High-toughness pipe

A high-toughness, pipe technology, used in rigid pipes, pipes, pipe components, etc., can solve the problems of adjusting the inner wall, hidden dangers, pipe rupture, etc., to improve the buffer capacity, reduce the impact, and improve the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

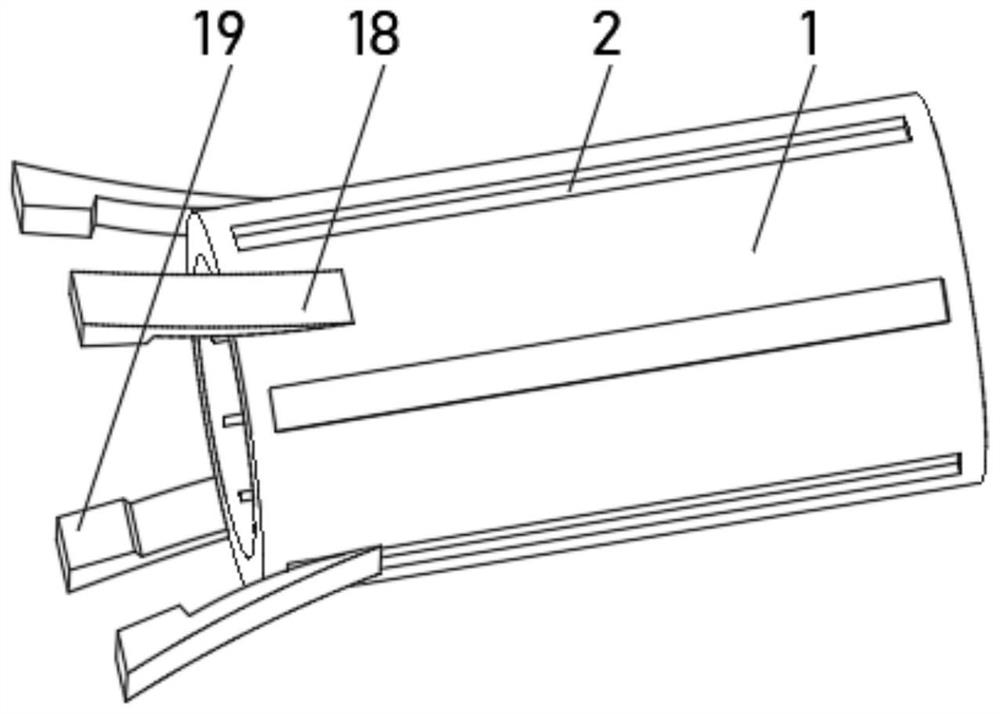

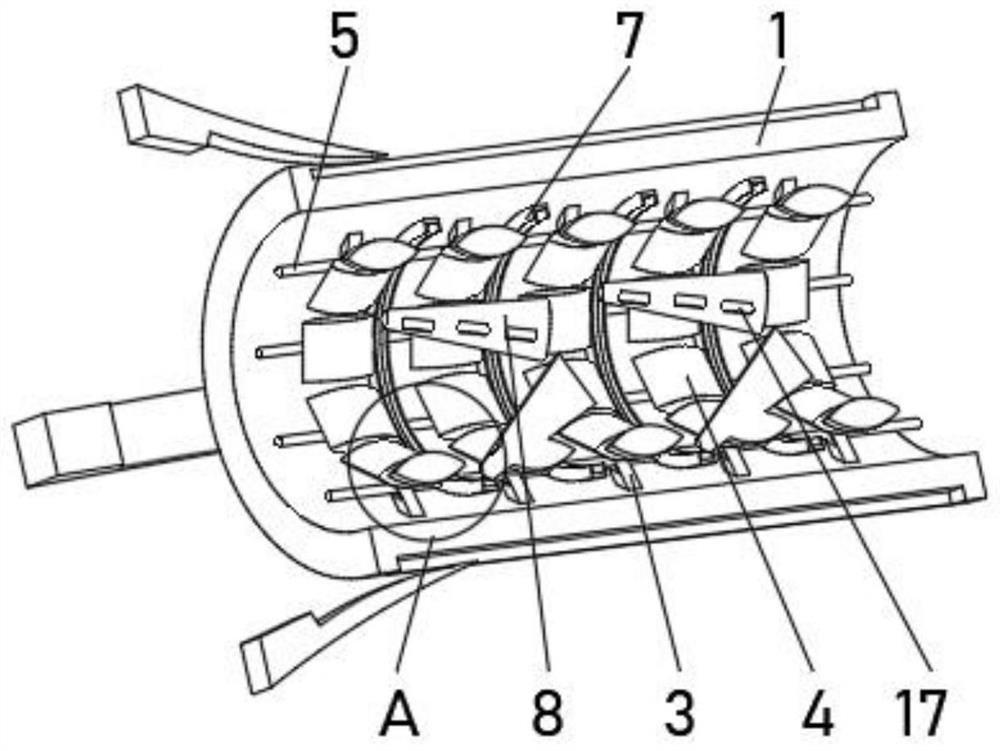

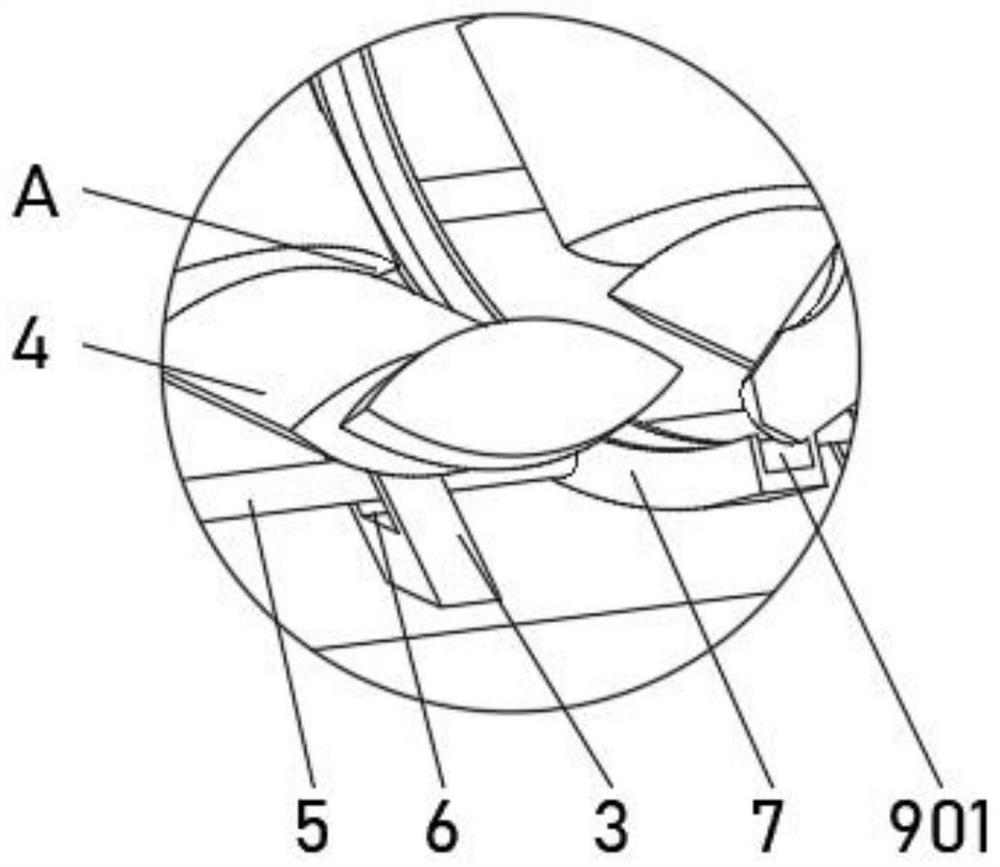

[0029] see Figure 1-4 , the present invention provides a technical solution: a high-toughness pipe, including an outer tube 1, the outer side of the outer tube 1 is evenly provided with an anti-skid groove 2, and the inner wall of the outer tube 1 is evenly equipped with an elastic rod 3, and one end of the elastic rod 3 is fixed Rigid arcs 4 are connected, one side of the elastic rod 3 runs through a pull rope 5, one side of the elastic rod 3 is provided with a guide hole 6 suitable for the pull rope 5, and evenly installed between the pull ropes 5 A control ring 7, a detection rod 8 is evenly installed on one side of the control ring 7, a trigger device 9 is installed inside the control ring 7, and the trigger device 9 is connected with the detection rod 8.

[0030] The trigger device 9 includes a trigger groove 901, one side of the inner wall of the trigger groove 901 is fixedly connected with a constricting block 903 through an elastic rope 902, the pulling rope 5 is fixe...

Embodiment 2

[0037] see Figure 1-4 , the present invention provides a technical solution: on the basis of Embodiment 1, a cleaning device 10 is installed on the inner wall of the outer tube 1 close to the rigid arc 4, the cleaning device 10 includes a swing rod 101, one end of the swing rod 101 is connected to the rigid The arc piece 4 is rotatably connected, and the end of the swing rod 101 away from the rigid arc piece 4 is fixedly connected with a cleaning head 102 , and the cleaning head 102 is slidingly connected with the inner wall of the outer tube 1 .

[0038] A track groove 103 is opened inside the swing rod 101 , and a metal ball 104 is slidably connected to one side of the inner wall of the track groove 103 .

[0039] The inner wall of the outer tube 1 is fixedly connected with the limit block 13 near the position of the swing rod 101, and the limit block 13 is provided with a limit groove 14 on the side close to the swing rod 101, and one side of the inner wall of the limit gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com