Patents

Literature

101results about How to "Improve water barrier effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

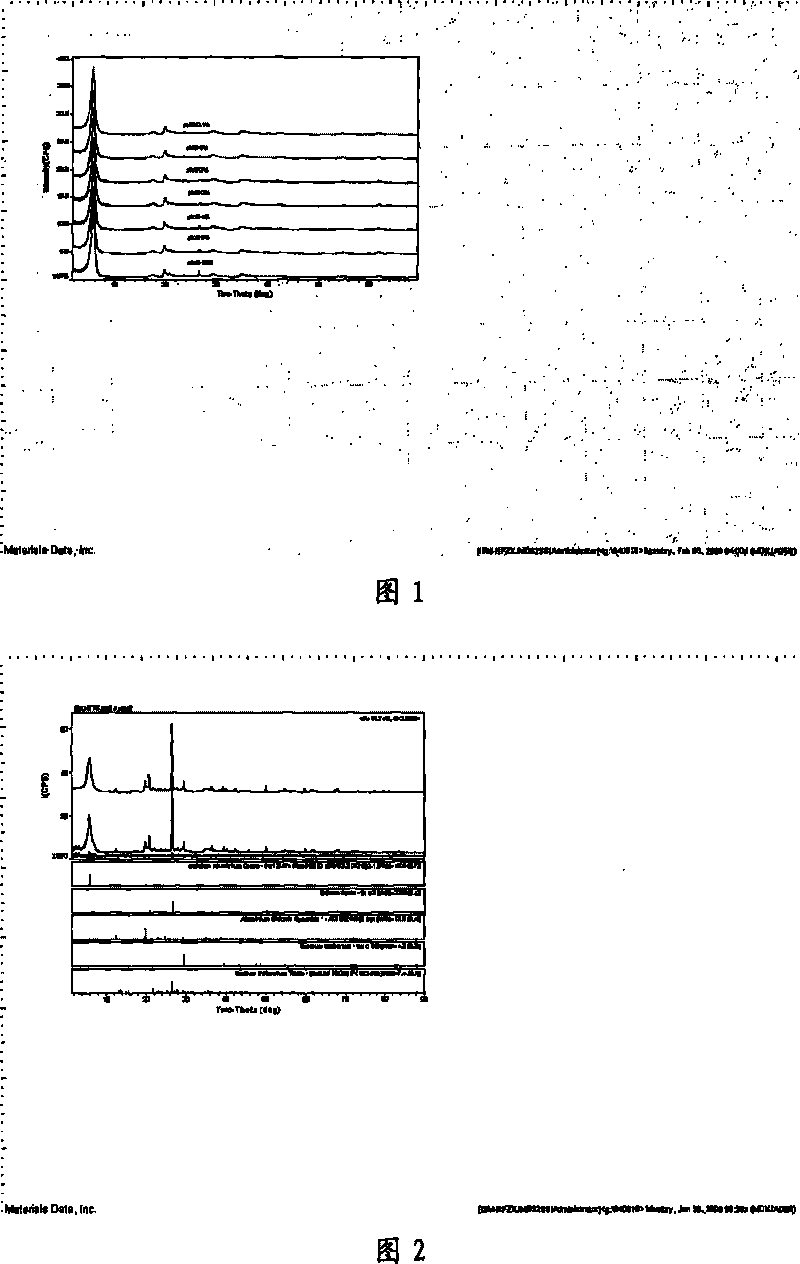

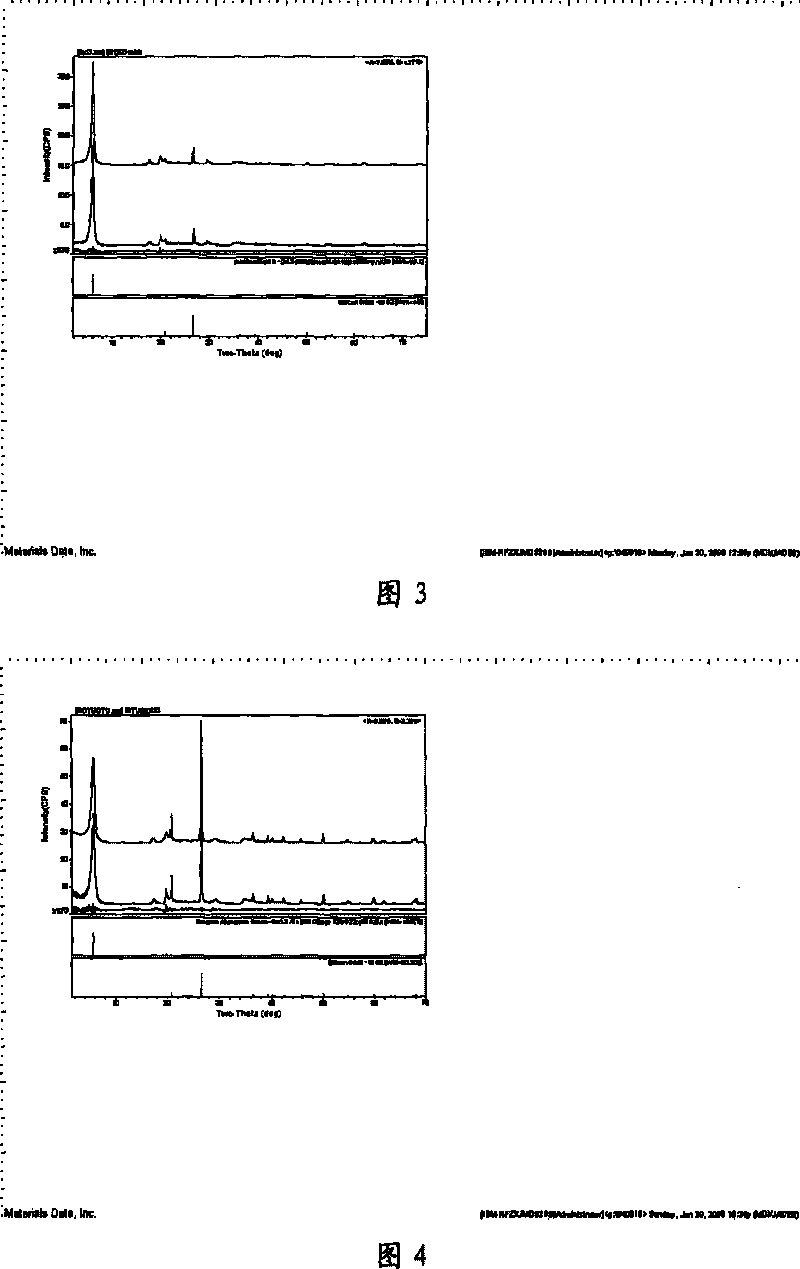

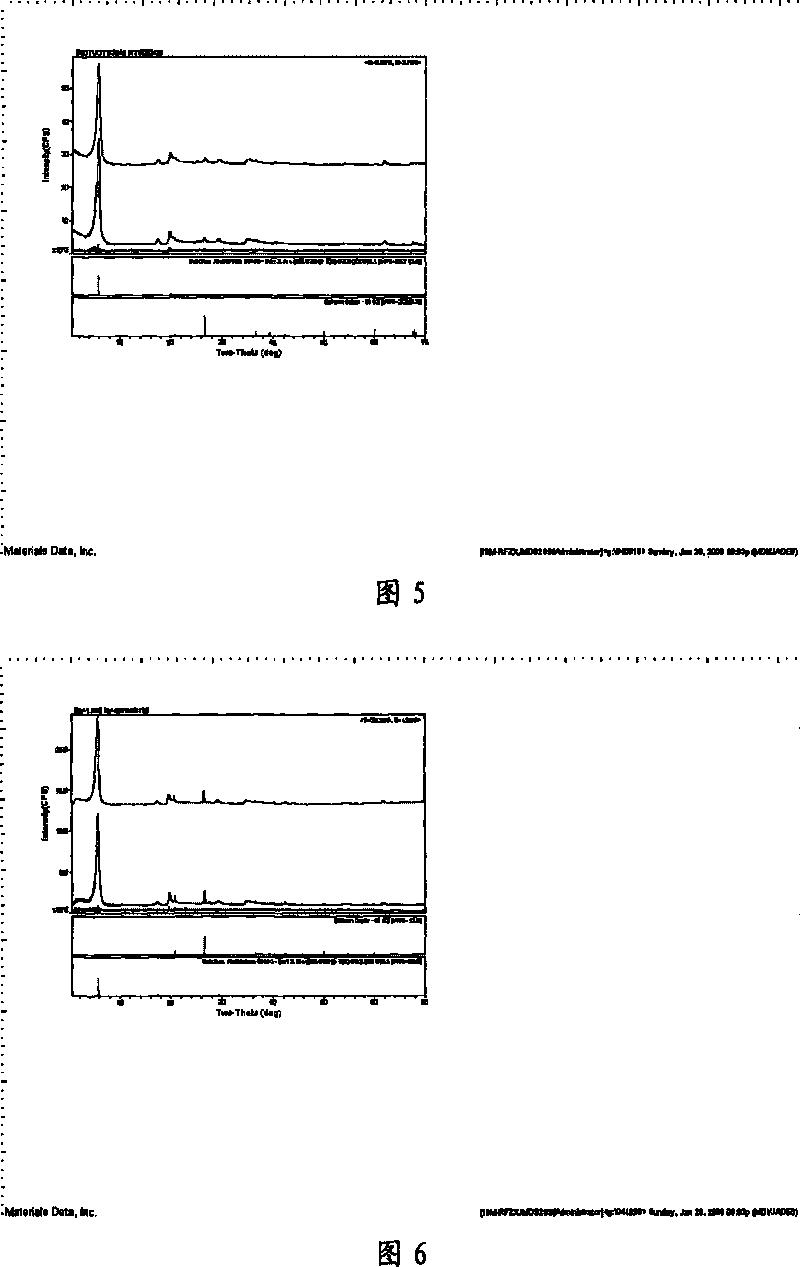

Modified smectite and method for producing the same and its application

ActiveCN101272986ANot easy to raise dustReduce moisture contentCosmetic preparationsOther chemical processesChemical compositionMontmorillonite

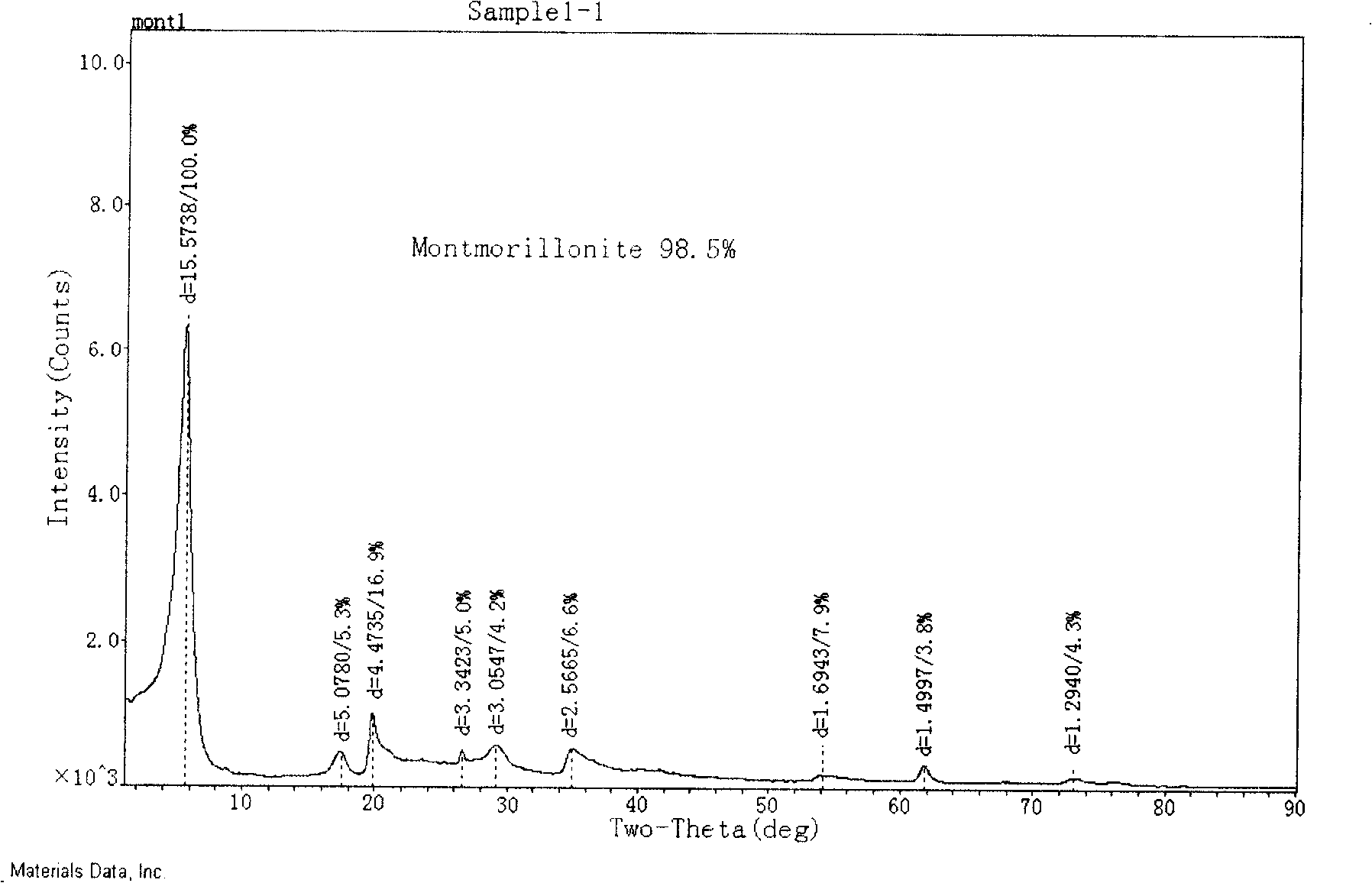

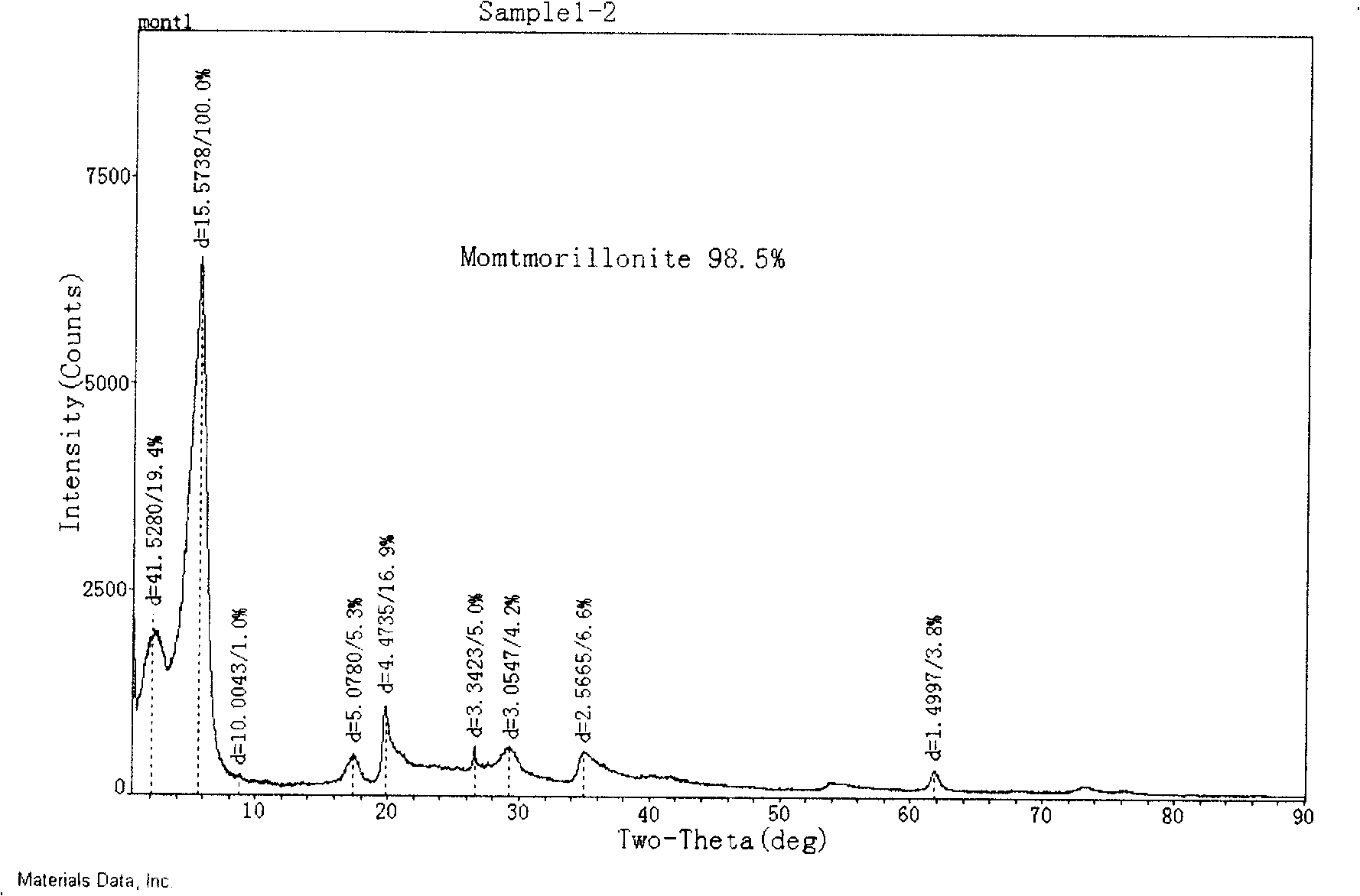

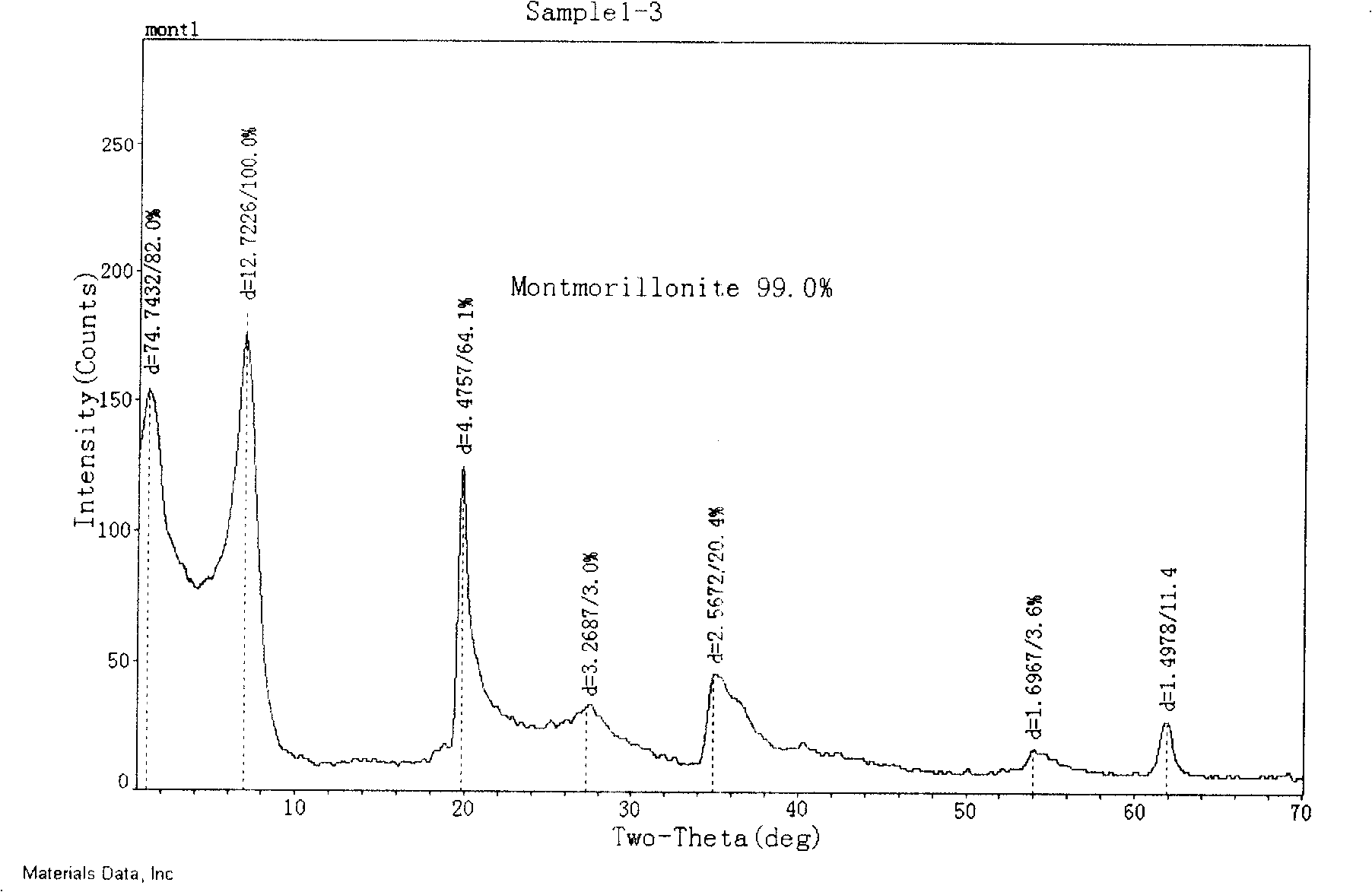

Disclosed is an inorganic medicine, particularly modified montmorillonite, method for preparing the same and use thereof. The said modified montmorillonite means that dioctahedron of natural montmorillonite is not destroyed and basic chemical composition for the same is not changed, and the microstructure stacked from dioctahedron layer is changed to decrease the thickness of stacking layer and to expose and increase the end face charge and the interlayer charge of montmorillonite, thereby resulting in its lower degree of C axis order. The present medical use of montmorillonite is thus significantly strengthened, particularly the reversal treatment effect on chronic atrophic gastritis. Also disclosed are a medicine composition containing modified montmorillonite and the reversal treatment effect of natural montmorillonite on chronic atrophic gastritis.

