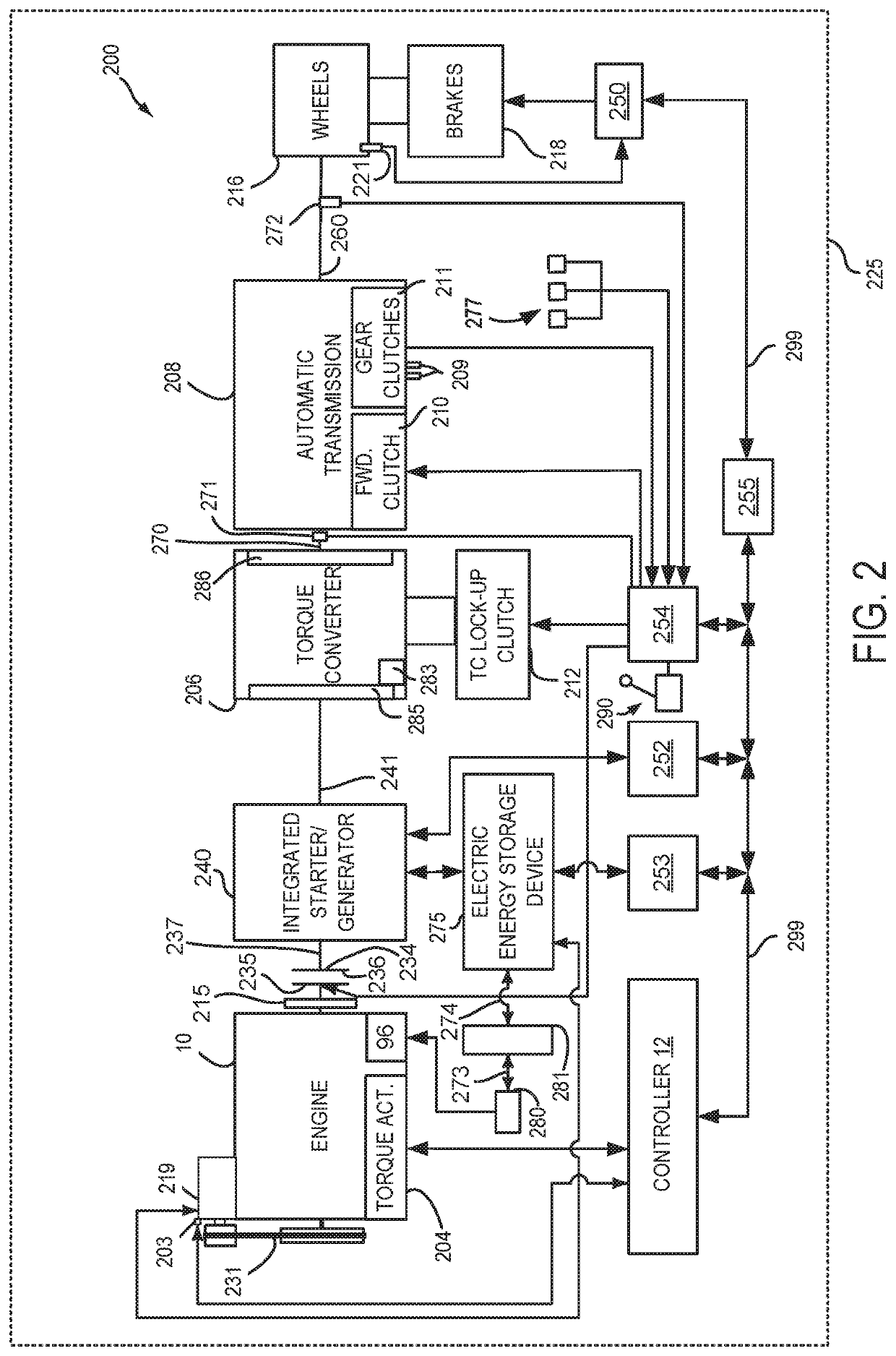

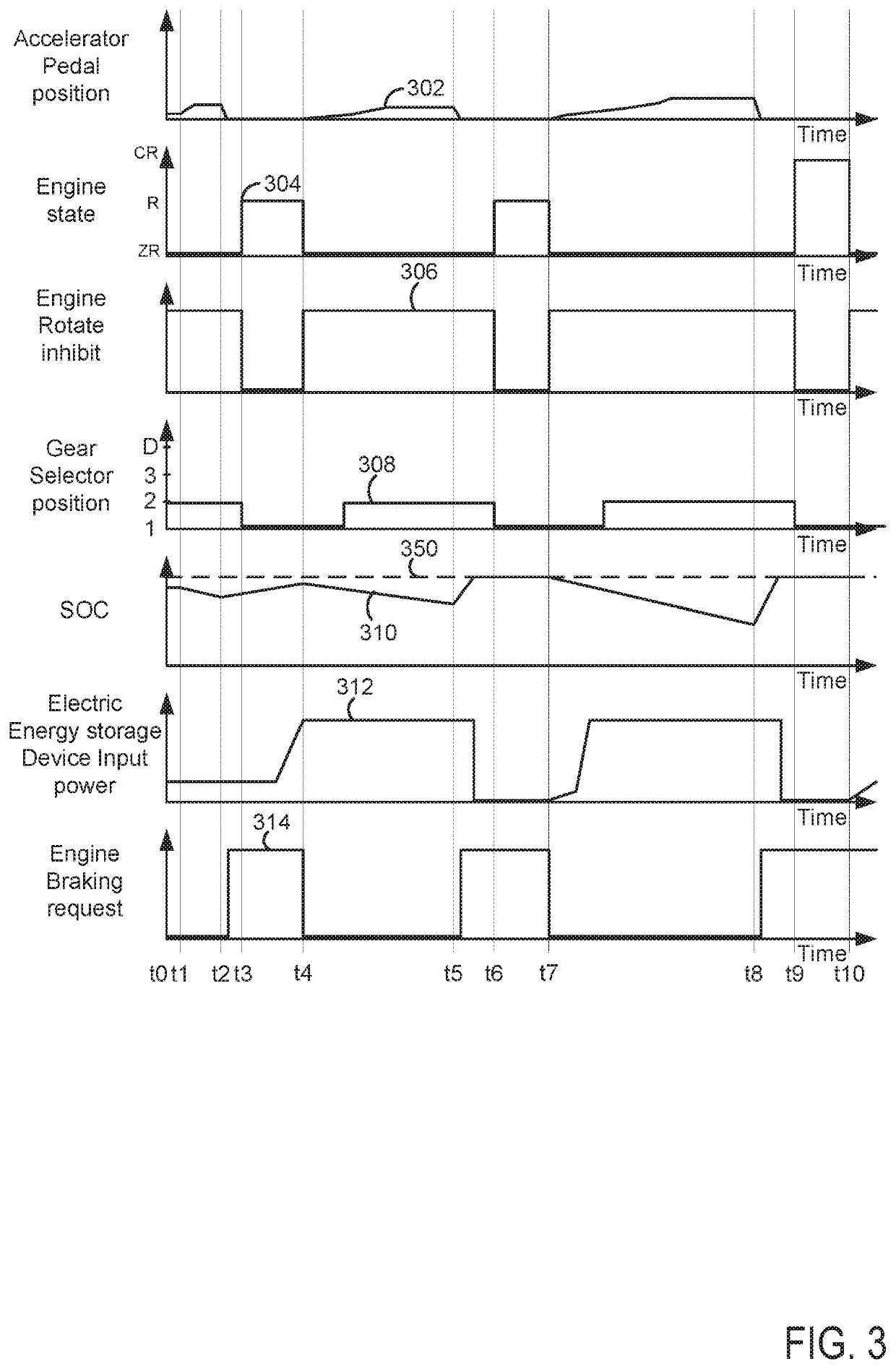

Methods and system for engine braking

ActiveUS20200189556A1Reduce the possibilitySlow vehicleBraking element arrangementsEngine controllersElectric generatorHybrid powertrain

Systems and methods for operating a hybrid powertrain or driveline that includes an engine and an integrated starter / generator are described. In one example, rotation of an automatically stopped engine may be inhibited when engine braking is requested so that the engine may not be rotated without providing a desired outcome.

