Container carrier

A technology for containers and flaps, applied in the field of container brackets, can solve problems such as cracking and nuisance, and achieve the effect of eliminating the danger of cracking and avoiding noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

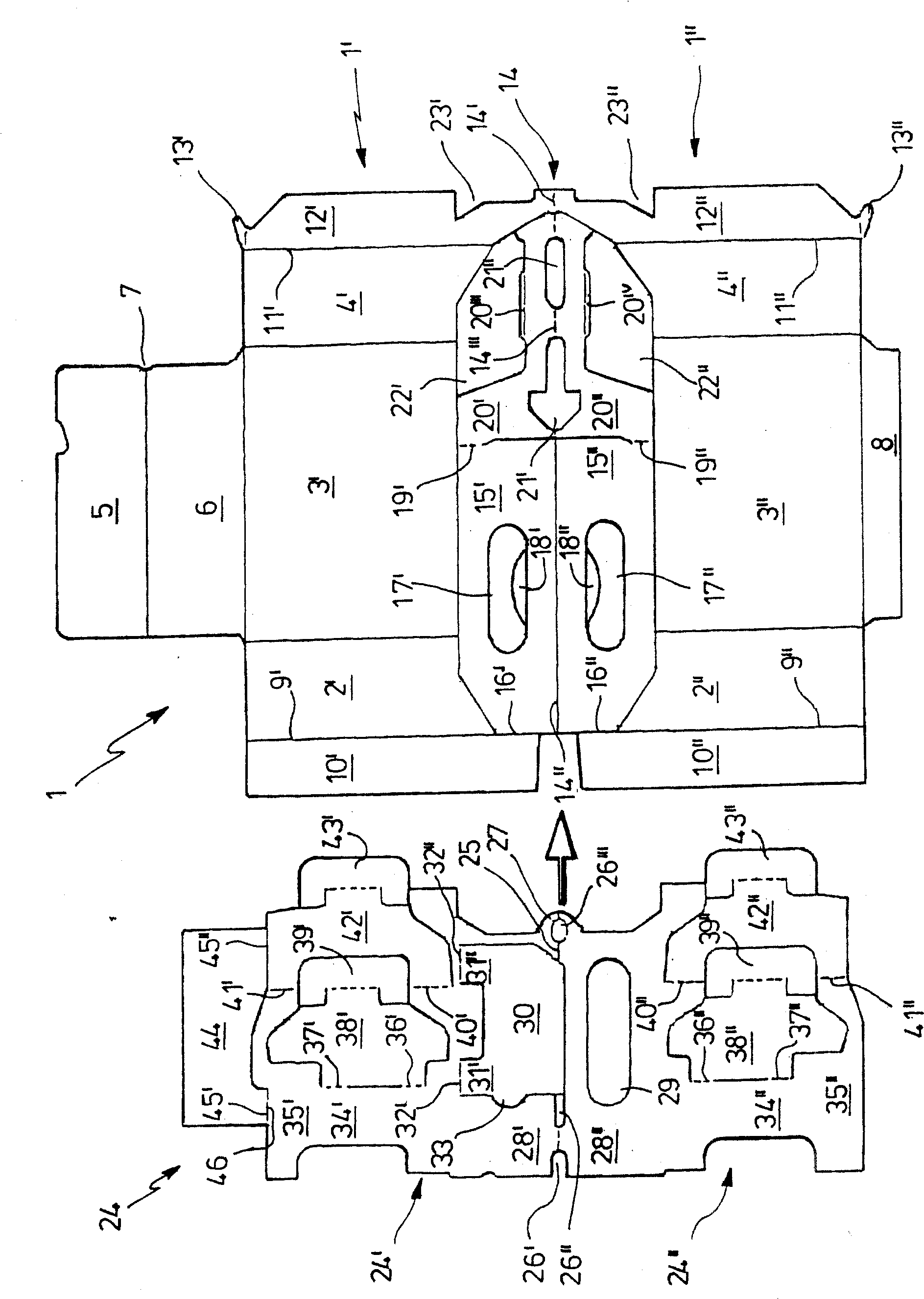

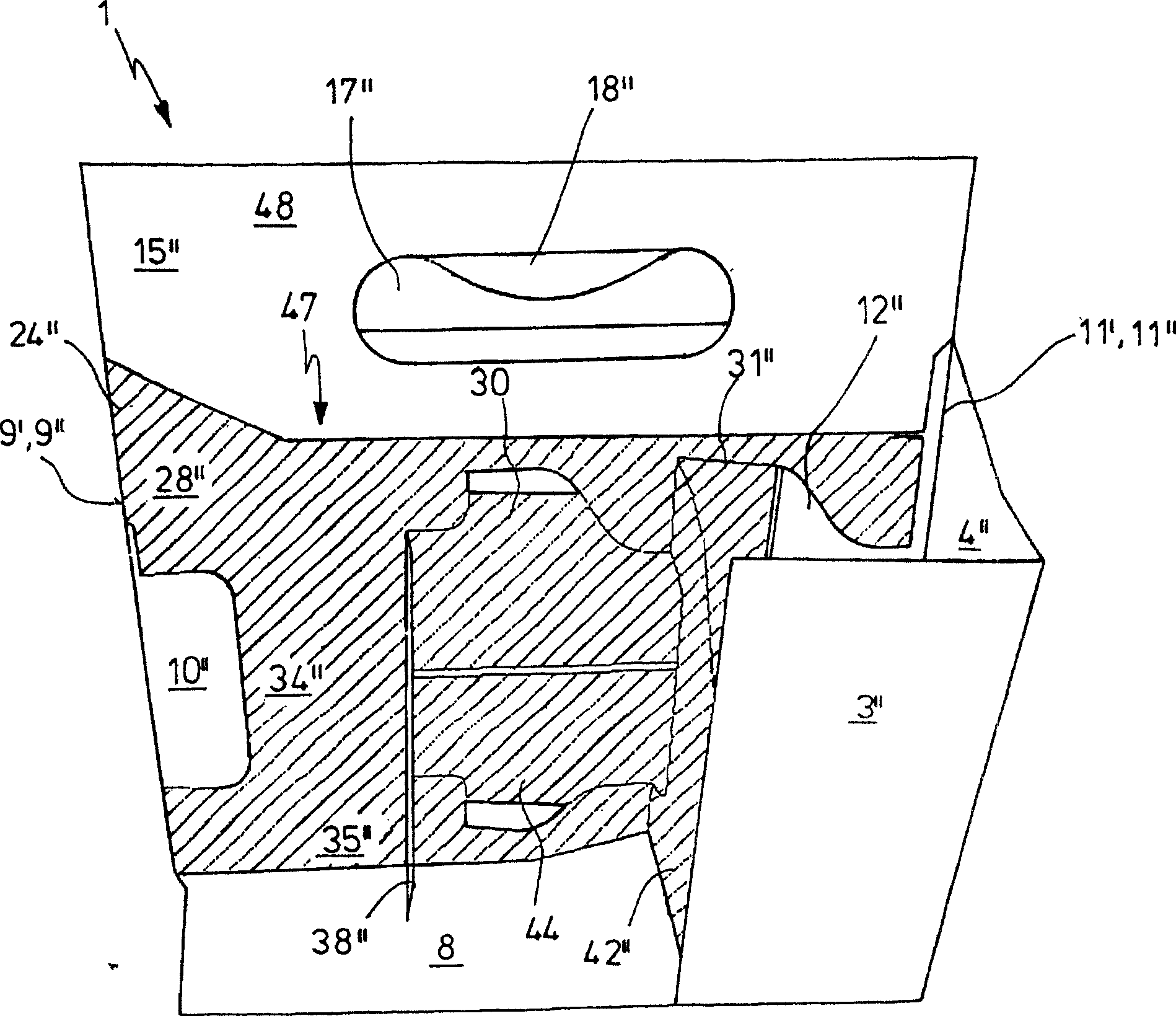

[0028] exist figure 1 The cut-out blank 1 for a carrier container (also denoted by 1 below) shown in , is produced in one piece from an externally painted recycled cardboard. One of the end wall sections 2', one side wall 3' and one end wall section 4' are hinged to each other along their transverse sides. At the lower longitudinal edge, the side wall 3' has a base wall 5 which is segmented longitudinally by a fold center line 6. On the folding center line 6 there is a receptacle 7 for a hook.

[0029] Furthermore, the cut blank has an end wall section 2", a side wall 3" and an end wall section 4", which are likewise hinged to one another along the transverse sides. A bottom plate 8 is hinged to the lower longitudinal edge of the side wall 3".

[0030] The end wall panels 10', 10" are hinged at the transverse sides 9', 9" of the end wall sections 2', 2" opposite their hinge lines on the side walls 3', 3". Correspondingly, the end wall panels 12', 12" are hinged at the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com