Brake power supply for construction hoist and control method

A technology for construction elevators and power supplies, which is applied in the direction of AC motor control, control systems, electrical components, etc., can solve the problems of construction elevators sliding down and down, and achieve the effects of enhancing safety, optimizing costs, and facilitating project realization and product installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

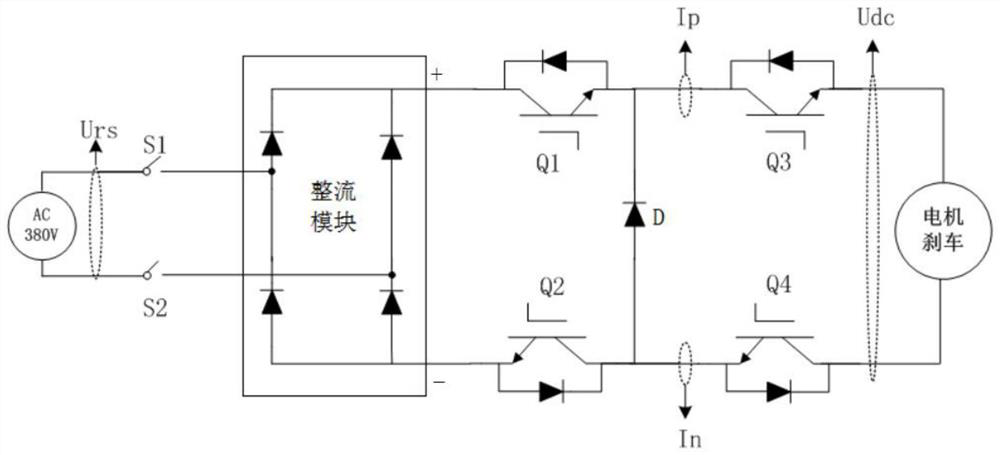

[0022] Example 1: See figure 1 , a brake power supply for a construction elevator, including a 380V power supply, a switch S1, a switch S2, a rectifier module, an IGBT switch Q1, an IGBT switch Q2, an IGBT switch Q3, an IGBT switch Q4, and a diode D, including a 380V power supply through the switch S1 and the switch S2 Connect the input terminal of the rectifier module, the output terminal of the rectifier module + the drain of the IGBT switch Q1, the source of the IGBT switch Q1 is connected to the cathode of the diode D and the drain of the IGBT switch Q3, and the source of the IGBT switch Q3 is connected to the motor brake module , the output terminal of the rectifier module-connect to the source of IGBT switch Q2, the drain of IGBT switch Q2 is connected to the anode of diode D and the source of IGBT switch Q4, the drain of IGBT switch Q4 is connected to the other end of the motor brake module, the IGBT switch The gates of Q1, IGBT switch Q2, IGBT switch Q3, and IGBT switc...

