Built-in louver broken bridge aluminum window

A technology of broken bridge aluminum and louver, applied in the direction of windows/doors, door/window protection devices, building components, etc., can solve the problems that double-glazed windows are difficult to expect, and temperature or pressure changes cannot play a normal buffering effect. , to achieve strong waterproof performance, prevent dust or be polluted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

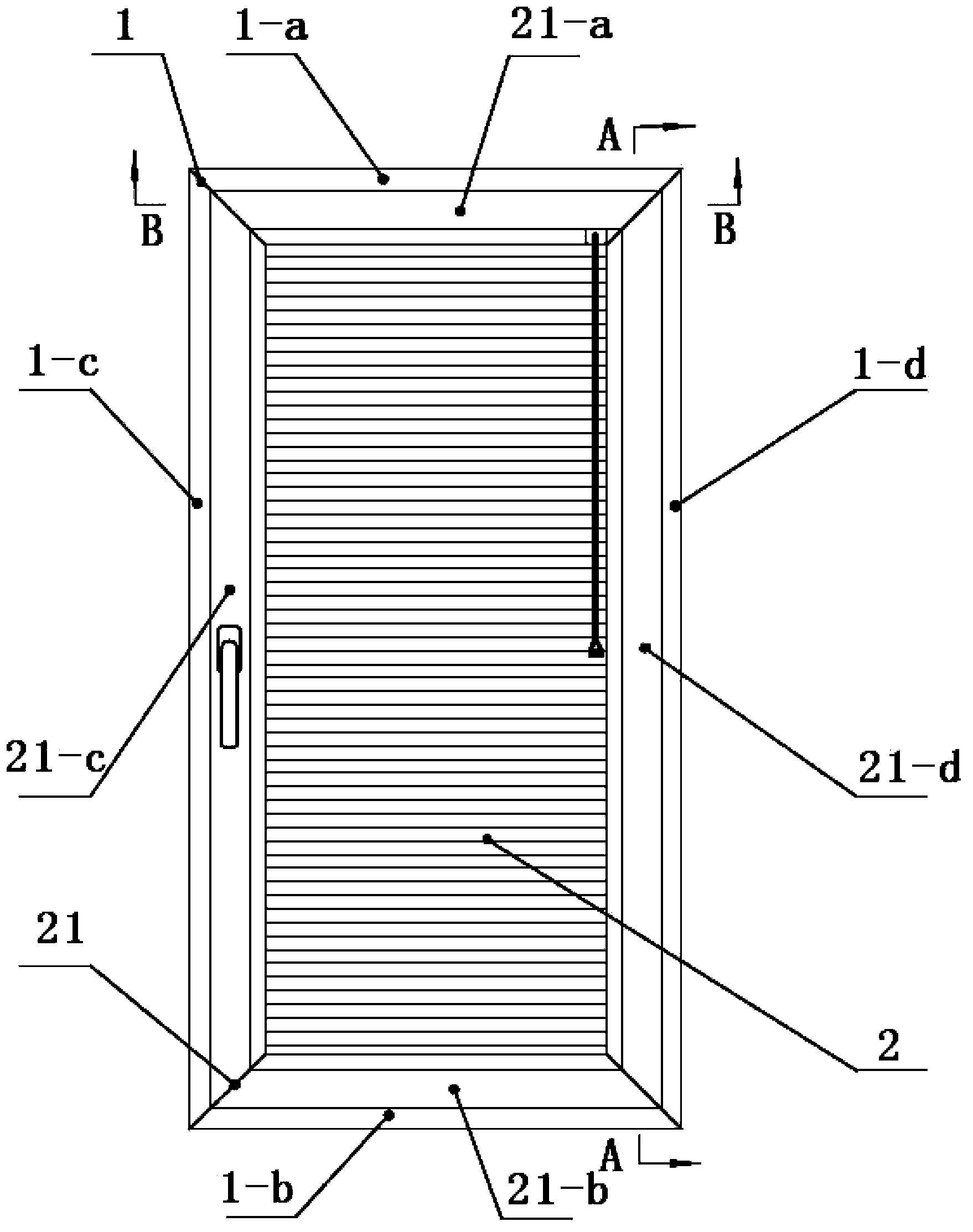

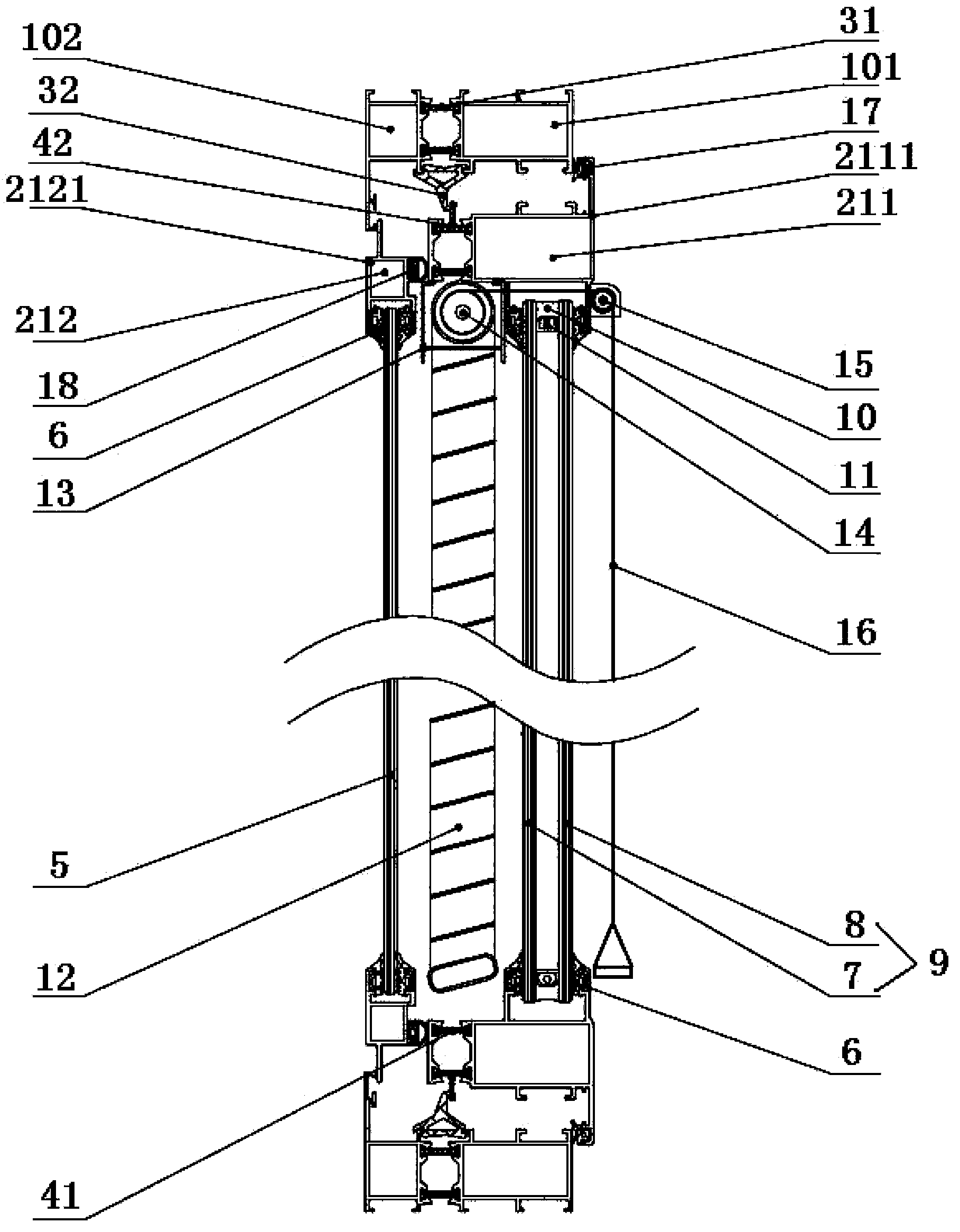

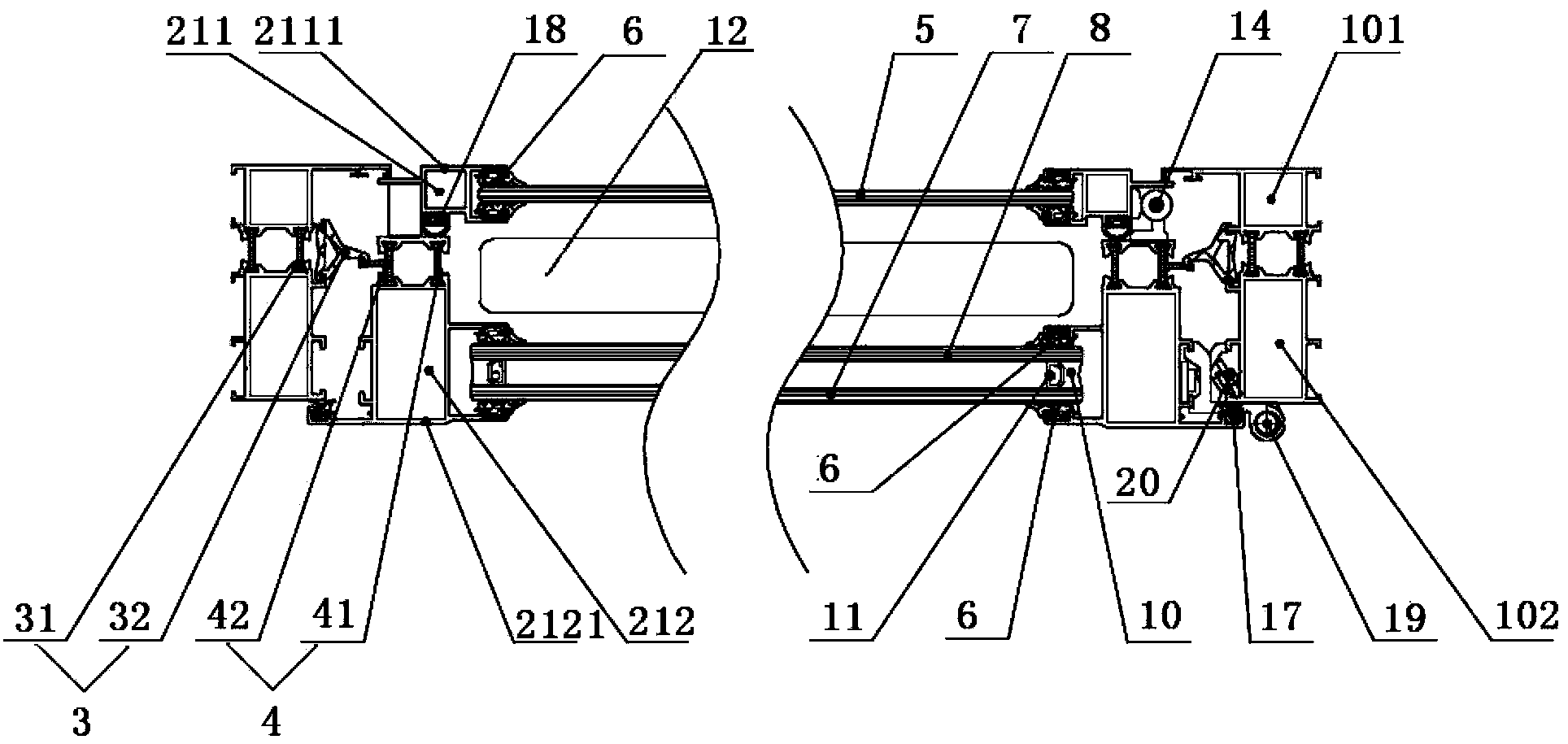

[0018] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is an A-A sectional view of the present invention, image 3 It is a B-B sectional view of the present invention, combined with figure 1 , figure 2 and image 3 As shown, a broken bridge aluminum window with built-in louvers includes a frame 1 and a window sash 2. The frame 1 is composed of upper, lower, left and right frame sides 1-a, 1-b, 1-c, 1-d through hardware connectors Connection composition, each frame side all comprises frame inner layer 101 and frame outer layer 102 that are connected by plastic frame broken bridge 3; The outer layer 212 is also composed of upper, lower, left and right sash sides 21-a, 21-b, 21-c, 21-d connected by hardware connectors, and each sash side is connected by a plastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com