Owner:FORD GLOBAL TECH LLC

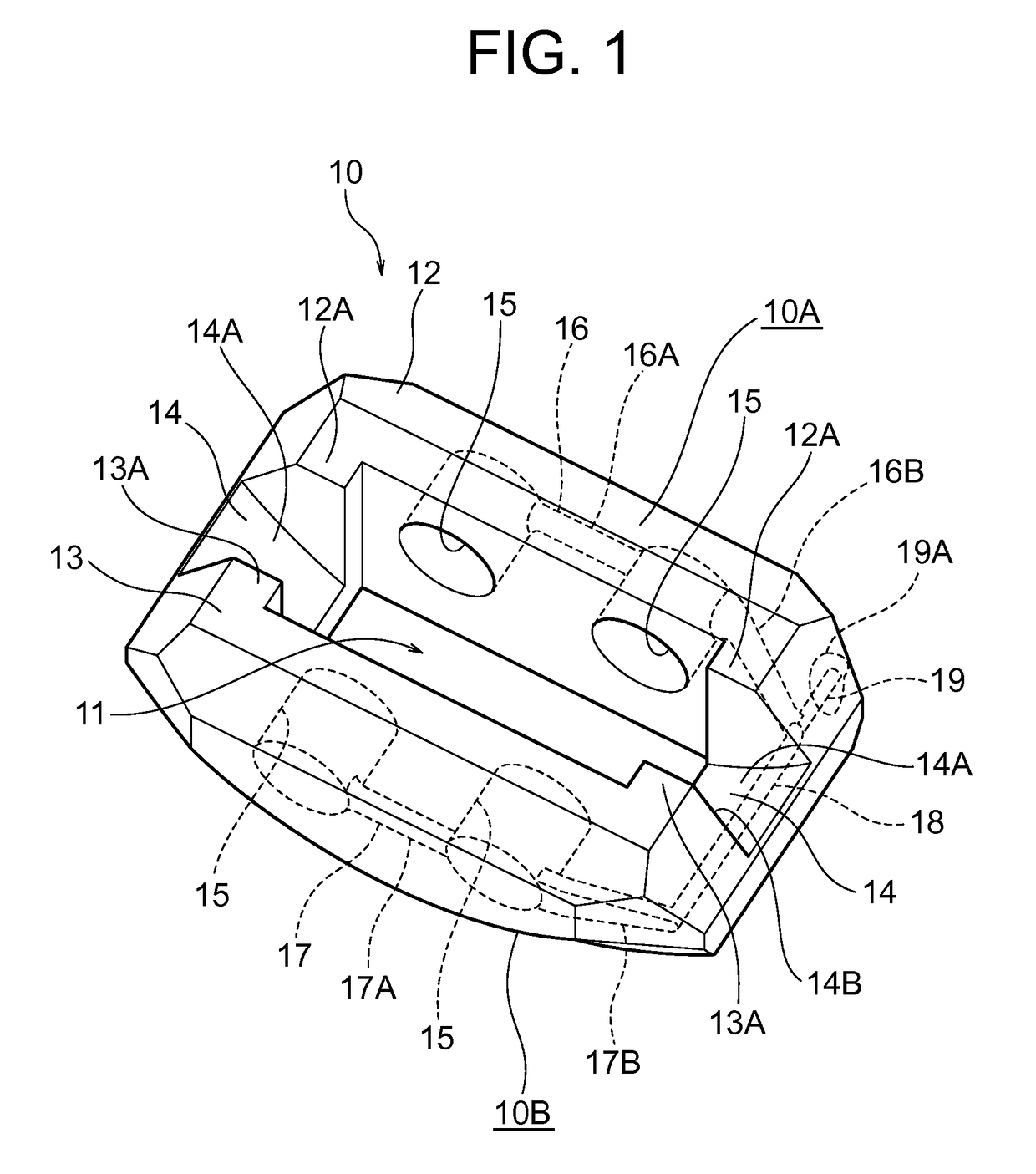

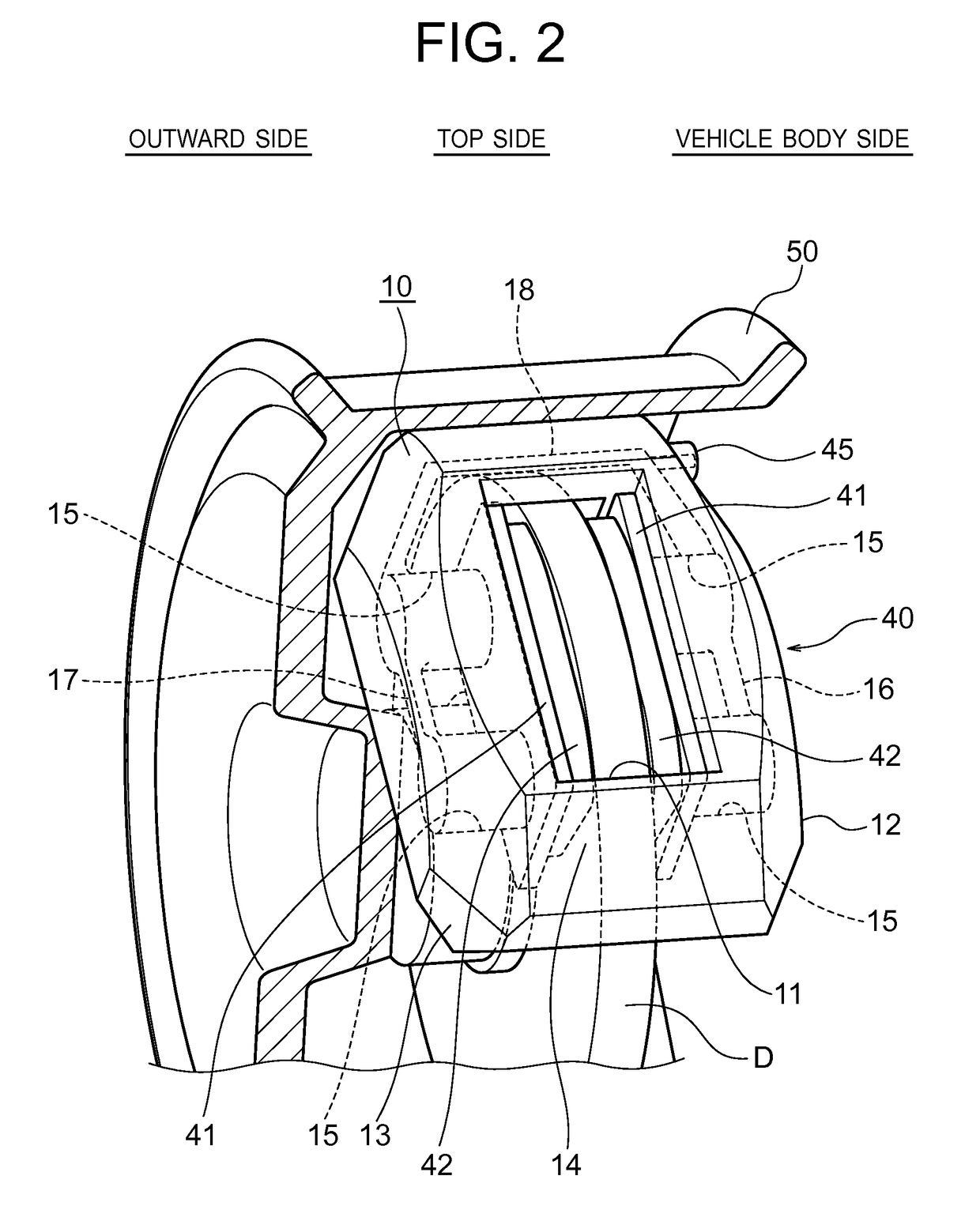

Caliper for disc brakes

ActiveUS9599175B2Improve productivityUnnecessary to performAxially engaging brakesFoundry mouldsHydraulic cylinderEngineering

A caliper comprises a hydraulic linking channel provided in a bridge section linking hydraulic cylinders, on an inner caliper section side, and hydraulic cylinders, on an outer caliper section side, to a cylinder-side hydraulic channel disposed on the back end of each respectively. A connecting channel forming section, which corresponds to each cylinder-side hydraulic channel and the hydraulic linking channel is provided, in advance, in a core used during casting of the inner caliper section, the outer caliper section, and the bridge section, and is formed by setting in a situation to be embedded at the same time as each caliper section and the bridge section are being integrally cast.

Owner:NIPPON LIGHT METAL CO LTD

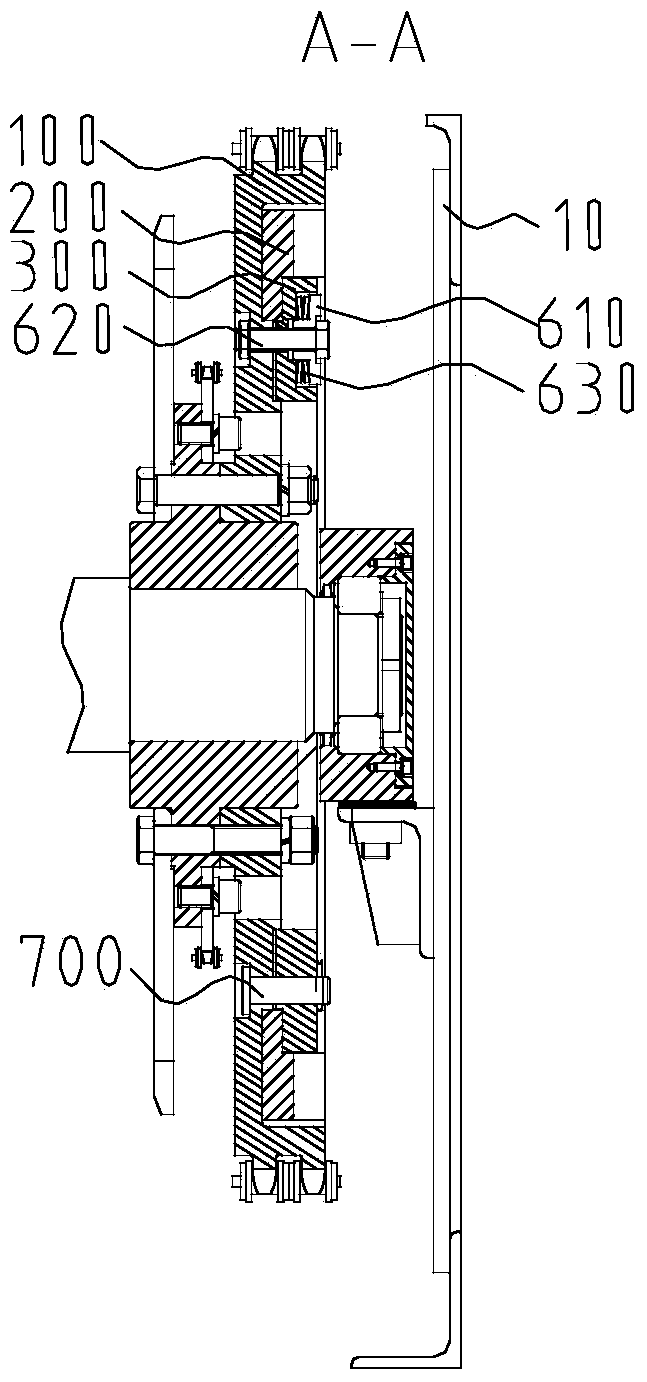

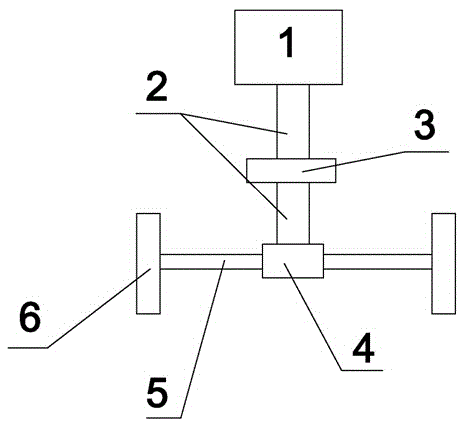

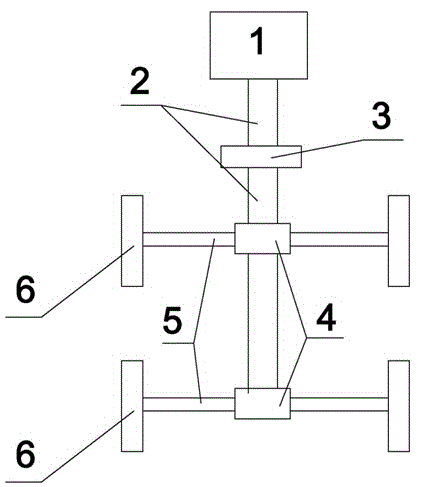

Transmission-shaft type vehicle brake system

InactiveCN104973034AEfficient driveReduce fuel consumptionMechanical braking transmissionDrive shaftVehicle driving

The invention provides a transmission-shaft type vehicle brake system. The transmission-shaft type vehicle brake system comprises a brake 1 arranged on a transmission shaft. The transmission shaft is connected with a rear transmission shaft half axle of the vehicle through a differential machine, and rear wheels are connected on the rear transmission shaft half axle. The brake is a seal-box fraction brake or a piston crankshaft transmission type brake. The vehicle brake system can decelerate vehicle braking without generating high temperature, so that the brake performance and stability when the vehicle goes down a microslope can be increased greatly, the vehicle is guaranteed to be driven well, frequent used of a traditional vehicle bake is decreased, and the service life of the traditional vehicle brake is prolonged. At the same time, according to the technical scheme of the transmission-shaft type vehicle brake system, engine load when a third brake is used can be decreased, fuel consumption of the vehicle is saved, the service life of the engine is prolonged, and the security of vehicle driving is improved. Braking with the assistant of the traditional brake in an emergency can improve the brake performance and the stability greatly.

