Weak glue cementation water partition similar material and preparation method

A technology of similar materials and cemented materials, which is applied in the field of similar materials with weak cementation and strong water-repellent properties and its preparation, can solve the problems of high water-repellent properties, low strength, and inability to realize permeability coefficients, etc., and achieve the effect of strong water-repellent properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

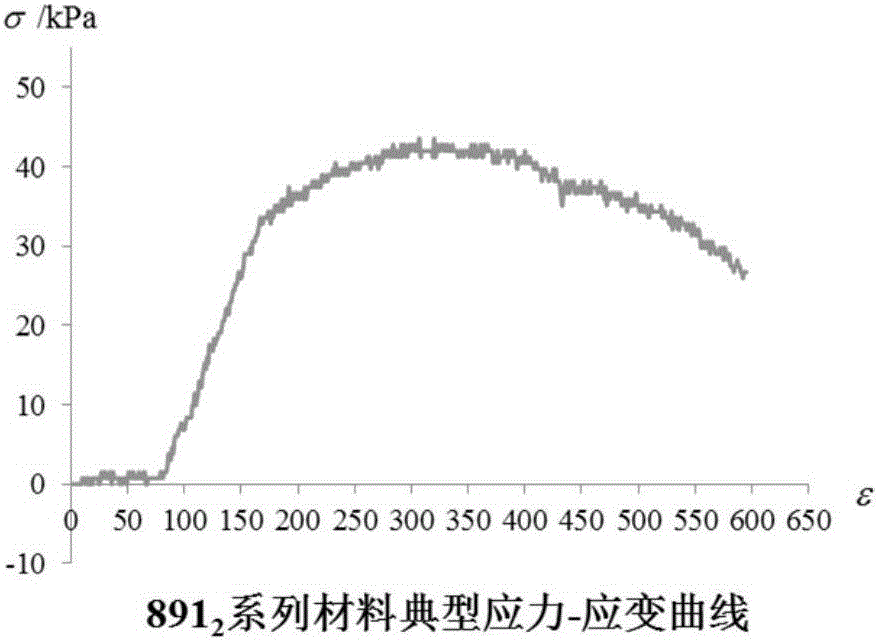

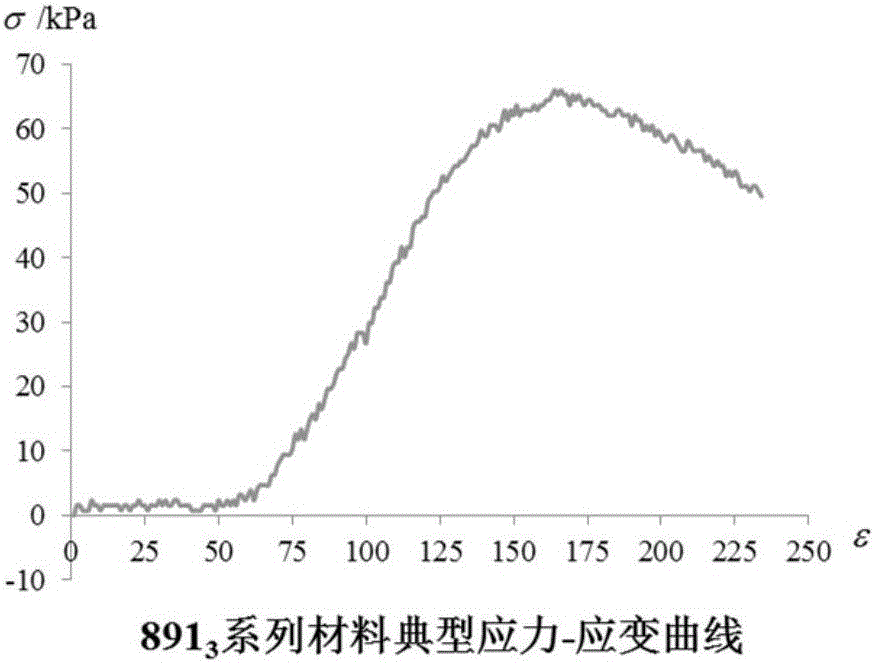

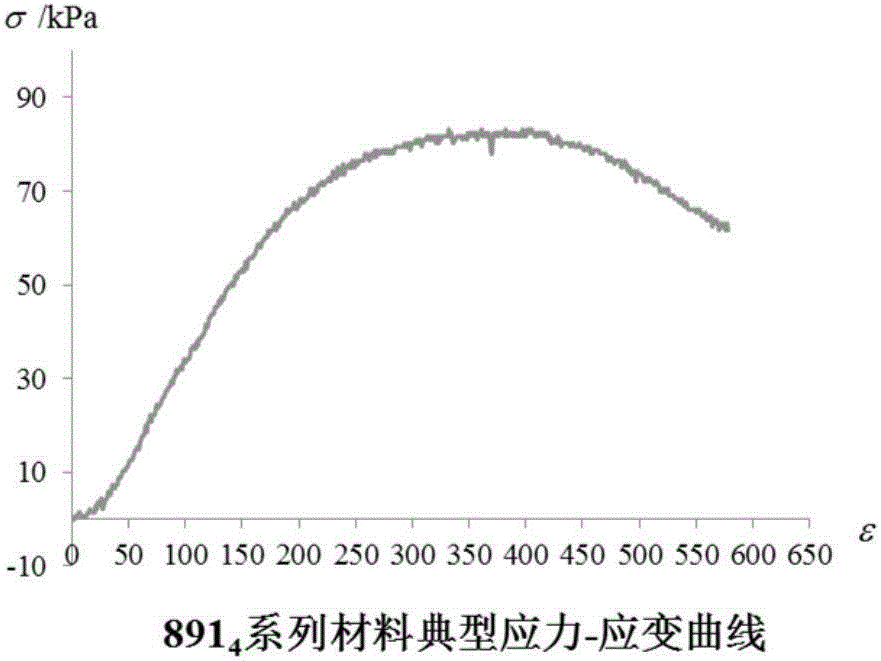

[0053] Example 1: A low-strength, weakly cemented, strong water-repellent similar material ratio, the ratio series are 891 2 series, 891 3 series, 891 4 series, 891 5 series:

[0054] The detailed ratio experiment process is as follows:

[0055] (1) Select a standard sieve with a diameter of 1.18mm to screen fine river sand with sufficient particle size;

[0056] (2) According to the proportioning requirements of each component material of different proportioning series, take the fine river sand, bentonite, gypsum, solid paraffin, methyl silicone oil and water of the required weight respectively with an electronic scale;

[0057] (3) fully mix the fine river sand, bentonite, and gypsum dry material that weighed, and stir evenly;

[0058] (4) Add the water weighed into the mixture of fine river sand, bentonite and gypsum three dry materials stirred in step (3), and fully stir to ensure that the material is not agglomerated, hardened, or large particles;

[0059] (5) Add t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com