A friction material, a brake pad prepared by using the friction material and a preparation method thereof

A technology of friction materials and brake pads, which is applied in the field of auto parts, can solve the problems of metal-type brake pads that are easy to rust, short storage period, and not environmentally friendly enough, so as to improve storage, improve environmental protection, and increase storage period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

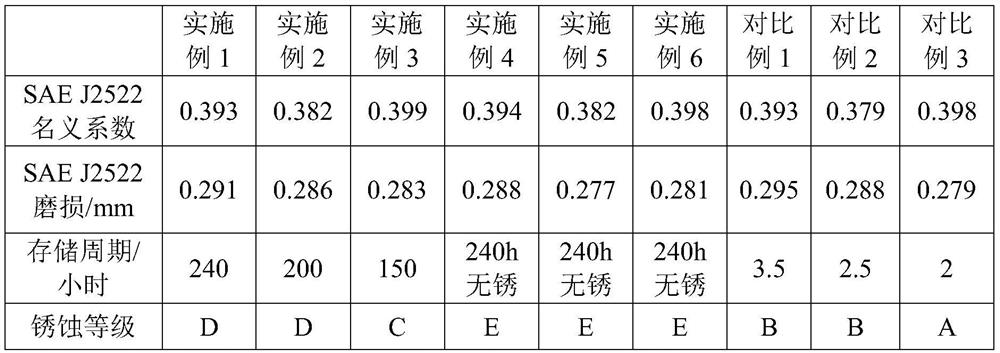

Embodiment 1

[0070] The copper-free metal friction material includes the following raw material components and parts by weight: 7 parts of binder, 15 parts of inorganic fiber, 5 parts of organic regulator, 13 parts of friction enhancer, 13 parts of wear reducer, 20 parts of filler, antirust 22 parts of treated steel fiber, 5 parts of antirust treated iron powder;

[0071] Wherein the binder is phenolic resin; the inorganic fiber includes 10 parts of mineral fiber, 5 parts of ceramic fiber; the organic regulator includes 3 parts of friction powder, 2 parts of tire powder; the friction enhancer includes 3 parts of α -Alumina, 10 parts of flaky iron oxide; the antifriction agent includes 3 parts of flake graphite, 3 parts of synthetic graphite, 2 parts of tin sulfide and 5 parts of antimony sulfide; the filler includes 2 parts of glass flakes, 2 parts of hydroxide Calcium and 16 parts barite;

[0072] The preparation method of the disc brake pad is as follows:

[0073] The method for prepar...

Embodiment 2

[0081] The copper-free metal friction material includes the following raw material components and parts by weight: 15 parts of binder, 5 parts of inorganic fiber, 2 parts of organic regulator, 15 parts of friction enhancer, 20 parts of wear reducer, 20 parts of filler, antirust 18 parts of treated steel fiber, 5 parts of antirust treated iron powder;

[0082] Wherein the binder is phenolic resin; the inorganic fiber includes 2 parts of mineral fiber, 3 parts of ceramic fiber; the organic regulator includes 1 part of friction powder, 1 part of tire powder; the friction enhancer includes 5 parts of α - Aluminum oxide, 10 parts of flaky iron oxide; the friction reducer includes 5 parts of flake graphite, 5 parts of synthetic graphite, 3 parts of tin sulfide and 7 parts of antimony sulfide; the filler includes 2 parts of glass flakes, 2 parts of hydroxide Calcium and 16 parts barite;

[0083] Wherein, the treatment steps of the steel fiber or iron powder of antirust treatment are...

Embodiment 3

[0086] The copper-free metal friction material includes the following raw material components and parts by weight: 11 parts of binder, 20 parts of inorganic fiber, 7 parts of organic regulator, 8 parts of friction enhancer, 7 parts of wear reducer, 8 parts of filler, antirust 30 parts of treated steel fiber, 9 parts of antirust treated iron powder;

[0087] Wherein the binder is phenolic resin; the inorganic fiber includes 13 parts of mineral fiber, 7 parts of ceramic fiber; the organic regulator includes 1 part of friction powder, 6 parts of tire powder; the friction enhancer includes 3 parts of alpha - Aluminum oxide, 5 parts of flaky iron oxide; the friction reducer includes 1 part of flake graphite, 1 part of synthetic graphite, 1 part of tin sulfide and 4 parts of antimony sulfide; the filler includes 3 parts of glass flakes, 1 part of hydroxide calcium and 4 parts barite;

[0088] Wherein, the treatment steps of the steel fiber or iron powder of antirust treatment are: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com