Owner:ZHEJIANG HAILISHENG PHARM CO LTD

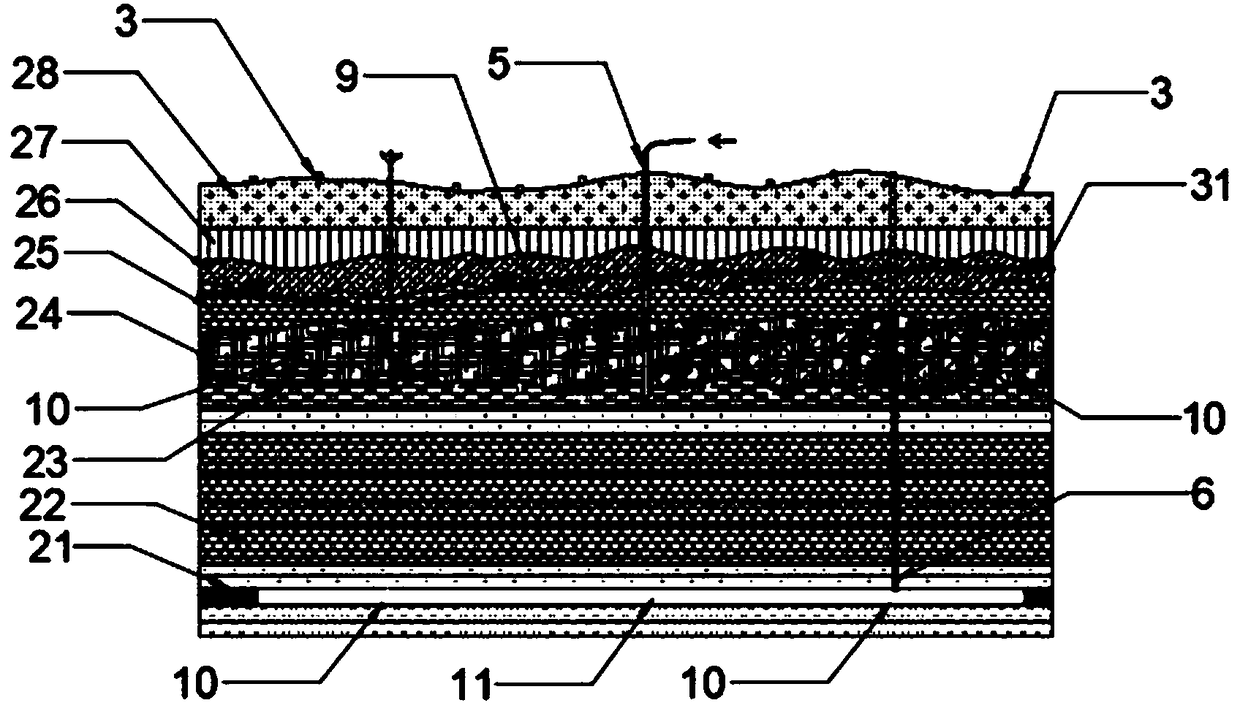

Three-layer composite waterproof corrugated board and preparation technology thereof

InactiveCN110154488AHigh strengthImprove waterproof performanceSpecial paperLaminationEmulsionMoisture

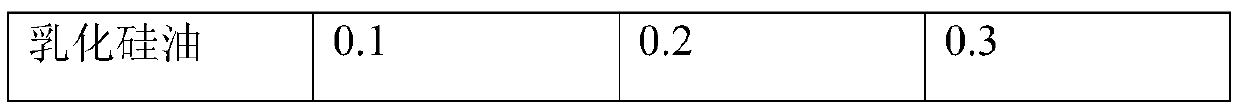

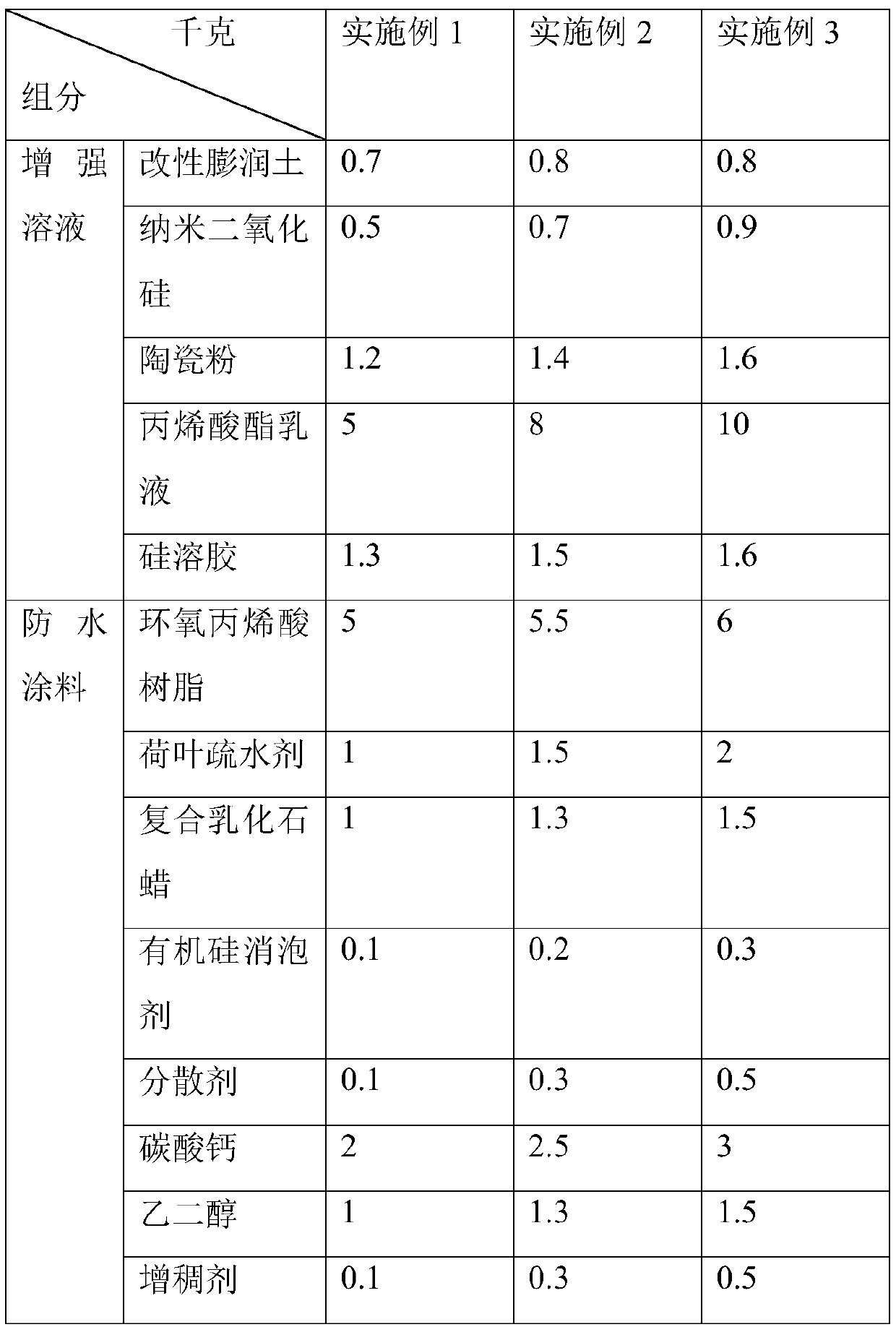

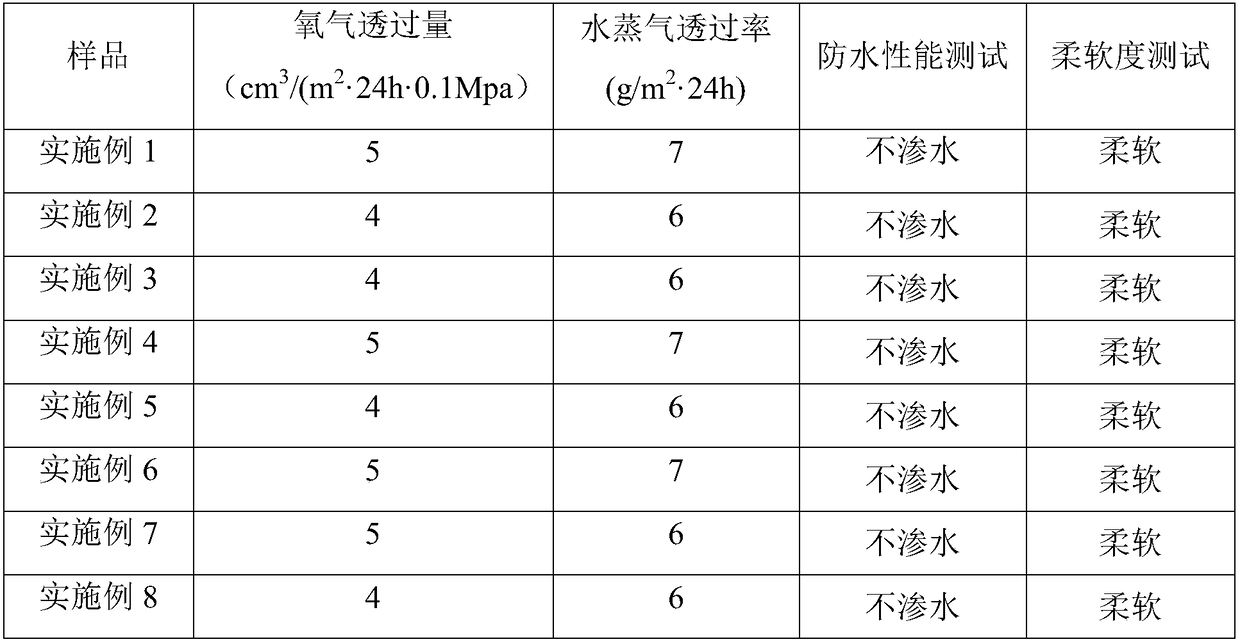

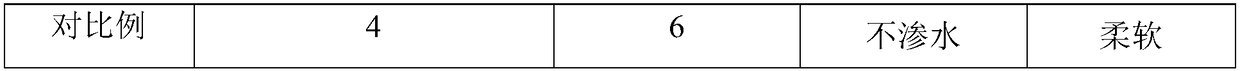

The invention discloses a three-layer composite waterproof corrugated board and a preparation technology thereof. The preparation technology of the three-layer composite waterproof corrugated board comprises the following steps: 1, preparing corrugated paper layers; 2, treating surface paper and inner paper: immersing the surface paper and inner paper in a reinforcing solution, taking out the surface paper and the inner paper after the surface paper and the inner paper are completely soaked, and drying the surface paper and the inner paper in a 45-55 DEG C environment, wherein the reinforcingsolution is prepared through mixing, by weight, 0.7-1.1 parts of modified bentonite, 0.5-0.9 part of nano-silica, 1.2-1.6 parts of ceramic powder, 5-10 parts of an acrylate emulsion and 1.3-1.6 partsof silica sol; 3, performing gluing and compounding; and 4, coating with a waterproof coating. The three-layer composite waterproof corrugated board of the invention has the advantages of high strength, good bending resistance, and good waterproof and moisture-proof performances; and the preparation technology of the invention has a simple preparation process.

Owner:广东新力德包装科技有限公司

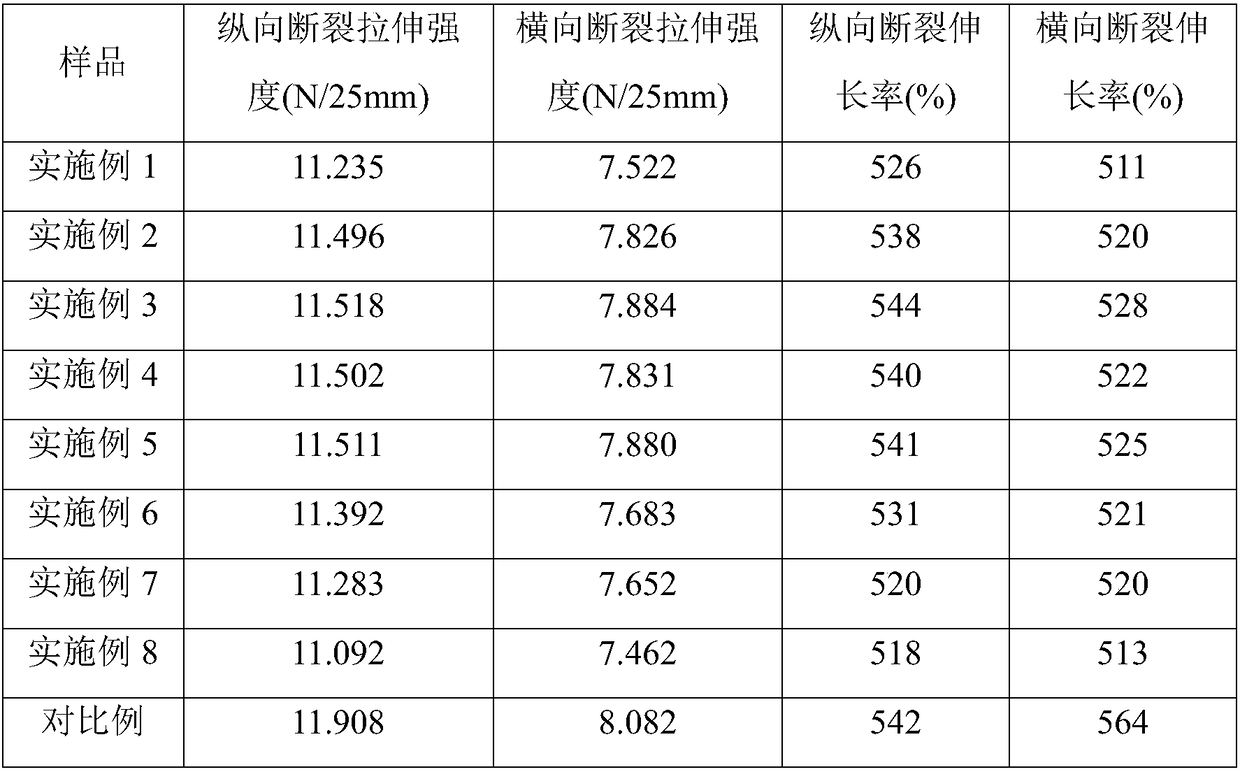

Ultrathin cast film as well as preparation method thereof and application thereof

InactiveCN108129735AImprove water barrier effectEasily brokenFlexible coversWrappersCast filmsMaterials science

The invention discloses an ultrathin cast film. According to the technical scheme, the key point isThe ultrathin cast film is characterized that the ultrathin cast filmby comprises comprising the following components: 7-12 parts of LDPE, 20-25 parts of LLDPE, 30-55 parts of HDPE, 3-5 parts of MLLDPE, 1-3 parts of PP and 5-8 parts of color master batch. The invention further discloses a preparation method for the ultrathin cast film, and the preparation method comprises the following steps: adding materials; performing extrusion plastifying; , extrusion casting, calendaring, setting and cooling; performing corona treatment; and trimming and rolling, wherein during calendaring, setting and cooling, the temperature of a rubber roller is set to be 50-55 DEG C, the temperature of an embossed steel stick is set to be 60-65 DEG C and pulling speed is 60-80 m / min. On the premise of keeping barrier properties, waterproof properties, softness, tensile properties and breakage properties of the cast film, the thickness of the cast film is reduced, the unit weight yield is increased, and the cost is reduced.

Owner:天津市德利塑料制品有限公司

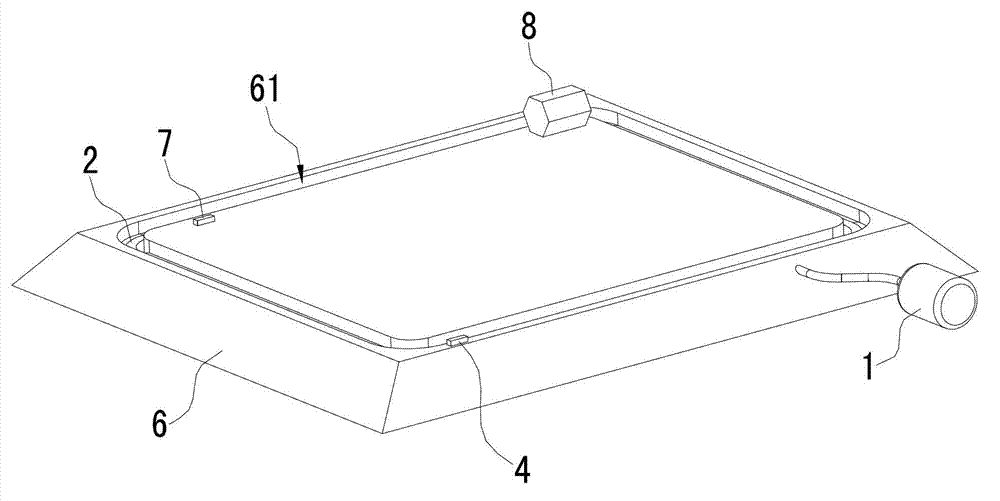

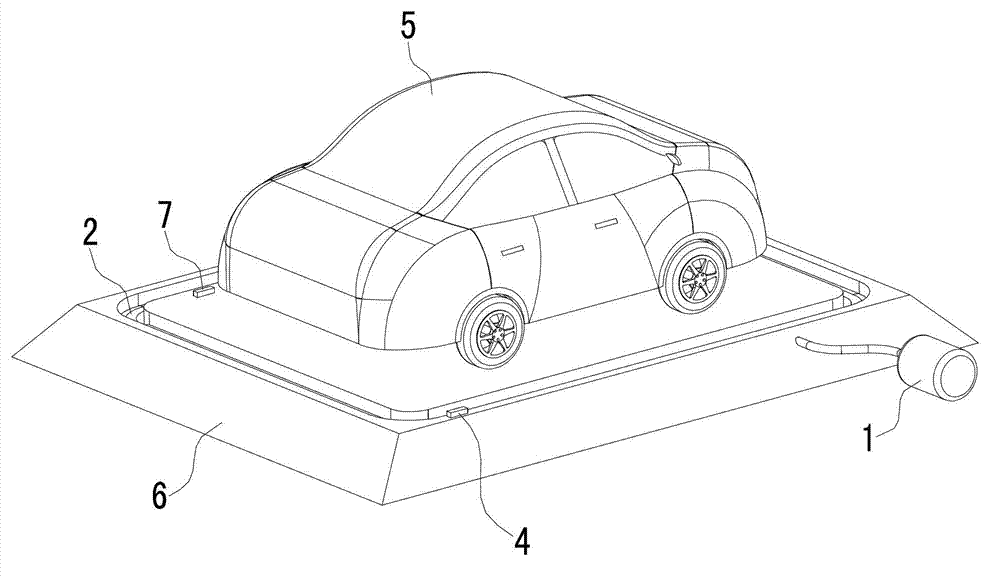

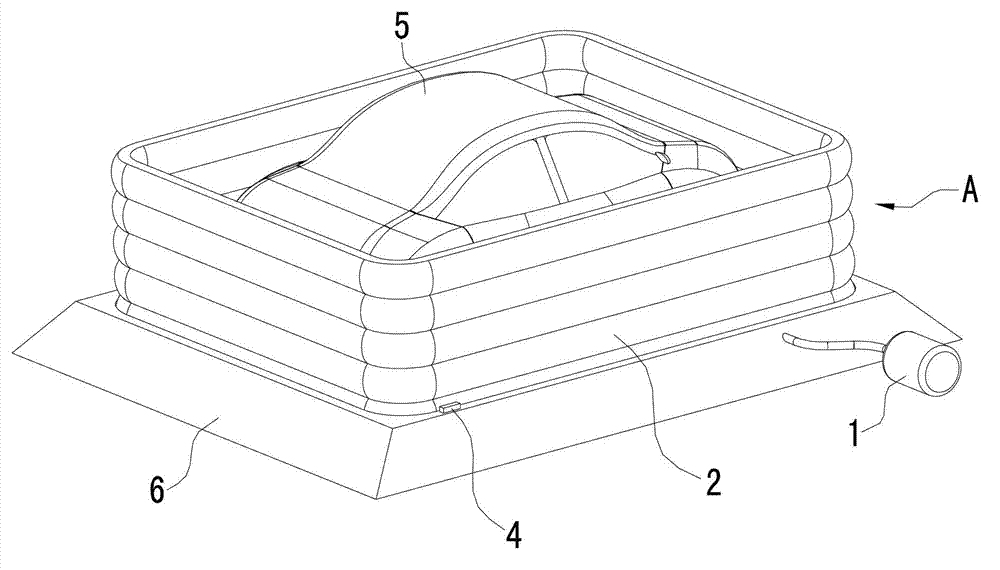

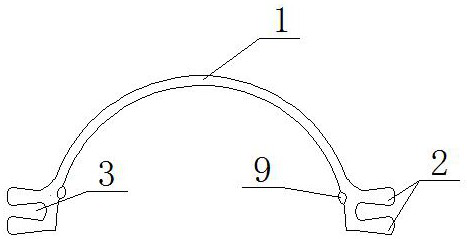

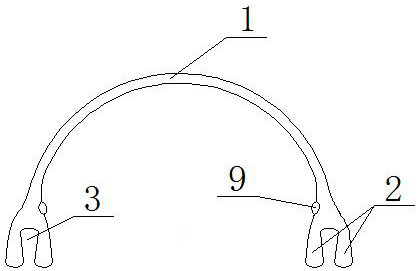

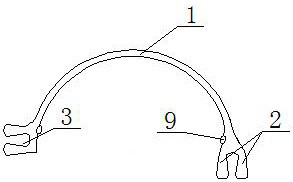

Flooding prevention device for parking lot

The invention relates to a flooding prevention device for a parking lot. The flooding prevention device comprises an air pump, an air sac, a controller and a first water level sensor. The bottom of the air sac is fixedly arranged on the ground of the parking lot, and the first water level sensor is arranged on the outer side of the air sac and is electrically connected with the controller. When the first water level sensor detects water outside the air sac, the first water level sensor transmits an alarm signal to the controller, the controller controls the air pump to inflate the air sac so that the air sac can uprise, and after the air sac rises, a first closed water wall is formed around a vehicle packed on the parking lot to isolate the vehicle from the water. The flooding prevention device for the parking lot is high in practicality, and can isolate the vehicle from the water by a physical isolation method when in a flood, so that the vehicle is effectively protected from immersing in the flood, and loss is reduced. Besides, by the aid of the air sac serving as an isolation tool, the air sac can be inflated to rise and can wrap the vehicle effectively, so that vehicle paint cannot be damaged while the vehicle can be sufficiently protected.

Owner:中山市中山纪念中学

Antibacterial low temperature-resistant heat insulation material

The invention provides an antibacterial low temperature-resistant heat insulation material. The antibacterial low temperature-resistant heat insulation material comprises, by weight, 10-25 parts of LDPE resin, 5-10 parts of modified melamine resin, 20-30 parts of an antibacterial agent, 15- silicone rubber, 20-30 parts of ethylene propylene rubber, 15-25 parts of butadiene rubber, 10-20 parts of styrene butadiene rubber, 3-5 parts of aromatic oil, 1-3 parts of stearic acid, 2-4 parts of a coupling agent, 5-8 parts of a compatibilizer, 10-15 parts of a foaming agent, 5-20 parts of a filler, 1-2 parts of an antioxidant, 1-3 parts of an antioxidant, 3-7 parts of a plasticizer, 5-10 parts of paprika, 5-10 parts of a mildew inhibiotor, 15-25 parts of high-low temperature resistance carbon black, 3-5 parts of nanometer calcium carbonate, 5-15 parts of glass fibers, 5-15 parts of ceramic fibers, 20-35 parts of a flame retardant, 5-10 parts of methylvinyldimethoxysilane and 10-15 parts of kaolin. The antibacterial low temperature-resistant heat insulation material has the advantages of good heat and cold resistance, excellent heat insulation performance, excellent mechanical properties and strong antibacterial property.

