Water-cooled efficient vacuum condenser system

A vacuum condensation and condenser technology, which is applied in the production of sucrose, sugar production, boiling/evaporation of sugar solution, etc., can solve the problems of large investment cost, large water volume, difficult adjustment, etc., and achieves increased labor intensity and convenient disassembly and maintenance. , the effect of improving condensation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

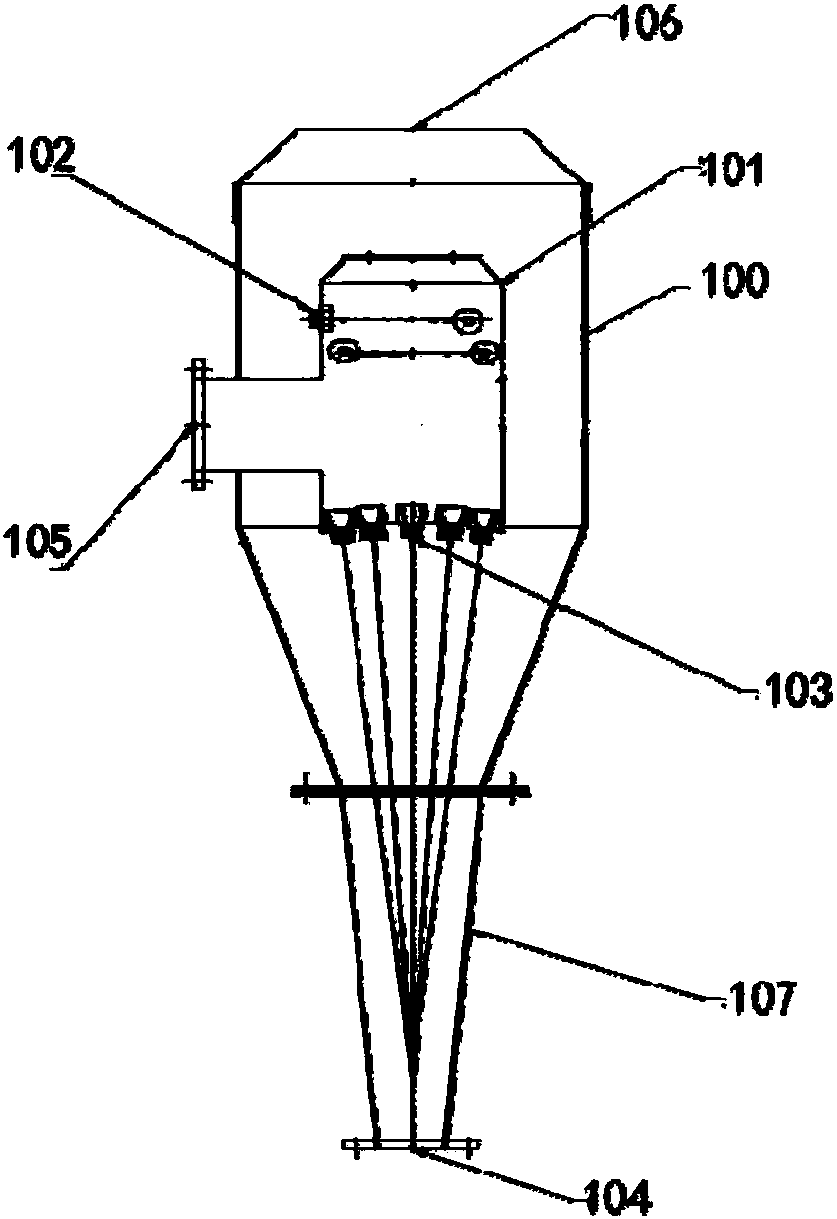

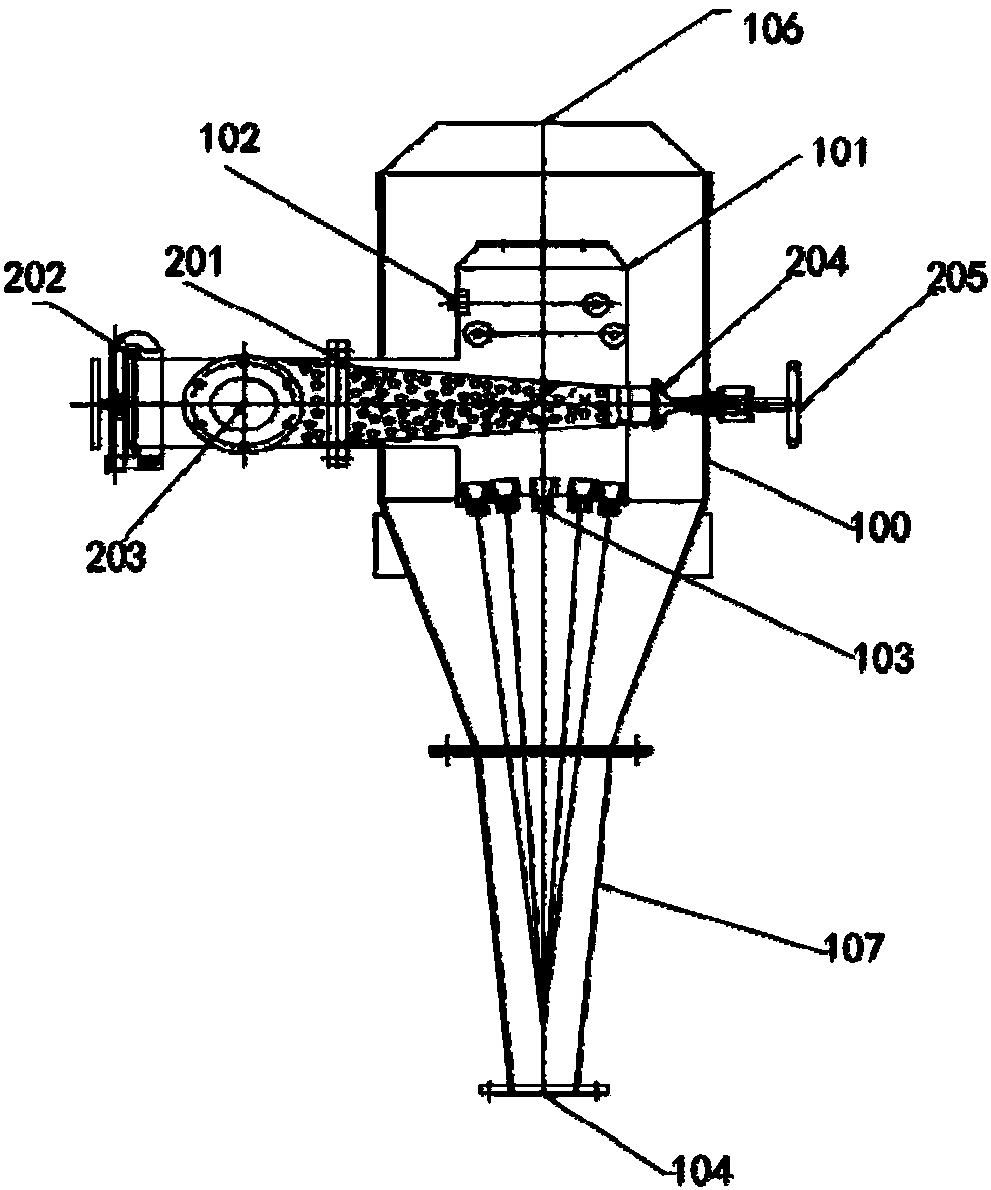

