Sheet pile type steel wall and steel pile

A technology for steel sheet piles and steel sheet walls, which is applied to sheet pile walls, water conservancy projects, artificial islands, etc., can solve the problems of inability to use automatic welding machines, different waterproof and reliable functions, and deformation of female joints. The effect of automatic welding, reducing welding cost and reducing water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

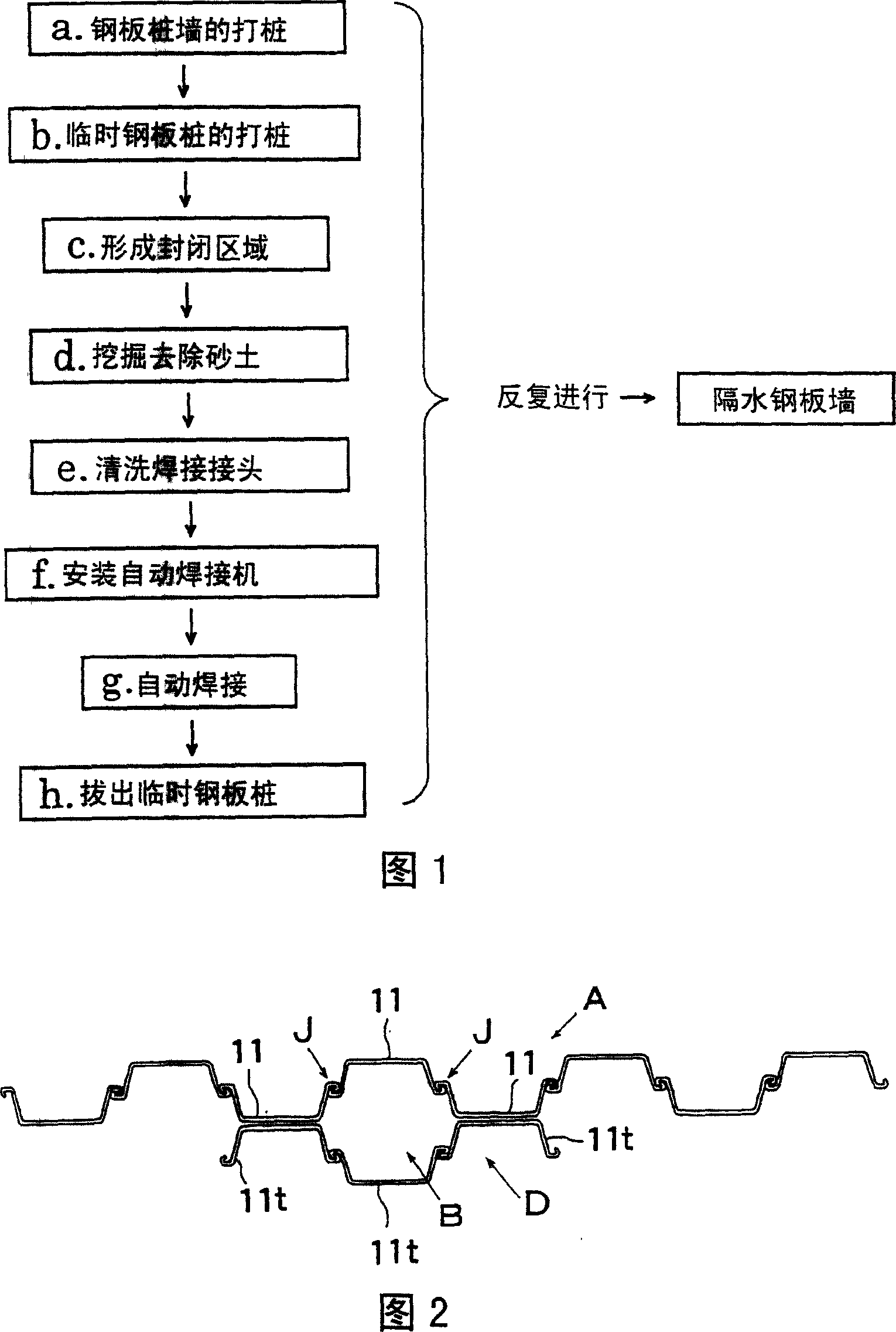

[0163] Fig. 1 shows a flow chart of an example of the construction procedure when using steel sheet piles as steel materials with joints and temporary steel materials as the first invention of the present invention, and work is performed in this order below.

[0164] According to the construction capacity of the steel sheet pile driving machine and the number of machines used, the construction of the steel sheet pile wall starts from any part of the water-resistant steel sheet wall (Fig. 1a).

[0165] In at least one place, temporary sheet piles are driven in (Fig. 1b) to create an area enclosed by a part of the sheet pile wall and the temporary sheet piles (Fig. 1c).

[0166] After excavating to remove sand and soil in the enclosed area (Fig. 1d), the joints of the steel sheet pile walls in the area were cleaned (Fig. 1e).

[0167] Then, install an automatic welding machine (Figure 1f) in the area for automatic welding (Figure 1g).

[0168] After confirming that the water is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com