Owner:HEFEI ZHENXUN LOW TEMPERATURE TECH CO LTD

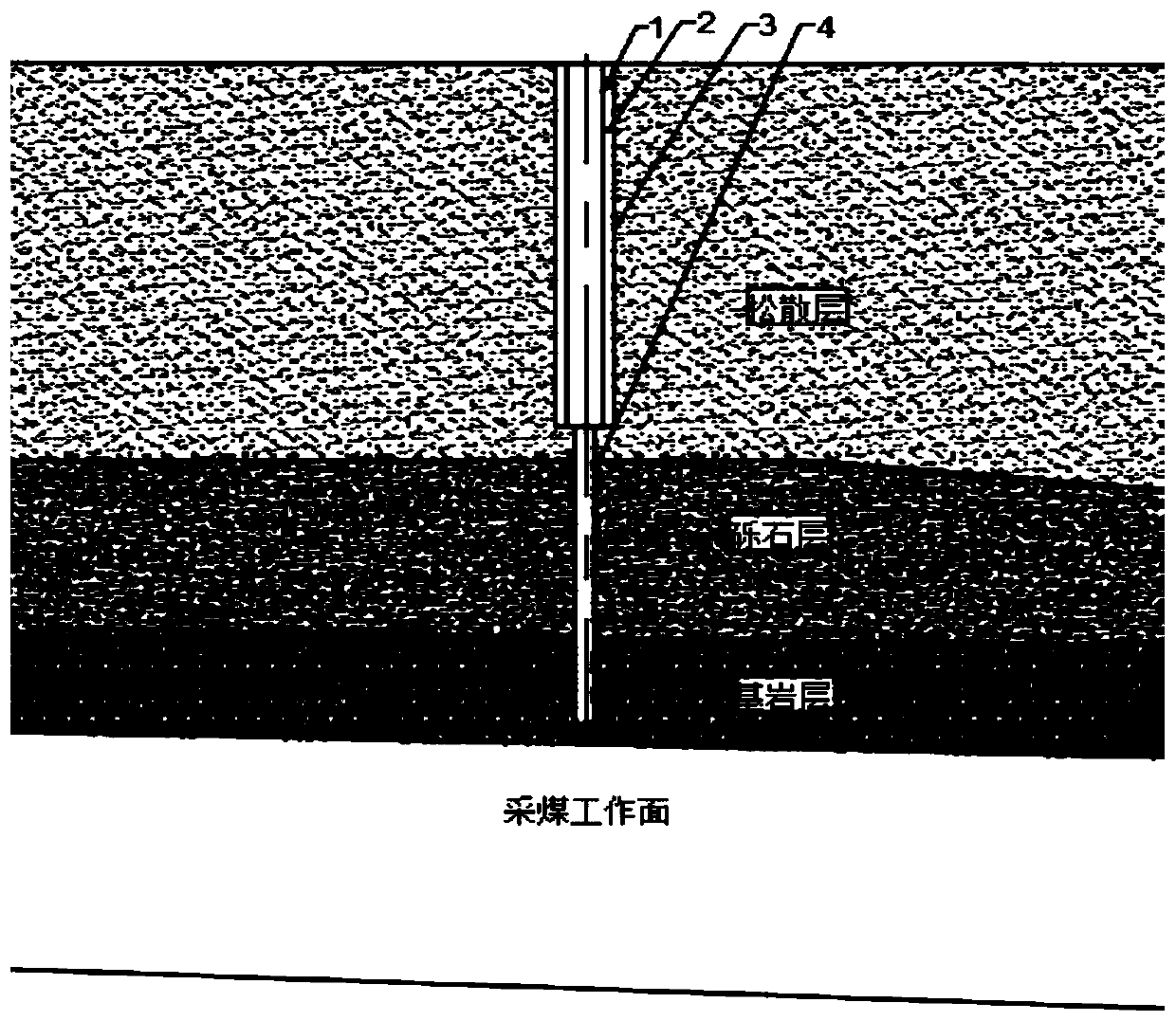

Working face collapse column grouting waterproof treatment method

InactiveCN111075482APrevent beingImprove water barrier effectUnderground chambersSealing/packingDrill holeCoal

The invention relates to the technical field of coal mine disaster treatment, in particular to a working face collapse column grouting waterproof treatment method. The method comprises the following steps that a working face cut opening is pushed, and pushing is stopped until the safe distance between the working face cut opening and the collapse column is kept; two grouting auxiliary roadways anda plurality of grouting drill nests are tunneled at the positions, corresponding to the collapse column, of a transportation crossheading, and a plurality of corresponding grouting drill nests are tunneled at the positions, corresponding to the collapse column, of an air return crossheading; and inclination grouting drill holes are constructed in the grouting auxiliary roadways and the grouting drill nests in the transportation crossheading, inclination grouting drill holes are constructed in the grouting drill nests in the air return crossheading, and the final hole layers of all the grouting drill holes are controlled to be located in a bottom plate aquifer between the two bottom plate water-resisting layers of the coal seam. The method is not only suitable for preventing the situationthat the non-water-guide collapse column is activated and guides water due to mining influence, but also can reinforce the water-guide collapse column in a multi-layer grouting mode, the water insulation capacity can be improved, and it is ensured that no water damage accident occurs when the coal face is pushed over.

Owner:NORTH CHINA INST OF SCI & TECH +4

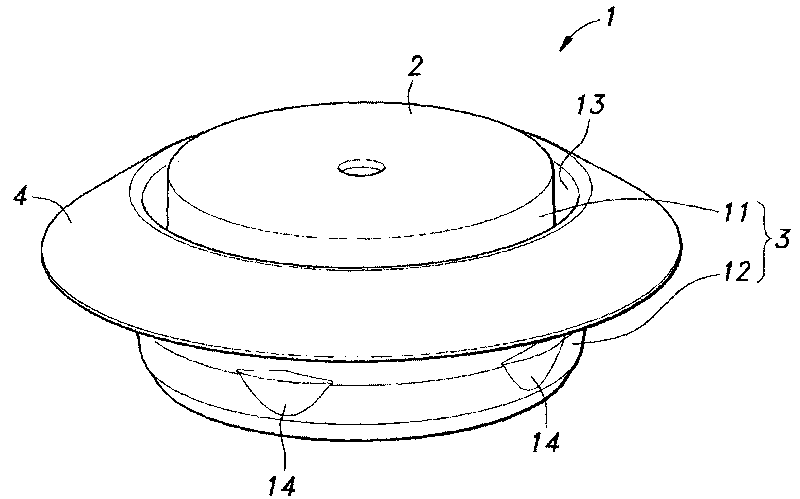

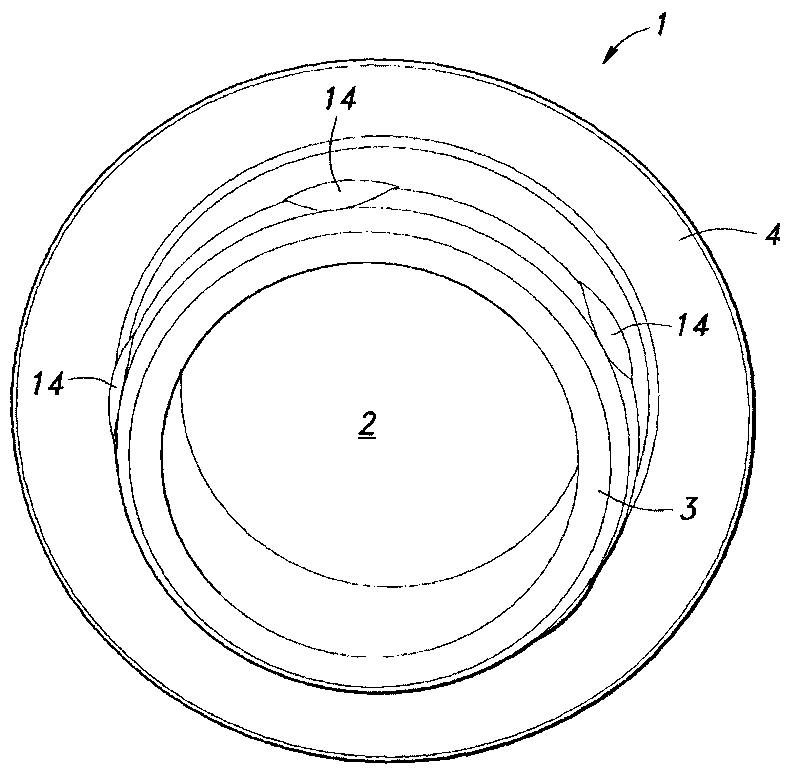

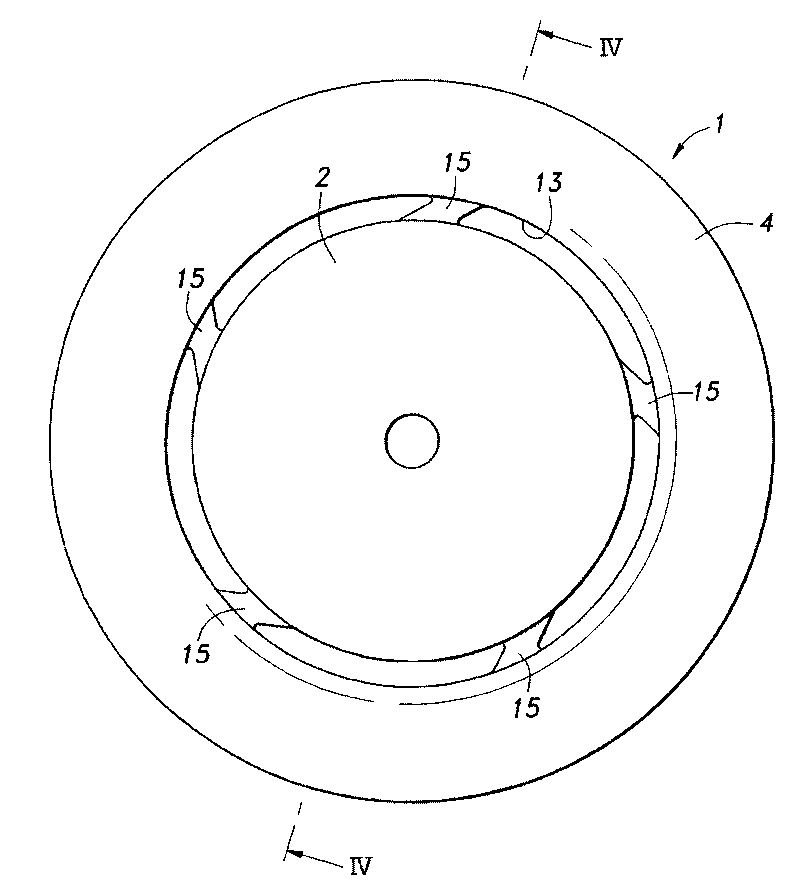

Hole plug

InactiveCN101712339AAvoid breakingImprove pullout forceSuperstructure subunitsPressure vesselsPull forceEngineering

A hole plug, wherein the hole plug is configured so as to withstand a high pulling force and so that a load acting on an engaging claw when the hole plug is separated from a mold is reduced. A leg (3) of a hole plug (1) is provided with an inner tube (11), an outer tube (12) surrounding the inner tube, a rib (15) interconnecting the inner and outer tubes, and an engaging claw (14) provided to theouter peripheral surface of the outer tube and engaged with the peripheral edge of the leg when the leg is inserted in a hole (22) in a body panel (21). The rib is provided to a position corresponding to the position of the engaging claw and is tilted relative to the radial direction of the hole plug when viewed in the direction of insertion of the leg.

Owner:NIFCO INC

Grouting method of waterproof curtain of burnt rock covering on working surface to be mined of coal mine

ActiveCN108843343AImprove anti-seepage performanceImprove anti-seepage effectUnderground chambersDrainageGeomorphologySlurry

The invention belongs to the technical field of water control of mine shafts, and particularly relates to a grouting method of a waterproof curtain of burnt rock covering on a working surface to be mined of a coal mine so as to solve the problems existing in the prior art that slurry between grouting holes is difficult to sufficiently diffuse and overlap, the leakproof effect of a grouting curtainof the burnt rock is poor, and the water shutoff rate is not high. The technical scheme adopted by the invention lies in that the grouting method comprises the steps of (1) performing hole drilling arrangement on the curtain; (2) grouting inner-row curtain holes; and (3) grouting outer-row curtain holes.

Owner:SHENMU ZHANGJIAMAO COAL MINING CO LTD OF SHAANXI COAL & CHEM IND GRP +1

Expansive soil embankment structure improved and reinforced by sandwich method and construction method

InactiveCN106676991AReduce in quantityLow costRoadwaysClimate change adaptationWater dischargeSurface layer

The invention discloses an expansive soil embankment structure improved and reinforced by a sandwich method and a construction method. The structure comprises a subgrade bed surface layer, a subgrade bed bottom layer and a subgrade body in sequence from top to bottom, wherein the subgrade body is composed of an expansive soil filling region and an improved soil filling region which are distributed at interval; anti-running slipping grids are arranged on side slopes at two sides of the subgrade body; transverse water drainage slopes are arranged at the bottoms of the subgrade bed surface layer and the subgrade bed bottom layer, and the bottom of the expansive soil filling region in the subgrade body; an inclined water discharge hole is buried in the transverse water drainage slope of the expansive soil filling region; a reversed filtering layer is arranged at the periphery of the inclined water discharge hole. According to the expansive soil embankment structure disclosed by the invention, a technical problem that expansive soil cannot be used for carrying out embankment filling is solved, and the quality meets the requirements after embankment filling construction of an expansive soil region is carried out; the improvement cost can be greatly reduced, and a flow of a construction process is simplified; large-scale construction and continuous filling are convenient to carry out, and the aims of reasonable technology and reduced cost are realized; the expansive soil embankment structure has a wide popularization and application value.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

Method for purifying montmorillonite, purified montmorillonite and combination thereof

ActiveCN101340979BReduce moisture contentAvoid cakingWet separationClaywaresPhysical chemistryMontmorillonite

A method for purification and separation of inorganic mineral, especially for purification and separation of montmorillonite from natural bentonite is provided. The said method is simple, and uses high-speed centrifugal device to well solve the problems present in purification of montmorillonite that a-quartz and cristobalite are difficult to be separated and removed and purified slurry is difficult to be concentrated and dehydrated. The purity of montmorillonite thus obtained is not less than 95%.

