Friction material, brake pad prepared by friction material and preparation method of brake pad

A friction material and brake pad technology, applied in the field of auto parts, can solve the problems of easy rusting of metal brake pads, short storage period, and insufficient environmental protection, so as to improve storage, improve environmental protection, and increase storage period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

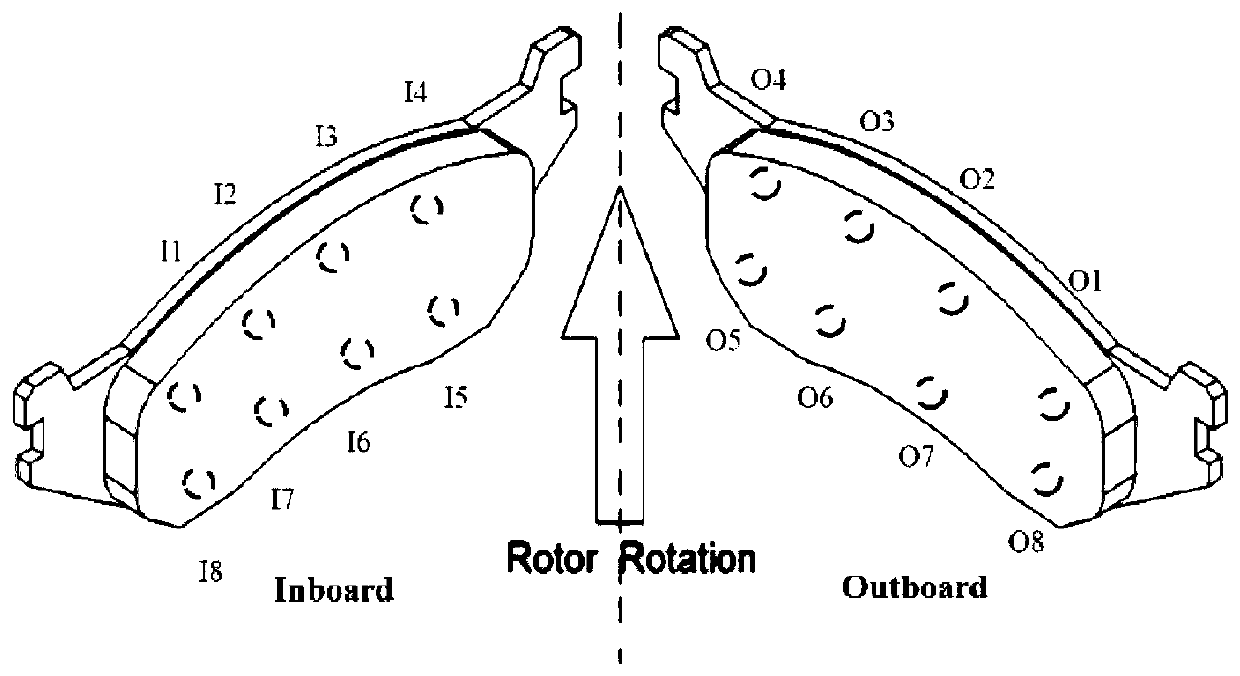

Image

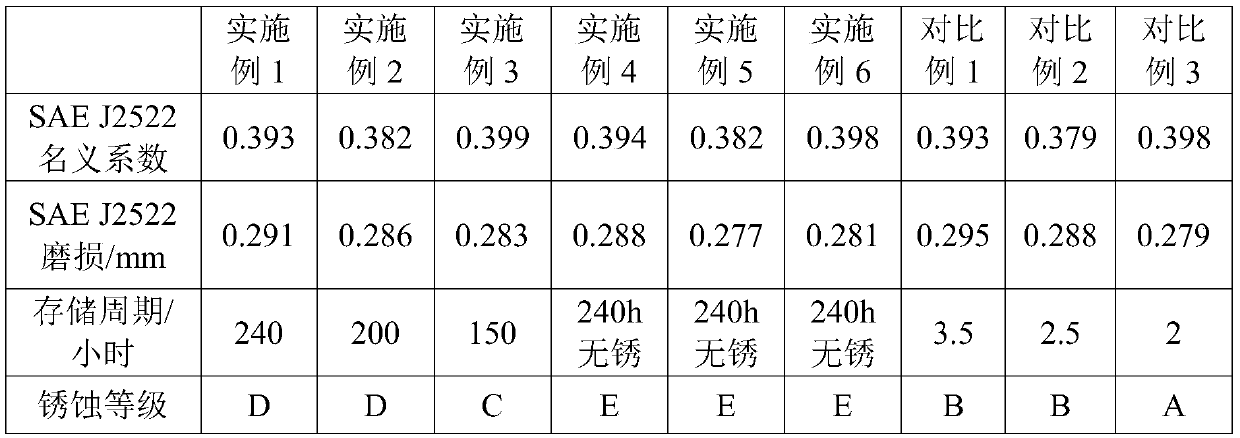

Examples

Embodiment 1

[0070] The copper-free metal friction material includes the following raw material components and parts by weight: 7 parts of binder, 15 parts of inorganic fiber, 5 parts of organic regulator, 13 parts of friction enhancer, 13 parts of wear reducer, 20 parts of filler, antirust 22 parts of treated steel fiber, 5 parts of antirust treated iron powder;

[0071] Wherein the binder is phenolic resin; the inorganic fiber includes 10 parts of mineral fiber, 5 parts of ceramic fiber; the organic regulator includes 3 parts of friction powder, 2 parts of tire powder; the friction enhancer includes 3 parts of α -Alumina, 10 parts of flaky iron oxide; the antifriction agent includes 3 parts of flake graphite, 3 parts of synthetic graphite, 2 parts of tin sulfide and 5 parts of antimony sulfide; the filler includes 2 parts of glass flakes, 2 parts of hydroxide Calcium and 16 parts barite;

[0072] The preparation method of the disc brake pad is as follows:

[0073] The method for prepar...

Embodiment 2

[0081] The copper-free metal friction material includes the following raw material components and parts by weight: 15 parts of binder, 5 parts of inorganic fiber, 2 parts of organic regulator, 15 parts of friction enhancer, 20 parts of wear reducer, 20 parts of filler, antirust 18 parts of treated steel fiber, 5 parts of antirust treated iron powder;

