Braking systems with cooling

A brake system and brake ring technology, applied in the direction of brake type, brake components, mechanical equipment, etc., can solve the problems of reduced space, easy to be interrupted, and reduced heat dissipation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

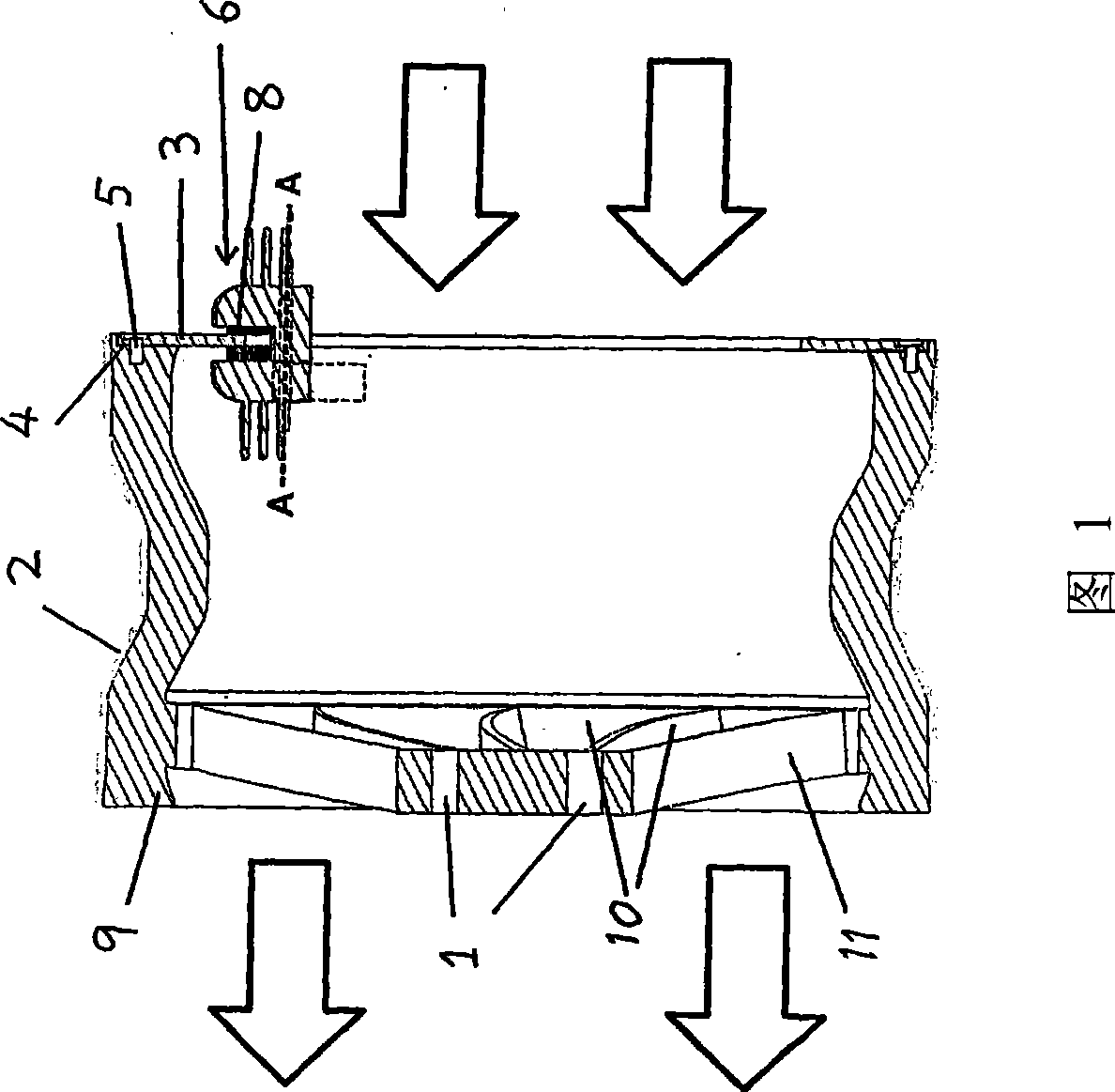

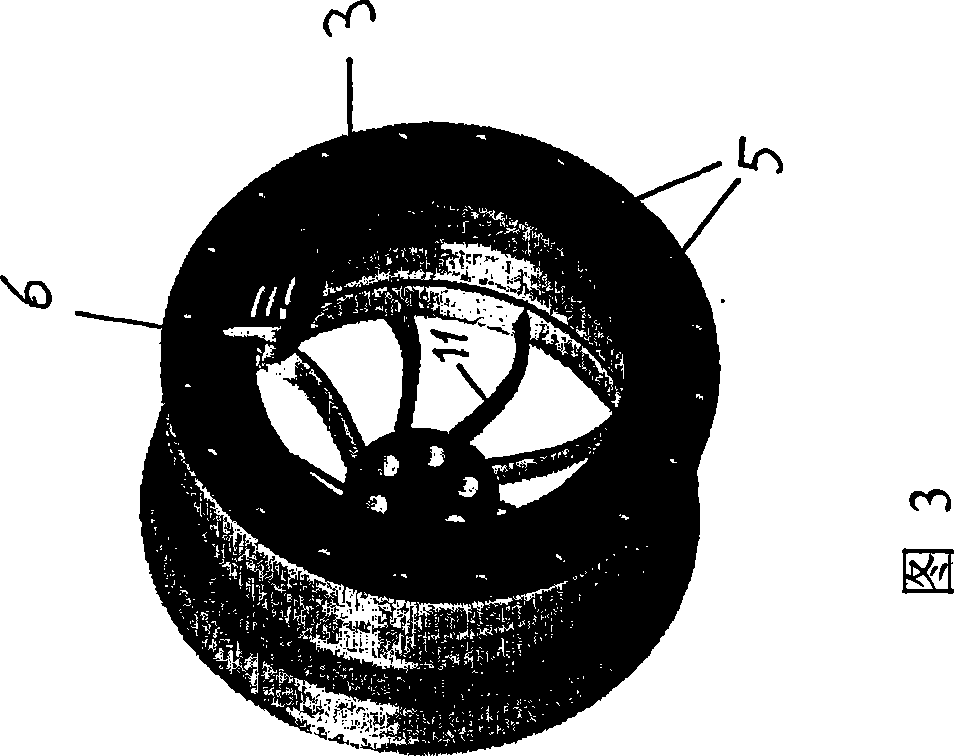

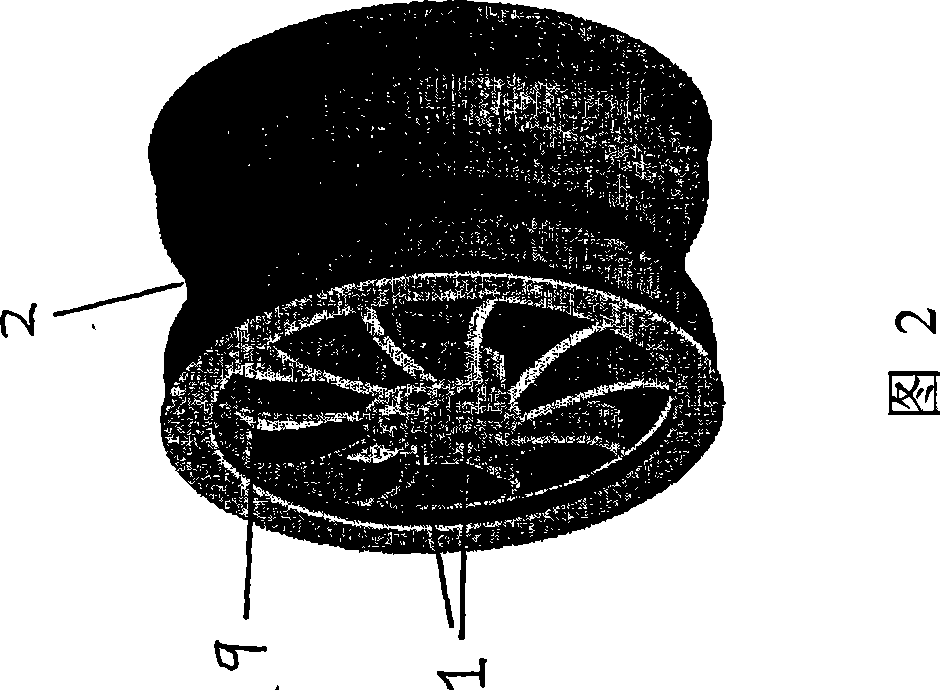

[0034] The car wheel shown in Figure 1 is the same as the existing wheels in that it includes a mounting hole 1 for positioning to the vehicle axle and a support 9, and the support 9 includes a wheel for fixing a pneumatic tire (not shown). Edge 2. It differs from existing motor vehicle wheels in that it comprises an annular brake ring 3 which is positioned in an annular recess 4 of the wheel rim 2 by countersunk screws 5 . The support member 9 extends from the center of the wheel to the rim 2 and is provided with a plurality of openings 10 .

[0035] The braking force applied to the brake ring 3 is applied to the brake ring 3 through the brake caliper 6 connected to the vehicle suspension. The braking force can be pushed to the brake ring 3 through a hydraulic brake hose (not shown) through a hydraulic brake hose (not shown). Moving washer 8, and make the latter friction fit with brake ring 3.

[0036] In use, the air flows over the brake caliper 6 and over the brake ring 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com