Owner:ZHEJIANG HAILISHENG PHARM CO LTD

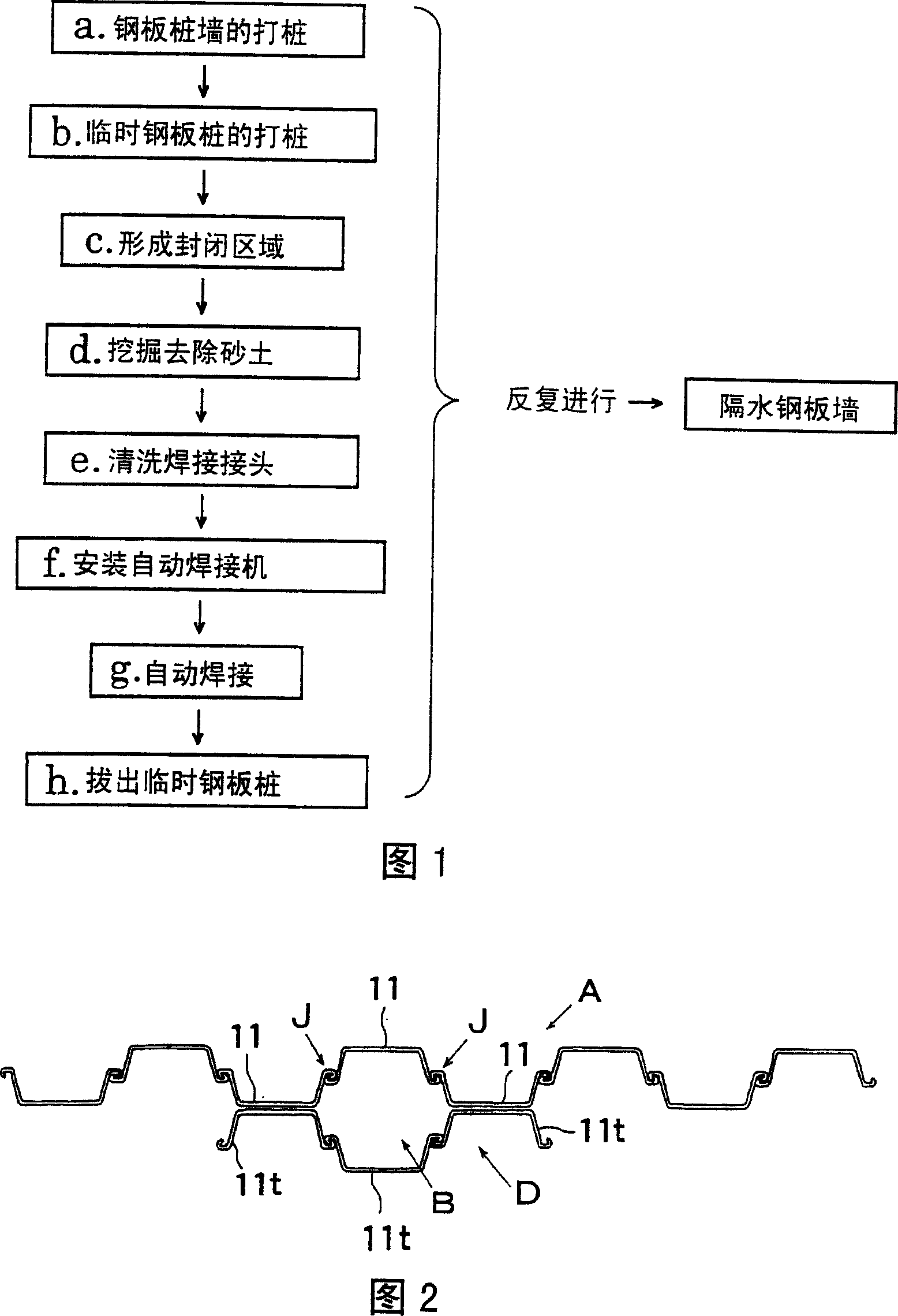

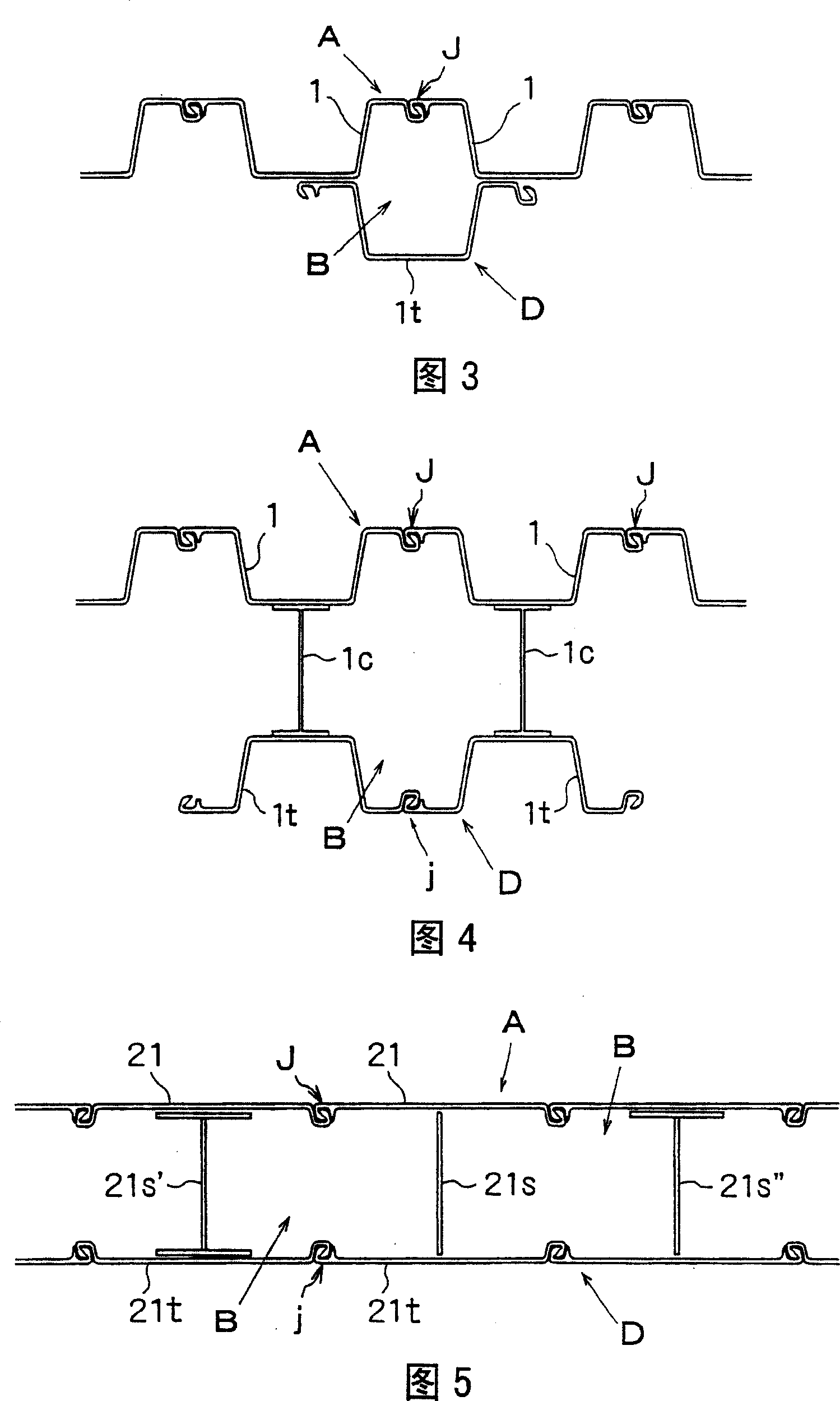

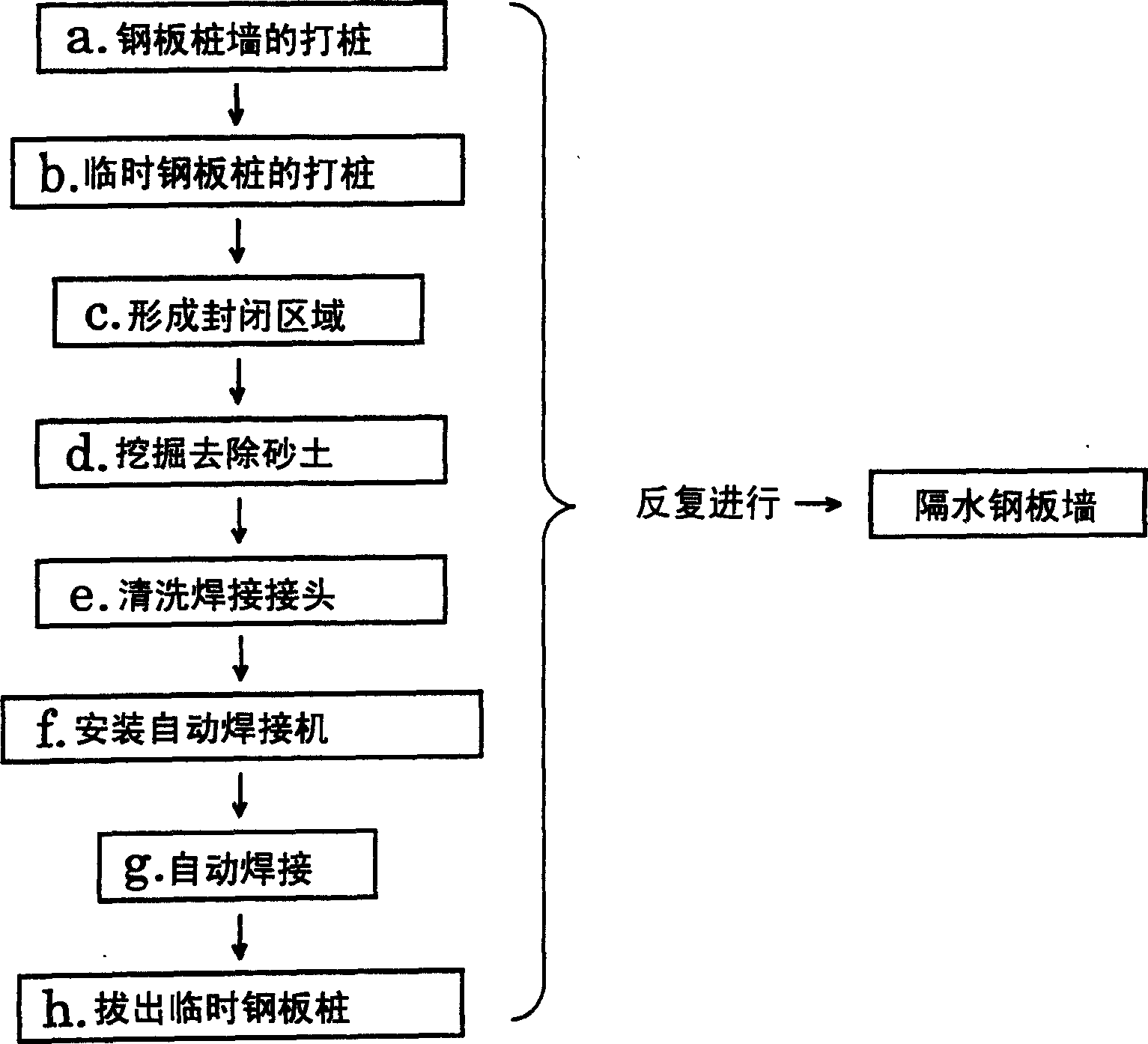

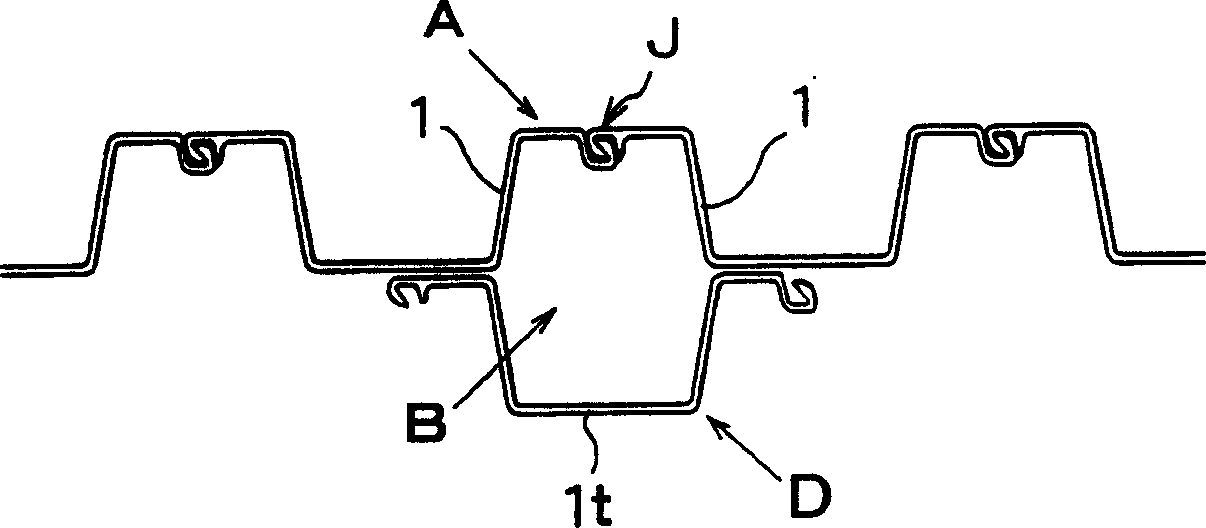

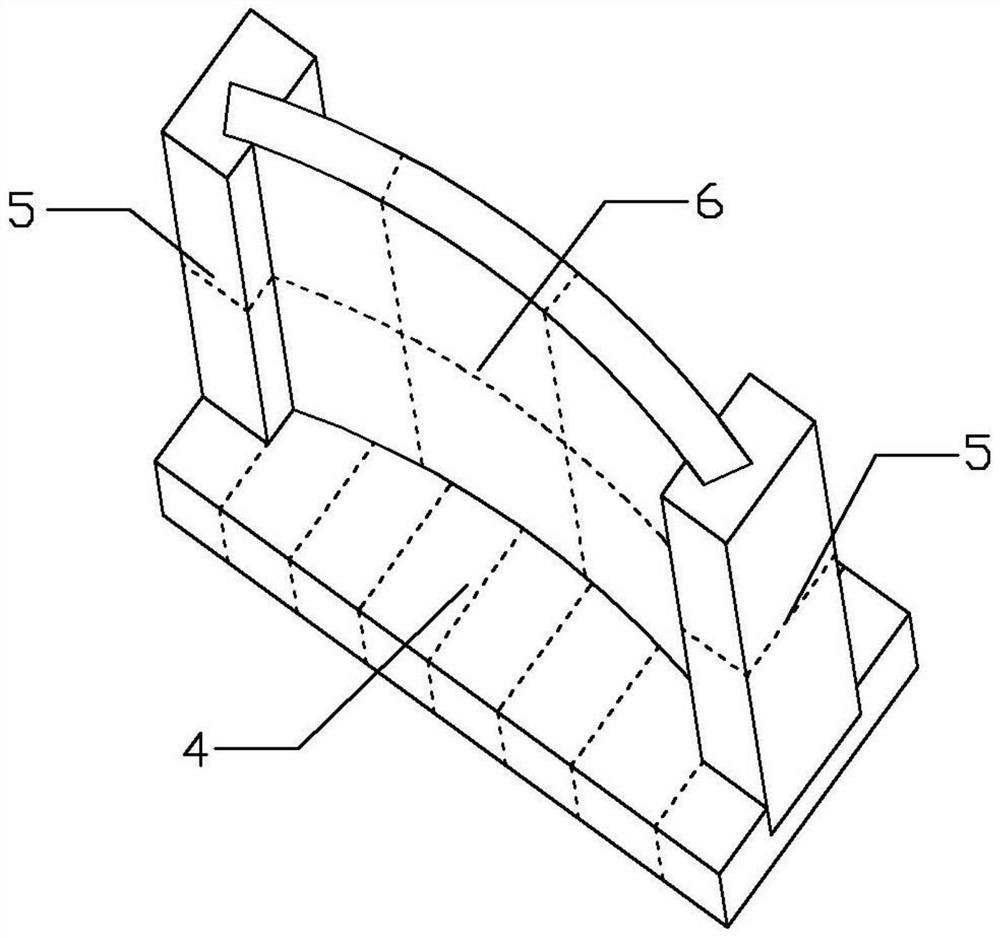

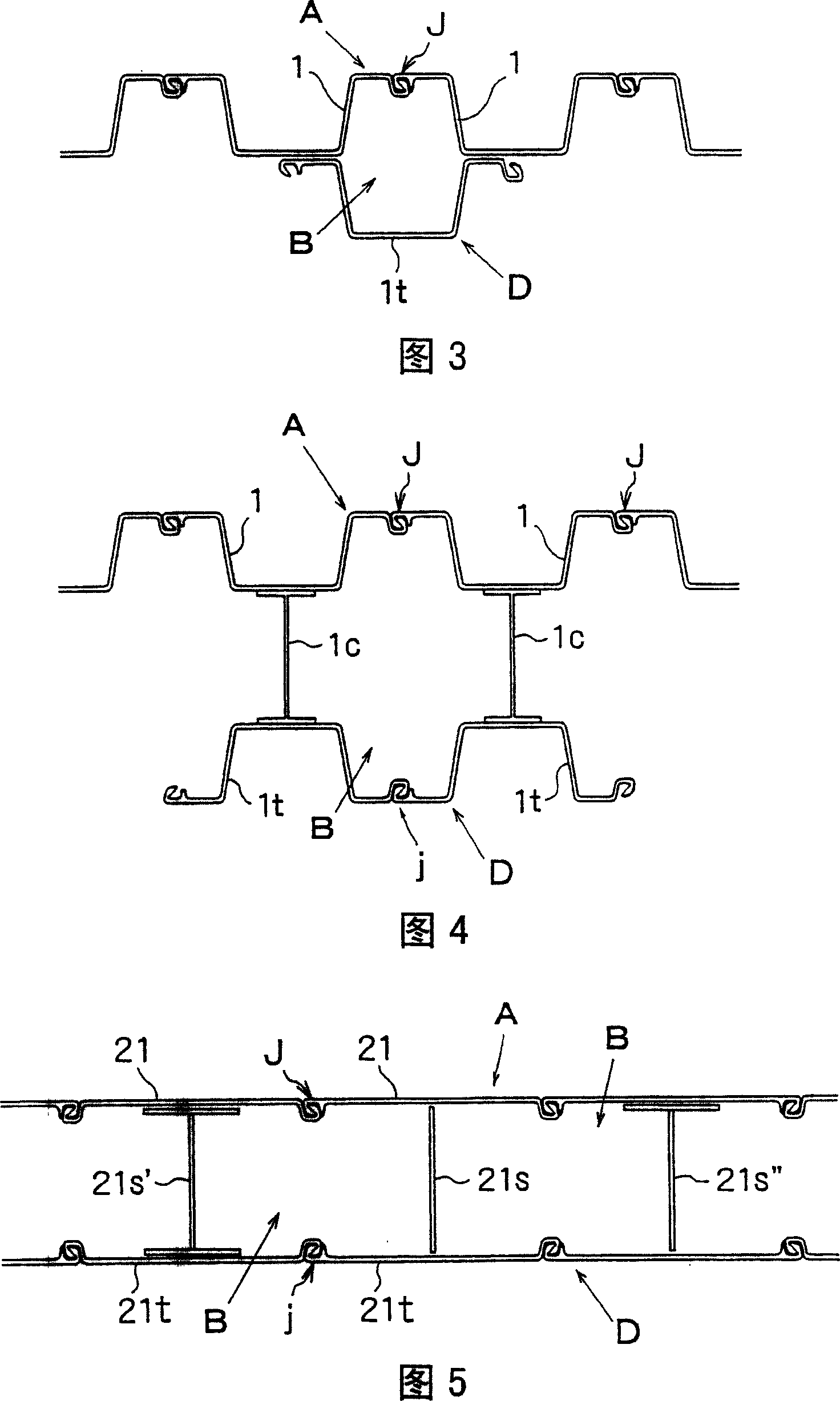

Steel wall and the manufacture method thereof

InactiveCN101016742AQuality WeldingWelding quality of weld lengthArtificial islandsUnderwater structuresSheet steelEngineering

The invention relates to a steel wall and a manufacturing method thereof. The steel sheet wall is constructed by connecting plural steel sheets with joints on both ends by the joints, wherein, the sectional steels for cutting off water cover the joints to weld the sectional steels for cutting off water and the steel sheets, and / or between the sectional steels for cutting off water along a length direction in a continuously gapless welding manner. Thereby, the weldable space can be ensured and the welding can be performed by automatic welding, etc, through removing sand and water near the welding position.

Owner:NIPPON STEEL CORP +1

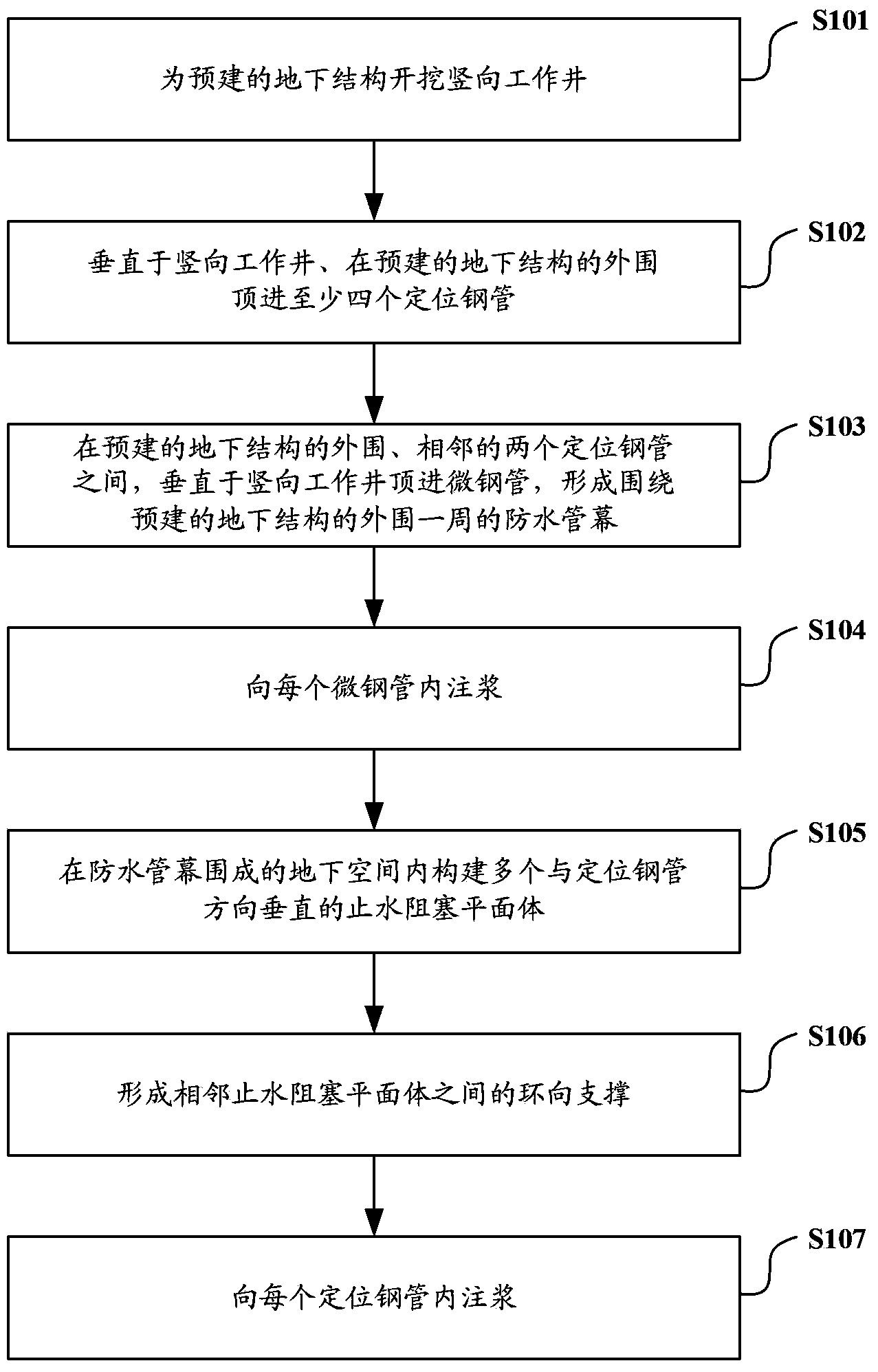

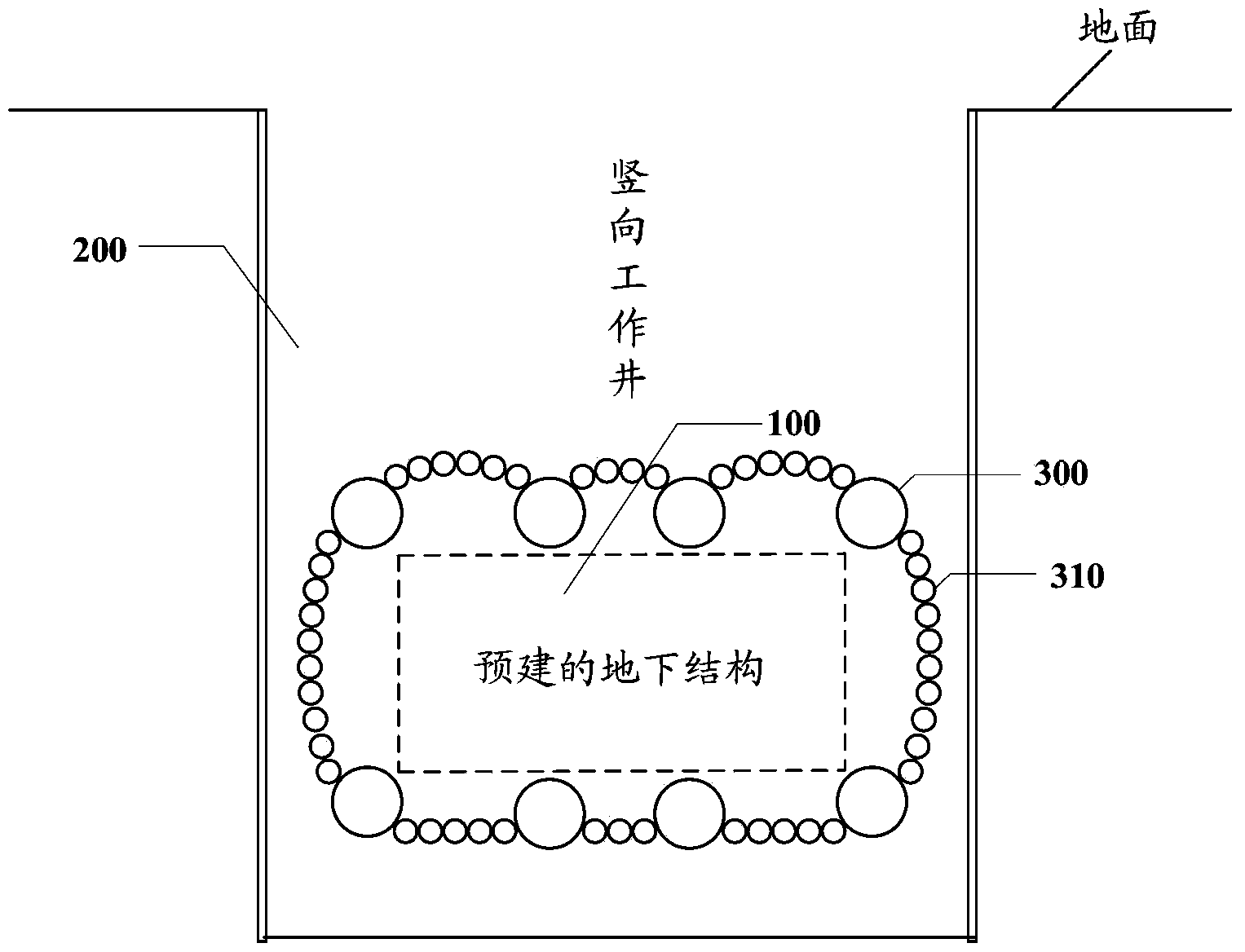

Method for constructing water proof structure and constructing underground construction in water proof mode

ActiveCN103437789AImprove water barrier effectEnhance water and soil pressureUnderground chambersTunnel liningStructure of the EarthUnderground space

The invention discloses a method for constructing a water proof structure and constructing underground construction in a water proof mode. The method for constructing the water proof structure includes the steps that positioning steel tubes are laid on the outer periphery of prebuilt underground construction in the direction perpendicular to the extending direction of a vertical shaft after the vertical shaft is excavated for the prebuilt underground construction; micro steel tubes are jacked into the space between adjacent positioning steel tubes on the outer periphery of the prebuilt underground construction in the direction perpendicular to the extending direction of the vertical shaft; the adjacent positioning steel tubes and the micro steel tubes are connected through fore shafts and adjacent micro steel tubes are connected though fore shafts to form a water proof tube curtain encircling the outer periphery of the prebuilt underground construction; grout is injected into the micro steel tubes; water stop blocking plane bodies perpendicular to the positioning steel tubes and away from the vertical shaft at different distances are constructed in the underground space defined by the water proof tube curtain; annular supporting bodies parallel to the water stop blocking plane bodies are formed between adjacent water stop blocking plane bodies along the inner side wall of the water proof tube curtain. The water proof structure constructed through the method has the good water proof effect, and enables the water proof tube curtain to have strong rigidity.