[0082] Wherein the binder is phenolic resin; the inorganic fiber includes 2 parts of mineral fiber, 3 parts of ceramic fiber; the organic regulator includes 1 part of friction powder, 1 part of tire powder; the friction enhancer includes 5 parts of α - Aluminum oxide, 10 parts of flaky iron oxide; the friction reducer includes 5 parts of flake graphite, 5 parts of synthetic graphite, 3 parts of tin sulfide and 7 parts of antimony sulfide; the filler includes 2 parts of glass flakes, 2 parts of hydroxide Calcium and 16 parts barite;

[0083] Wherein, the treatment steps of the steel fiber or iron powder of antirust treatment are...

Embodiment 3

[0086] The copper-free metal friction material includes the following raw material components and parts by weight: 11 parts of binder, 20 parts of inorganic fiber, 7 parts of organic regulator, 8 parts of friction enhancer, 7 parts of wear reducer, 8 parts of filler, antirust 30 parts of treated steel fiber, 9 parts of antirust treated iron powder;

[0087] Wherein the binder is phenolic resin; the inorganic fiber includes 13 parts of mineral fiber, 7 parts of ceramic fiber; the organic regulator includes 1 part of friction powder, 6 parts of tire powder; the friction enhancer includes 3 parts of alpha - Aluminum oxide, 5 parts of flaky iron oxide; the friction reducer includes 1 part of flake graphite, 1 part of synthetic graphite, 1 part of tin sulfide and 4 parts of antimony sulfide; the filler includes 3 parts of glass flakes, 1 part of hydroxide calcium and 4 parts barite;

[0088] Wherein, the treatment steps of the steel fiber or iron powder of antirust treatment are: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com