Owner:张敬首

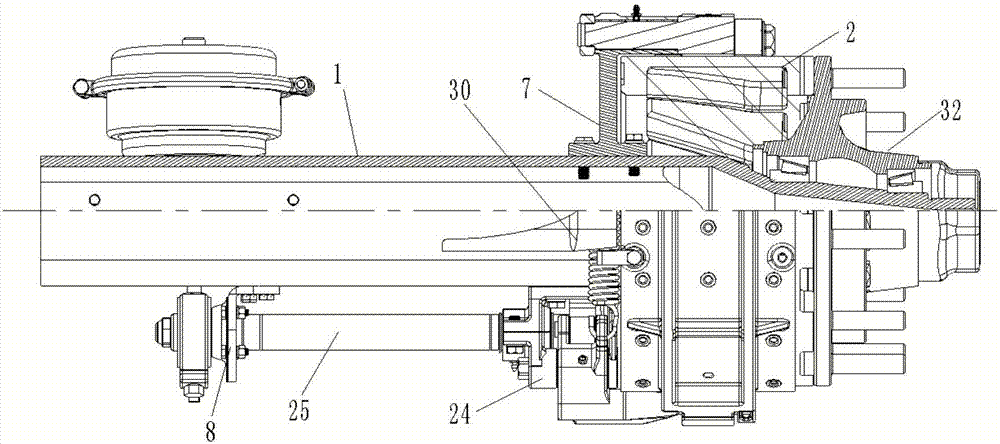

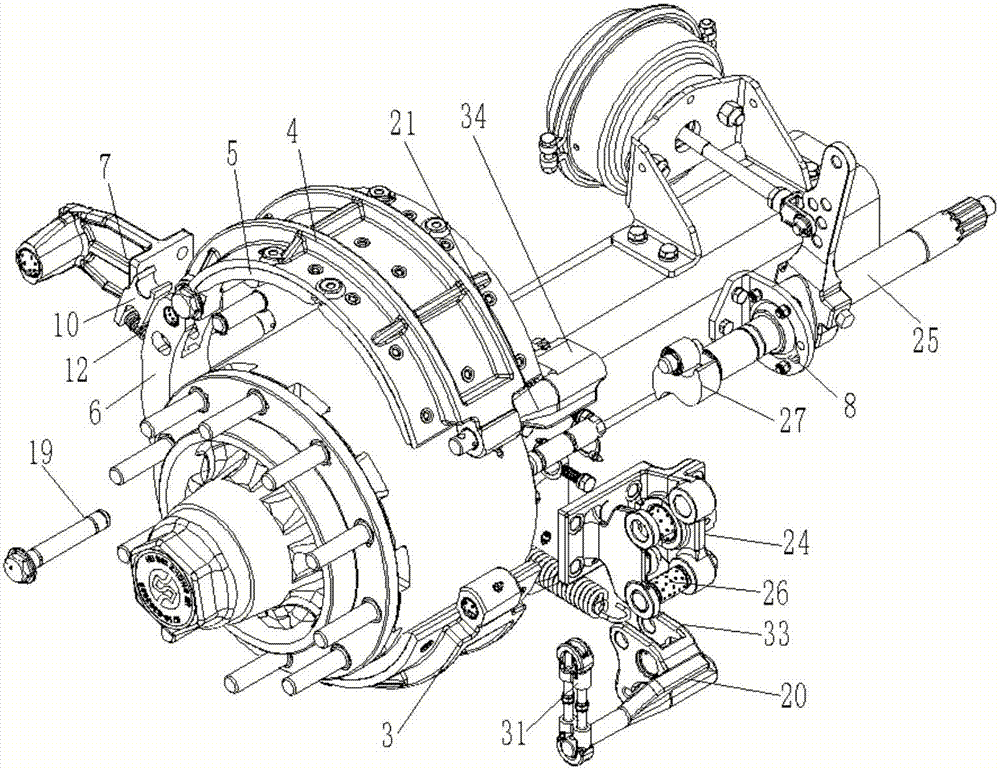

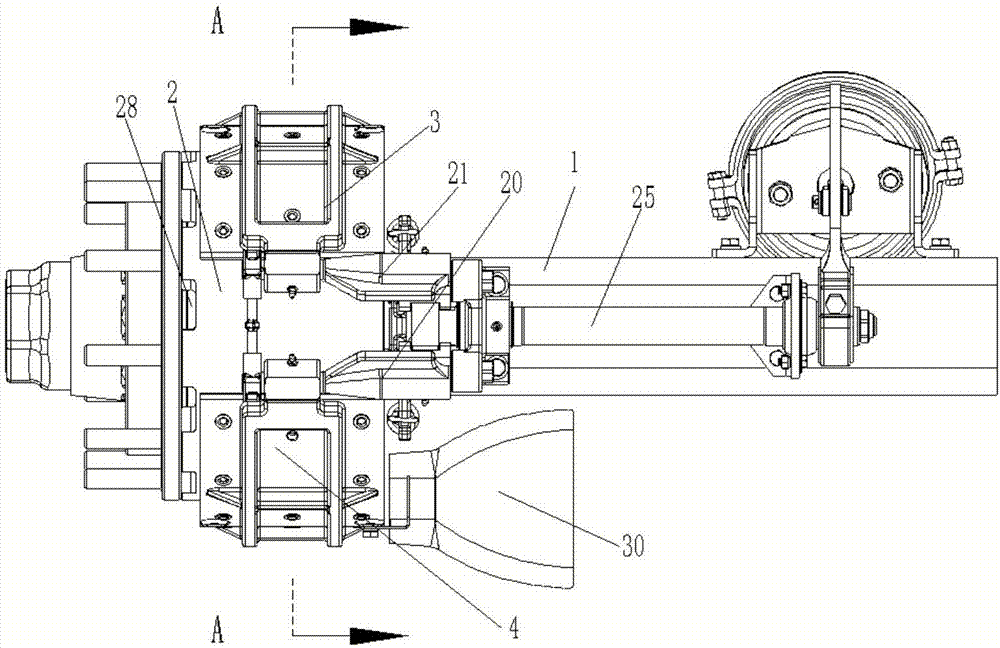

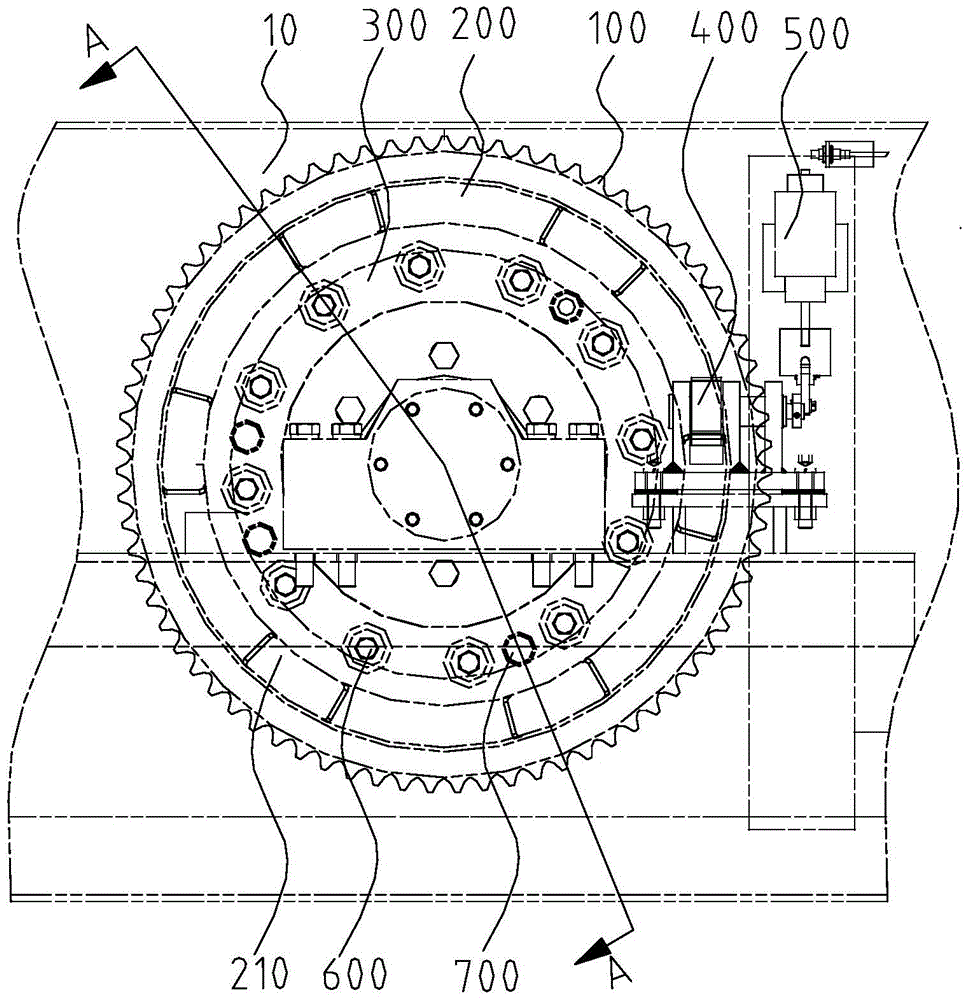

Side-arranged circumferential-embracing braked axle of motor truck

ActiveCN106979260AIncrease the effective braking areaEliminate the risk of ruptureMechanically actuated drum brakesRolling resistance optimizationCamTruck

The present invention provides a side-arranged circumferential-embracing braked axle of a motor truck. The axle comprises an axle shaft and a wheel hub, the inner side of the wheel hub is connected with a brake wheel synchronously running therewith, a circumferential-embracing brake shoe is arranged corresponding to the peripheral surface of the brake wheel, the brake shoe comprises a semi-arc left shoe piece and a semi-arc right shoe piece, a braking friction plate is disposed at an inner circumferential surface of each of the left shoe piece and the right shoe piece, the axle shaft is provided with a cam and swing arm embracing mechanism and a floating-type single axle mechanism, and one end of each of the left shoe piece and the right shoe piece is connected with the floating-type single axle mechanism while the other end is connected with the cam and swing arm embracing mechanism. The cam and swing arm embracing mechanism is arranged at one side of the brake shoe, so the effective braking area of the brake shoe is enlarged. With adoption of the floating-type single axle mechanism, the left shoe piece and the right shoe piece move in a uniformly-spaced manner in relative to the left shoe piece and the right shoe piece, so the working faces of the shoe pieces can simultaneously attach to the brake wheel for braking, the braking effect is improved, abrasion of the shoe pieces is reduced, and the braking life of the shoe pieces is prolonged.

Owner:HUBEI ZHONGER AXLE CO LTD

additional brake

Owner:HITACHI ELEVATOR GUANGZHOU ESCALATOR

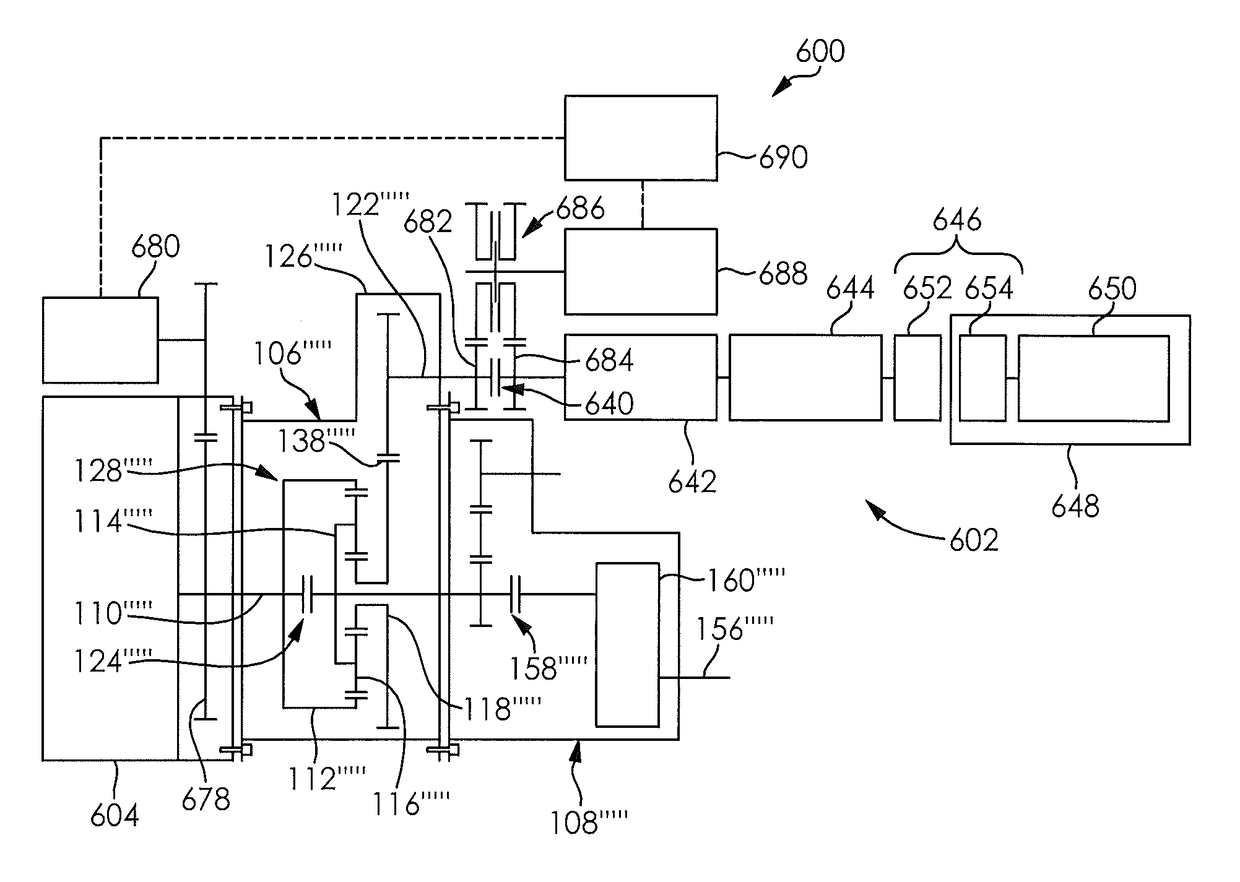

System and method for reducing aircraft brake wear

ActiveUS11254422B2Reduced brake wearExtend brake lifeEnergy efficient operational measuresAxially engaging brakesControl theoryMechanical engineering

Owner:HYDRO AIRE AEROSPACE CORP

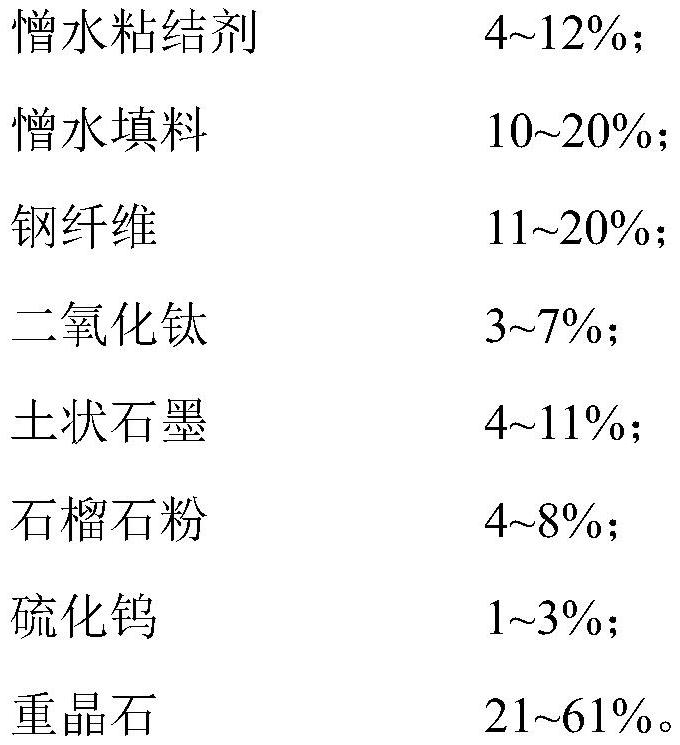

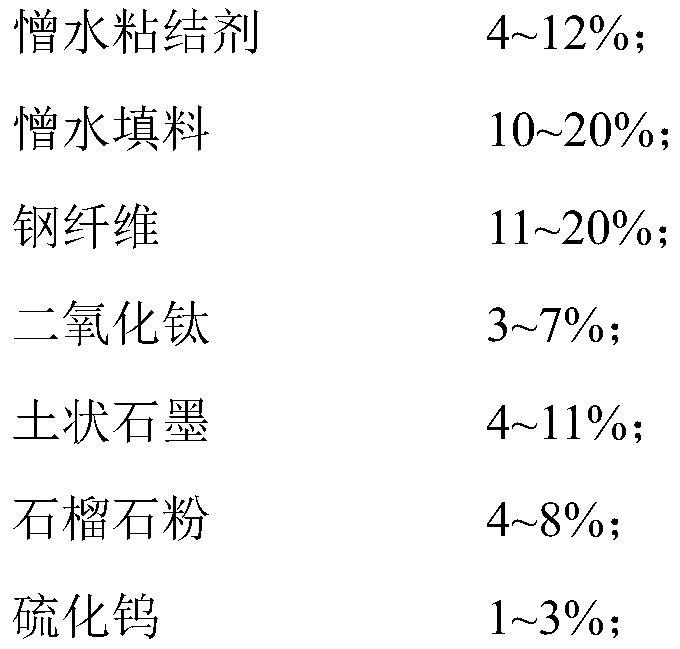

Hydrophobic friction material, brake pad and preparation method

ActiveCN112940448AGood hydrophobic effectGood high temperature performanceCoatingsFriction liningTitanium dioxideAdhesive