Owner:BEIJING RAIL & TRANSIT DESIGN & RES INST

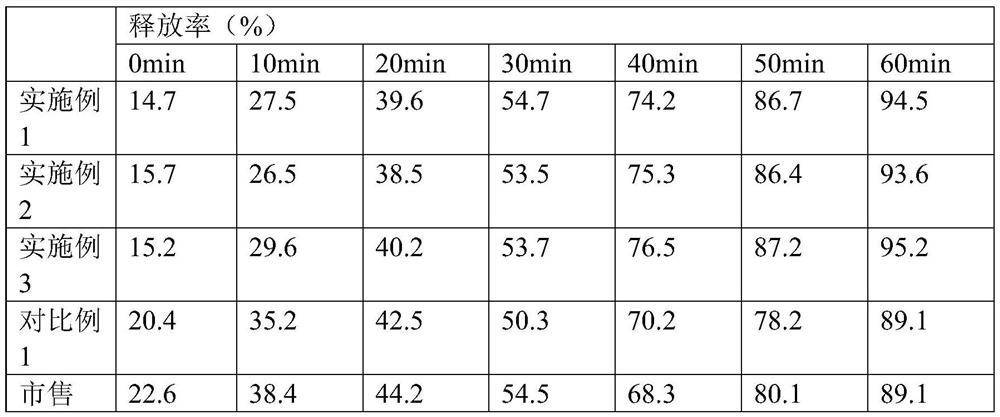

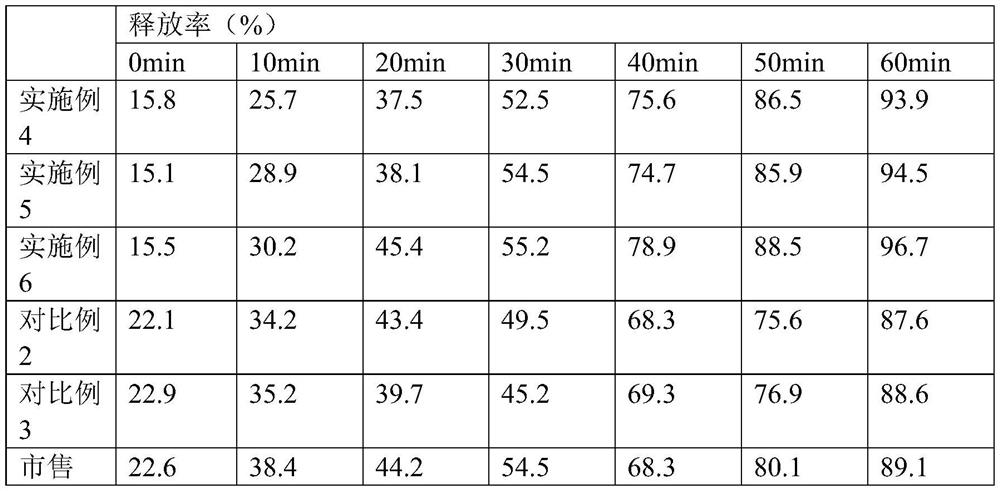

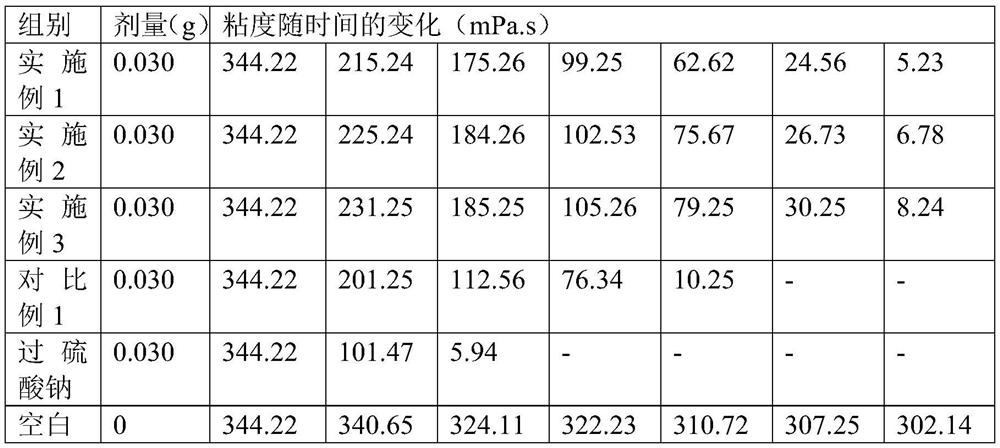

High-temperature-resistant capsule gel breaker for fracturing and preparation method thereof

ActiveCN111876142AGuaranteed viscosityGel break time controllableDrilling compositionPolyesterCellulose

The invention provides a capsule gel breaker for high-temperature fracturing, the capsule gel breaker takes an active substance, a dispersing agent and an emulsifying agent as a capsule core, a capsule coating is a capsule coating A or a capsule coating B, and the capsule coating A is prepared by reacting linear polystyrene with polyisopropylacrylamide and p-bis(chloromethyl)benzene; the capsule coating B is prepared from sodium carboxymethyl cellulose, polyvinyl alcohol, polyesteramide, acrylic resin, Tween 80, triethyl citrate, stearic acid, ethanol and water. The capsule gel breaker is uniform in particle and good in smoothness, the selected membrane material has delayed degradation and temperature resistance and water repellency, and the problem that the application range of the capsule gel breaker is limited is solved.

Owner:XIAN AODE PETROCHEM ENG TECH CO LTD

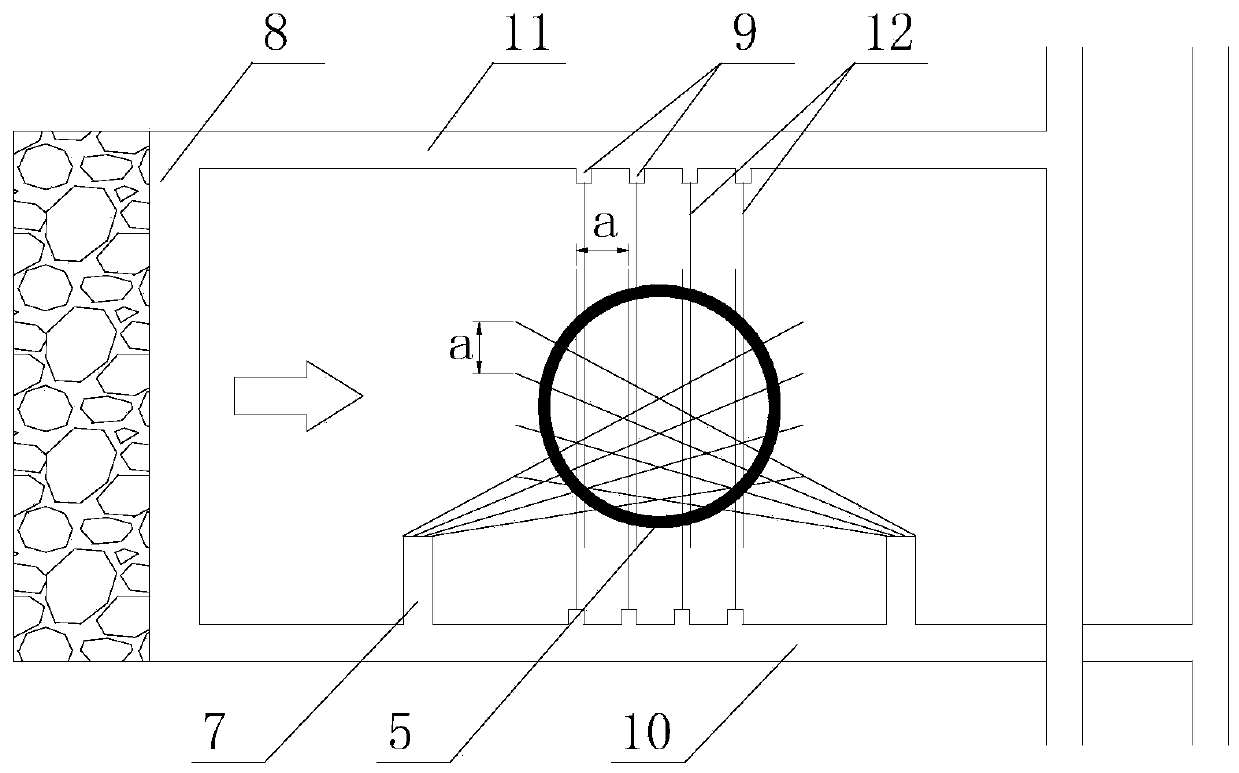

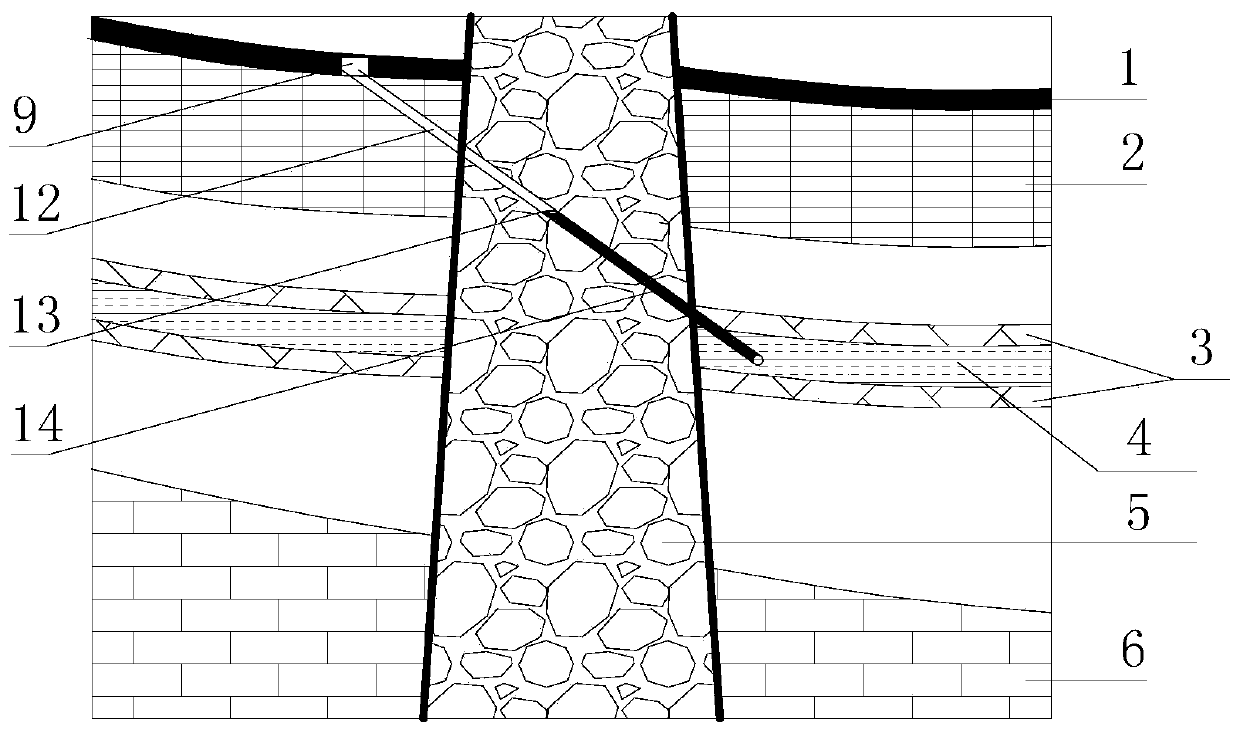

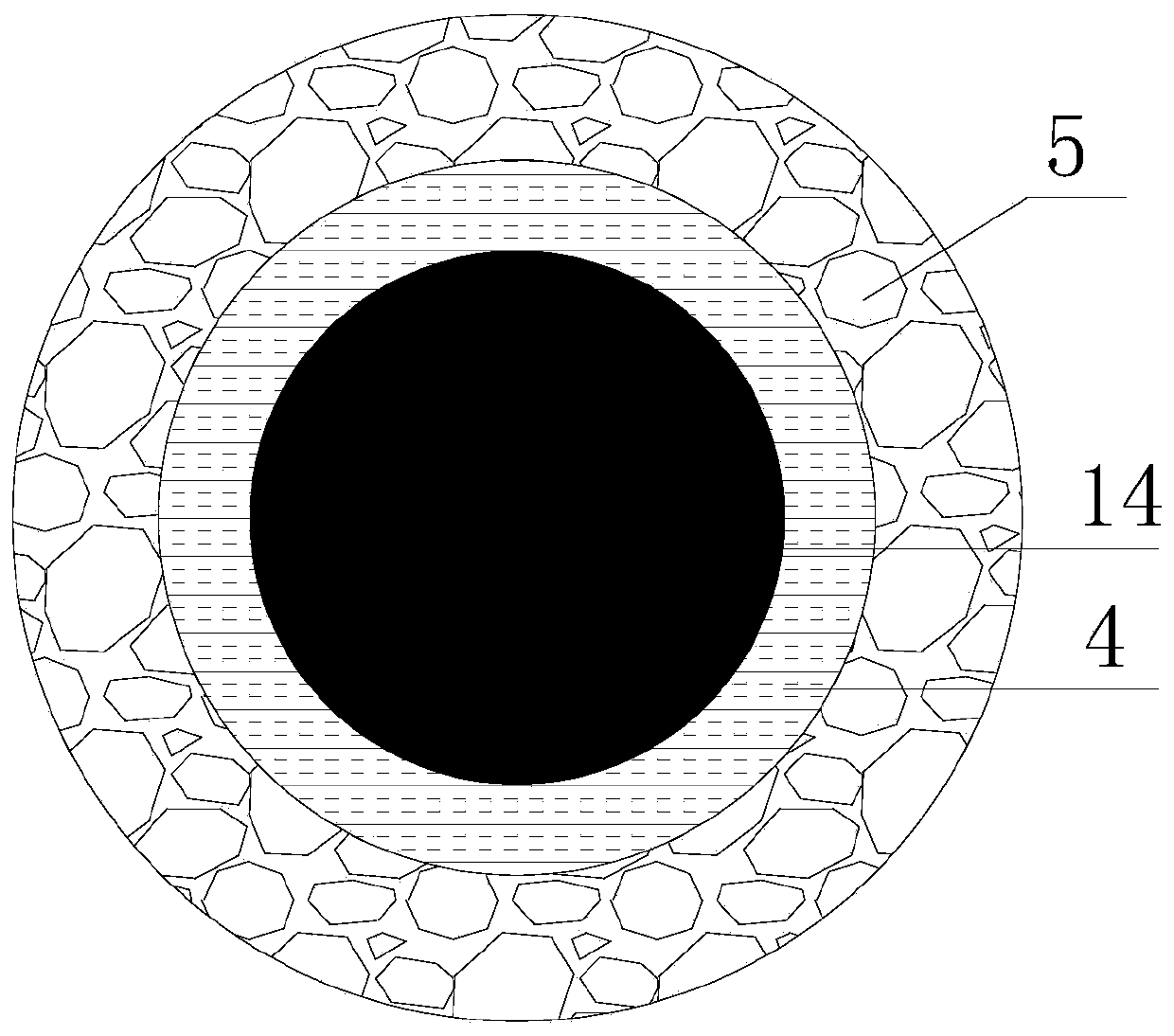

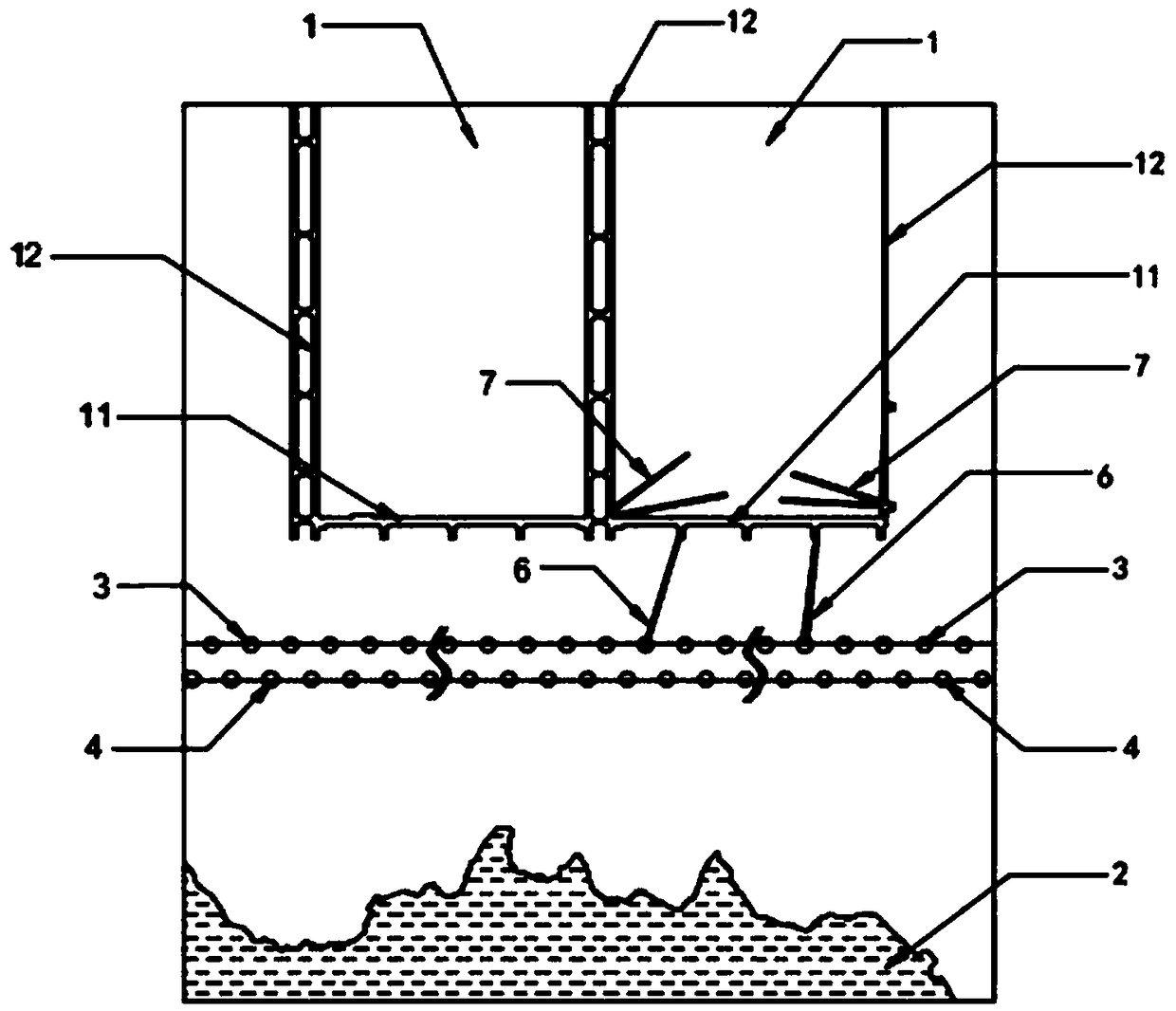

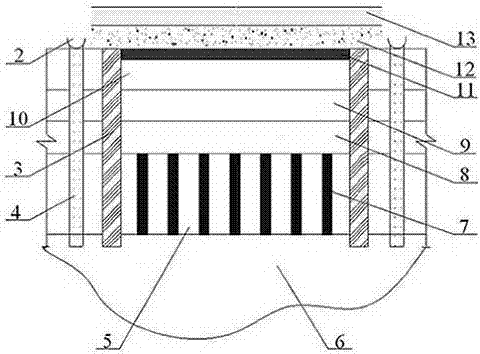

Processing method of large-thickness collapsible loess foundation of subway station

InactiveCN107090842AGuaranteed stabilityReduces chances of collapsingProtective foundationEmbankmentsSlurry wallSubway station

The invention relates to a processing method of a large-thickness collapsible loess foundation of a subway station. The method includes the steps that an underground continuous wall (3) is arranged on the periphery of the foundation of the subway station (1); a collapsible loess layer (5) can conduct self-weight collapsible sedimentation in a pre-soaking manner, and reinforcement processing is conducted on soil mass on the upper layer of the foundation after sedimentation deformation is stable; a waterproof cushion layer (11) is arranged on a backfilled soil layer (10) in a filing manner; water guide wells (4) are perpendicularly formed outside the underground continuous wall (3); a water guide cushion layer (12) is arranged on the waterproof cushion layer (11) and the water guide wells (4) in a filling manner, and a horizontal water drainage pipe (2) communicating with the water guide wells (4) is arranged in the water guide cushion layer (12); and a water blocking cushion layer (13) is arranged on the water guide cushion layer (12) in a filling manner. According to the processing method, three aspects of soaking, water blocking and water drainage are comprehensively considered, influences of later-period rainfall, underground water and other factors on the collapsible loess layer in the foundation are reduced, and the possibility that collapsibility is caused to the collapsible loess layer again is effectively lowered.

Owner:SEISMOLOGICAL BUREAU OF GANSU PROVINCE CHINA EARTHQUAKE ADMINISTRATION

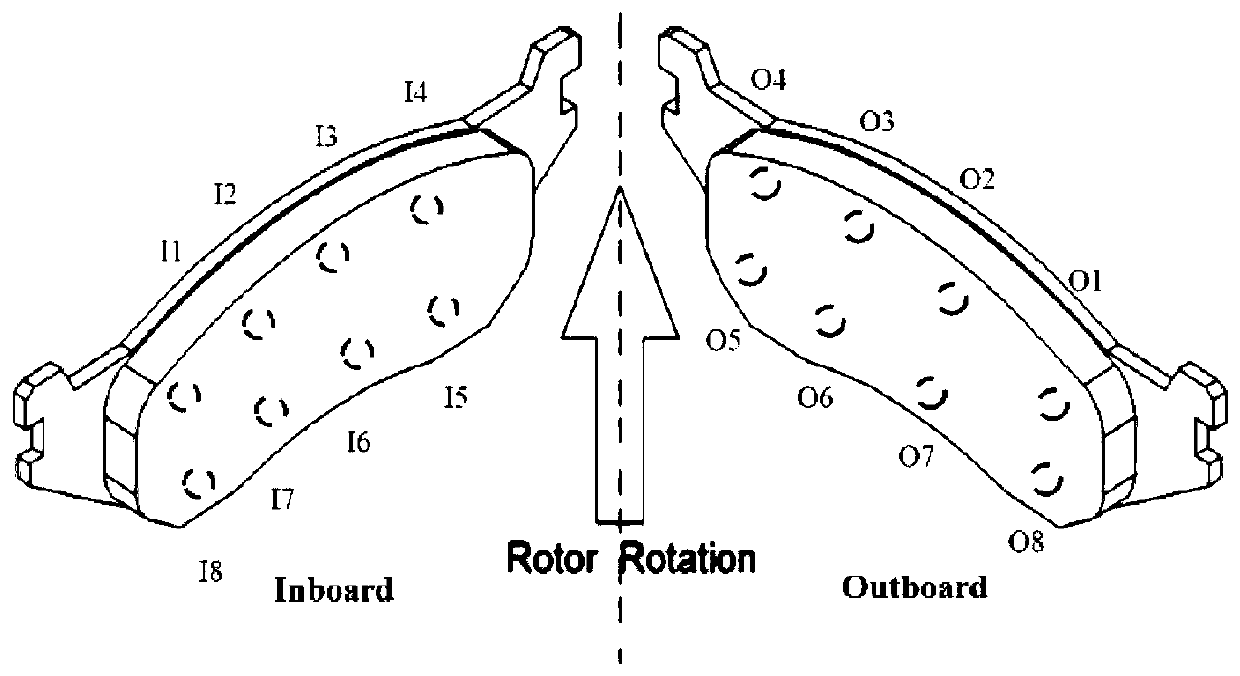

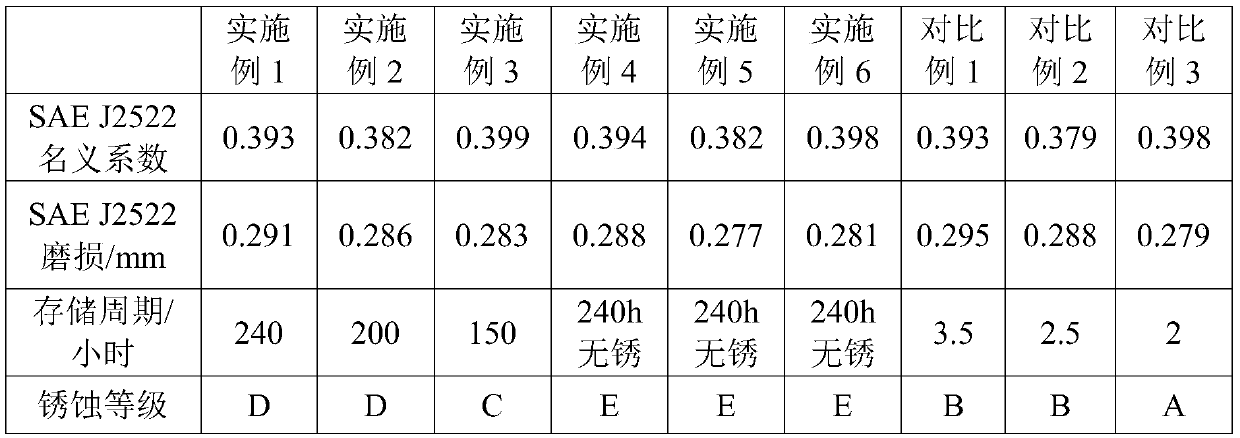

Friction material, brake pad prepared by friction material and preparation method of brake pad

ActiveCN110081107AEasy to storeImprove transportation cycleFriction liningActuatorsOxidation resistantMechanical engineering

The invention discloses a friction material, a brake pad prepared by the friction material and a preparation method of the brake pad. The preparation method of the brake pad comprises the following steps that (1) preparation of a copper-free metal friction material is performed; (2) hot-pressing molding is performed, wherein the copper-free metal friction material in the step (1) is placed in a hot-pressing mold cavity to be spread and flattened, a cushion layer material is put in the hot-pressing mold cavity to be spread and flattened, a steel backing is placed, hot-pressing molding is performed, and then demolding is performed; (3) a demolded sample undergoes heat treatment, and then is cooled to room temperature; and (4) post-treatment is performed on the sample after being treated in the step (3) to prepare the brake pad. According to the preparation method of the brake pad, the storage, transport cycle and oxidation resistance of the friction material in the brake pad can be obviously improved through rust prevention treatment.

