Hydrolysis and alcoholysis resistant modified nylon 66 material for automotive water chamber and preparation method of modified nylon 66 material

A modified nylon and hydrolysis-resistant technology, applied in the field of polymer materials, can solve the problems of poor compatibility between graphene and nylon, reduced binding force, poor injection molding performance, etc., achieve good dimensional stability, improve tensile properties, and facilitate Processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

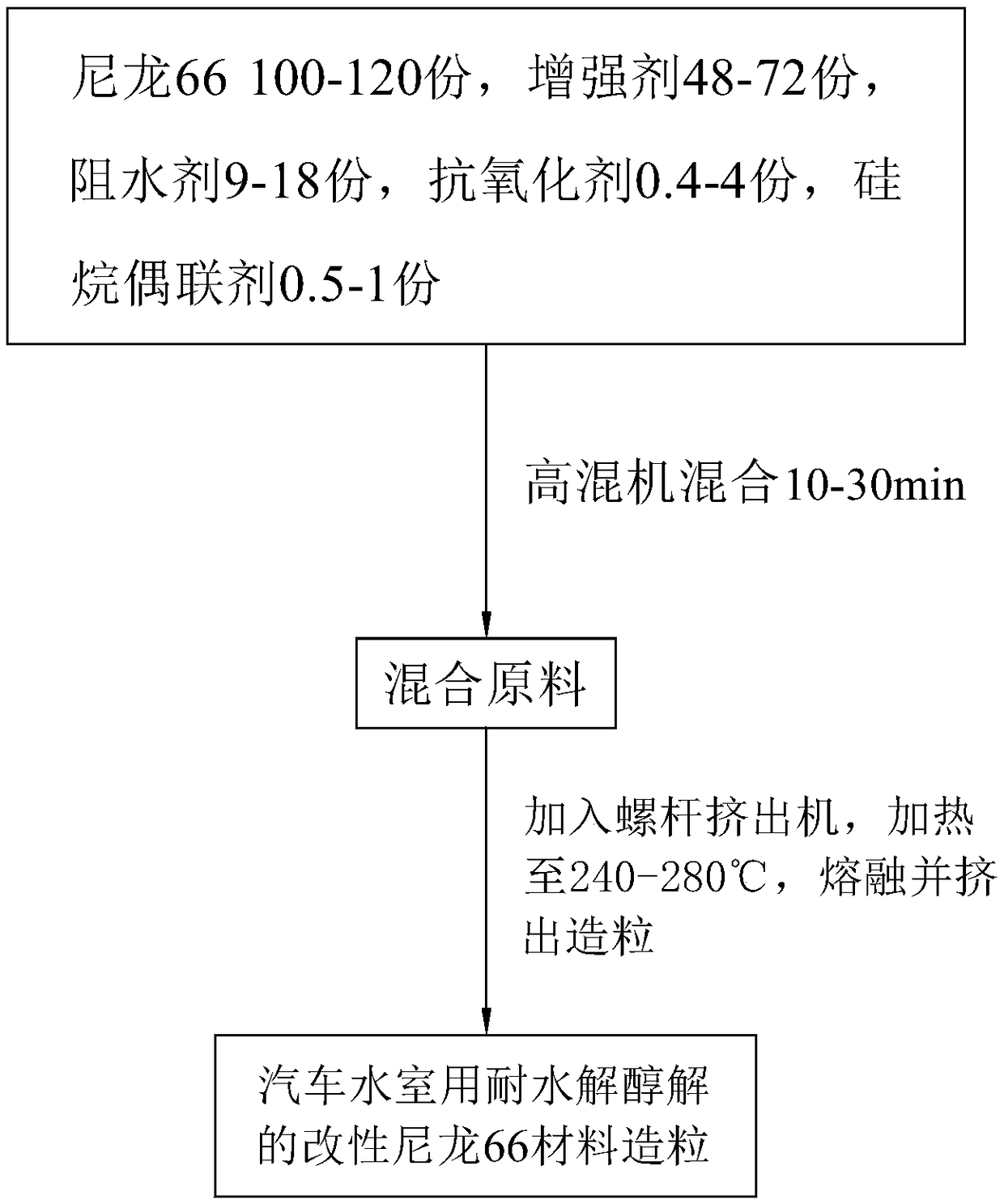

Method used

Image

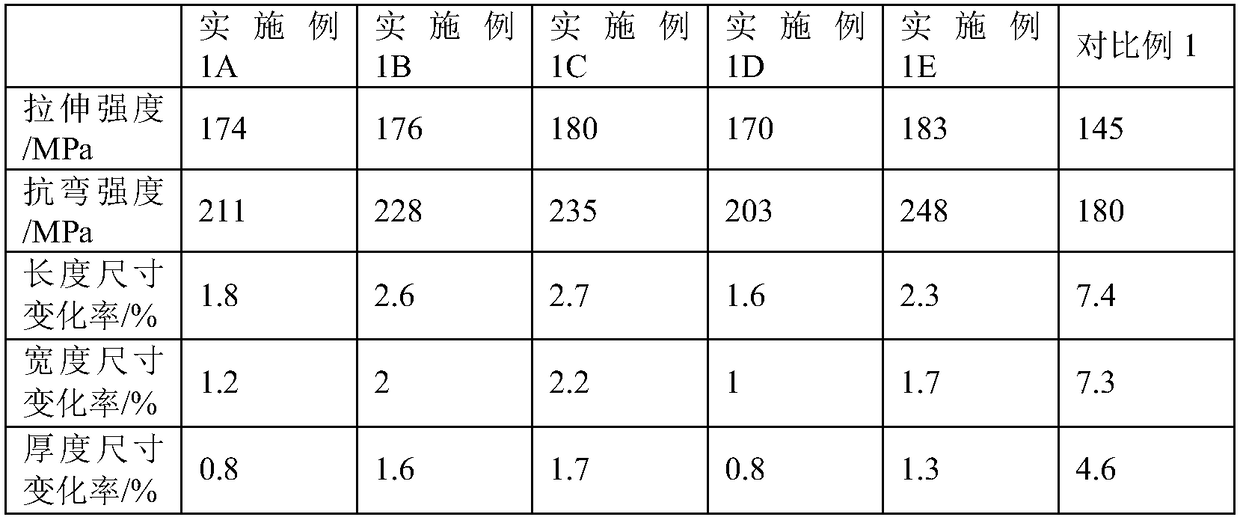

Examples

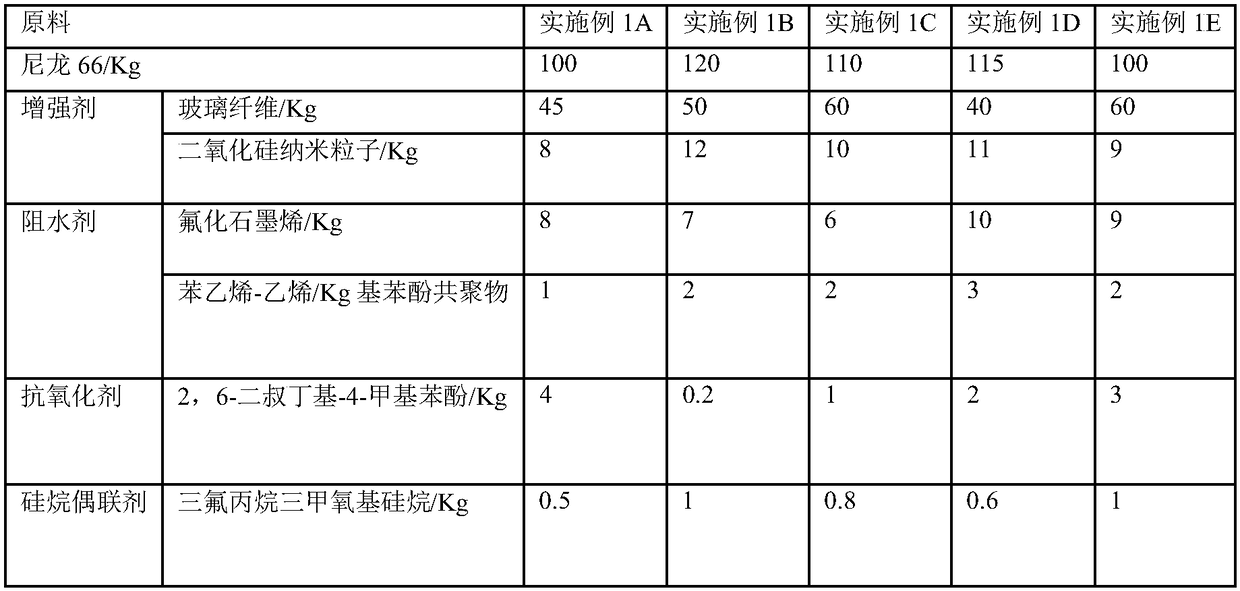

Embodiment 1

[0051] A modified nylon 66 material resistant to hydrolysis and alcoholysis for an automobile water tank, the raw materials of which are as follows and are calculated in parts by mass,

[0052] Nylon 66 100-120 parts,

[0053] Enhancer 48-72 parts,

[0054] Water blocking agent 9-18 parts,

[0055] Antioxidant 0.4-4 parts,

[0056] Silane coupling agent 0.5-1 part.

