Coal face top plate water-rich gravel layer drilling and grouting method

A coal mining face, drilling and grouting technology, applied in mining equipment, earthwork drilling, directional drilling, etc., can solve problems such as complex construction technology, dense drilling, failure to meet expected requirements and progress goals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

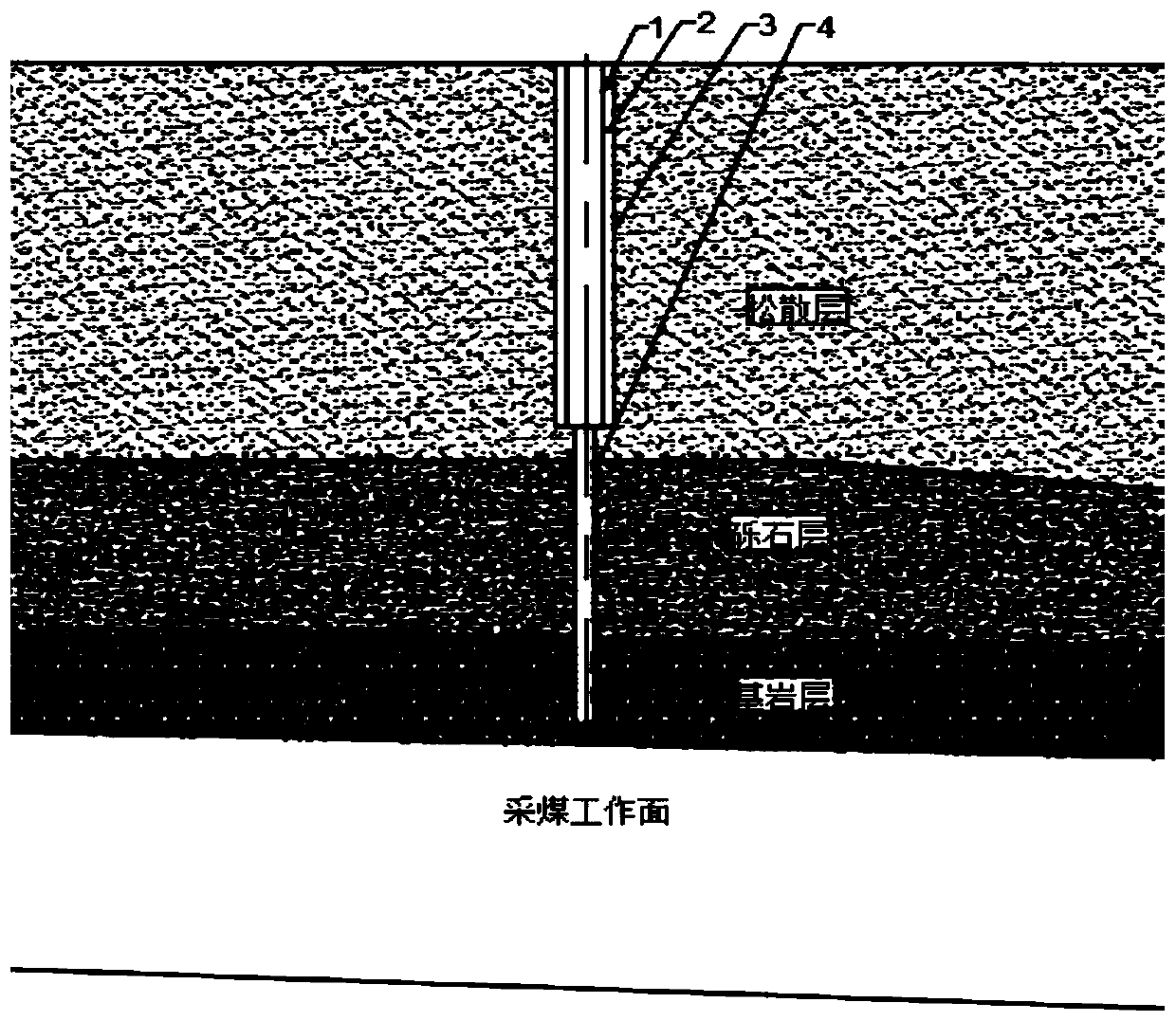

[0019] A drilling and grouting method for a water-rich gravel layer on the roof of a coal mining face, comprising the following steps:

[0020] (1) The depth of the drilling hole is 236.21m, and the final hole layer reaches the bedrock of the coal seam roof;

[0021] (2) Aperture structure: 0~181.64m aperture is Φ152mm, 181.64~236.21m aperture is Φ94mm;

[0022] (3) Pipe diameter structure: Φ127mm casing from 0 to 148.6m;

[0023] (4) Grouting construction: grouting started on June 16, 2018, and ended on September 24, 2018; drilling and grouting were carried out in three sequences: ① From June 16, 2018 to June 2018 The first grouting was done on 22nd June, the hole depth was 197.27m (gravel layer), the orifice pressure was 2.7Mpa, the flow rate was 235L / min at the end of grouting, and the duration exceeded 30min; ②June 27, 2018 to September 2, 2018 The second grouting per day, the hole depth is 236.21m (final hole), the orifice pressure is 3.1Mpa, the flow rate is 236L / min a...

Embodiment 2

[0026] A drilling and grouting method for a water-rich gravel layer on the roof of a coal mining face, comprising the following steps:

[0027] (1) The depth of the drilling hole is 221.64m, and the final hole layer reaches the bedrock of the coal seam roof;

[0028] (2) Aperture structure: 0~130m aperture is Φ152mm, 130~184.55m aperture is Φ94mm, 184.55~221.64m aperture is Φ75mm;

[0029] (3) Pipe diameter structure: 0~130m is Φ127mm casing; 130~184.55m is Φ108mm casing;

[0030] (4) Grouting construction: The grouting started on June 13, 2018, and ended on August 16, 2018; two sequential groutings were carried out in the drilling: ① From June 13, 2018 to July 2018 The first grouting on the 2nd, the hole depth was 184.5m (gravel layer), the orifice pressure was 2.0Mpa, and the flow rate was 235L / min at the end of the grouting; ②The second grouting from July 14, 2018 to August 16, 2018 , the hole depth is 221.64m (final hole), the orifice pressure is 2.7Mpa at the end of gro...

Embodiment 3

[0033] A drilling and grouting method for a water-rich gravel layer on the roof of a coal mining face, comprising the following steps:

[0034] (1) The depth of the drilling hole is 232.19m, and the final hole layer reaches the bedrock of the coal seam roof;

[0035] (2) Aperture structure: 0~149.52m aperture is Φ152mm, 149.52~232.19m aperture is Φ94mm;

[0036] (3) Diameter structure: Φ127mm casing from 0 to 141.62m;

[0037] (4) Grouting construction: grouting started on June 2, 2019, and ended on August 27, 2019; two sequences of drilling and grouting were carried out: ① From June 2, 2018 to June 2018 The first grouting was performed on 29th July, the hole depth was 212.04m (gravel layer), the orifice pressure was 3.2Mpa, the flow rate was 250L / min at the end of the grouting, and the duration exceeded 30min; ②July 1, 2018 to August 27, 2018 The second time of grouting per day, the hole depth is 232.19m (final hole), the orifice pressure is 4.2Mpa, the flow rate is 35L / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com