The invention provides a hydrophobic friction material which comprises the following components in percentage by mass based on the total mass of raw material components of the hydrophobic friction material: 4-12% of a hydrophobic binder, 10-20% of a hydrophobic filler, 11-20% of steel fibers, 3-7% of titanium dioxide, 4-11% of amorphous graphite, 4-8% of garnet powder, 1-3% of tungsten sulfide and 21-61% of barite. The hydrophobic friction material has good hydrophobicity, and coefficient reduction of the friction material after the friction material encounters water can be effectively inhibited; and a brake pad prepared from the hydrophobic friction material is stable in friction coefficient, and the braking safety after a vehicle wades into water is guaranteed. The invention further provides a preparation method of the brake pad, the process is simple, and operation is convenient.

Owner:SHANDONG GOLD PHOENIX

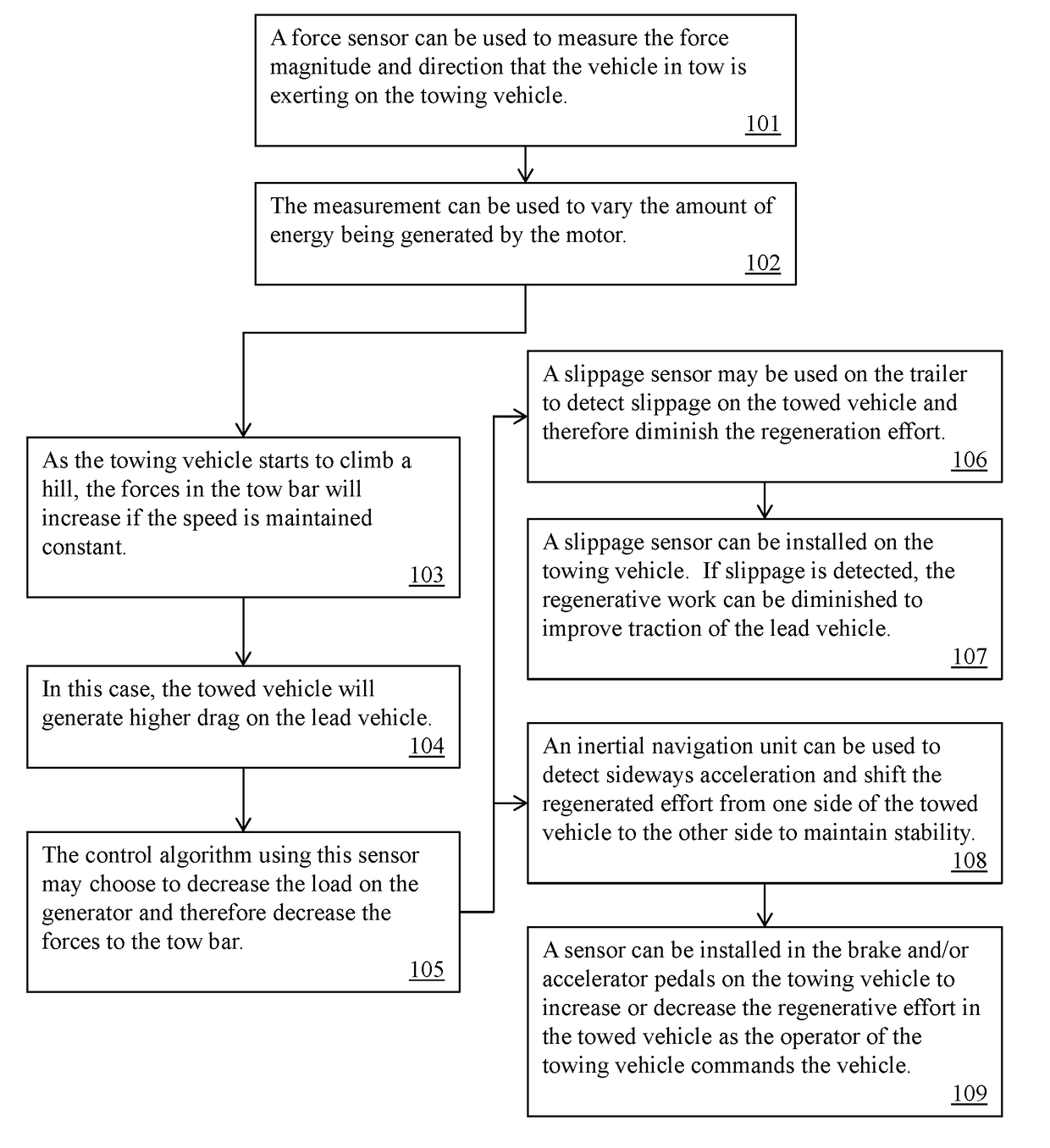

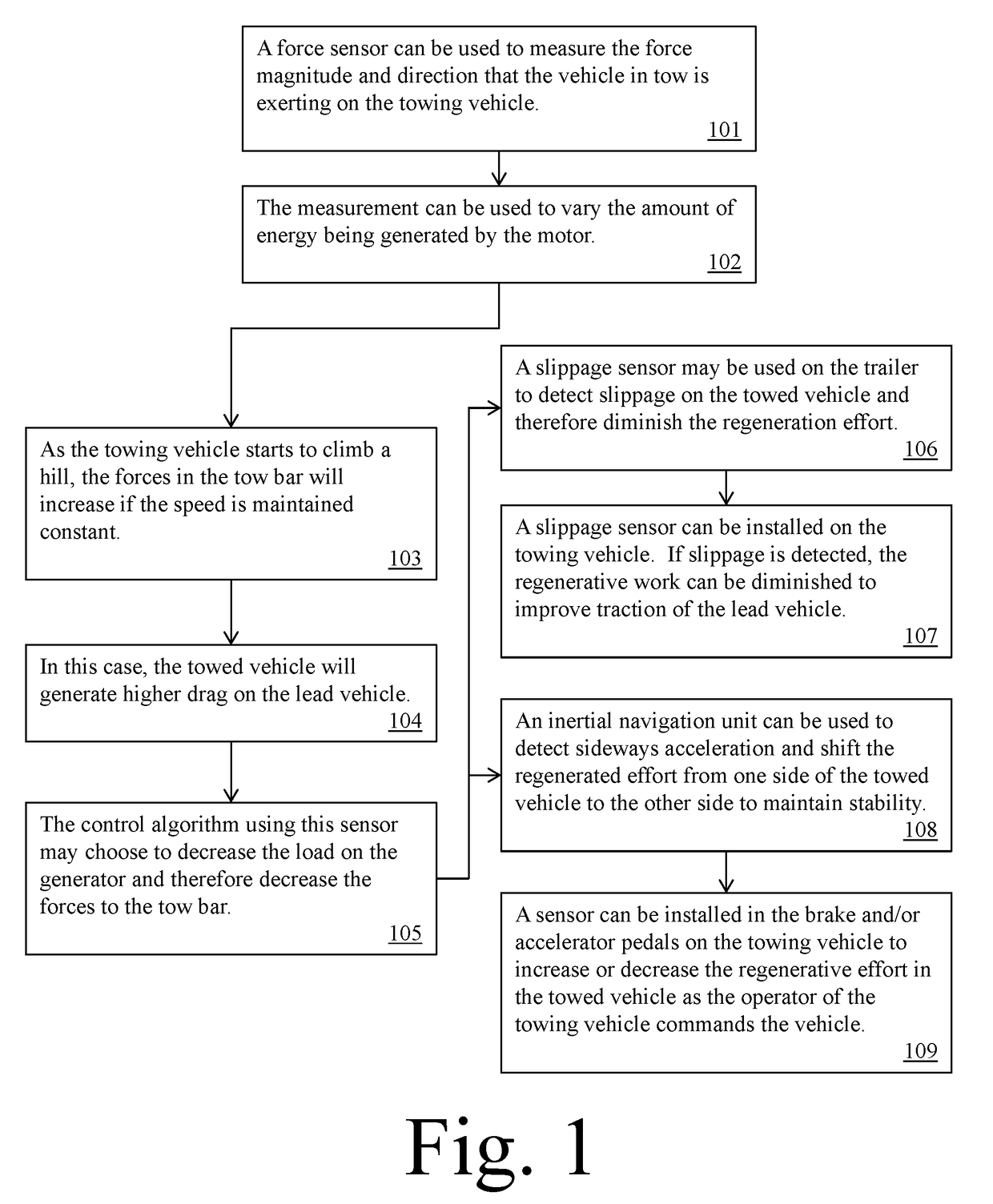

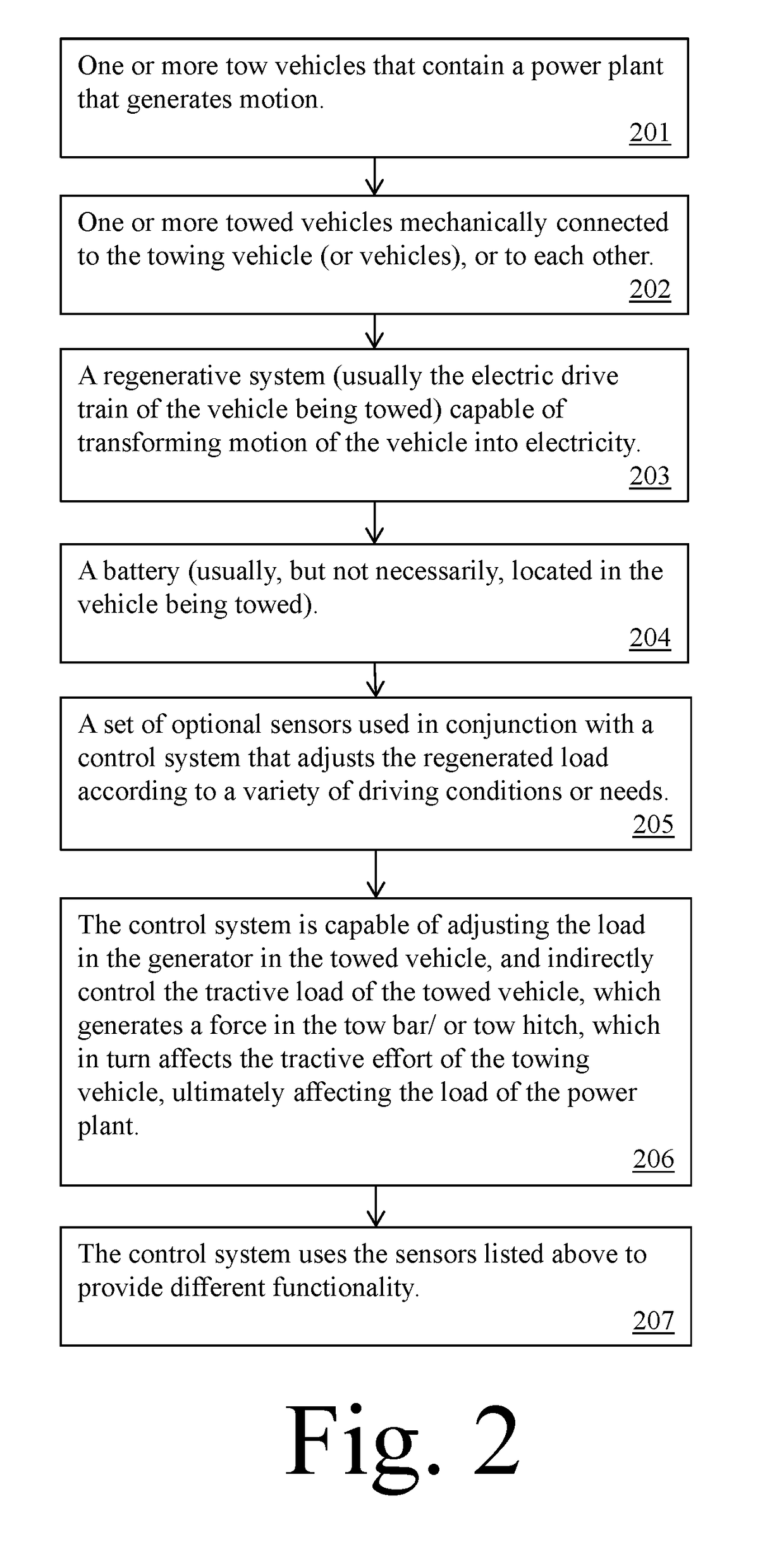

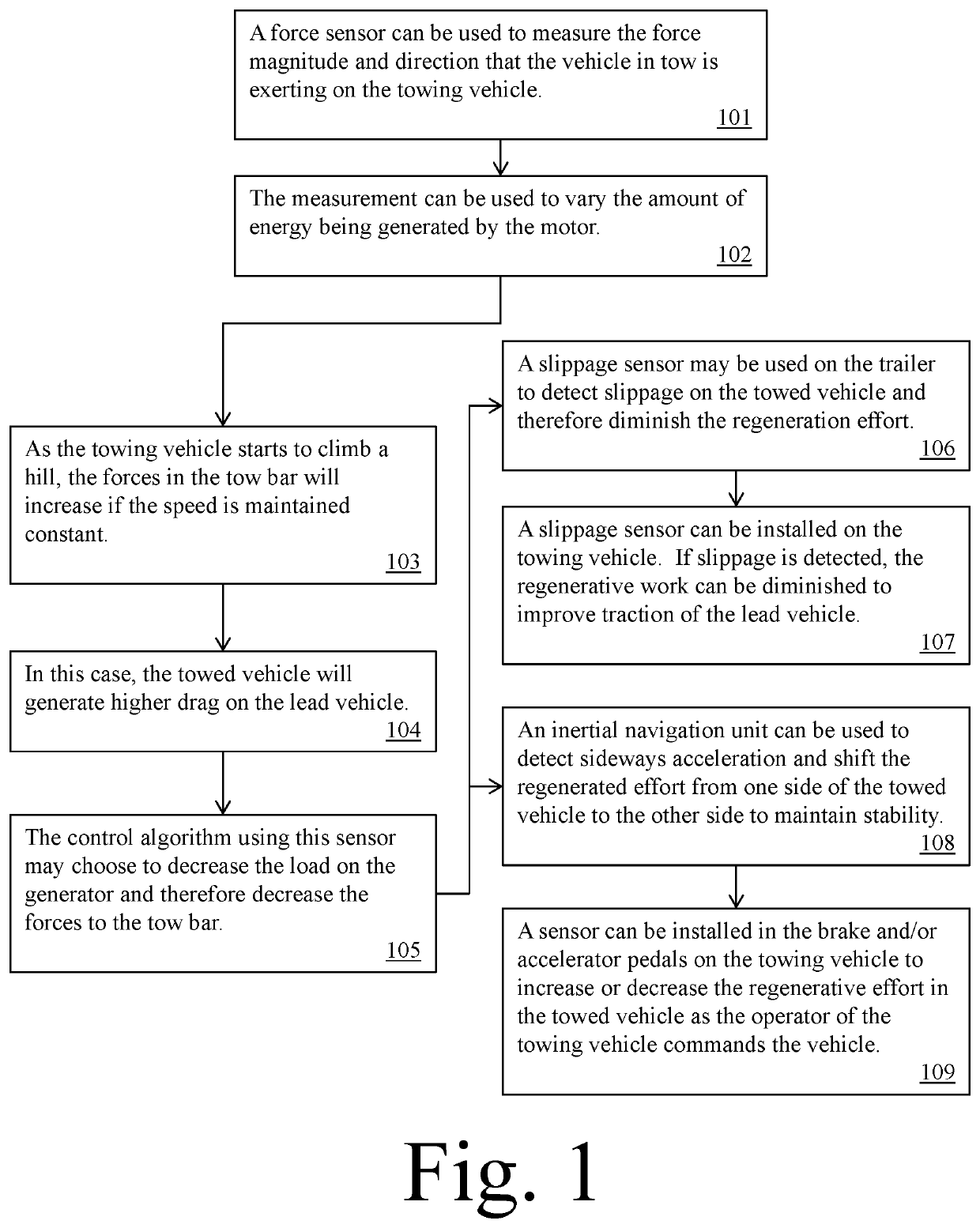

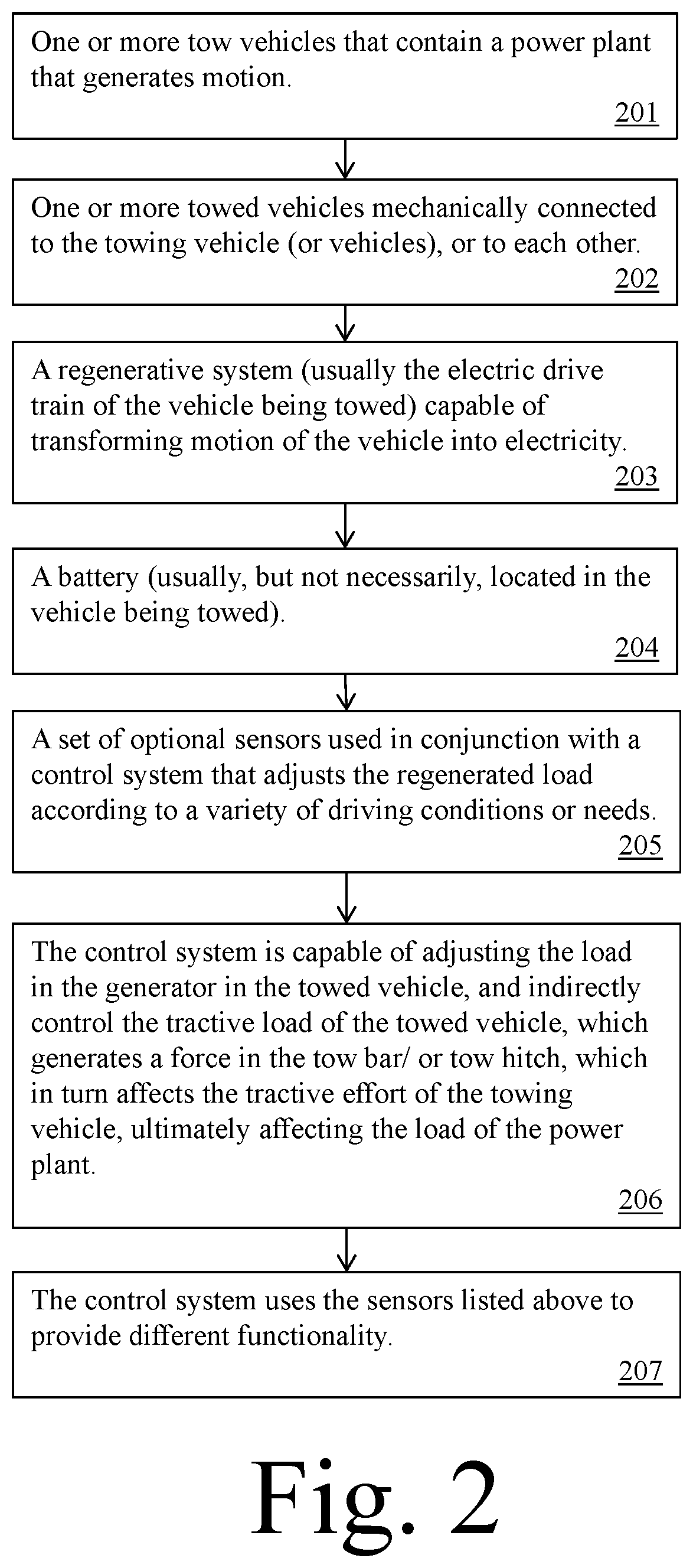

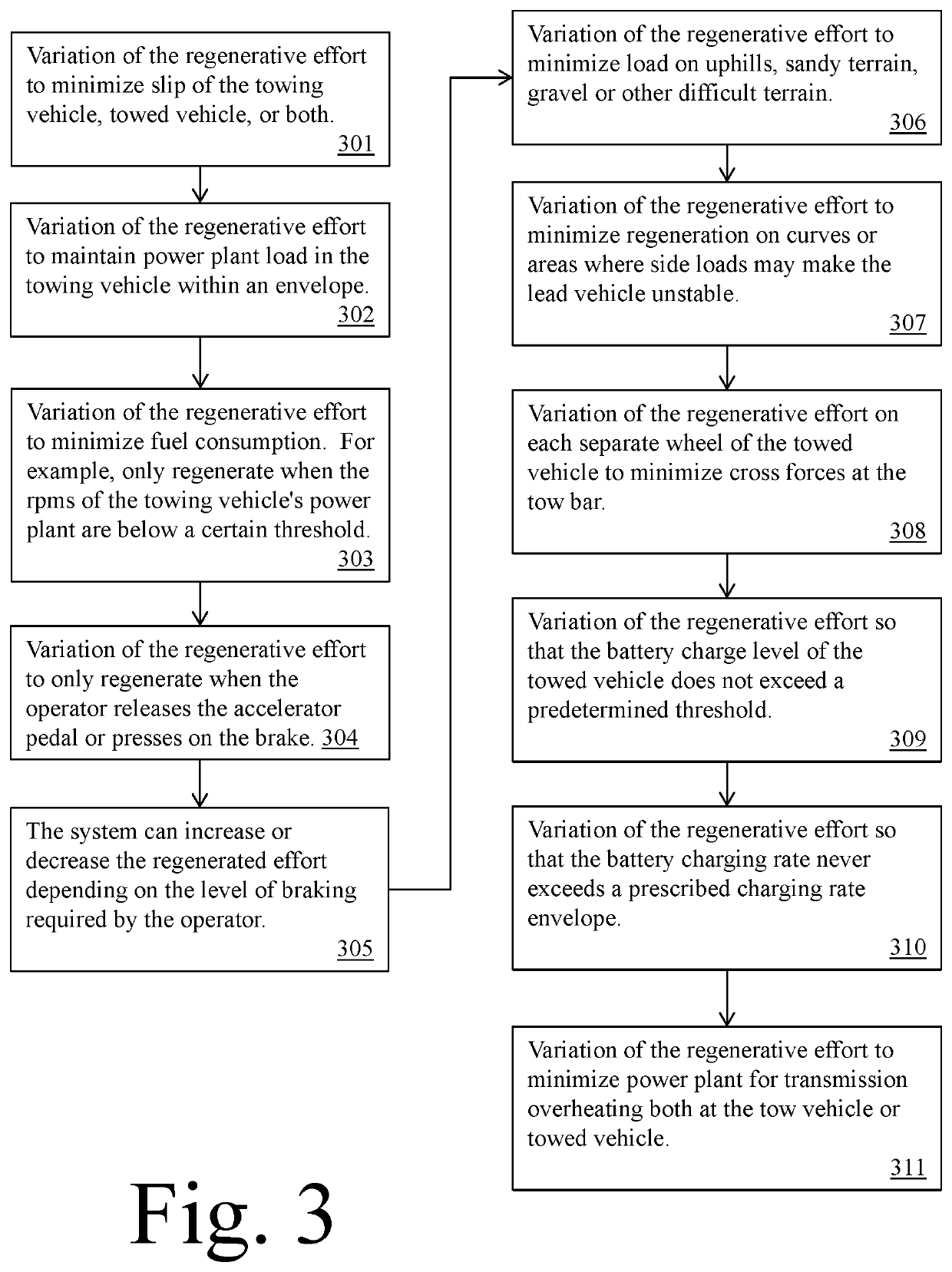

Energy Harvester While in Tow

ActiveUS20180312066A1Extend brake lifeImprove performance boundaryBraking element arrangementsElectrodynamic brake systemsElectric vehicleElectric energy

The invention being presented uses the motors already included in an electric vehicle to charge its batteries while in tow. The charging process provided by the invention is compatible with the charging speed of current battery technology. It will provide an effective way of charging vehicles in theater, when other sources of electrical energy may not be available.Moreover, the proposed system can actually extend the brake life of the towing vehicle and improve performance boundaries of the overall system.

Owner:ROBOTIC RES OPCO LLC

Energy harvester while in tow

ActiveUS10632850B2Extend brake lifeImprove performance boundaryBraking element arrangementsElectrodynamic brake systemsEnergy harvesterElectrical battery

The invention being presented uses the motors already included in an electric vehicle to charge its batteries while in tow. The charging process provided by the invention is compatible with the charging speed of current battery technology. It will provide an effective way of charging vehicles in theater, when other sources of electrical energy may not be available.Moreover, the proposed system can actually extend the brake life of the towing vehicle and improve performance boundaries of the overall system.

