Preparation method and application of a carbon ceramic friction material

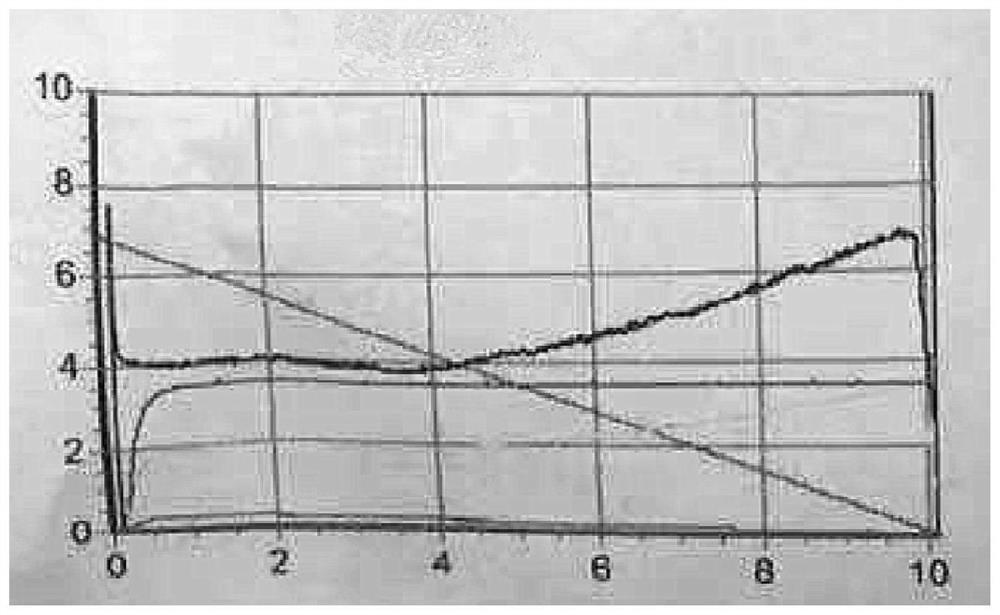

A technology of friction materials and carbon ceramics, which is applied in the direction of friction linings, mechanical equipment, gear transmission mechanisms, etc., can solve the problems of unstable braking performance, easy locking, and damage to material strength, so as to reduce the existence of residual silicon and brake Stable performance and extended brake life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

