A kind of fluorine-containing modified diallylamine water-soluble polymer and preparation method thereof

A technology of water-soluble polymer and diallylamine, applied in the field of fluorine-modified diallylamine water-soluble polymer and preparation thereof, can solve the problem of difficult to obtain pure polymer, difficult to remove surfactant, harsh reaction conditions, etc. problem, to achieve the effect of improving rigidity, improving hydrophobic association ability, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, preparation of fluorine-modified diallylamine monomer

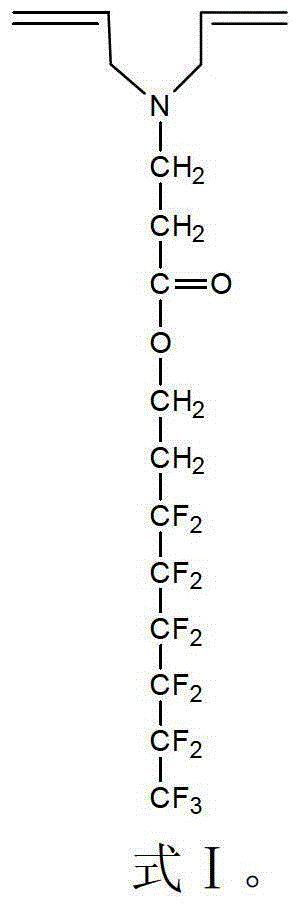

[0042] Weigh 5.18g (12mmol) of perfluorohexylethyl acrylate and 30mL of absolute ethanol, add them to a 50mL three-necked flask equipped with a condenser tube and a stirring bar, and start stirring. Then weigh 0.972 g (10 mmol) of diallylamine and add it into a three-necked flask. After the solution is mixed evenly, put it into a constant temperature water bath at 60°C, and react for 6 hours. After the reaction, the residual solvent was removed by rotary evaporation under reduced pressure to obtain a brownish yellow liquid, that is, 5.1346 g of a fluorine-modified diallylamine monomer with the structure shown in formula I, with a yield of 97.5%.

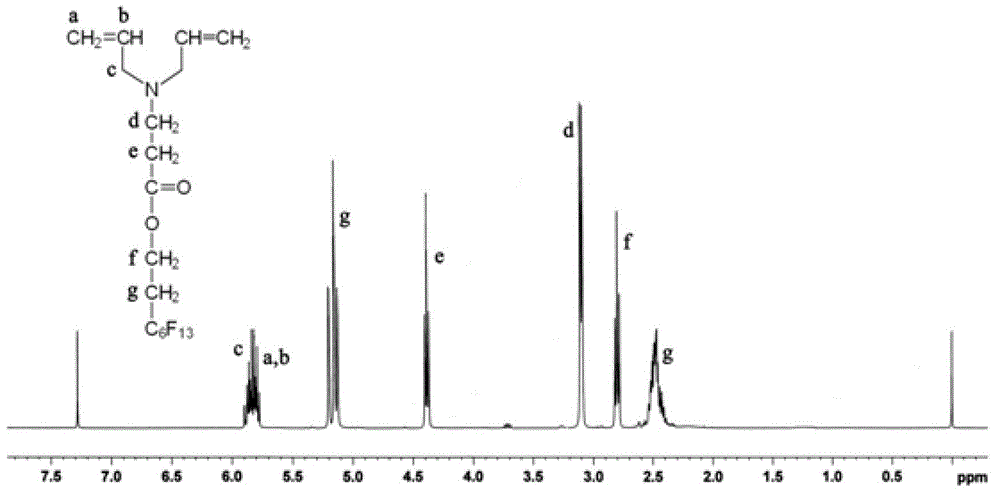

[0043] Fluorine-modified diallylamine monomer shown in formula I 1 H-NMR spectrum as figure 1 As shown, after analysis, the structure of the monomer prepared in this embodiment is correct.

Embodiment 2

[0044] Embodiment 2, preparation of fluorine-containing modified diallylamine water-soluble polymer

[0045] Weigh 0.132g (0.2563mmol) of the fluorine-modified diallylamine monomer shown in Formula I prepared in Example 1, and measure 50mL of dimethyl sulfoxide, add a nitrogen tube, a condenser tube and a 100mL In the three-neck flask, start stirring and feed nitrogen. Then weigh 3.532 g of acrylamide (0.0498 mol, the molar ratio of fluorine-modified diallylamine monomer to acrylamide is 1:194), and add it into a three-necked flask. After the solution is mixed evenly, put it into a constant temperature water bath at 60°C. Weigh 0.41g of azobisisobutyronitrile (the amount added is 0.501% of the total molar weight of fluorine-modified diallylamine monomer and acrylamide), and add it to a three-necked flask. In this reaction body, fluorine-modified diallylamine The total molar concentration of allylamine monomer and acrylamide is 1mol L -1 .

[0046] The reaction ended after ...

Embodiment 3

[0050] Embodiment 3, the preparation of polymer containing fluorinated diallylamine structure

[0051] The specific preparation steps are basically the same as in Example 2, except that the monomer feeding is changed to 3.515 g of acrylamide and 0.264 g of fluorine-modified diallylamine to obtain the fluorine-containing modified diallylamine water-soluble polymer powder products, the 1 H-NMR and 19 The F-NMR spectrogram is substantially the same as the polymer prepared in Example 2; wherein, the weight-average molecular weight is 1.523 × 10 5 g / mol.

[0052] When the concentration of the aqueous solution of the fluorine-containing modified diallylamine aqueous polymer prepared in this example is 10 mg / mL at room temperature, the surface tension test of the hanging plate method shows that the surface tension of the aqueous solution can be reduced to 37 mN / m.

[0053] The fluorine-modified diallylamine aqueous solution polymer prepared in this example has relatively high ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| thermal degradation temperature | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com