Owner:ROBOTIC RES OPCO LLC

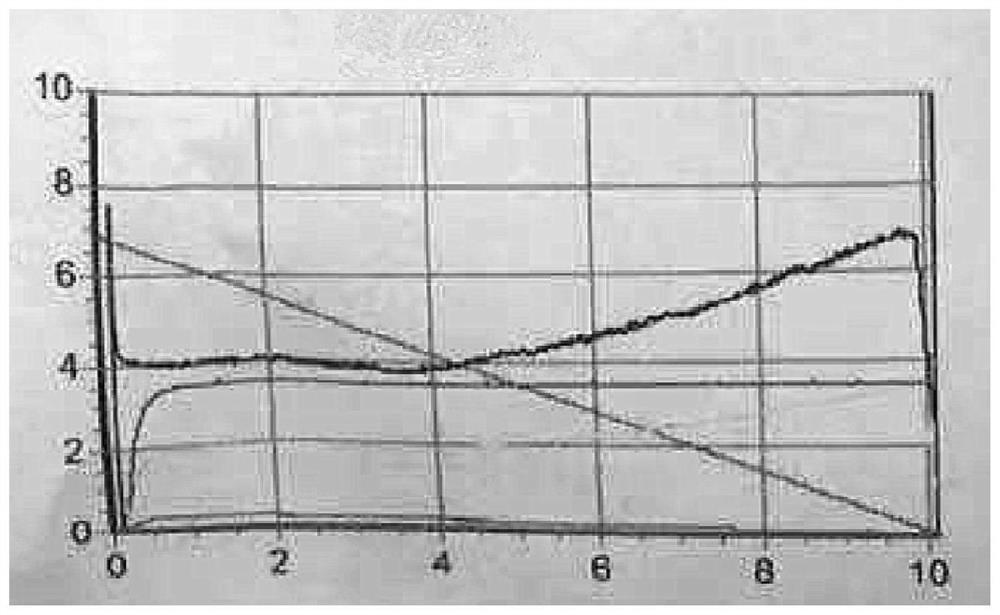

ABS system and energy recovery matched brake control method

InactiveCN111572355AImprove braking energy recoveryReduce overheating and wear problemsElectrodynamic brake systemsElectric vehicle charging technologyElectric machineryBrake control

The invention provides an ABS system and energy recovery matched brake control method. The method comprises the following steps: 1) acquiring a depth of a brake pedal by a vehicle control unit, and calculating to obtain a brake torque demand T0; 2) making the vehicle control unit communicate with a battery management system to obtain maximum rechargeable power of a continuous current and the maximum rechargeable power of a pulse current; 3) making the vehicle control unit communicate with the motor controller to obtain a motor braking torque T1 of a maximum continuous energy recovery current and a motor braking torque T2 of a maximum pulse energy recovery current; and 4) using the vehicle control unit to determine a braking energy recovery mode according to a wheel locking torque T, a braking torque demand T0, the motor braking torque T1 of the maximum continuous energy recovery current and the motor braking torque T2 of the maximum pulse energy recovery current. In the invention, thebraking energy recovery is carried out in a manner of synchronizing with a braking torque change waveform sent by the ABS auxiliary braking system so that a braking energy recovery rate can be improved to the maximum extent.

Owner:汉腾新能源汽车科技有限公司

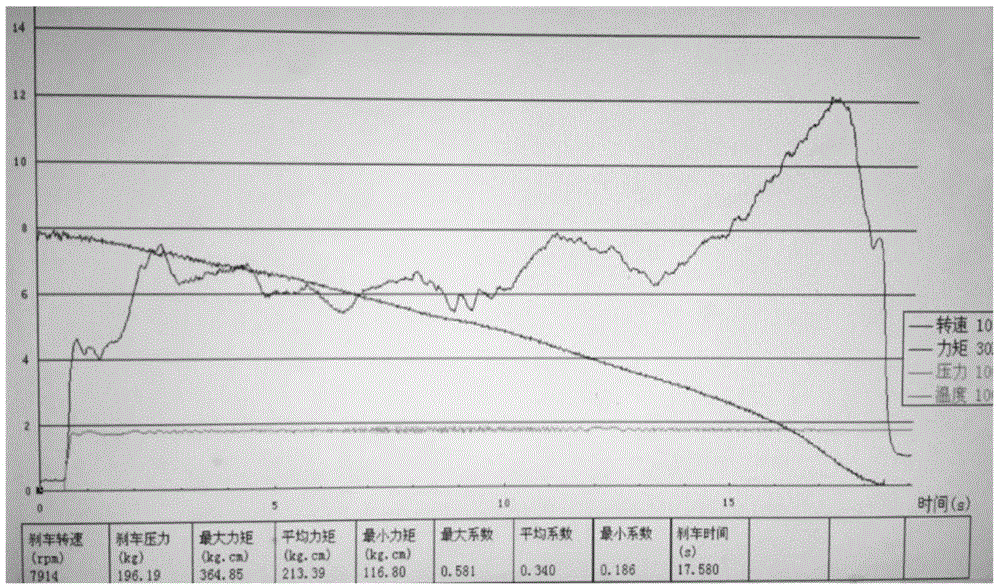

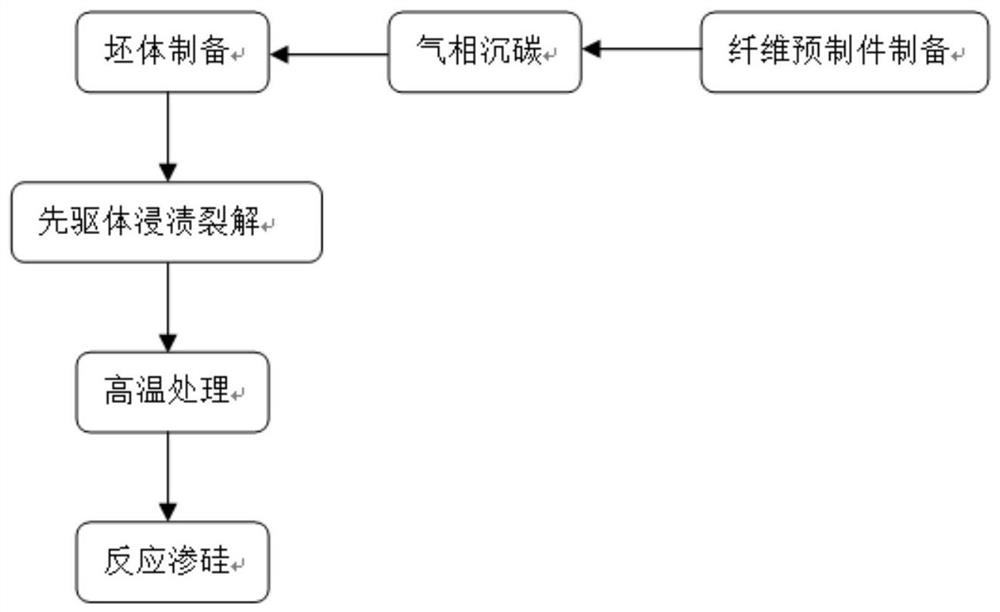

A kind of preparation method and application of carbon-ceramic composite material

ActiveCN105565837BThere is no problem of large distribution gradientReduce wearBraking discsActuatorsCeramic compositeDelivery system

The invention relates to a preparation method and application of a carbon / ceramic composite material, in particular to a preparation method and application of a carbon / ceramic composite material needed for braking a high-momentum delivery system. The preparation method includes: using a C / C composite material of 1.2-1.5 g / cm3 in density as a raw material; disposing the raw material in impregnation liquid I for impregnation, pyrolyzing in a protective atmosphere after impregnation, repeating impregnating-pyrolyzing operations until a carbon / ceramic composite material of 1.85-1.9 g / cm3 in density is obtained; treating the carbon / ceramic composite material obtained at high temperature until density of the carbon / ceramic composite material is lowered to 1.82-1.88 g / cm3 to obtain a pre-finished product; disposing the pre-finished product in impregnation liquid II, decomposing in a protective atmosphere after impregnation is completed, polishing after decomposing, and repeating impregnating-decomposing-polishing operations until a carbon / ceramic composite material finished product of 1.93-2.0 g / cm3 is obtained.

Owner:HUNAN BOWANG CARBON CERAMIC CO LTD

Hybrid drivetrain and method of operation thereof

InactiveUS9636986B2Improve fuel economyExtend brake lifeGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingFreewheelDrivetrain

A driveline for a vehicle is provided. The driveline includes a power source, a planetary gearset, a lockout clutch, a transmission, and a kinetic energy recovery system. The planetary gearset includes a sun gear, a carrier having a plurality of planet gears rotatably disposed thereon, and a ring gear. The power source is in driving engagement with a portion of the planetary gearset. The lockout clutch is capable of placing the planetary gearset in a locked out condition. The transmission is in driving engagement with another portion of the planetary gearset. The kinetic energy recovery system includes an accessory clutch and a flywheel. The accessory clutch facilitates driving engagement between the flywheel and another portion of the planetary gearset. The lockout clutch and the accessory clutch are selectively engaged to facilitate a transfer of energy to and from the transmission and the flywheel.

Owner:DANA CORP

A friction material, a brake pad prepared by using the friction material and a preparation method thereof

ActiveCN110081107BImprove water barrier effectImprove surface water barrierFriction liningActuatorsOxidation resistantMechanical engineering

The invention discloses a friction material, a brake pad prepared by the friction material and a preparation method of the brake pad. The preparation method of the brake pad comprises the following steps that (1) preparation of a copper-free metal friction material is performed; (2) hot-pressing molding is performed, wherein the copper-free metal friction material in the step (1) is placed in a hot-pressing mold cavity to be spread and flattened, a cushion layer material is put in the hot-pressing mold cavity to be spread and flattened, a steel backing is placed, hot-pressing molding is performed, and then demolding is performed; (3) a demolded sample undergoes heat treatment, and then is cooled to room temperature; and (4) post-treatment is performed on the sample after being treated in the step (3) to prepare the brake pad. According to the preparation method of the brake pad, the storage, transport cycle and oxidation resistance of the friction material in the brake pad can be obviously improved through rust prevention treatment.

Owner:SHANDONG GOLD PHOENIX

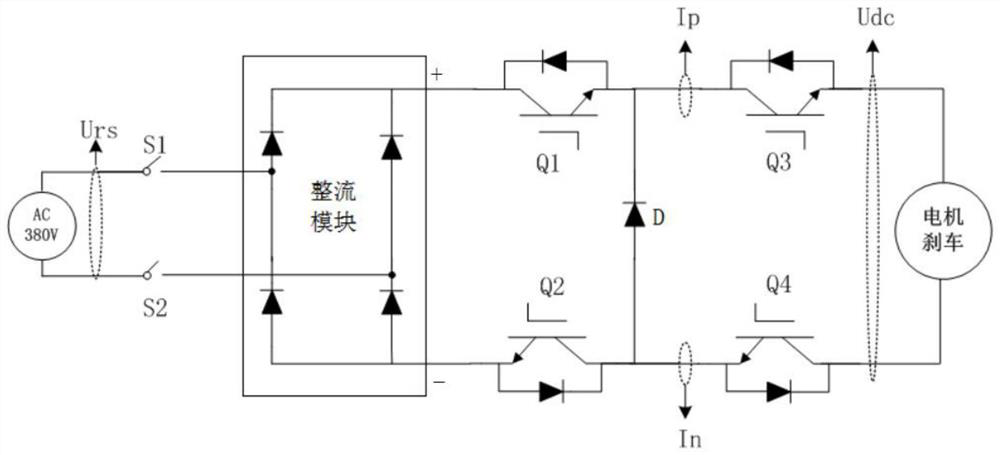

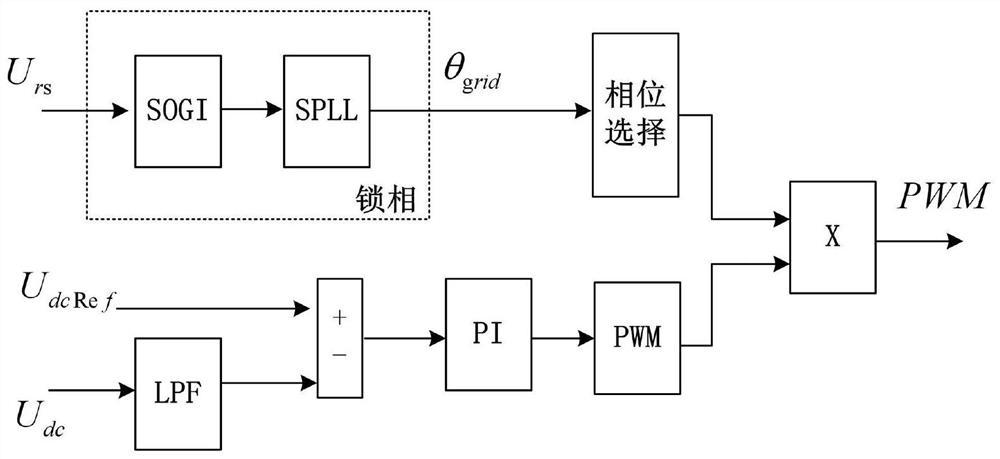

Brake power supply for construction hoist and control method

ActiveCN113541505ALow costEasy to implementAC motor controlAc-ac conversionLoop controlPower switching

The invention discloses a brake power supply for a construction hoist and a control method. The brake power supply comprises a 380V power supply, a switch S1, a switch S2, a rectification module, an IGBT switch Q1, an IGBT switch Q2, an IGBT switch Q3, an IGBT switch Q4 and a diode, the 380V power supply is connected with the input end of the rectification module through the switch S1 and the switch S2, the output end + of the rectification module is connected with the drain electrode of the IGBT switch Q1, and the source electrode of the IGBT switch Q1 is connected with the diode and the drain electrode of the IGBT switch Q3. A design scheme different from a traditional brake power supply is adopted, and controllable rectification voltage reduction output voltage is achieved by designing a novel power electronic topological structure; and secondly, an independent chip is used for controlling and protecting the brake power supply, so that the stability and the safety of brake control are improved. Particularly, in the aspect of software control, stable and reliable direct-current output voltage is realized by adopting a more accurate closed-loop control mode.

