Preparation method and application of carbon/ceramic composite material

A carbon-ceramic composite material and composite material technology, applied in the field of preparation of carbon-ceramic composite materials, can solve the problems of carbon-ceramic brake discs such as poor controllability, uneven composition distribution, poor thermal shock resistance, etc., to achieve composition and The effect of controllable content, uniform distribution of silicon carbide and stable friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

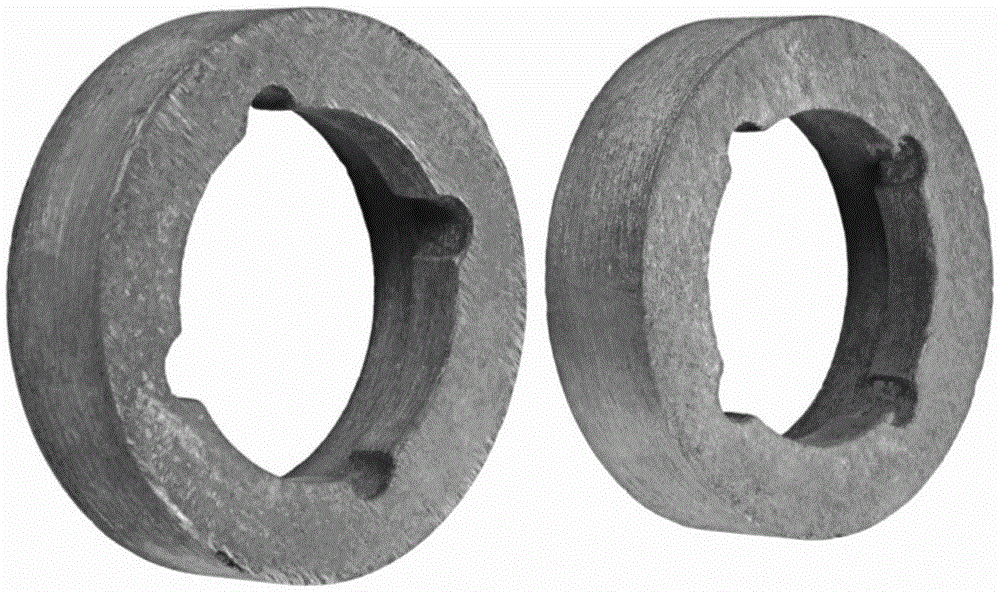

Embodiment 1

[0053] Carbon pottery aircraft brake disk will be prepared in the embodiment of the present invention 1, and its used raw material is that density is 1.2-1.5g / cm 3 C / C composite materials. The density is 1.2-1.5g / cm 3 The preparation method of the C / C composite material is:

[0054] The density is 0.5-0.55g / cm 3 2.5D needle-punched carbon fiber full-mesh tire, carbon deposited to a density of 1.3g / cm 3 , under a protective atmosphere, a high temperature treatment of 2300 ° C is carried out. After processing according to the net size of the aircraft brake disc, it is about 1.26g / cm 3 Density C / C composite aircraft brake disc body. When carbon deposition is performed, propylene or natural gas is used as the carbon source, and argon is used as the dilution gas. During deposition, the pressure in the furnace is controlled at 2.0-3.0KPa and the temperature is 900-1000°C; The volume ratio is 1:5-1:1.

[0055] step one

Embodiment 2

[0088] Carbon pottery aircraft brake disk will be prepared in the embodiment 2 of the present invention, and its used raw material is that density is 1.2-1.5g / cm 3 C / C composite materials. The density is 1.2-1.5g / cm 3 The preparation method of the C / C composite material is:

[0089] The density is 0.5-0.55g / cm 3 2.5D needle-punched carbon fiber full-mesh tire, carbon deposited to a density of 1.55g / cm 3 , under a protective atmosphere, a high temperature treatment of 2300 ° C is carried out. After processing according to the net size of the aircraft brake disc, it is about 1.5g / cm 3 Density C / C composite aircraft brake disc body. For carbon deposition, propylene or natural gas is used as the carbon source, and argon is used as the dilution gas. During the deposition, the pressure in the furnace is controlled at 2.0-3.0KPa and the temperature is 900-1000°C; The volume ratio is 1:5-1:1.

[0090] step one

[0091] Configure mass ratio, styrene:polymethylsilane as 15:100 i...

Embodiment 3

[0104] Will prepare carbon pottery aircraft brake disc in embodiment 3, and its used raw material is that density is 1.2-1.5g / cm 3 C / C composite materials. The density is 1.2-1.5g / cm 3 The preparation method of the C / C composite material is:

[0105] The density is 0.5-0.55g / cm 3 2.5D needle-punched carbon fiber full-mesh tire, carbon deposited to a density of 1.4g / cm 3 , under a protective atmosphere, a high temperature treatment of 2300 ° C is carried out. After processing according to the net size of the aircraft brake disc, it is about 1.37g / cm 3 Density C / C composite aircraft brake disc body. When carbon deposition is performed, propylene or natural gas is used as the carbon source, and argon is used as the dilution gas. During deposition, the pressure in the furnace is controlled at 2.0-3.0KPa and the temperature is 900-1000°C; The volume ratio is 1:5-1:1.

[0106] step one

[0107] Configure the impregnation solution with a mass ratio of styrene:polymethylsilane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com