Hydrophobic friction material, brake pad and preparation method

A technology of friction materials and brake pads, which is applied in the field of brake pads, can solve the problems of reducing the friction coefficient of brake pads, achieve stable friction coefficient, excellent high temperature performance, and improve the effect of reducing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

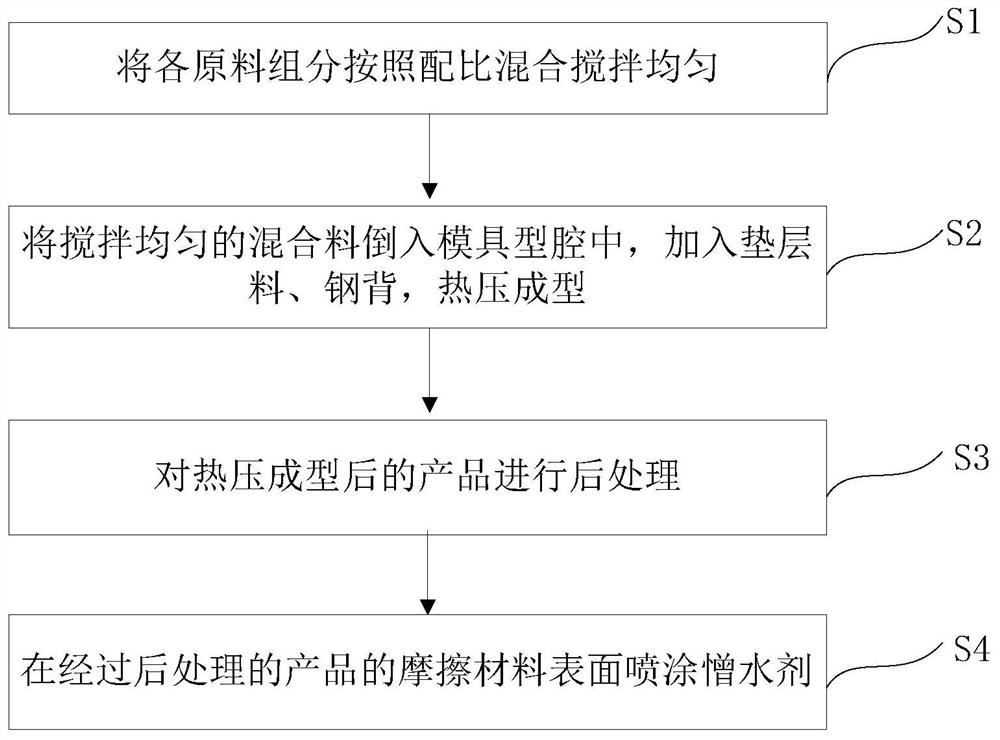

[0034] Please refer to the attached figure 1 , the preparation method of the brake pad comprising the above-mentioned hydrophobic friction material provided by the present invention comprises the following steps:

[0035] S1. Mix and stir the raw material components of the hydrophobic friction material according to the ratio;

[0036] S2. Pour the well-stirred mixture into the mold cavity, add cushion material and steel back, and heat press to form;

[0037] S3, post-processing the product after hot pressing;

[0038] S4. Spraying a water-repellent agent on the surface of the friction material of the post-treated product.

[0039] Specifically, in step S2, the mass of the cushion material added during hot pressing is 8% of the total mass of the raw materials of the friction material; wherein, the cushion material is made of raw materials such as resin, rock wool fiber, attapulgite, dolomite, etc. Mixture, which mainly plays the role of bonding friction material and steel ba...