Owner:SHANDONG GOLD PHOENIX

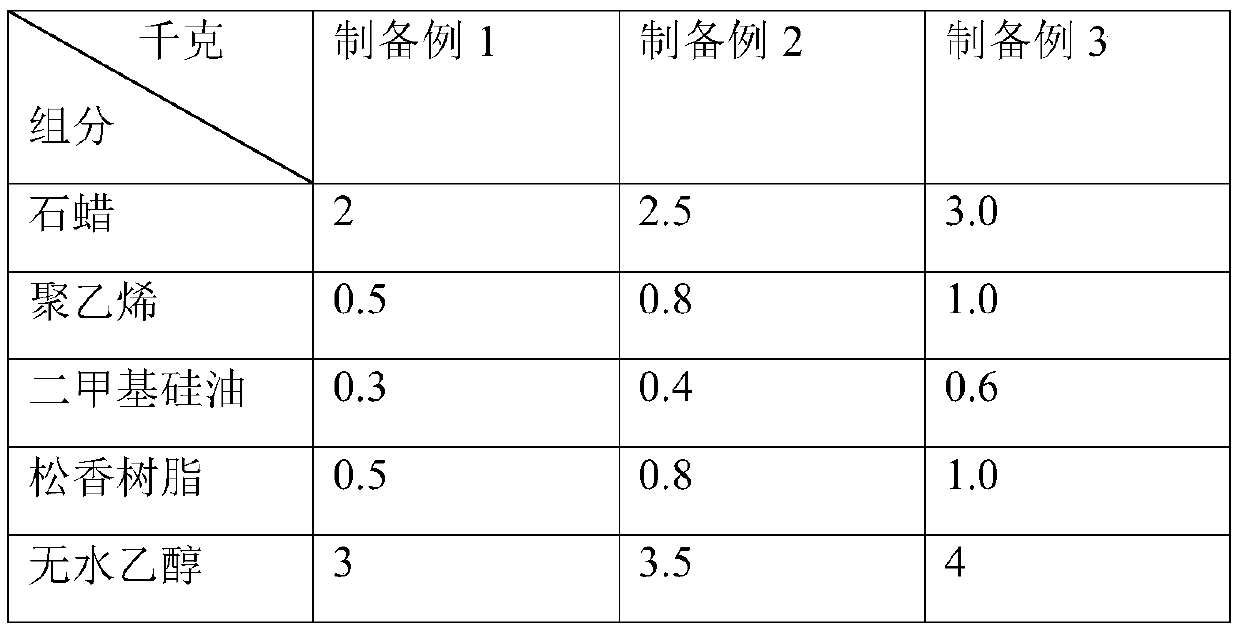

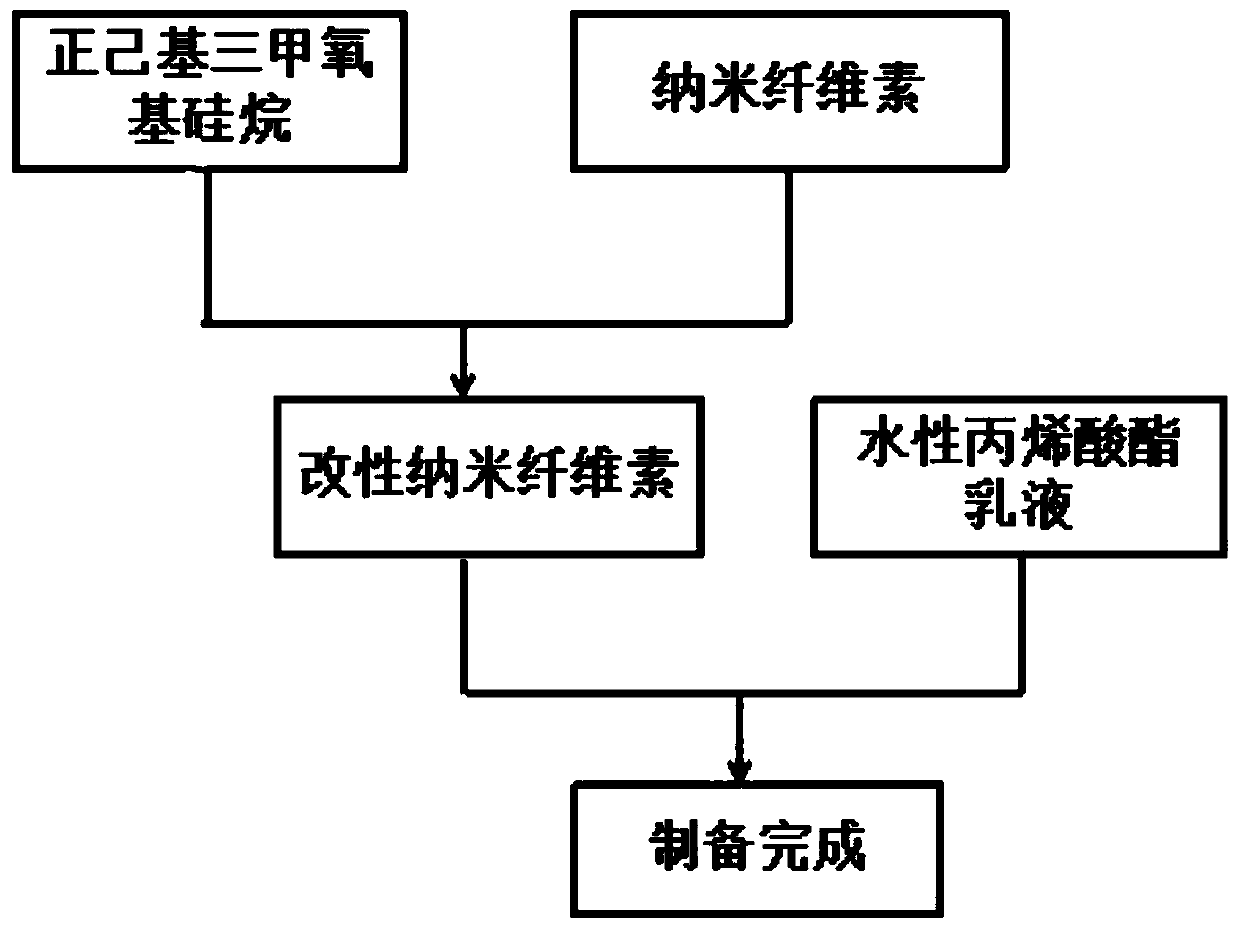

Preparation method and application of barrier hydrophobic paper-based paint

ActiveCN109629326AImprove hydrophilicityImprove water barrier effectWater-repelling agents additionCoatingsFiberAlcohol

The invention provides a preparation method of barrier hydrophobic paper-based paint. The preparation method comprises the following steps of (1) preparation of modified nanocellulose, wherein hexyltrimethoxysilane is hydrolyzed, an alcohols solvent is prepared, and nanocellulose fiber is added after stirring; (2) preparation of the barrier hydrophobic paper-based paint, wherein the modified nanocellulose is added into an aqueous acrylate emulsion for mechanical blending. The invention discloses the barrier hydrophobic paper-based paint by implementing the method. The barrier hydrophobic paper-based paint comprises the modified nanocellulose and the aqueous acrylate emulsion. The invention also discloses an application method of the paint. The method has the advantages that the environmental protection is achieved, the manufacturing process is simple, the cost is low, and the efficiency is high. The paint has excellent hydrophobic and air-blocking properties, and expands the application of food wrap paper in food packaging. In addition, the application method is simple and convenient, and the application range is wide.

Owner:SHANGHAI UNIV

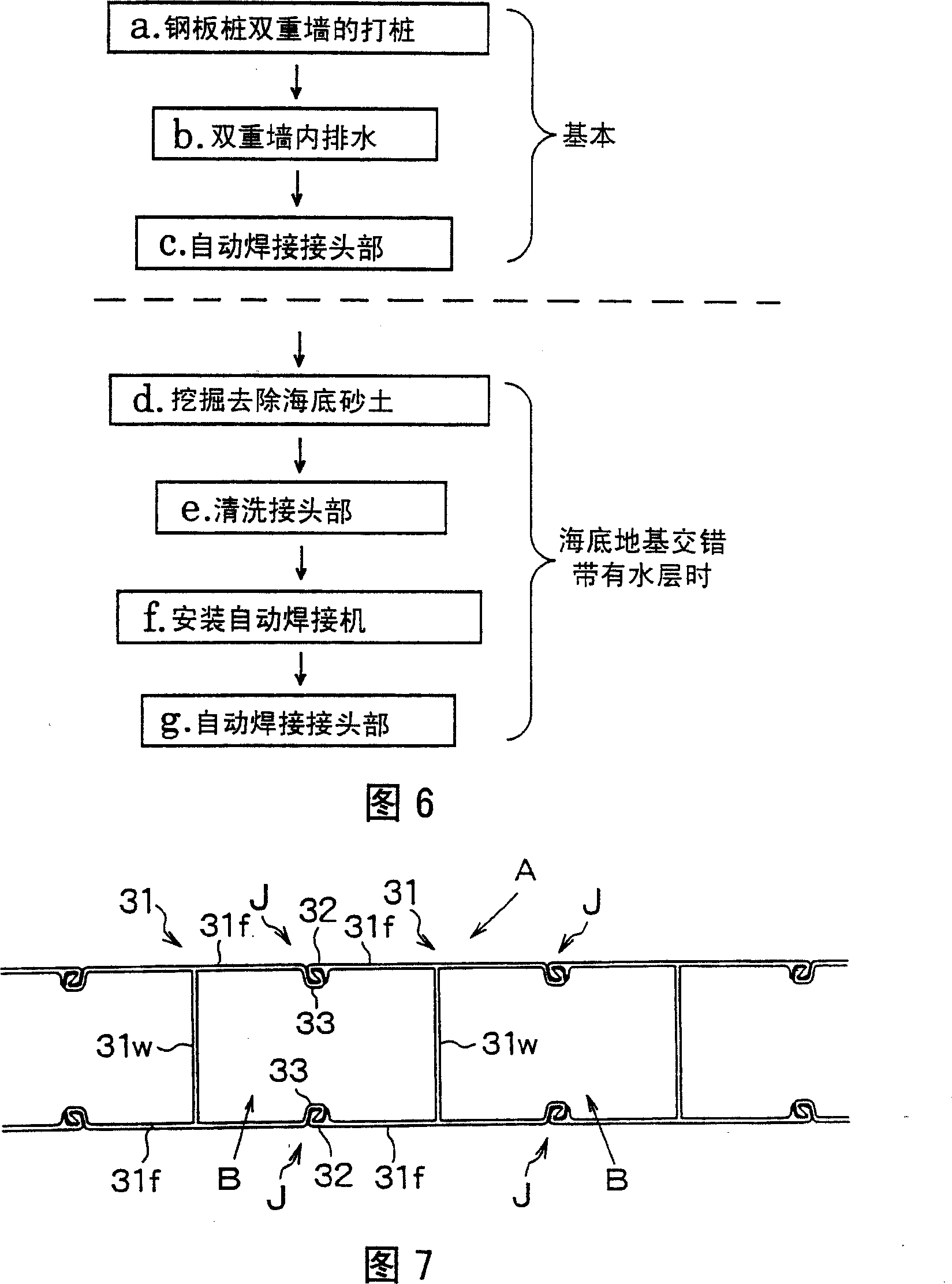

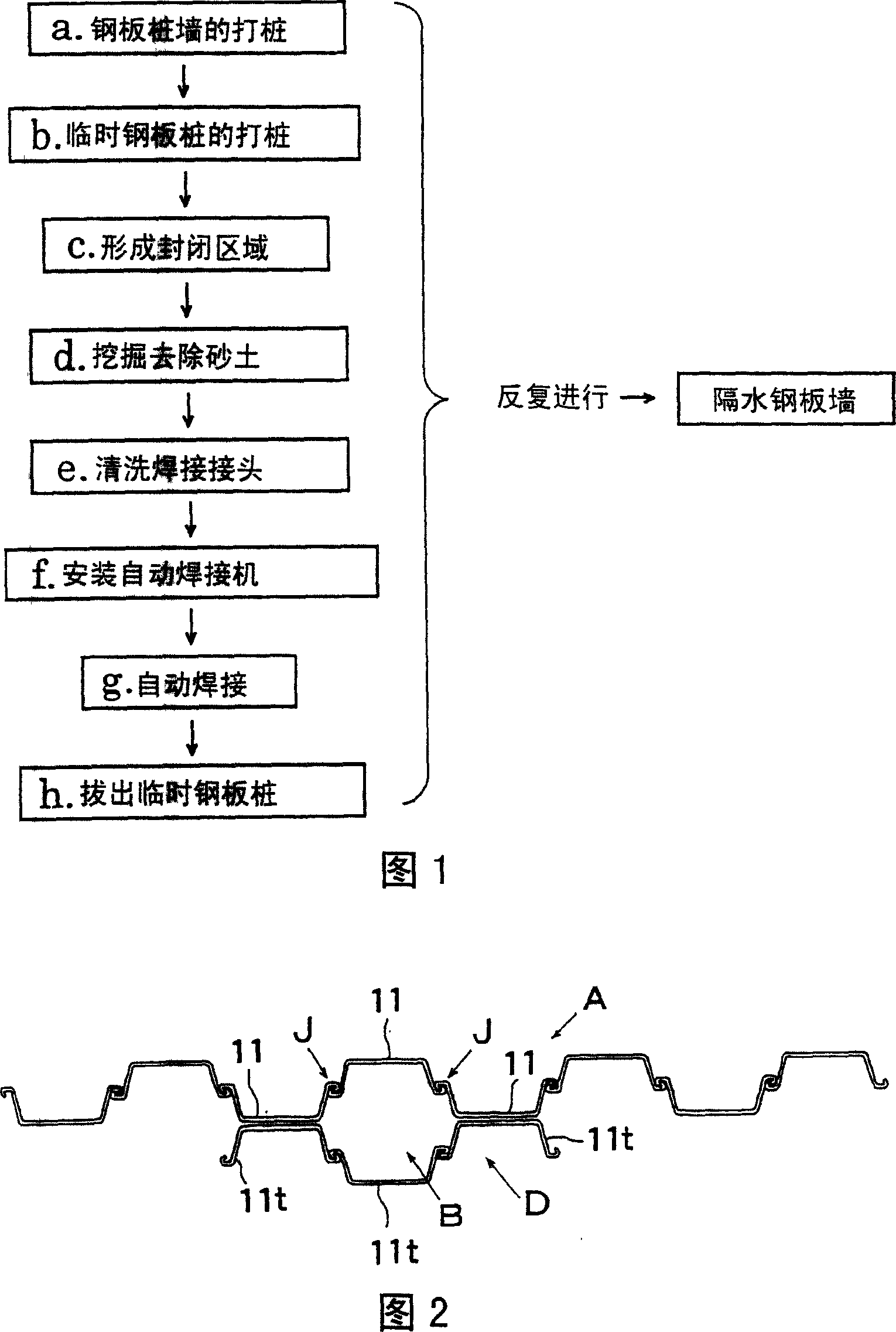

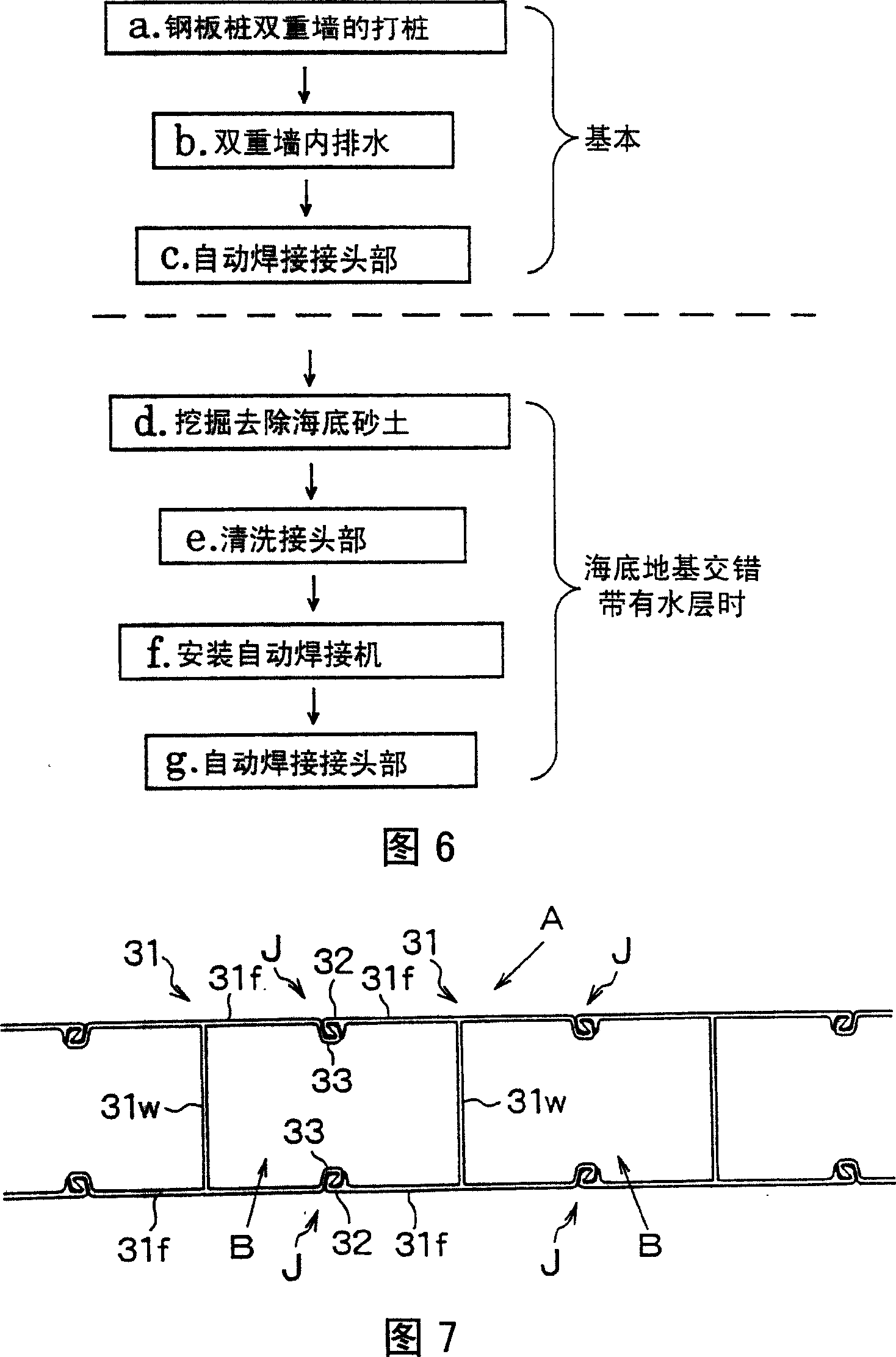

Steel plate wall and its mfg. method

InactiveCN1536170AQuality WeldingWelding quality of weld lengthArtificial islandsUnderwater structuresSheet steelEngineering

A steel wall and a manufacturing method thereof are provided to improve waterproofing efficiency and construction efficiency, and to cut down construction cost by forming the automatic welding space of the joint part and linearly connecting plural asymmetrical U-shaped steel sheets. A steel sheet wall is constructed(a), and a temporary steel sheet is constructed(b). A closed section is formed and surrounded by the part of the steel sheet wall and the temporary steel sheet(c). Earth or sand is excavated and removed from the closed section(d), and a joint part of the steel sheet wall is washed and cleaned in the closed section(e). An automatic welding machine is set in the closed section(f), and welding is automatically performed(g). The temporary steel sheet is removed after securing waterproofing(h). The waterproof steel wall is constructed by repeating the steps.

Owner:NIPPON STEEL CORP +1

Coal face top plate water-rich gravel layer drilling and grouting method

InactiveCN110145336AReduce usageEffective diffusionUnderground chambersDirectional drillingBedrockCement paste

The invention discloses a coal face top plate water-rich gravel layer drilling and grouting method. According to the method, ground construction drilling is adopted, vertical downward drilling is constructed from the ground and goes deep to 2-3 m above the gravel layer, a casing pipe is arranged in a drilled hole, and a ring gap between the casing pipe and the drilled hole is filled with cement for fixing; and downward descending advancing type drilling-grouting-hole penetrating cyclic grouting is adopted from the terminal end of the casing pipe, the end hole depth is a bed rock layer, and after the end hole grouting pressure reaches the grouting finishing standard, the hole is sealed through pure cement paste, and grouting is finished. By means of the coal face top plate water-rich gravellayer drilling and grouting method, a coal bed work face top plate can be effectively strengthened, a gravel water containing layer is transformed into a water resisting layer or a weak water containing layer, and threats to coal bed work face recovery due to hole gap water are eliminated.

