Steel wall and the manufacture method thereof

一种制造方法、钢板墙的技术,应用在板桩墙、水利工程、海域工程等方向,能够解决不能使用自动焊接机、隔水性及可靠功能不相同、雌接头材73变形等问题,达到容易自动焊接、降低焊接成本、降低漏水的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

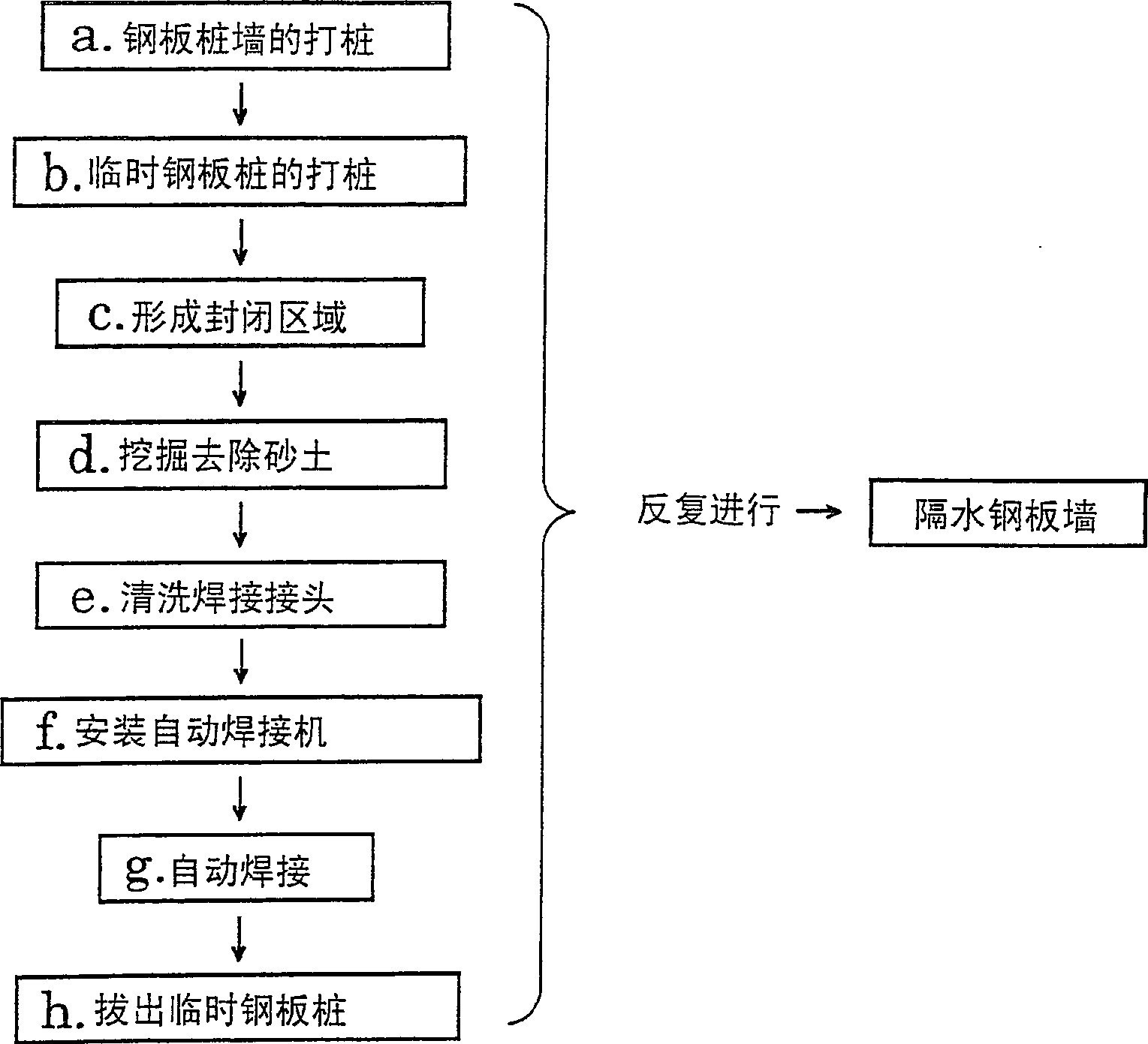

[0163] figure 1 A flow chart showing an example of the construction procedure when using the steel sheet pile as the jointed steel material and the temporary steel material as the first invention of the present invention is carried out in the following order.

[0164] According to the construction capacity of the steel sheet pile driving machine and the number of units used, the construction of the steel sheet pile wall starts from any part of the water-resistant steel sheet wall ( figure 1 a).

[0165] In at least one place, drive temporary sheet piles ( figure 1 b), forming an area enclosed by part of the sheet pile wall and temporary sheet piles ( figure 1 c).

[0166] Excavating to remove sand and soil in enclosed areas ( figure 1 After d), clean the joints of the steel sheet pile walls in the area ( figure 1 e).

[0167] Then, install automatic welding machines in the area ( figure 1 f), for automatic welding ( figure 1 g).

[0168] After confirming that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com