Additional brake

A technology of brakes and brake discs, applied in escalators, transportation and packaging, etc., can solve the problems of unstable braking speed and braking distance of additional brakes, large fluctuation range of friction plates, and high price of friction plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

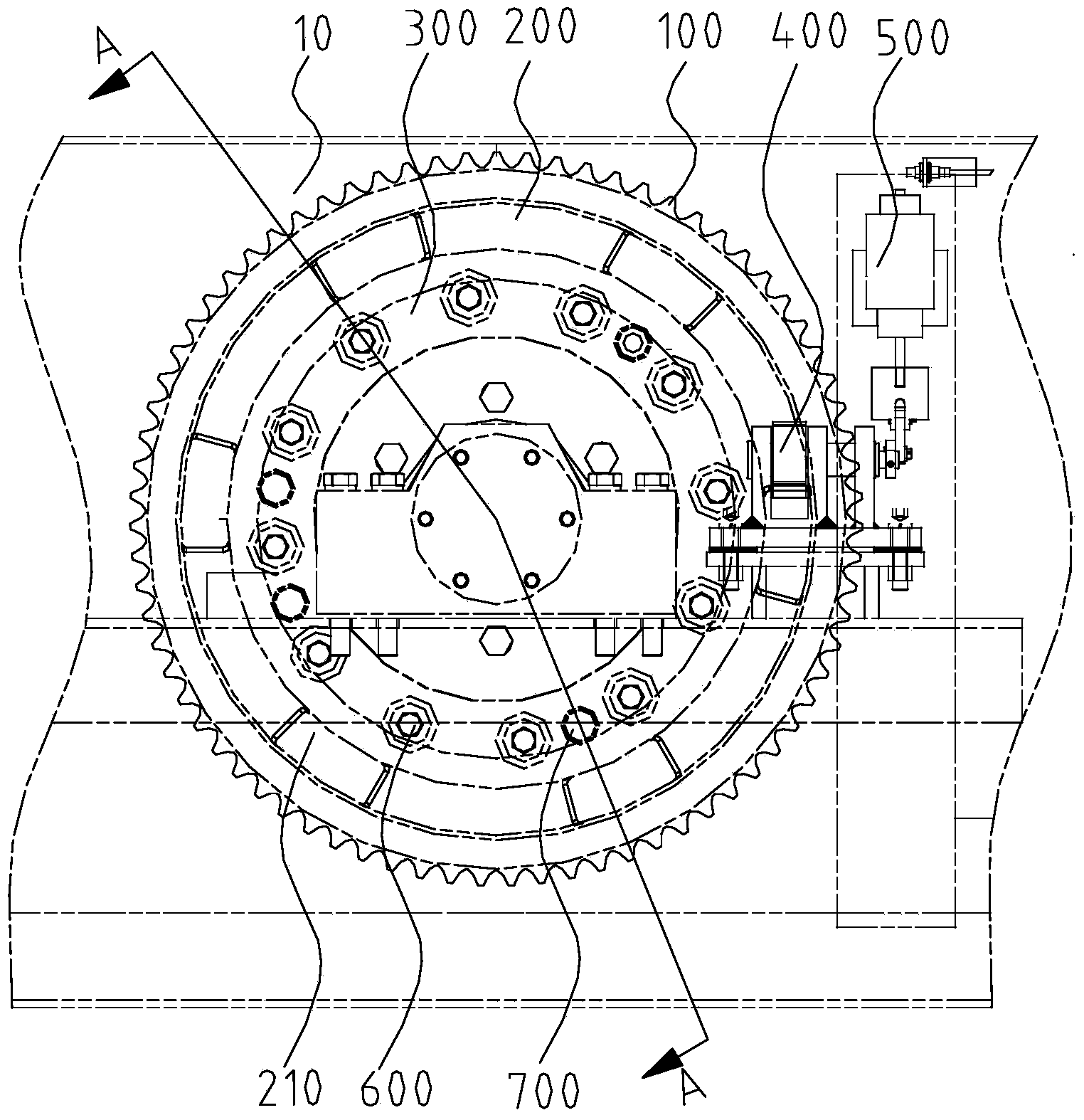

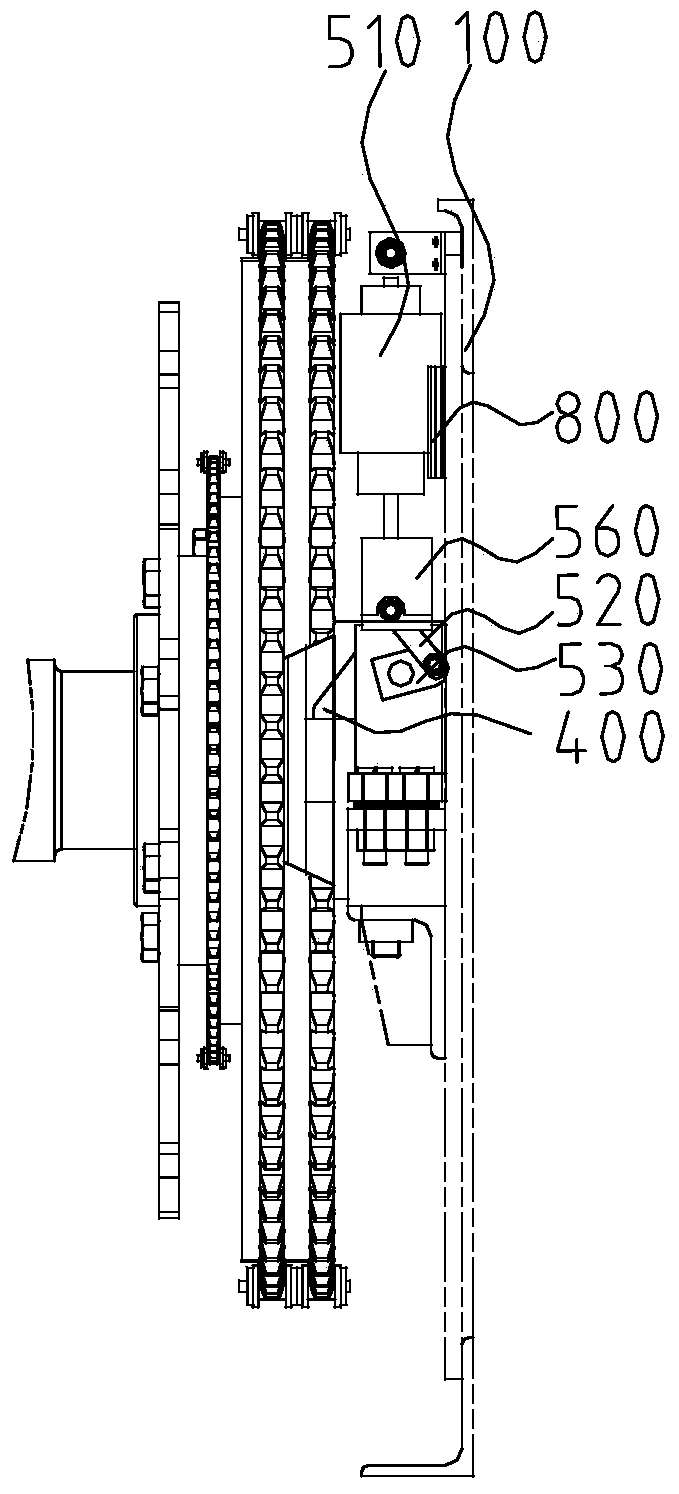

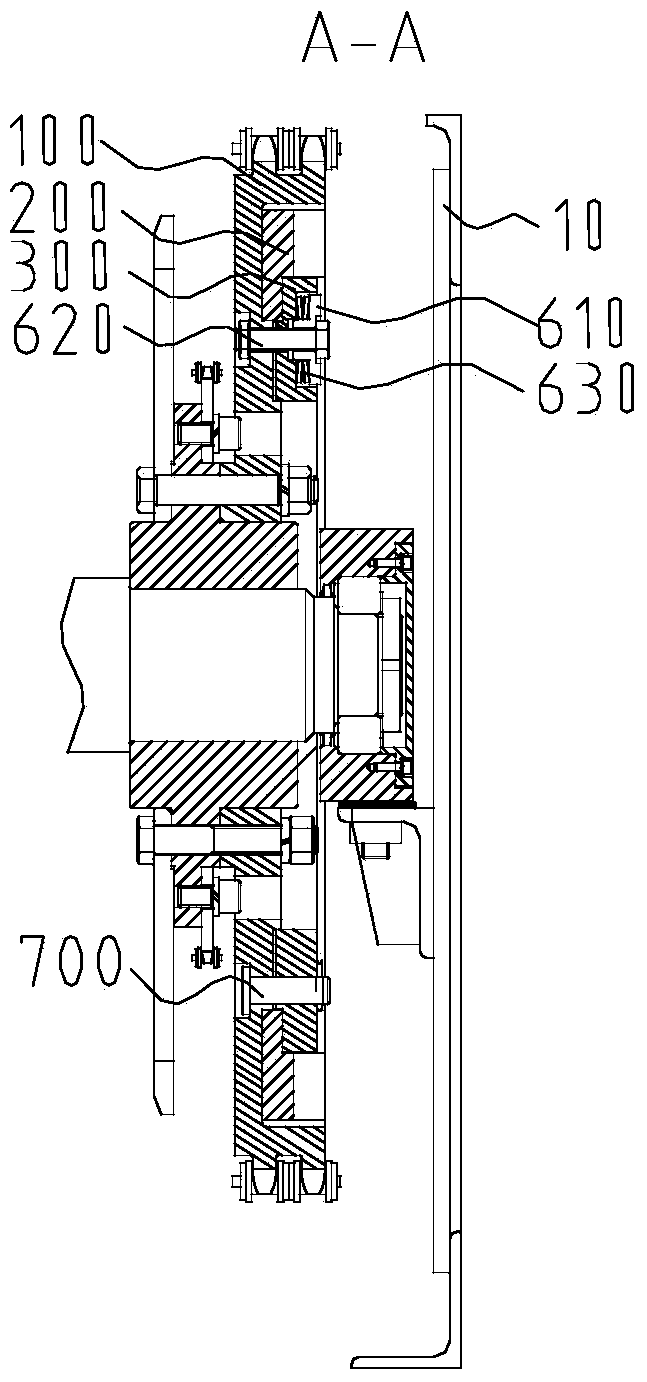

[0026] Such as figure 1 , figure 2 , image 3 As shown, an additional brake includes a drive sprocket 100, a brake disc 200, a pressure plate 300, a brake block 400, and a trigger assembly 500, and the brake disc 200 is arranged between the drive sprocket 100 and the pressure plate 300 , the pressure plate 300 is pressed on the brake disc 200, and is connected with the drive sprocket 100 through the locking assembly 600, the brake disc 200 is provided with a bump 210, and the brake block 400 is passed through the trigger assembly 500 The action remains engaged or disengaged with the bump 210 .

[0027] In this embodiment, additional brakes are added. During braking, the trigger assembly 500 is used to control the engagement of the brake block 400 with the protrusion 210, so that the brake disc remains stationary, and the drive sprocket 100 and the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com