Owner:JIAOZUO COAL IND GRP CO LTD +2

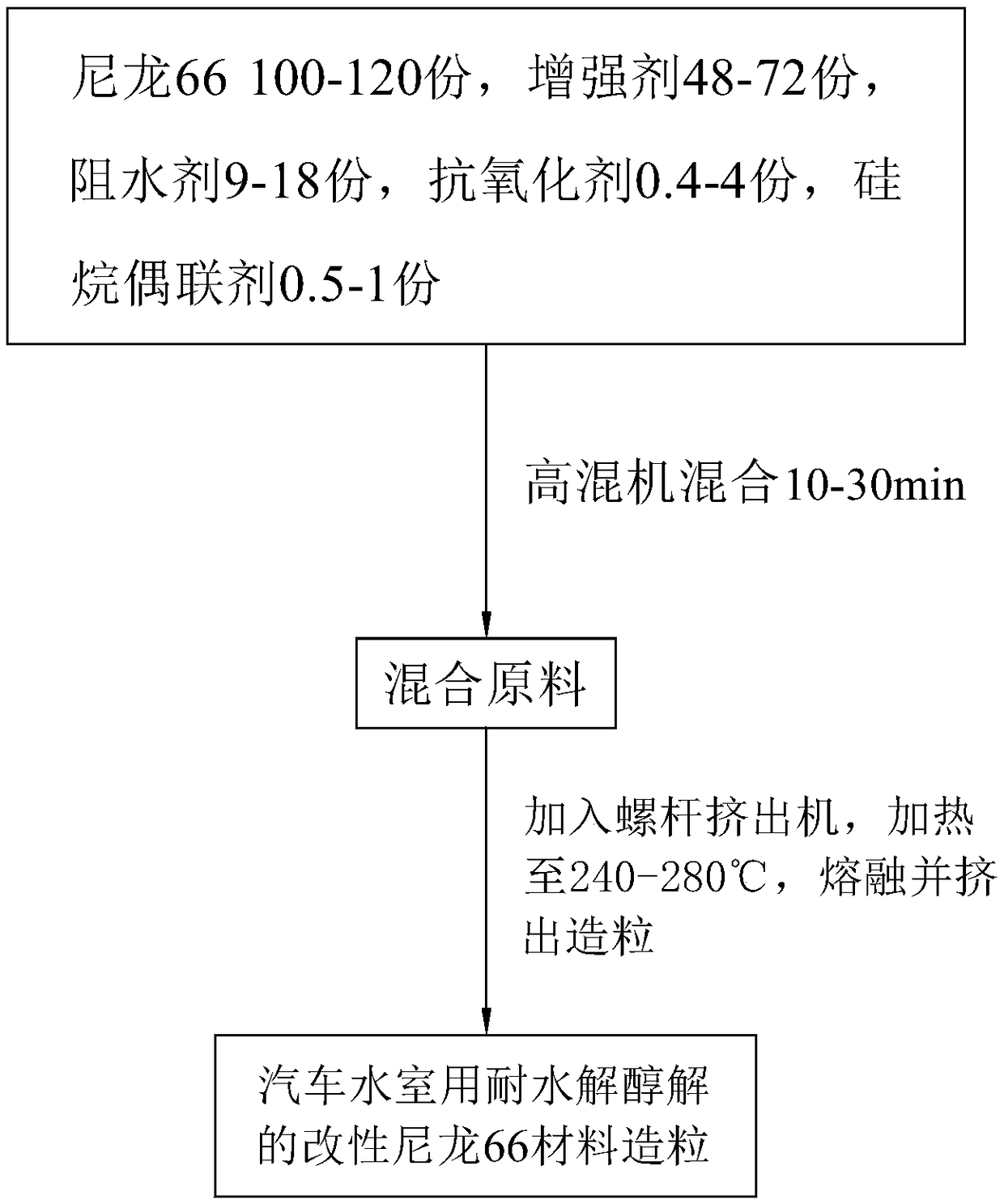

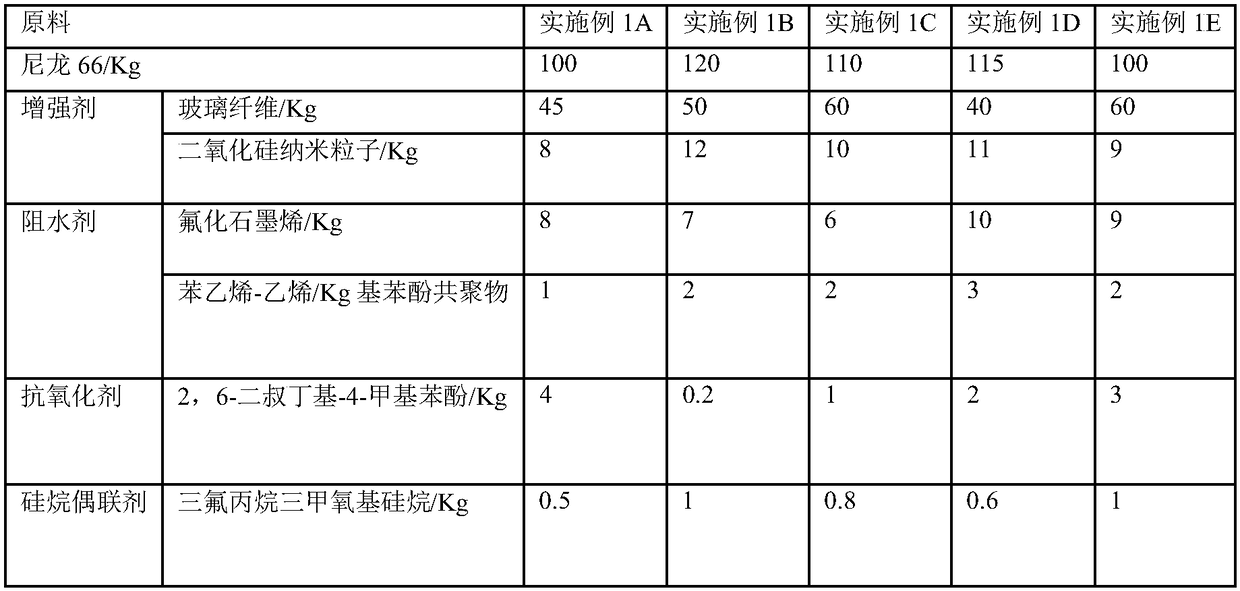

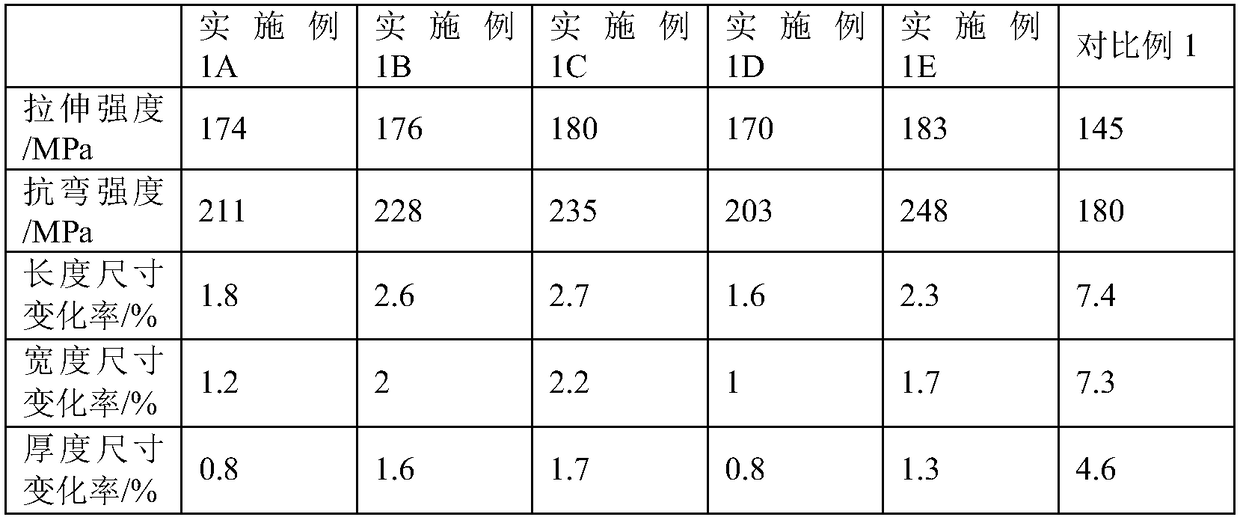

Hydrolysis and alcoholysis resistant modified nylon 66 material for automotive water chamber and preparation method of modified nylon 66 material

The invention relates to modified nylon materials and discloses a hydrolysis and alcoholysis resistant modified nylon 66 material for an automotive water chamber and a preparation method of the modified nylon 66 material. The modified nylon 66 material comprises the following raw materials: 100-120 parts of nylon 66, 48-72 parts of an enhancer, 9-18 parts of a water resistance agent, 0.4-4 parts of an antioxidant and 0.5-1 part of a silane coupling agent, wherein the enhancer comprises 40-60 parts of glass fibers; and the water resistance agent comprises 6-10 parts of fluorinated graphene and3-8 parts of a styrene-vinyl phenol copolymer. The preparation method comprises the following steps: weighing the raw materials in parts by mass, mixing after drying, adding the mixture into a screw extruder, heating and melting, and performing extrusion pelletizing, thereby obtaining the modified nylon 66 material. The tensile property and bending performance of the modified nylon 66 material areimproved, and the nylon material has hydrolysis and alcoholysis resistance and excellent dimensional stability, difficultly causes size distortion at a high temperature and meets the service conditions and environment of the automotive water chamber.

Owner:NINGBO EAGLE NEW MATERIAL

Resistance-reduction slurry for tube push bench in sandy soil and preparation method of resistance-reduction slurry

InactiveCN108531151AGood hydrationMud water loss is smallPipe laying and repairBuilding constructionsSodium carbonateSodium carboxymethylcellulose

The invention discloses resistance-reduction slurry for a tube push bench in sandy soil and a preparation method of the resistance-reduction slurry. The resistance-reduction slurry is prepared by, byweight, 100 parts of sodium bentonite, 0.6-0.9 part of sodium carbonate, 0.2-0.35 part of carboxymethyl cellulose, 0.2-0.3 part of potassium humate, 0.1-0.15 part of graphite powder, 10-15 parts of vegetable gelatin and 280-310 parts of water. The resistance-reduction slurry and the preparation method thereof have the advantages that solid content in the resistance-reduction slurry is lowered by mixing the sodium bentonite and the vegetable gelatin, the slurry has a lot of fine-particle clay and is good in hydration effect and low in water loss, and slurry cake formed by the slurry is compactand thin; the lubricating performance of the resistance-reduction slurry is increased by the graphite powder, and the potassium humate has a good diluting effect on the resistance-reduction slurry andcan effectively lower the thickness of the resistance-reduction slurry while the viscosity of the slurry is changed slightly.

Owner:中铁隧道集团二处有限公司

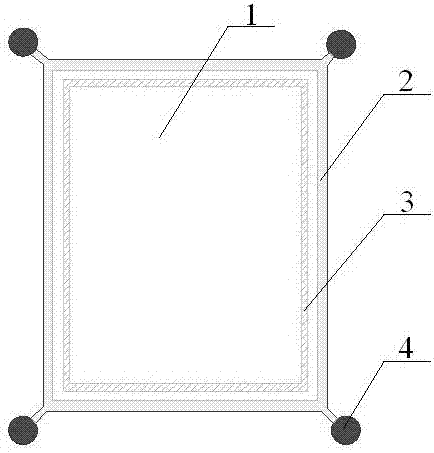

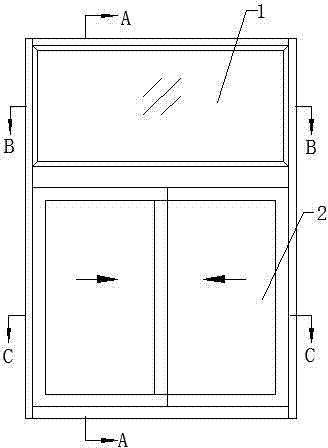

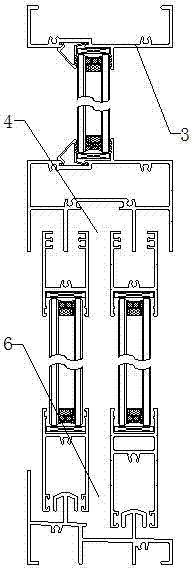

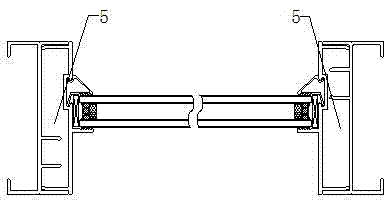

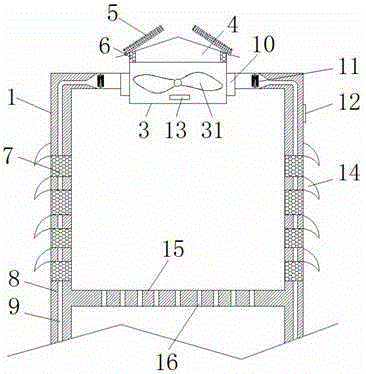

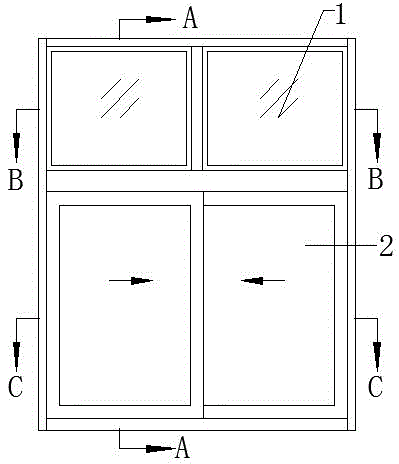

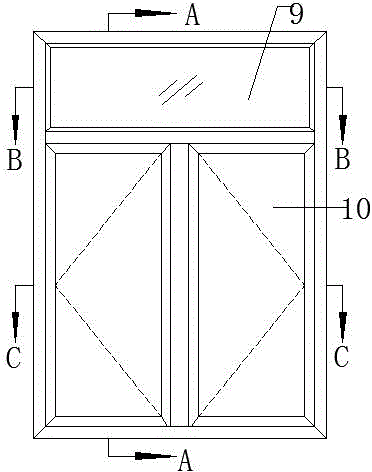

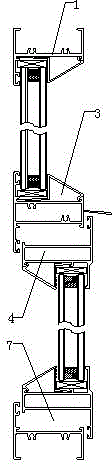

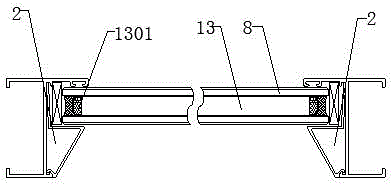

Section bar sliding door

ActiveCN104499893AInhibit sheddingImprove stabilityWing arrangementsSlide windowStructural engineering

The invention discloses a section bar sliding door. The section bar sliding door comprises a window body and two movable sliding doors, wherein the upper end of the window body is arranged in a top section bar frame, the bottom is arranged in a middle section bar frame, and the two sides are arranged in a first side section bar frame; the two sliding doors are arranged in parallel front and back, the top layers of the two sliding doors are both in sliding connection with the middle section bar frame, the bottom sides are arranged in the bottom section bar frame, the internal and external sides of one sliding door are respectively correspondingly arranged in a first end section bar frame and a second side section bar frame, and the internal and external sides of the other sliding door are respectively correspondingly arranged in a second end section bar frame and a third side section bar frame. The section bar sliding door is simple in structure, long in service life, convenient to mount and detach, convenient to push and pull, and labor-saving; the connection leak tightness between the sliding window body and the section bar structure of each side is higher, and the stability is excellent. The section bar sliding door has excellent water-proof, sound-proof and heat insulation effects and is suitable for mounting various doors such as vitreous body, wood body, and wide in application range.

Owner:ANHUI GAODE ALUMINUM

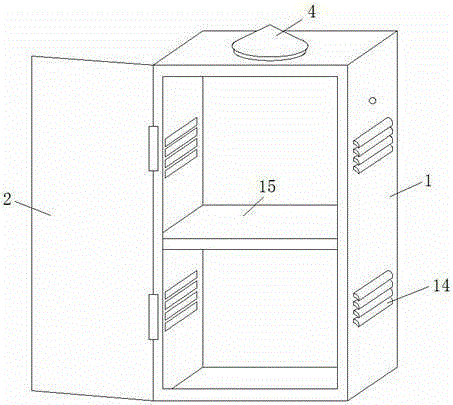

Safe outdoor electric power equipment cabinet with high efficiency

InactiveCN105281233AImproved water resistanceGuarantee the safety of useSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsFrostInductor

The invention discloses a safe outdoor electric power equipment cabinet with high efficiency. The top of the inner chamber of the cabinet body is provided with an air-exhaust box in the form of embedding. The inner part of an air outlet is filled with loose and porous water absorbing material. The inner of an interlayer is insertedly provided with a heating pipe. The inner side of an air inlet of the heating pipe is also provided with a heating rod in the form of embedding. The outer wall of the cabinet body is provided with a temperature inductor. The part of an air inlet window outside the cabinet has a louver structure. By adding the water absorbing material at the air inlet and the air outlet, the water-proof ability of the safe outdoor electric power equipment cabinet with high efficiency is greatly increased, the use safety of electric equipment is guaranteed. By use of the louver-type air inlet window, the efficiency of air inlet is increased and high-efficiency heat dissipation is achieved. In cold weather, frost attached to the cabinet body surface can be timely cleared by an intelligent heating system constituted of the heating rods, the temperature inductor and control chips, so that cabinet body damage due to the large temperature difference between inside and outside is avoided.

Owner:蓝灿玉

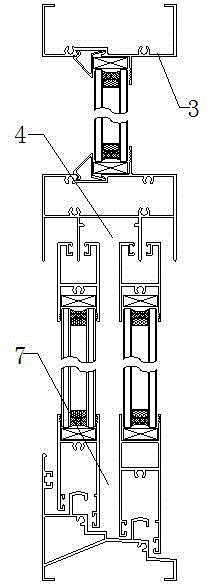

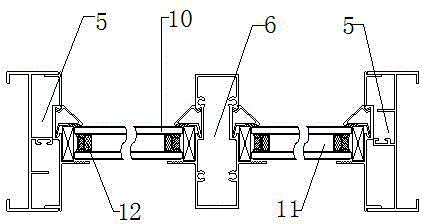

Sectional material sliding window

InactiveCN104453586AInhibit sheddingImprove stabilityWing arrangementsWing framesPush and pullSlide window

The invention discloses a sectional material sliding window. The sectional material sliding window comprises two fixed window bodies and two sliding window bodies, wherein each fixed window body consists of two glass bodies; each sliding window body also consists of two glass bodies; a variable wide groove is formed between each two glass bodies; a buffering cushion is arranged in each variable wide groove; the upper ends of the two fixed window bodies are assembled in a top sectional material frame; the bottom edges of the two fixed window bodies are assembled in a first middle sectional material frame; outer sides of the two fixed window bodies are assembled in a first side surface sectional material frame; inner sides of the two fixed window bodies are assembled in a second middle sectional material frame; the tops of the two sliding window bodies are slidably connected with the first middle sectional material frame; the bottom edges of the two sliding window bodies are assembled in a bottom sectional material frame; outer sides of the two sliding window bodies are assembled in a second side surface sectional material frame; and inner sides of the two sliding window bodies are respectively assembled in end sectional material frames. The sectional material sliding window is simple in structure, long in service life, convenient to mount and detach and convenient to push and pull; the labor is saved; the sealing performance of connection between each sliding window body and a sectional material structure of each side of the sectional material sliding window is high; the stability is high; and the sectional material sliding window has high waterproof, soundproof and heat-insulation effects.