Embodiment 1

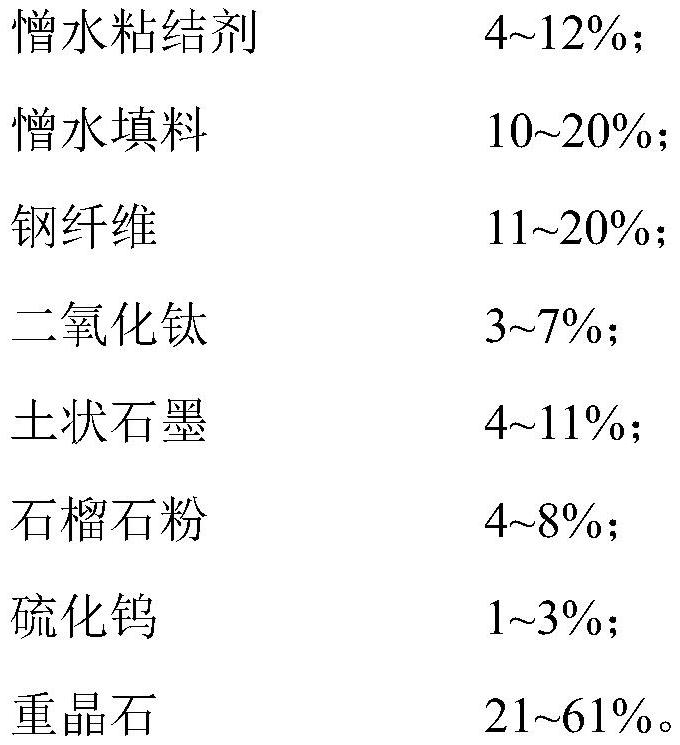

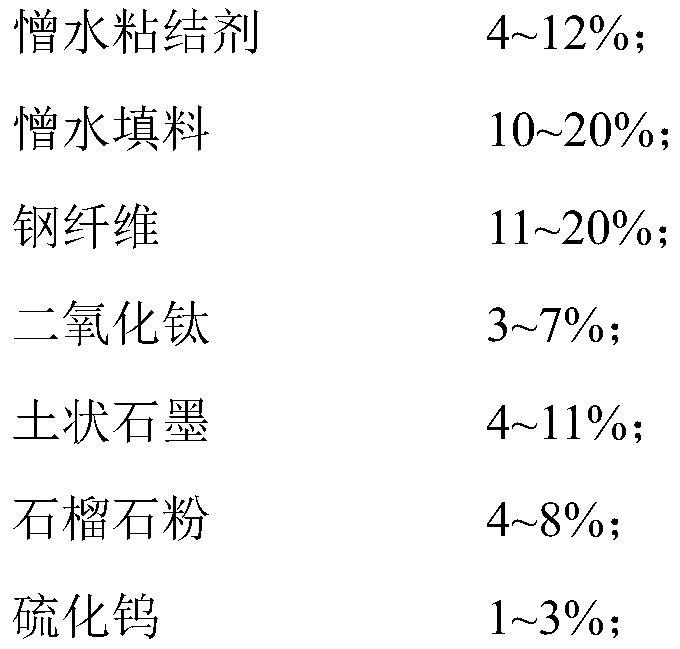

[0048] Based on the total mass of the raw material components of the hydrophobic friction material, the hydrophobic friction material includes the following components and mass percentages: 5% hydrophobic binder, 10% hydrophobic filler, 14% steel fiber, 4% titanium dioxide , earthy graphite 7%, garnet powder 5%, tungsten sulfide 2%, barite 53%. Wherein, the hydrophobic binder is silicone-modified phenolic resin, and the hydrophobic filler includes 2% polytetrafluoroethylene powder, 4% silicon rubber powder, and 4% polypropylene powder.

[0049] The preparation method of brake pad in the present embodiment comprises the following steps:

[0050] S1, mixing materials, adding the above raw material components into a high-speed mixer and stirring for 12 minutes, so that all raw materials are mixed evenly;

[0051] S2, hot press molding, add the mixture evenly stirred in step S1 into the mold cavity, flatten it with a tool, then add cushion material and steel back, hot press moldi...

Embodiment 2

[0055] Based on the total mass of the raw material components of the hydrophobic friction material, the hydrophobic friction material includes the following components and mass percentages: 10% hydrophobic binder, 20% hydrophobic filler, 20% steel fiber, 7% titanium dioxide , earthy graphite 11%, garnet powder 8%, tungsten sulfide 3%, barite 21%. Wherein the hydrophobic binder is silicone modified phenolic resin, the hydrophobic filler is 4% polytetrafluoroethylene powder, 8% silicon rubber powder, and 8% polypropylene powder.

[0056] The preparation method of the brake pad in this embodiment is the same as that in Embodiment 1, except that the water-repellent agent sprayed in step S4 is isooctenetriethoxysilane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com