Sectional material sliding window

A technology of sliding windows and profiles, which is applied in the field of building decoration, can solve problems such as unreliability, danger, and limitation of ventilation area, and achieve the effects of avoiding falling off, increasing friction coefficient, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

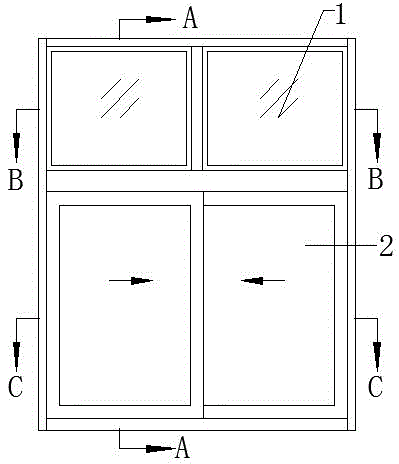

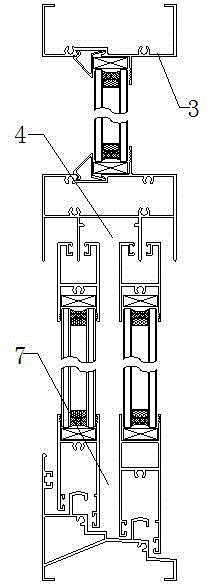

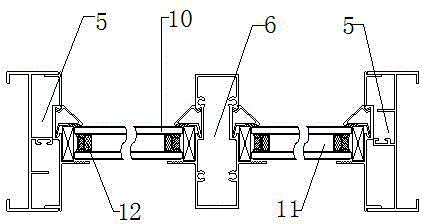

[0027] Refer to attached Figure 1-11 The shown profile sliding window includes two fixed windows 1 and two push-pull sliding windows 2, the two windows 1 are arranged on the upper ends of the two sliding windows 2, and the windows 1 and the two sliding windows 2 are composed of two glass bodies 10, a variable width body groove 11 is arranged between the two glass bodies 10, and a cushion body 12 is also arranged in the variable width body groove 11; The upper ends of the two windows 1 are installed in the top profile frame 3, the bottom edge is installed in the first middle profile frame 4, and the two outer sides are installed in the first side profile frame 5. The inner side of the body 1 is installed in the second middle profile frame 6; the two sliding windows 2 are arranged in parallel and front and back, and the top la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com