Owner:ANHUI GAODE ALUMINUM

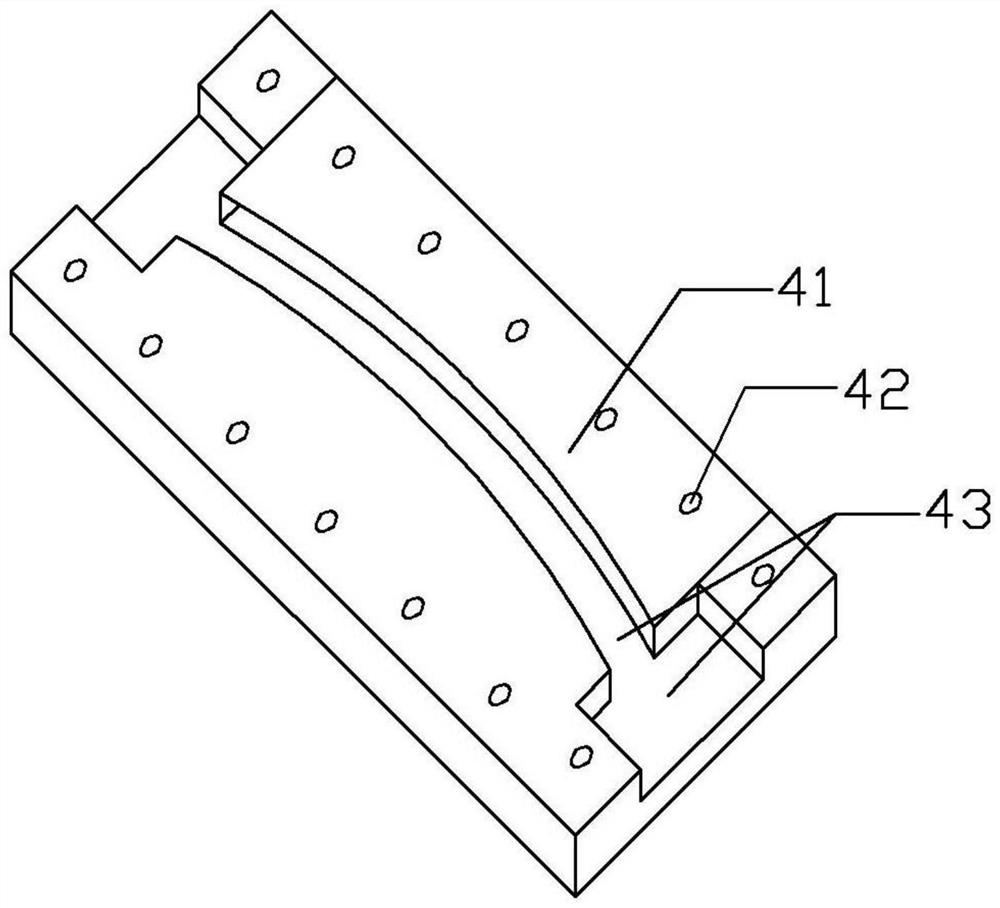

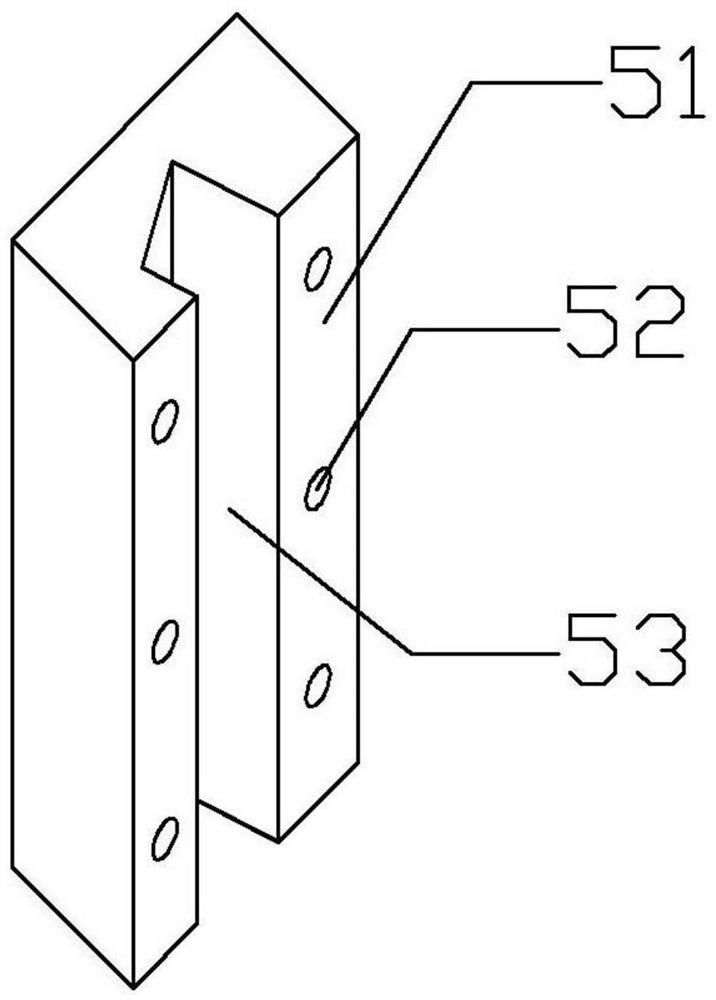

Coal mine underground reservoir assembly type arc-shaped artificial dam body and construction method thereof

ActiveCN113789759ASolve the problem of difficult transportation to undergroundHigh speedMining devicesArch damsMining engineeringCoal pillar

The invention discloses a coal mine underground reservoir assembly type arc-shaped artificial dam body and a construction method thereof. The artificial dam body is arranged between adjacent coal pillar dam bodies, wherein the artificial dam body is composed of a dam body base, wing plates on the two sides and an arc-shaped dam body, the dam body base, the wing plates and the arc-shaped dam body are all formed by assembling a plurality of modules, the dam body base is provided with grooves for embedding the wing plates on the two sides and the arc-shaped dam body, the wing plates on the two sides are also provided with grooves for embedding the arc-shaped dam body, the dam body base and the wing plates are provided with anchor rods, and the artificial dam body and surrounding rock mass can form a stable whole. The convex face of the arc dam body faces the underground reservoir, force is partially decomposed to the coal pillar dam bodies on the two sides, direct stress of the dam body is reduced, and therefore the thickness of the dam body is reduced; and by quantifying the size of the artificial dam body, building a standard dam body module on the ground and quickly assembling underground, the problems of long construction period and high manufacturing cost of the underground reservoir of the coal mine are solved, and the dam body can be prevented from instability damage and water seepage.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

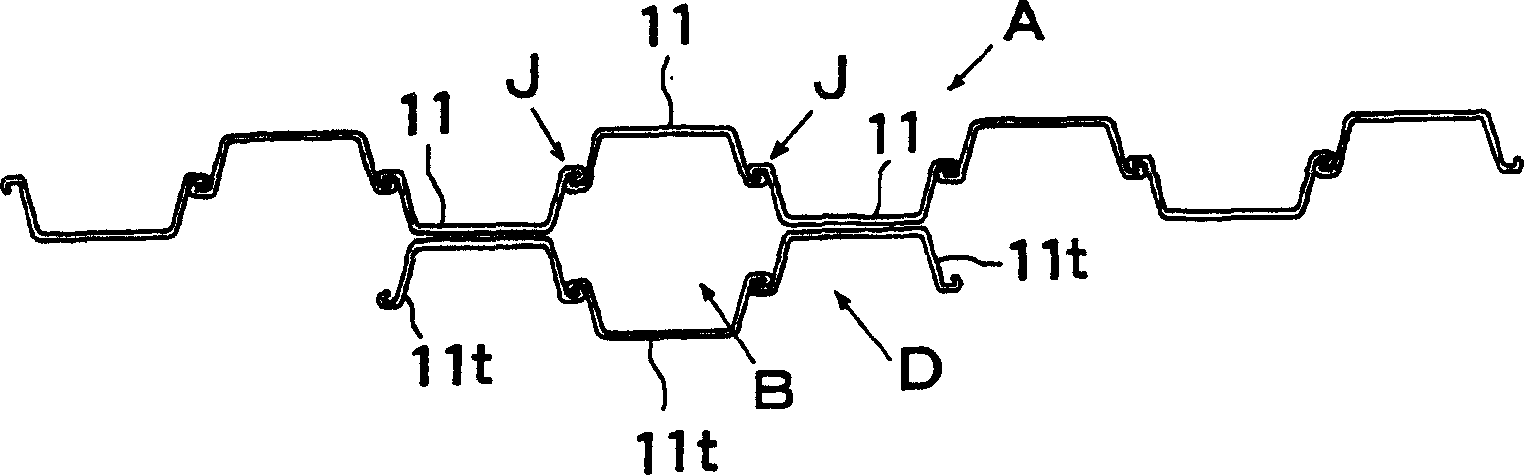

Sheet pile type steel wall and steel pile

InactiveCN101024955ADoes not impair constructionImprove efficiencyArtificial islandsUnderwater structuresSheet steelSheet pile

Owner:NIPPON STEEL CORP +1

Section bar double-opening casement window

ActiveCN104533233AAchieving a sealed connectionFirmly connectedCorner/edge jointsWing framesStructural symmetryEngineering

The invention discloses a section bar double-opening casement window which comprises an upper window body and two lower-opening window bodies, wherein the top layer of the upper window body is fixed in a first top-layer section bar connecting structure, two side surfaces of the upper window body are fixed in a first side surface section bar connecting structure, the bottom layer of the upper window layer is fixed in a first bottom-layer section bar connecting structure; the top layers of the two lower-opening window bodies are arranged in a second top-layer section bar connecting structure, two outer sides of the two lower-opening window bodies are arranged in a second side surface section bar connecting structure, two inner sides of the two lower-opening window bodies are arranged in a third side surface section bar connecting structure, and bottom layers of the two lower-opening window bodies are arranged in a second bottom-layer section bar connecting structure; the first bottom-layer section bar connecting structure and the second top-layer section bar connecting structure are in sealed and in fitted connection through a first middle connecting structure, two inner sides are in sealed and in fitted connection through a second middle connecting structure. The section bar double-opening casement window is simple in structure, strong in structural symmetry, simple in installation structure, easy to operate, high in stability, freely adjustable in thickness of window bodies, wide in applied range, lowered in production cost, and economical.

Owner:ANHUI GAODE ALUMINUM

Preparation method of bio-based composite material sheet and plastic suction tray manufactured by sheet

PendingCN110774712AImprove water barrier effectLow costSynthetic resin layered productsDomestic containersTemperature controlControl system

The invention discloses a preparation method of a bio-based composite material sheet and a plastic suction tray manufactured by the sheet, and belongs to the technical field of preparation of the bio-based composite material sheet and the plastic suction tray prepared by the sheet. The sheet disclosed by invention consists of three layers of resin with different components from inside to outside;sheet extrusion equipment consists of three extruding machines, control equipment, a sheet extrusion machine head and a temperature controlling system; and the phenomenon that the sheet product has strict thickness and is high in glossiness according to practical demands; the overall thickness of the sheet product can be adjusted in the range of 0.3mm to 2mm, wherein the thickness of an outer layer is 0.05mm to 0.5mm, occupying 5 percent to 15 percent of the total mass; the thickness of an inner layer is 0.05mm to 0.2mm, occupying 3 percent to 10 percent of the total mass; and the thickness ofa middle layer is 0.2mm to 2mm, occupying 70 percent to 90 percent of the total mass. The degradable sheet applied to the plastic suction tray provided by the invention has the advantages of being high in water resistance, high in moisture resistance, high in bacteria resistance and insect prevention property, reliable in strength, exquisite in appearance, and high in cleanness and environment protection properties, and has the ability to control degradation, and meanwhile, the sheet is low in cost, is convenient to process, and is suitable for mass industrial production.

Owner:黑龙江幸福人生态农业开发股份有限公司

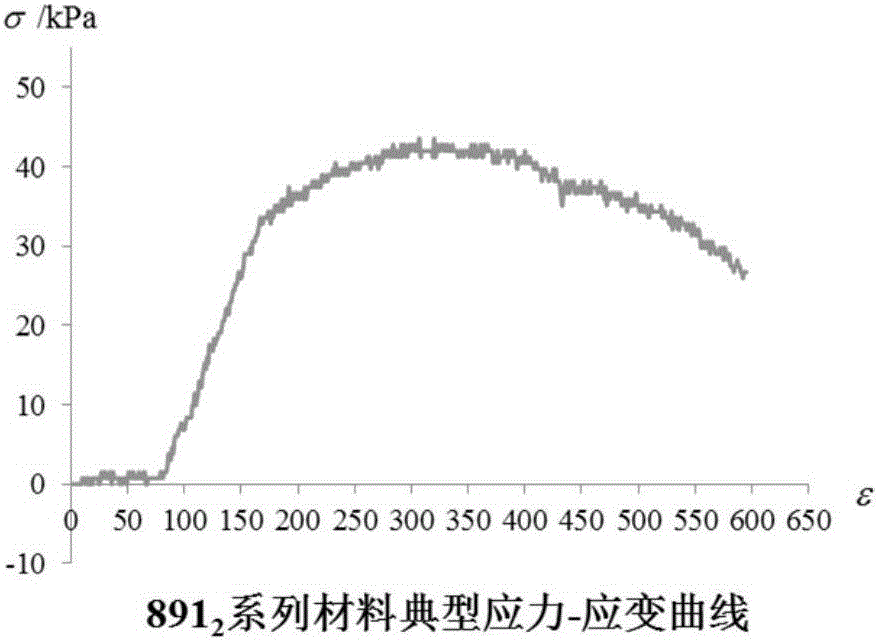

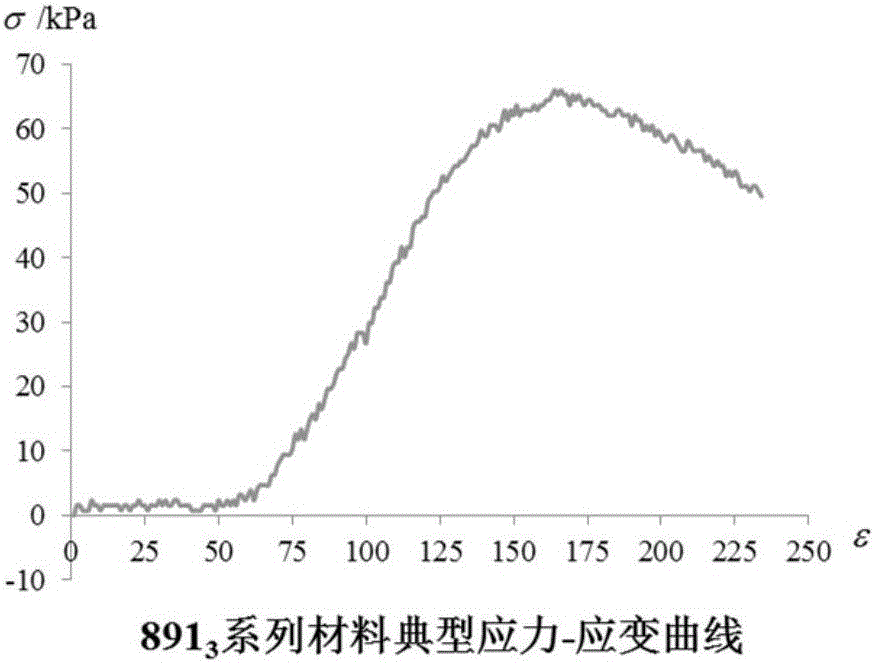

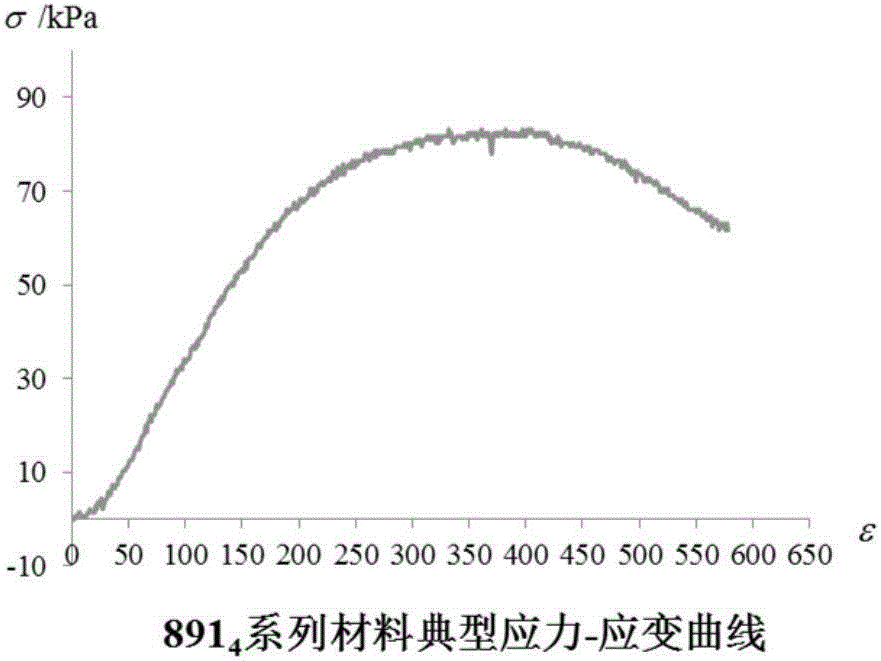

Weak glue cementation water partition similar material and preparation method

InactiveCN106404509AStrong waterproof performanceProportion raw material innovationPreparing sample for investigationRiver sandGypsum

Provide is weak glue cementation water partition similar material, belonging to geotechnical engineering similar material and preparation method. The weak glue cementation water partition similar material takes fine river sand, and dilated lubricating soil as an aggregate, plaster, and solid ceresin wax as a gluing material, cymene oil as additives. The weak glue cementation water partition similar material is prepared from, by weight, 8 parts of fine river sand (pellet level gradation: pellet way & lt; 1.18 mm); 0.9 part of pellet limit 220-325 target quality sodium base dilated lubricating soil; 0.1 part of pellet limit 1000 target plaster; 0.02-0.05 part of fusing spot 58 DEG solid ceresin wax; 1-1.8 parts of stickiness limit 1000 CS cymene oil (seizing sand, soil, plaster gross weight respectively 1 / 5, 1 / 6, 1 / 7, 1 / 8, 1 / 9); 1 part of hydrant. At the same time, taking single shaft magnitude and permeation parameter as judging parameters, the method develops the similar material successive proportioning of 8912, 8913, 8914, 8915, can satisfy the successive proportioning requirements of similar material proportioning for single shaft pressure resisting magnitude 8-93 kPa, permeation parameter 2-81 x 10-7 cm / s (scaling gradation 10-6 - 10-7 cm / s ). The similar material successive proportioning side improves the similar material proportioning method for weak glue cementation, low magnitude, and strong water partition, and provides a reference for researching similar material proportioning.

Owner:CHINA UNIV OF MINING & TECH

Water-stop type corner lug steel sheet pile and construction method

PendingCN113373904AIncrease pressureImprove stabilityBulkheads/pilesArchitectural engineeringSteel ball

The invention belongs to the field of underground engineering steel sheet pile supporting construction, and particularly relates to a water-stop type corner lug steel sheet pile and a construction method. The water-stop type corner lug steel sheet pile comprises a steel sheet pile body, wherein corner lugs are arranged on the two sides of the steel sheet pile body in the length direction, each corner lug comprises two tenons, and a wedge-shaped groove is defined between every two tenons; the width is gradually increased when the tenons extend outwards; the tenons are inserted into the grooves in a matched mode; and an oval hole is formed in the inner side of the steel sheet pile body in the length direction, a check ring is arranged in the oval hole, and an oval steel ball is placed in the check ring. The steel sheet pile can be used for different geological landforms, can be flexibly combined into various types of pile bodies, and has the remarkable advantages of being easy to construct, high in strength and stability, good in water-stop performance of a supporting structure, small in influence on the periphery and the like.

Owner:JINAN URBAN CONSTR GRP +4

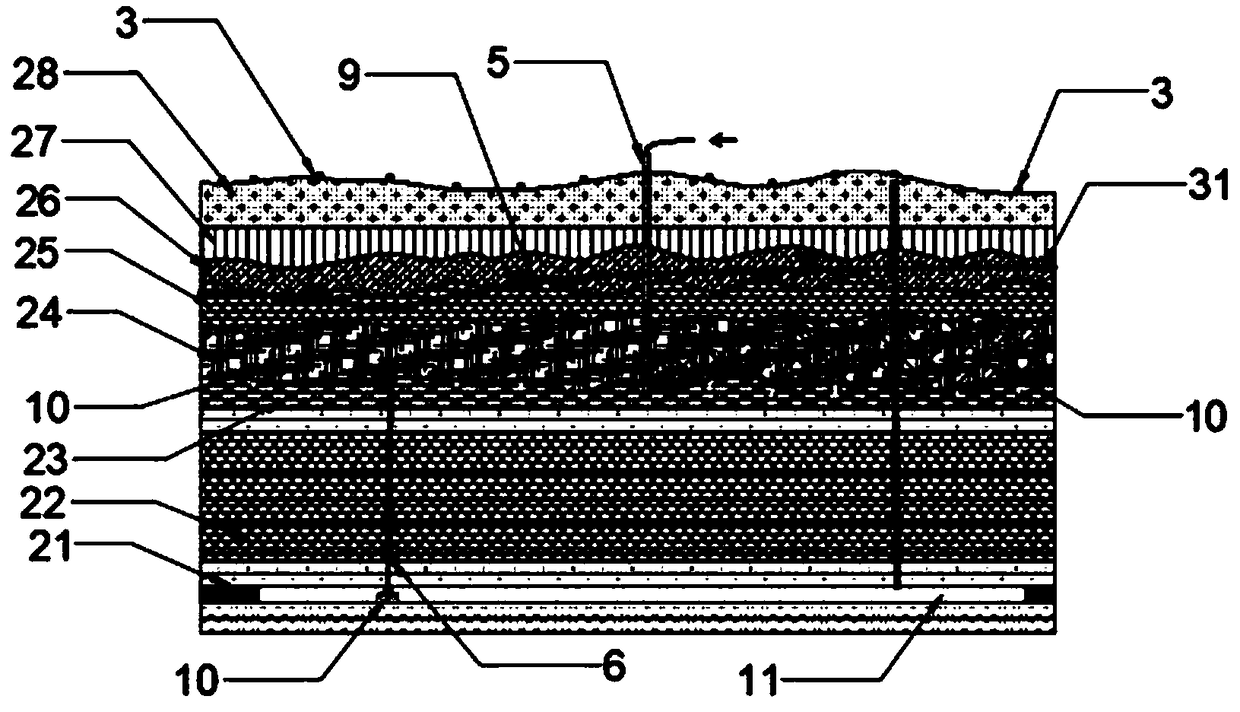

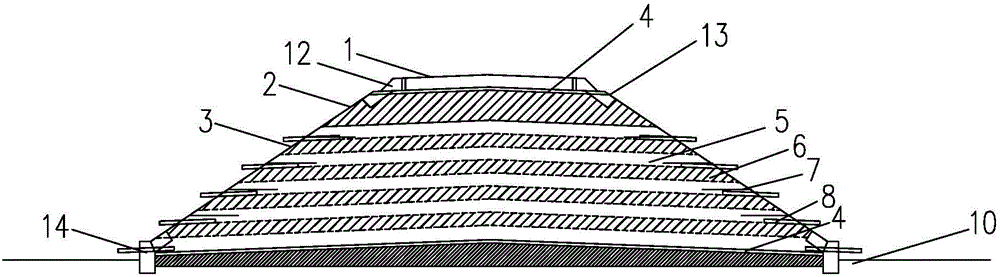

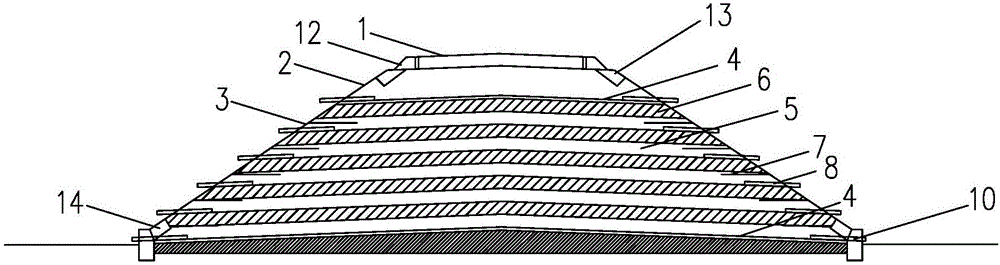

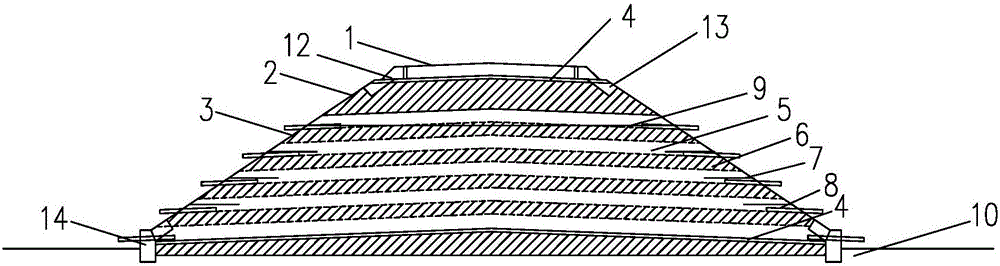

Production process of organic insulated solar backplate

InactiveCN106206804AImprove cooling effectImprove water barrier effectFinal product manufacturePhotovoltaic energy generationWeather resistanceInsulation layer

The invention relates to a production process of an organic insulated solar backplate. The solar backplate produced according to the process comprises a PET substrate, an organic insulation layer and a coating layer. The solar backplate is simple in structure and is convenient to use, electrical insulativity, weather resistance, excellent resistance to water vapor permeability, anti-hydrolysis property and anti-ultraviolet property of the solar backplate can be integrally improved, and the requirement for non-aging after 25-year application is met; and with the arrangement of the organic insulation layer, the cooling performance and the water insulation property of the solar backplate can be substantially improved.

Owner:WUXI SUNOCEAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com