Side-arranged circumferential-embracing braked axle of motor truck

A truck, side-mounted technology, used in drum brakes, mechanically driven drum brakes, brake types, etc., can solve the problems of brake drum rupture, uneven wear and consumption, and uneven force on the brake shoes. Improved stability and safety, improved heat dissipation performance and effect, improved stability and safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

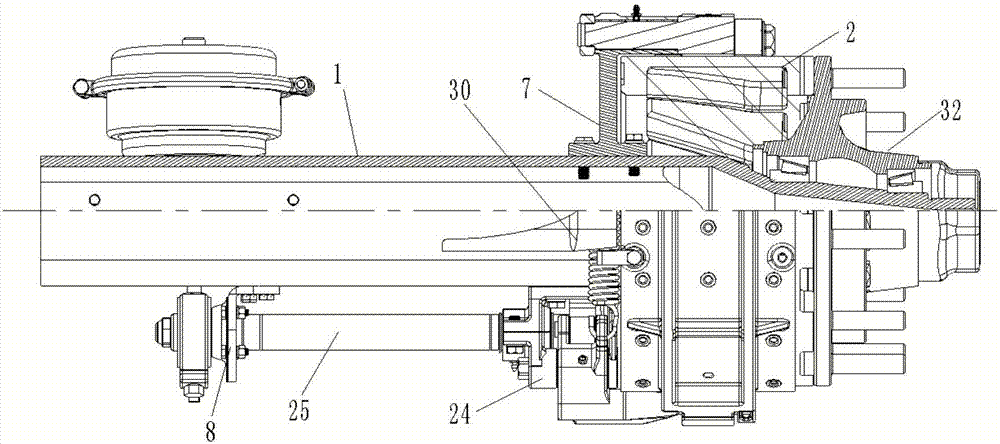

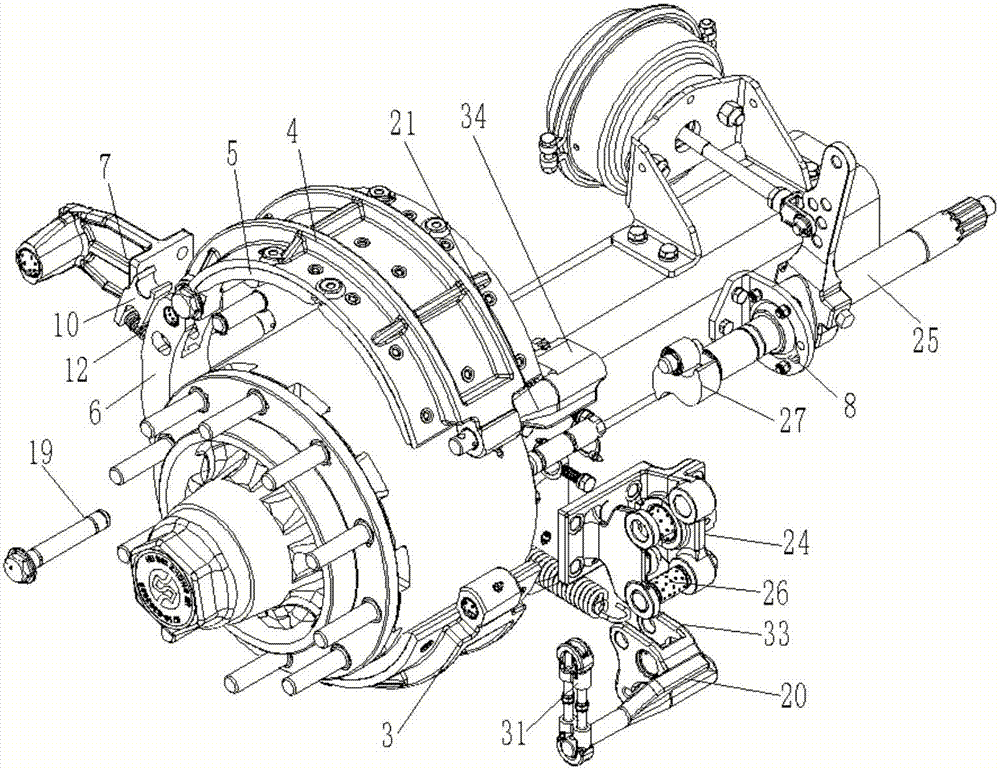

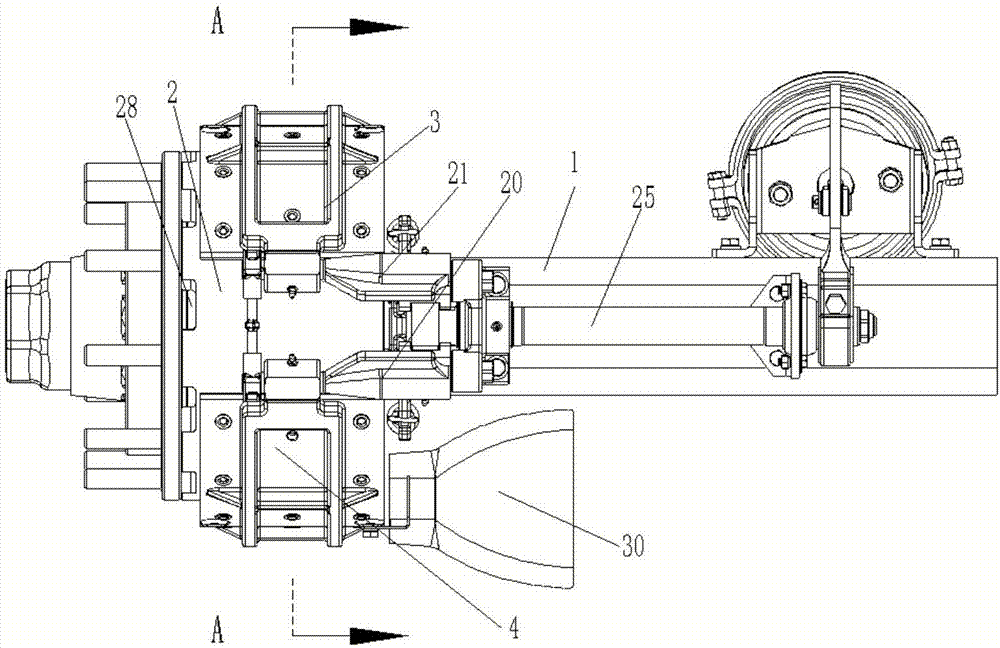

[0027] Such as Figure 1-3 As shown, a side-mounted circumferential brake axle of a truck includes an axle 1 and a hub 32. The inner side of the hub is connected to a brake wheel 2 that operates synchronously with it. Hold the brake shoe tightly. The brake shoe includes a semicircular arc-shaped left shoe 3 and a right shoe 4. A brake friction plate 5 is installed on the inner peripheral surface of each shoe, and a cam pendulum is arranged on the axle inside the brake shoe. An arm holding mechanism and a floating single-axis mechanism, one end of the left and right shoes is connected with the floating single-axis mechanism, and the other end is connected with the cam swing arm holding mechanism.

[0028] Such as Figure 4 , Figure 7 As shown, the floating uniaxial mechanism includes a uniaxial sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com