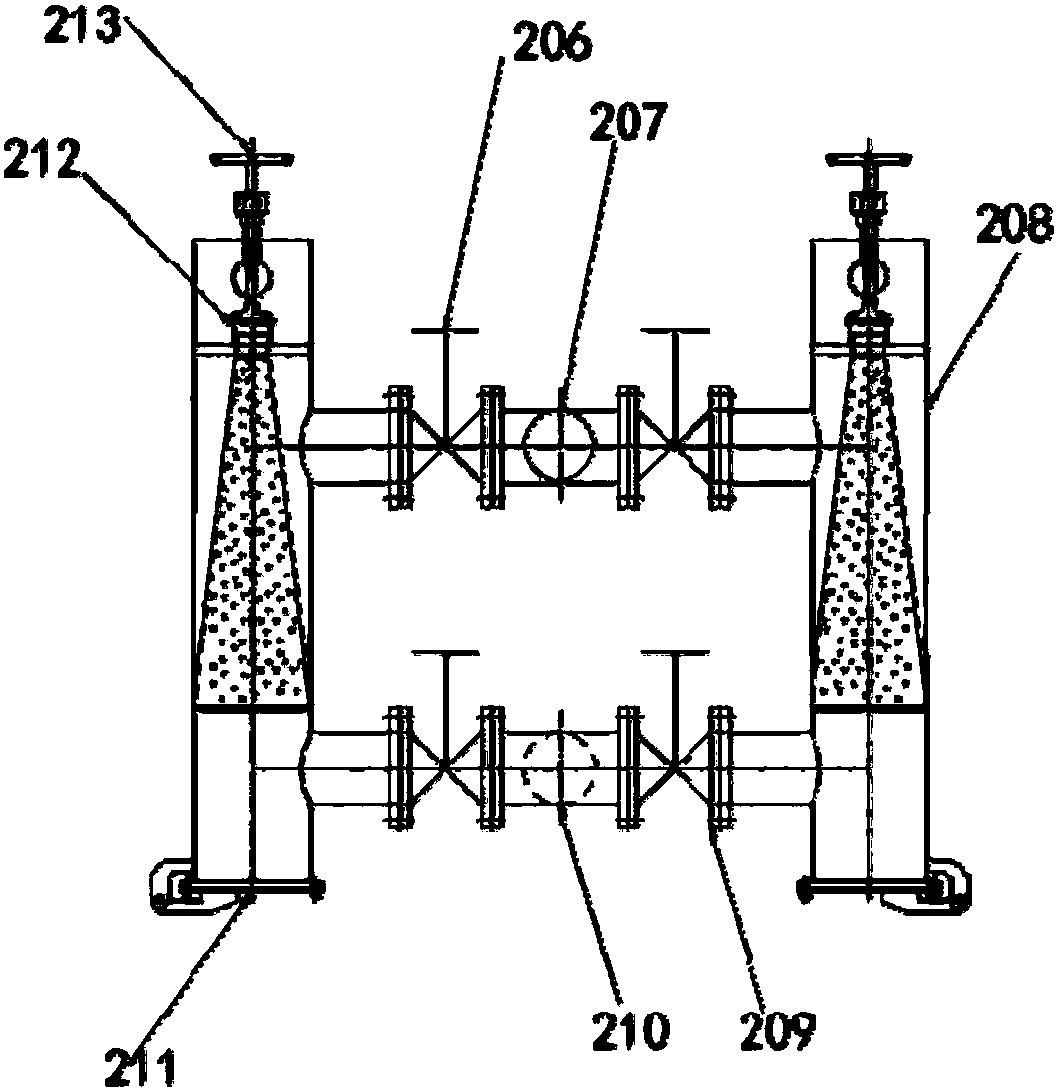

[0049] combine Figure 1-Figure 5 As shown, a water-cooled high-efficiency vacuum condenser system, the vacuum condenser system includes a juice vapor generating tank, a pipeline, a water filter device 200, a vacuum condensing device 100, a hot water collection pool, a circulating water pool 700, and a water suction pump 800, It is characterized by:

[0050] combine Figure 4 , Figure 5 As shown, the juice vapor generating tank, vacuum condensing device 100, water filtering device 200, hot water collection tank, suction pump 800, and circulating water pool 700 are connected together through pipelines;

[0051] combine Figure 4 , Figure 5 As shown, the pipeline includes a juice vapor pipe 400, a water inlet pipe 300, and a tailpipe 110; the water suction pump 800 is installed above the circulating pool 700 and is fixedly connected to one end of the water inlet pipe 300, and the other end of the water inlet pipe 300 is connected to a vacuum Condensing device 100; one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com