[0057] Wherein the reinforcing agent is 40-60 parts of glass fiber and 8-12 parts of silicon dioxide nanoparticles. The glass fiber is one or both of short glass fiber and non-alkali short glass fiber. This time it is non-alkali short glass fiber, which is a commercially available product purchased from Jushi Group with the article number JSWX021. The silicon dioxide nanoparticles are fumed nano silicon dioxide, which is a commercially available product HL-380 fumed white carbon black purchased from Yichang Huifu Silicon Material Co., Ltd. The water blocking agent is 6-10 parts of fluorinated graphene and 3-8...

Embodiment 2

[0082] A modified nylon 66 material resistant to hydrolysis and alcoholysis for automobile water tanks, improved on the basis of Example 1, its silane crosslinking agent is a chlorosilane containing a fluoroalkyl group, where the chlorosilane containing a fluoroalkyl group Use (3,3,3-trifluoropropyl)trichlorosilane. According to the preparation method in Example 1 and the raw material ratio of Examples 1A-1E, the modified nylon 66 material was prepared to obtain Examples 2A-2E. And the modified nylon 66 material prepared in Examples 2A-2E was tested, and the test results were as follows.

[0083] 1. No hydrolysis and alcoholysis.

[0084]

[0085] 2. After the hydrolysis of the mixed solution of ethylene glycol and water with a mass ratio of 1:1.

[0086]

[0087] It can be seen from the above that the hydrolysis and alcoholysis resistance, physical properties and dimensional stability of the modified nylon 66 plastics are improved by using chlorosilanes containing flu...

Embodiment 3

[0089] A modified nylon 66 material resistant to hydrolysis and alcoholysis for an automobile water tank, improved on the basis of Example 2, the antioxidant includes 0.2-2 parts of phosphite, and the phosphite is tris(nonylphenol)phosphorous acid Any of esters, tri-isooctyl phosphite and tris(2,4-di-tert-butylphenyl) phosphite.

[0090] According to the preparation method of Example 1, the modified nylon 66 material was prepared to obtain Examples 3A-3E, and the specific raw material dosage parameters are as follows.

[0091]

[0092]

[0093]The modified nylon 66 materials obtained in Examples 3A-3E were subjected to mechanical property tests, dimensional stability tests, and hydrolysis and alcoholysis resistance tests.

[0094] 1. No hydrolysis and alcoholysis.

[0095]

[0096] 2. After the hydrolysis of the mixed solution of ethylene glycol and water with a mass ratio of 1:1.

[0097]

[0098] It can be seen from the above that phosphite, as a good antioxida...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com