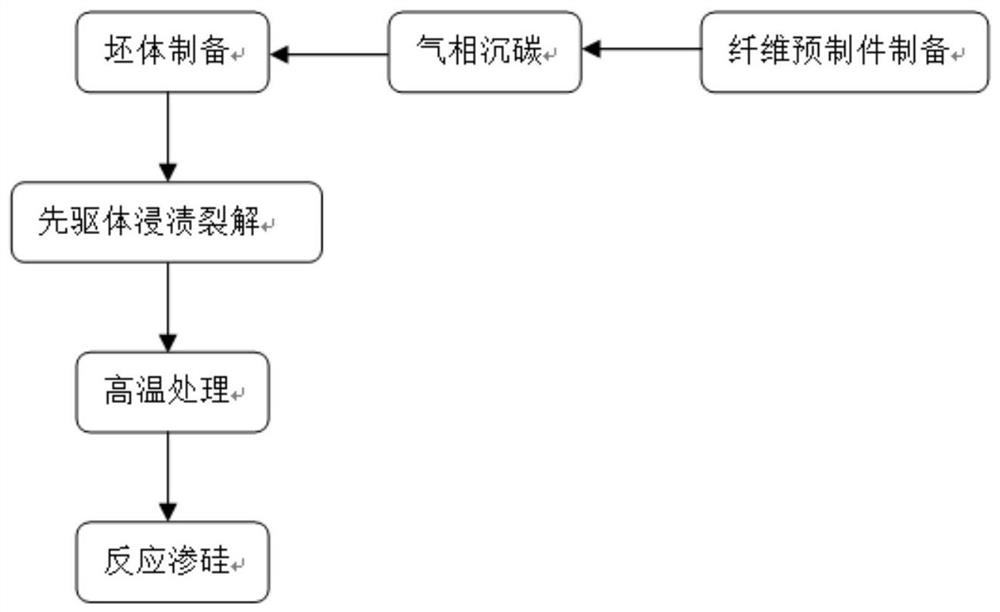

Method used

Image

Examples

Embodiment 1

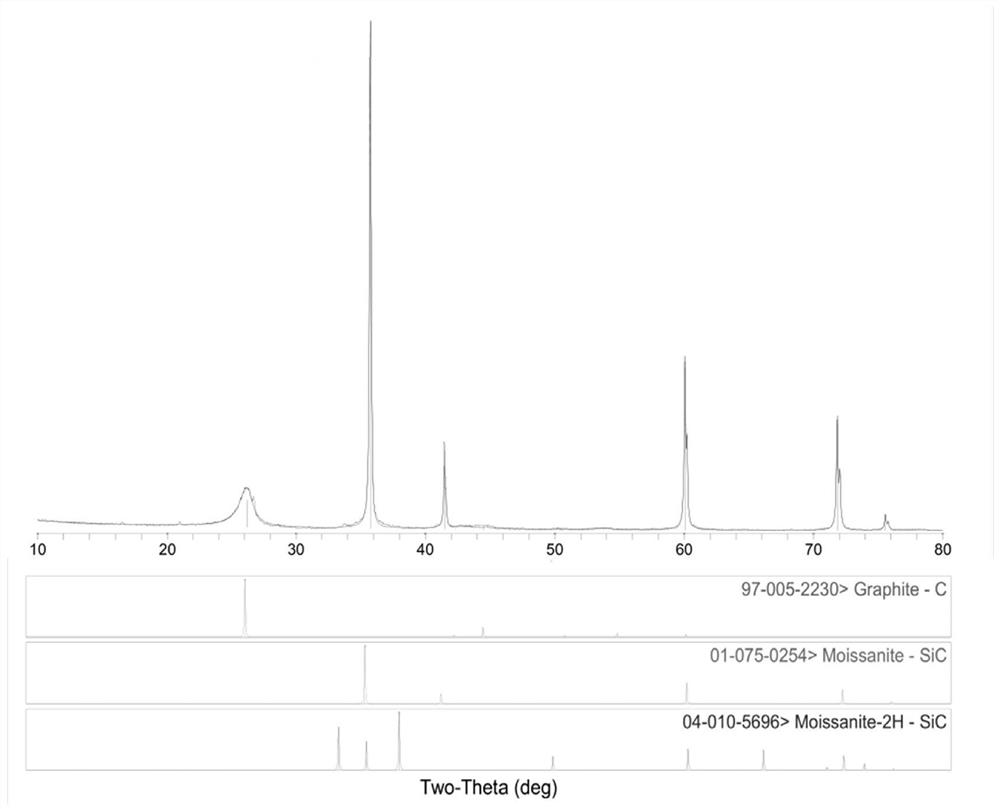

[0045] The carbon-ceramic sample that will be prepared in the embodiment 1 of the present invention, its green body used is that density is 1.28, 1.37g / cm 3 Two pieces of C / C composite material.

[0046] step one:

[0047] The impregnating solution is prepared according to the mass ratio of polymethylsilane: styrene = 100:30, and the C / C green body is placed in a metal impregnating tank, vacuum impregnated for 2 hours, and pressure impregnated for 6 hours. After the impregnation is completed, the impregnation liquid is released, and the impregnated green body is put into a graphite tooling and put into a cracking furnace at 900°C for cracking. The whole process is protected by a nitrogen atmosphere, and the above impregnation-cracking process is repeated twice. During vacuum impregnation, the vacuum degree is controlled to be ≤10Pa, and the pressurized impregnation pressure is 5.5MPa.

[0048] Step two:

[0049] heat treatment. The pre-finished product prepared in step 1 ...

Embodiment 2

[0062] The carbon-ceramic sample that will be prepared in the embodiment 2 of the present invention, its green body used is that density is 0.92, 1.05g / cm 3 Two pieces of C / C composite material.

[0063] step one:

[0064] The impregnating solution is prepared according to the mass ratio of polymethylsilane: styrene = 100:40, and the C / C green body is placed in a metal impregnating tank, vacuum impregnated for 3 hours, and pressure impregnated for 4 hours. After the impregnation is completed, the impregnation liquid is released, and the impregnated green body is put into a graphite tooling and put into a cracking furnace for cracking at 1000°C. The whole process is protected by a nitrogen atmosphere, and the above impregnation-cracking process is repeated 3 times.

[0065] During vacuum impregnation, the vacuum degree is controlled to be ≤10Pa, and the pressurized impregnation pressure is 4MPa.

[0066] Step two:

[0067] Carbon ceramic brake discs are heat treated. The p...

Embodiment 3

[0079] The carbon-ceramic sample that will be prepared in the embodiment 3 of the present invention, its green body used is that density is 1.42, 1.50g / cm 3 Two pieces of C / C composite material.

[0080] step one:

[0081] Prepare the impregnating solution according to the mass ratio of polymethylsilane: styrene = 100:20, put the C / C green body into the metal impregnation tank, adopt vacuum impregnation for 1 hour, and pressure impregnation for 6 hours. After the impregnation is completed, the impregnation liquid is released, and the impregnated green body is put into a graphite tooling and put into a cracking furnace at 800°C for cracking. The whole process is protected by a nitrogen atmosphere, and the above impregnation-cracking process is repeated 3 times.

[0082] During vacuum impregnation, the vacuum degree is controlled to be ≤10Pa, and the pressurized impregnation pressure is 6MPa.

[0083] Step two:

[0084]Carbon ceramic brake discs are heat treated. The pre-fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com