Processing method of large-thickness collapsible loess foundation of subway station

A technology of collapsible loess and treatment method, which is applied in the field of large-thickness collapsible loess foundation treatment of subway stations, which can solve problems such as structural damage, poor treatment effect, and high engineering cost, and reduce the possibility of collapsibility , economical and practical, and improve the effect of water isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

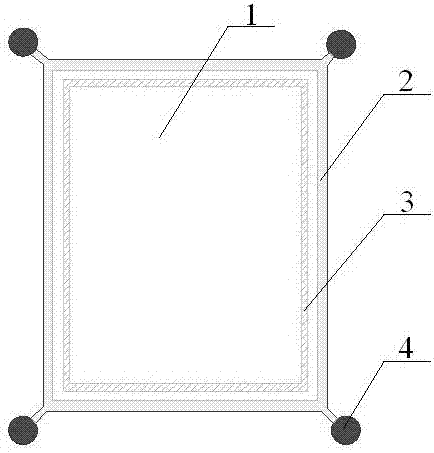

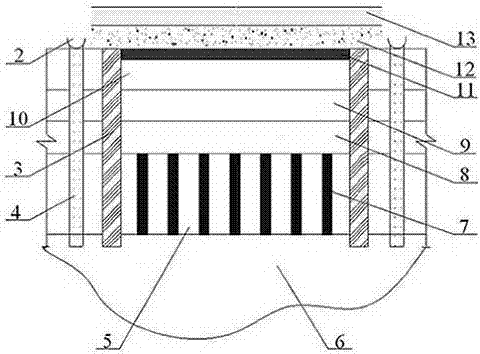

[0026] In the embodiment of the present invention, a method for processing large-thickness collapsible loess foundation of a subway station, the plan view is as follows figure 1 As shown, an underground diaphragm wall 3 is arranged around the square subway station 1, and the periphery of the underground diaphragm wall 3 is surrounded by a circle of horizontal drain pipes 2, and the horizontal drain pipe 2 leads to the water guide wells 4 at the four corners; the processing method may include the following specific steps :

[0027] Step S1, after determining the scope of the foundation of the subway station 1, set up a circle of underground diaphragm walls 3 along the periphery of the foundation.

[0028] Among them, the underground diaphragm wall 3 is a water-retaining wall, and its bottom penetrates the collapsible loess layer 5 and enters the non-collapsible loess layer 6, which is used to keep the surrounding water out to ensure the collapsibility in the underground diaphra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com