Owner:长沙市日业电气有限公司

A kind of copper-free NaO friction material and its preparation method and application

The invention discloses a copper-free NAO friction material and a preparing method and application thereof, and belongs to the technical field of car parts. The copper-free NAO friction material comprises following raw materials including, in parts by weight, 4 to 17 parts of a binder, 6 to 30 parts of reinforced fibers, 1 to 10 parts of an organic conditioner, 3 to 23 parts of friction increasingfiller, 2 to 18 parts of metal sulfide, 15 to 40 parts of carbon materials, 5 to 35 parts of titanate filler and 5 to 57 parts of space filler. The carbon materials are selected from composition of synthetic graphite, granular coke, crystalline flake graphite and bamboo charcoal powder; the space filler is a composition of attapulgite and barite; according to the material and the preparing methodand application thereof, the brake service life of the NAO friction material can be obviously prolonged, the whole density and the unit size cost of a brake pad are reduced, the heat resistance and the noise of the friction material are effectively improved, an attapulgite hole structure absorbs fine dust and formaldehyde generated by friction surface wear, dust falling can be effectively avoided, and environment friendliness is improved.

Owner:SHANDONG GOLD PHOENIX

Methods and system for engine braking

ActiveUS11192537B2Reduce the possibilitySlow vehicleBraking element arrangementsEngine controllersControl theoryHybrid powertrain

Systems and methods for operating a hybrid powertrain or driveline that includes an engine and an integrated starter / generator are described. In one example, rotation of an automatically stopped engine may be inhibited when engine braking is requested so that the engine may not be rotated without providing a desired outcome.

Owner:FORD GLOBAL TECH LLC

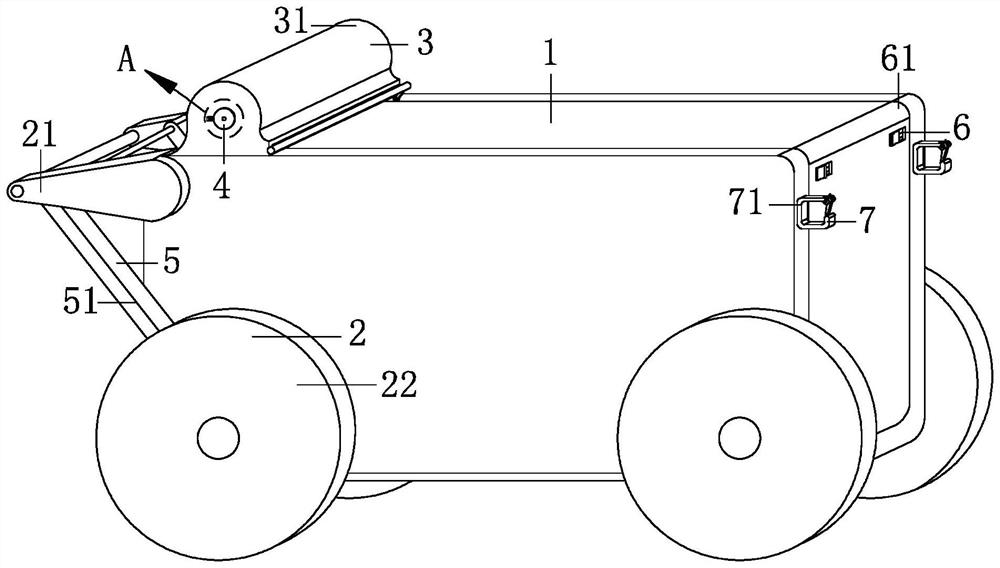

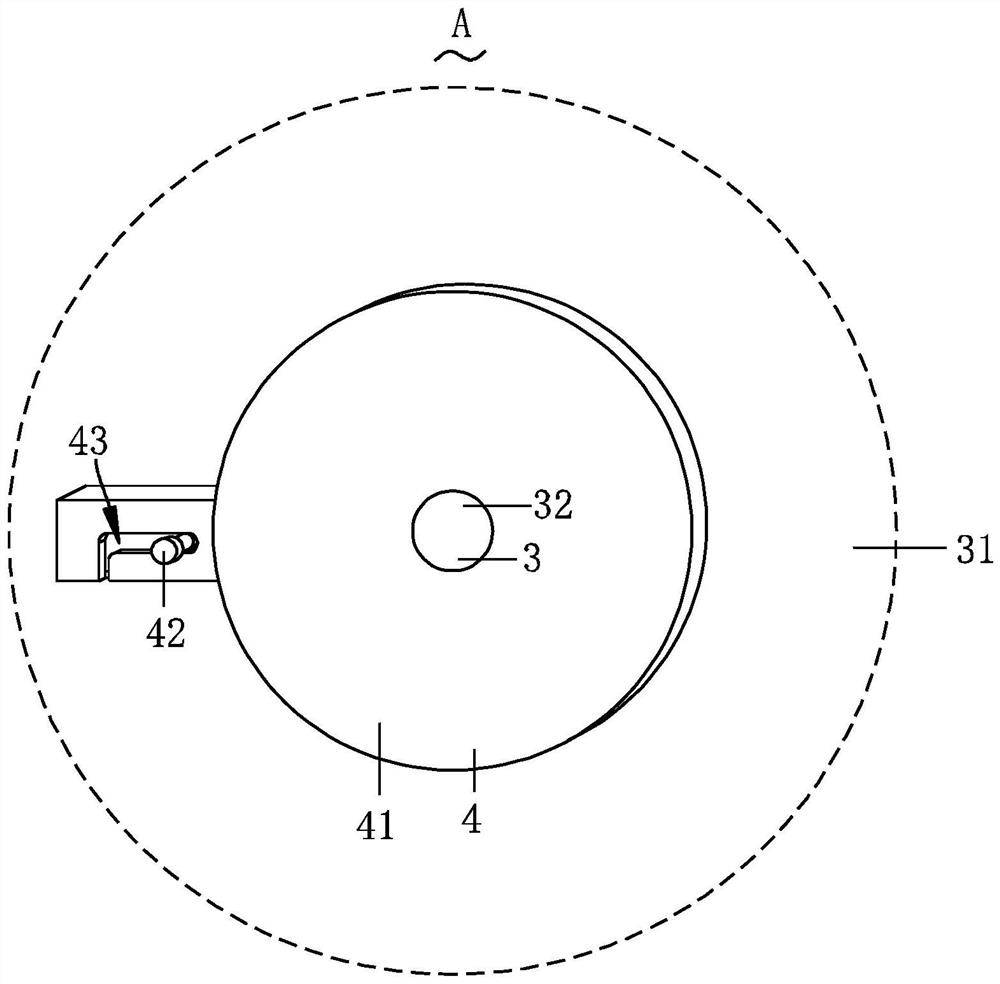

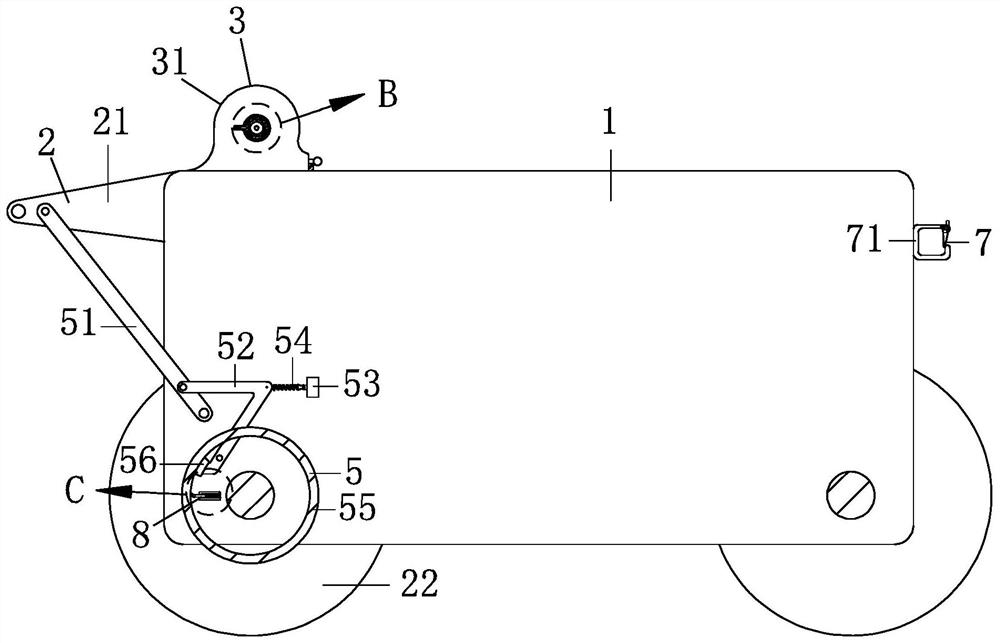

Nutrient soil carrying device with rain shielding performance

PendingCN114802374AEasy to transportAvoid getting wetCleaning using toolsVehicle cleaningSoil scienceEnvironmental engineering

The invention relates to the technical field of garden equipment, in particular to a nutrient soil carrying device with rain shielding performance, which comprises a main body, a moving structure, a shielding structure, a limiting structure, a braking structure, a rotating structure, a fixing structure, a rubbing structure and a cleaning structure, further, the main body is conveniently pushed through the moving structure, so that the nutrient soil is conveniently transported; nutrient soil in the main body can be prevented from being wetted by rainwater through the shielding structure, and fertility decline is avoided; the braking structure can limit movement of the device, personal safety is guaranteed, and then nutrient soil feeding and discharging of the main body are facilitated; through the fixing structure, the shielding structure can be well fixed, and the situation that fixation is not firm under the condition of strong wind is avoided; the rubbing structure can clean the braking structure, and the braking service life is prolonged; the cleaning structure can prevent nutrient soil from being brought into the shielding structure.