Embodiment 2

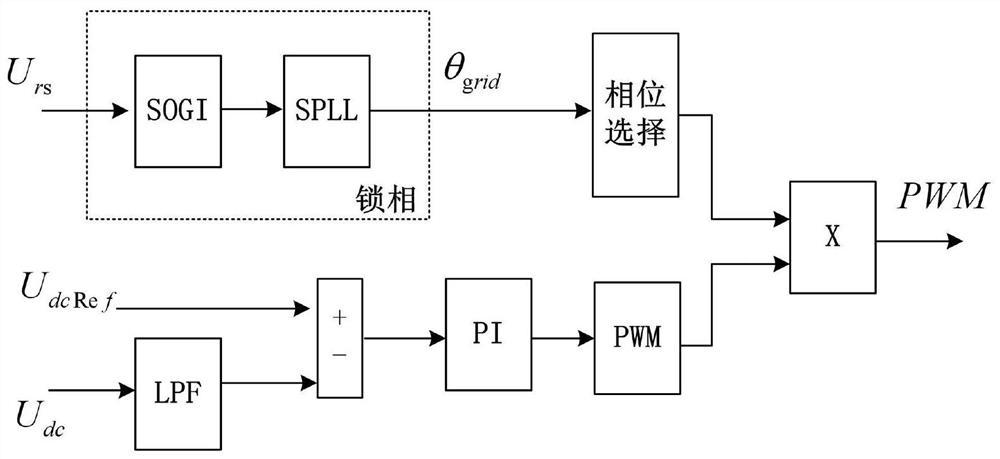

[0026] Example 2, such as figure 2 As shown, in order to realize the controllability of the output voltage, it is necessary to introduce closed-loop control. After the collected feedback Udc is low-pass filtered LPF, compared with the given voltage UdcRef, it enters the PI controller, and the result of the PI output generates a corresponding PWM Wave, the information of the power grid can be obtained through strict phase-locking for control. Urs in the figure is the RS line voltage in the three-phase input power supply, which uses a second-order generalized integrator (SOGI) and a software phase-locked loop (SPLL). Combined way to achieve phase-locking, to obtain the phase θ of the power grid grid , through phase control, the voltage area that needs to be chopped can be distinguished to achieve the purpose of rectifying and stepping down.

Embodiment 3

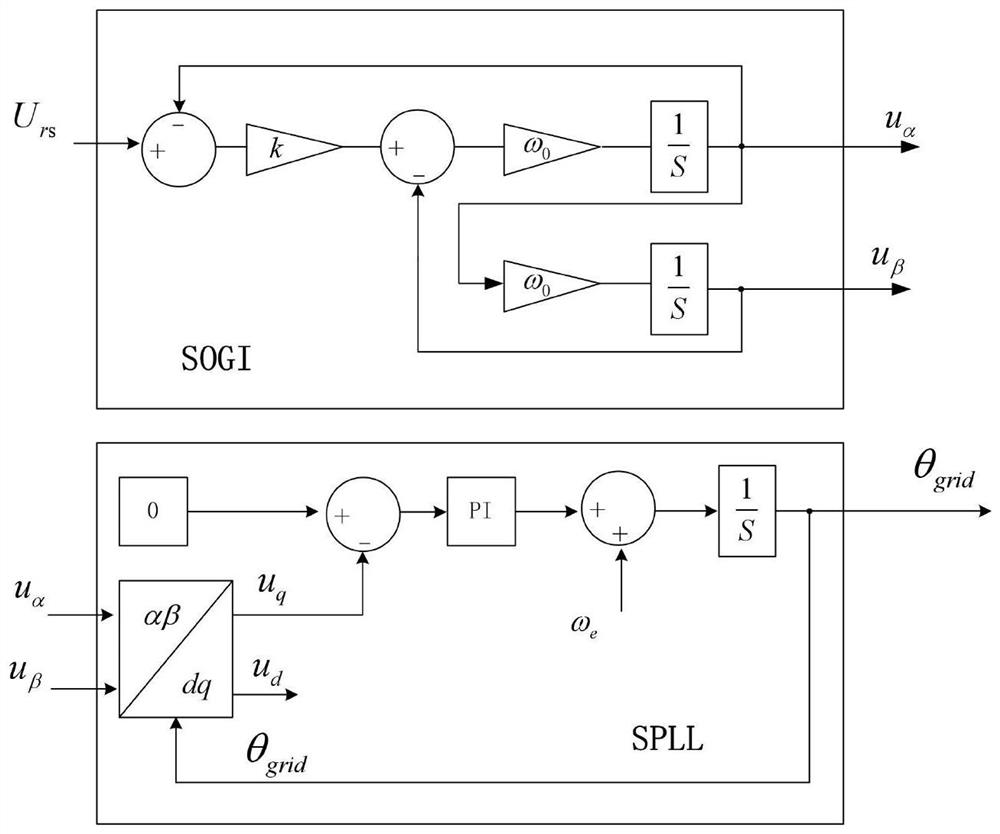

[0027] Example 3, such as image 3 As shown, it is the process of software phase-locking, where in SOGI, k is the adjustment proportional coefficient, ω 0 is the SOGI resonant frequency, and the quadrature voltage component u can be obtained after integration respectively α , u β , which is used for the software phase-locked loop control of the next level. After Park transformation, the DC component voltage Ud and Uq are obtained. Using the software phase-locked idea, the q-axis voltage is controlled to be 0, in the figure ω e is the frequency of the grid voltage, which can speed up the convergence process of the phase-locked loop. Usually, we need to convert it into a transfer function in the continuous domain, as shown in Equation 1, and then use the bilinear transformation method to discretize it.

[0028]

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com