Multi-composite modified hydrophobic stone-like coating and preparation method thereof

A composite modification and real stone paint technology, applied in the field of real stone paint, can solve the problems of reducing the contact area between water and film, not wear-resistant, easy to peel, etc., to improve the hydrophobic effect and water resistance, reduce the hydrophilic and hydrophobic effects. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

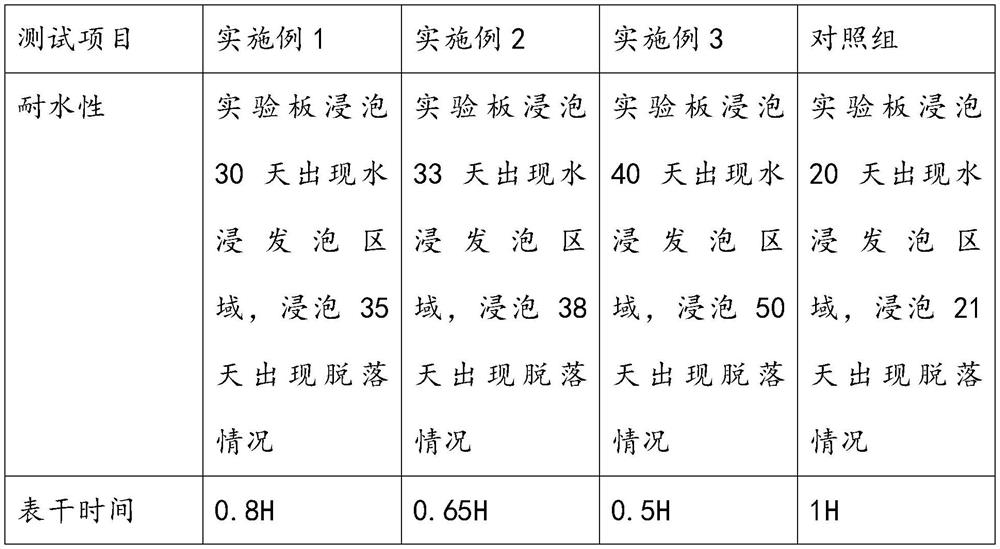

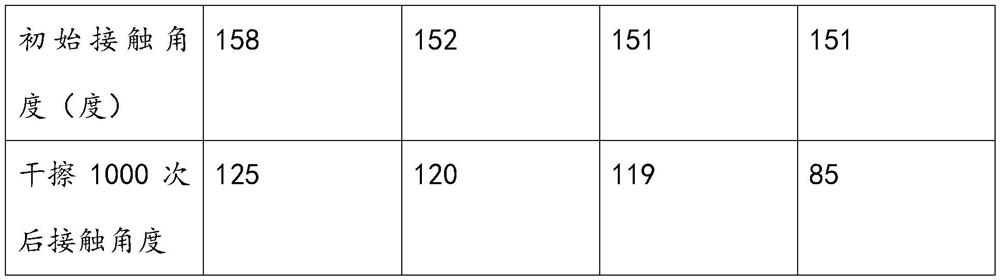

Embodiment 1

[0020] In the embodiment of the present invention, a multi-composite modified hydrophobic real stone paint is prepared by including the following raw materials in parts by weight: including 100 parts of silicone modified acrylic emulsion, hydrophobic side chain type water-based polyurethane associative thickener 1 part, 400 parts of natural stone powder, 1 part of lotus leaf hydrophobic agent, 50 parts of long-chain siloxazane emulsion, 5 parts of film-forming aid, 1 part of butyl p-hydroxybenzoate, 1 part of defoamer, deionized water 50 parts, first introduce deionized water into the reactor, the reactor has a built-in high-speed disperser for stirring, turn on the disperser and keep the speed not lower than 500RPM; introduce half of the components of film-forming aids and defoamers into the reaction Stir evenly in the kettle, and the stirring time is 5-10 minutes; introduce the hydrophobic side chain type water-based polynitrogen ester associative thickener into the reaction ...

Embodiment 2

[0022] In the embodiment of the present invention, a multi-composite modified hydrophobic real stone paint is prepared from the following raw materials in parts by weight: 150 parts of silicone-modified acrylic emulsion, hydrophobic side chain type water-based polyurethane associative thickener 3 parts, 500 parts of natural stone powder, 3 parts of lotus leaf hydrophobic agent, 75 parts of long-chain siloxazane emulsion, 12 parts of film-forming aid, 3 parts of paraben preservative, 6 parts of defoamer, 75 parts of ionized water; first, introduce deionized water into the reactor, which has a built-in high-speed disperser for stirring, turn on the disperser and keep the speed not lower than 500RPM; Import into the reaction kettle and stir evenly, the stirring time is 5-10 minutes; import the hydrophobic side chain type water-based polynitrogen ester associative thickener into the reaction kettle and stir evenly, the speed is increased to not less than 800RPM, and the stirring ti...

Embodiment 3

[0024] In the embodiment of the present invention, a multi-composite modified hydrophobic real stone paint is prepared from the following raw materials in parts by weight: 150 parts of silicone-modified acrylic emulsion, hydrophobic side chain type water-based polyurethane associative thickener 3 parts, 500 parts of natural stone powder, 3 parts of lotus leaf hydrophobic agent, 75 parts of long-chain siloxazane emulsion, 12 parts of film-forming aid, 3 parts of paraben preservative, 6 parts of defoamer, 75 parts of ionized water; first, introduce deionized water into the reactor, which has a built-in high-speed disperser for stirring, turn on the disperser and keep the speed not lower than 500RPM; Import into the reaction kettle and stir evenly, the stirring time is 5-10 minutes; import the hydrophobic side chain type water-based polynitrogen ester associative thickener into the reaction kettle and stir evenly, the speed is increased to not less than 800RPM, and the stirring ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com