Owner:高怀秀

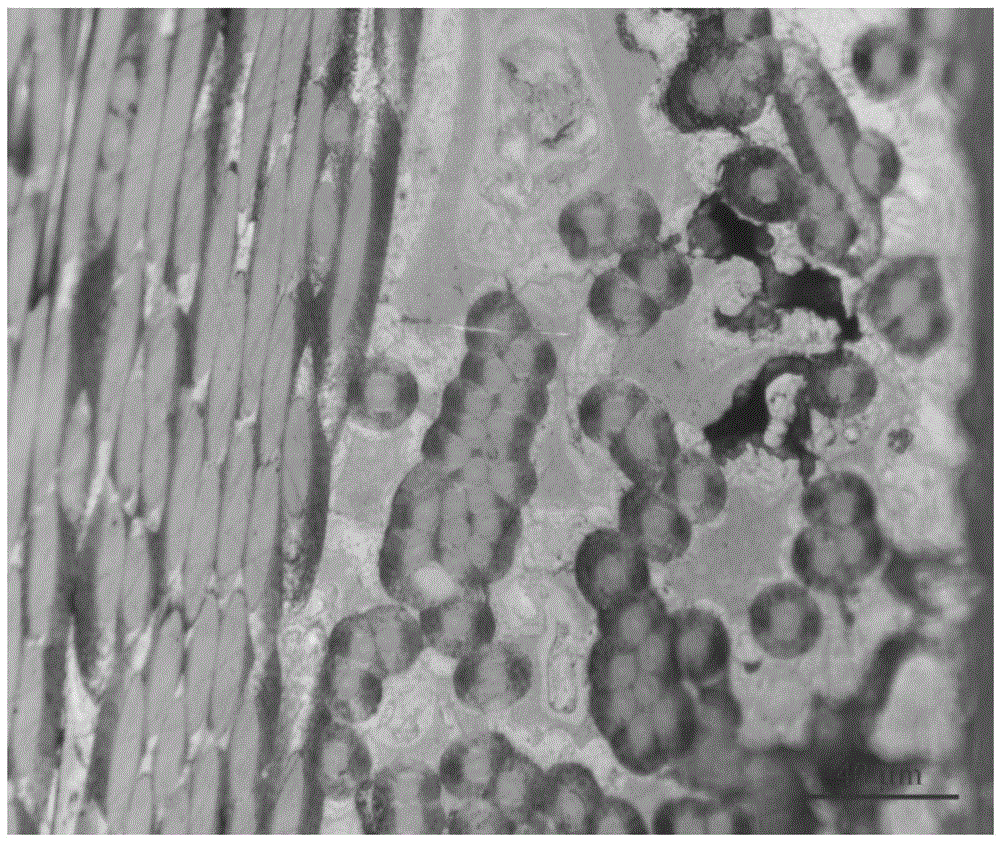

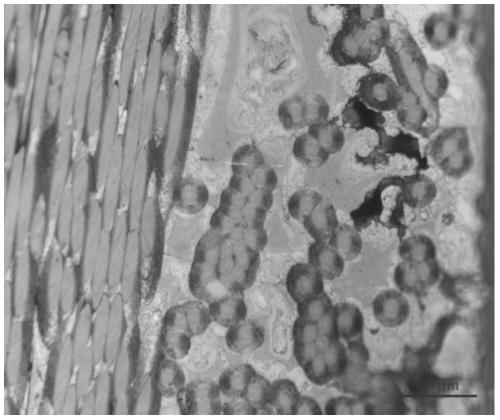

Preparation method and application of a carbon ceramic friction material

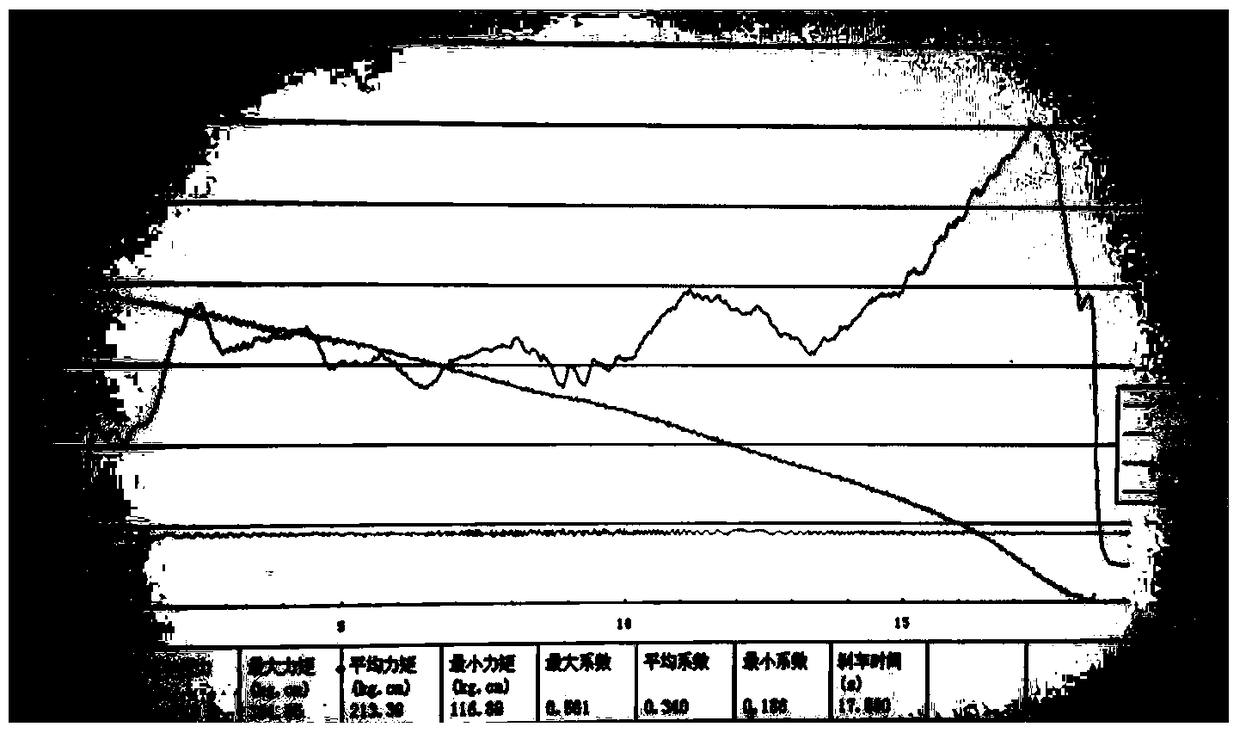

ActiveCN110395999BHardness adjustmentReduce wearFriction liningActuatorsAirplaneTemperature treatment

The invention discloses a preparation method and application of a carbon-ceramic friction material. The preparation method comprises the following steps: 3 The C / C composite material is a green body that undergoes PIP treatment, high temperature treatment, and RMI treatment in sequence to obtain a density of 1.9‑2.2g / cm 3 carbon-ceramic friction material; the RMI treatment process is to place the high-temperature-treated green body in a graphite mold paved with silicon powder and amorphous silicon carbide powder, and under vacuum conditions, the siliconization reaction, the non- Shaped silicon carbide powder is obtained by sintering silicon carbide ceramic precursors at 800-1000°C. The carbon-ceramic friction material prepared by the method of the present invention adjusts the particle size gradation and content of different silicon carbides in the material, and the obtained friction material has an adjustable and stable friction coefficient, a small amount of wear, no obvious vibration during the braking process, and the braking curve is rectangular. , stable, no tail warping, no large attenuation in the wet state after friction, suitable for brake discs required for the braking of aircraft, automobiles, heavy trucks, high-speed trains and other transportation systems.

Owner:HUNAN BOWANG CARBON CERAMIC CO LTD

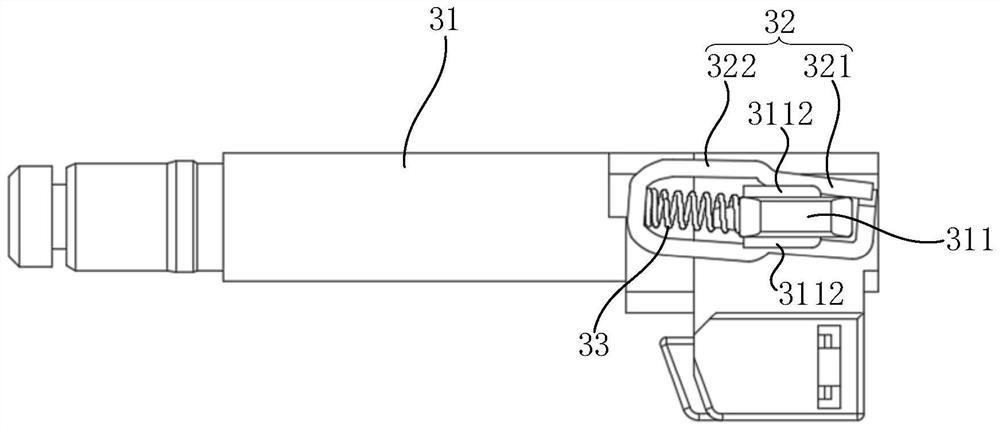

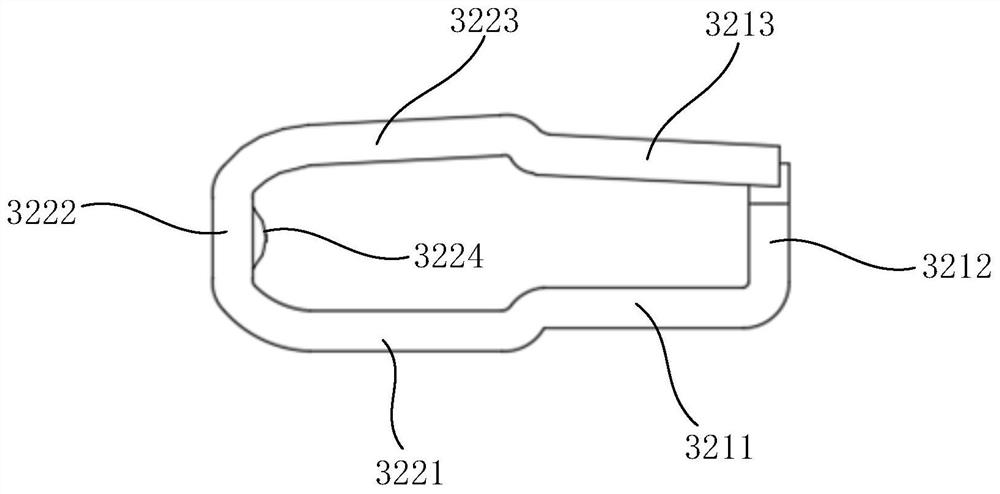

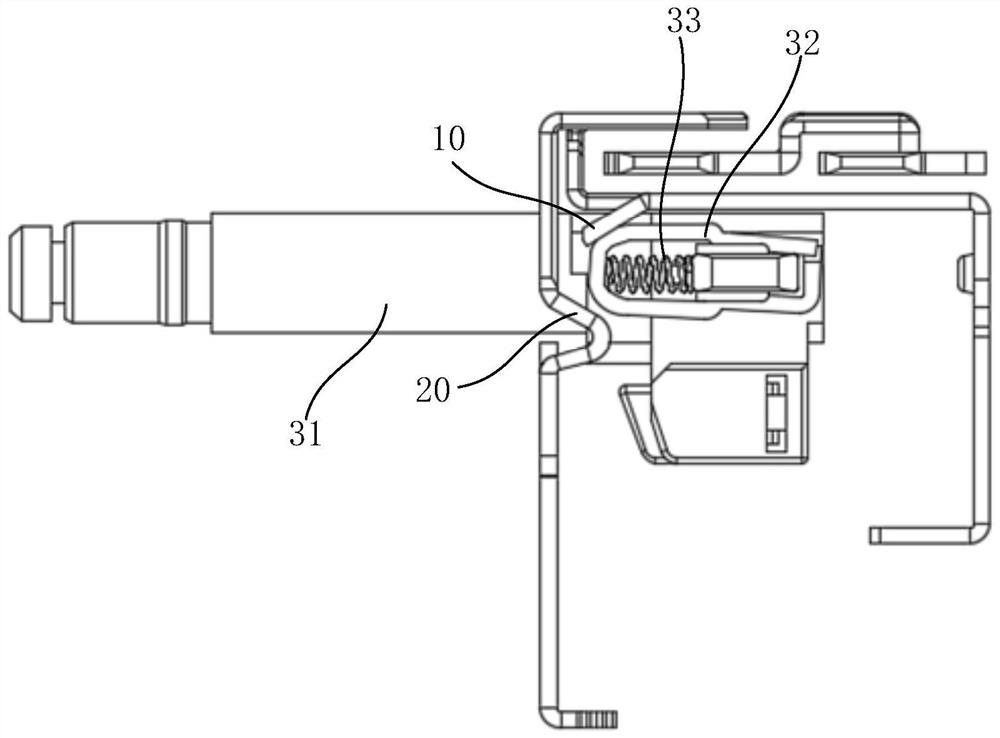

Brake assembly, electric tool switch and electric tool

PendingCN114188170AExtended service lifeExtend brake lifeElectric switchesPortable power-driven toolsPower toolControl theory

The invention discloses a brake assembly, an electric tool switch and an electric tool, the brake assembly is partially arranged in the electric tool switch, is used for short circuit of a terminal D connected with a motor and a main loop terminal in the electric tool switch, and comprises a push rod, a brake pad and a brake spring, the brake pad is installed on the push rod, and the brake spring is installed on the brake pad. The brake spring is arranged between the brake pad and the push rod, the brake pad comprises a short circuit part, the brake pad has an initial state and a brake state, and when the brake pad is in the initial state, the short circuit part is obliquely arranged towards the side close to the D terminal; when the brake pad is in a braking state, the short circuit part and the push rod are arranged in parallel, and the short circuit part abuts against the D terminal and the main loop terminal. The brake assembly can prolong the brake service life of the electric tool switch and prolong the service life of the electric tool. Correspondingly, the invention further provides an electric tool switch and an electric tool.

Owner:SHANGHAI BAICHENG ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com