Full automatic control water jet condenser with characteristics of concentric diameter changing throat part, temperature control, constant water pressure and adjustable nozzles

A water jet condenser and condenser technology, applied in the field of vacuum system, can solve the problems of enterprise economic loss, misleading production, etc., and achieve the effect of stable high vacuum degree, good use effect, and stable water pressure maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

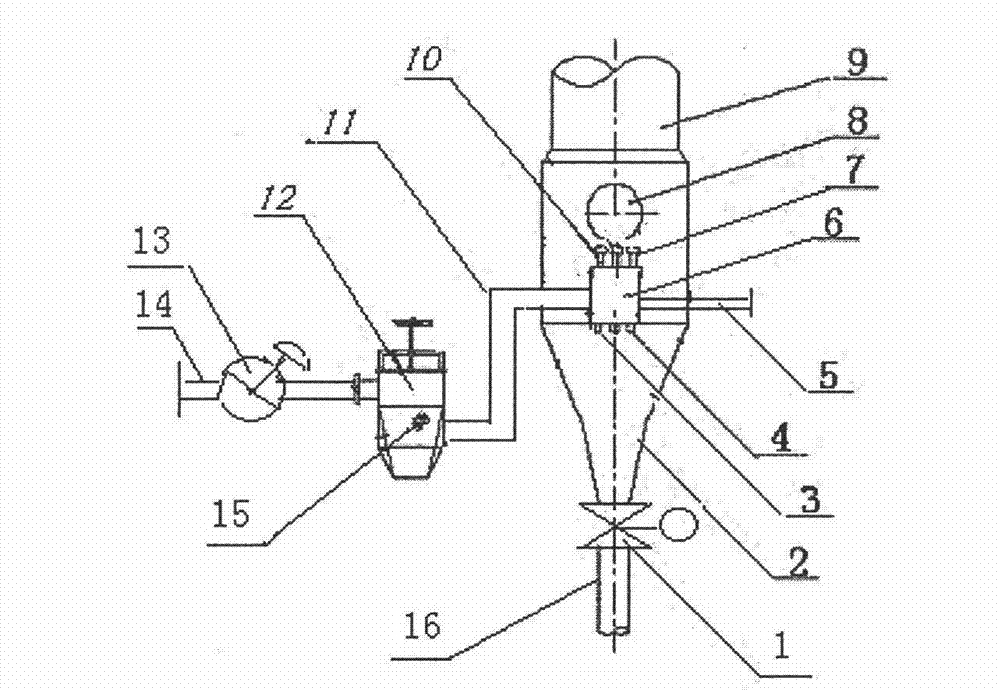

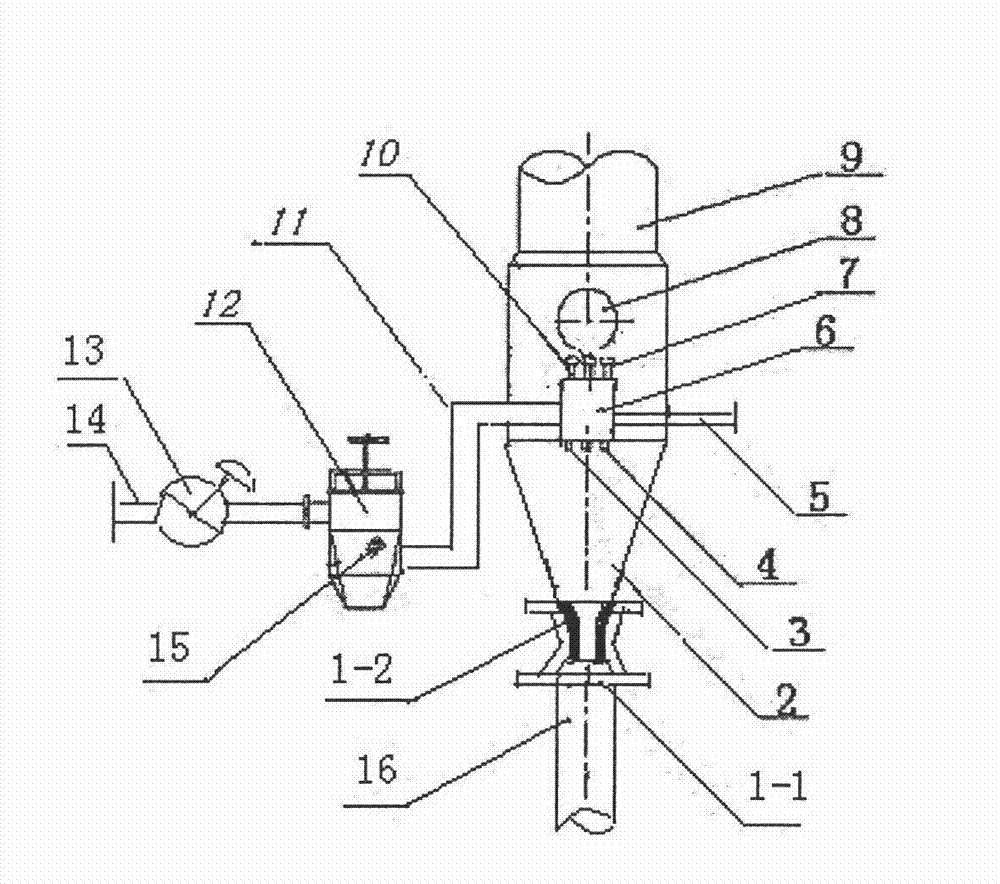

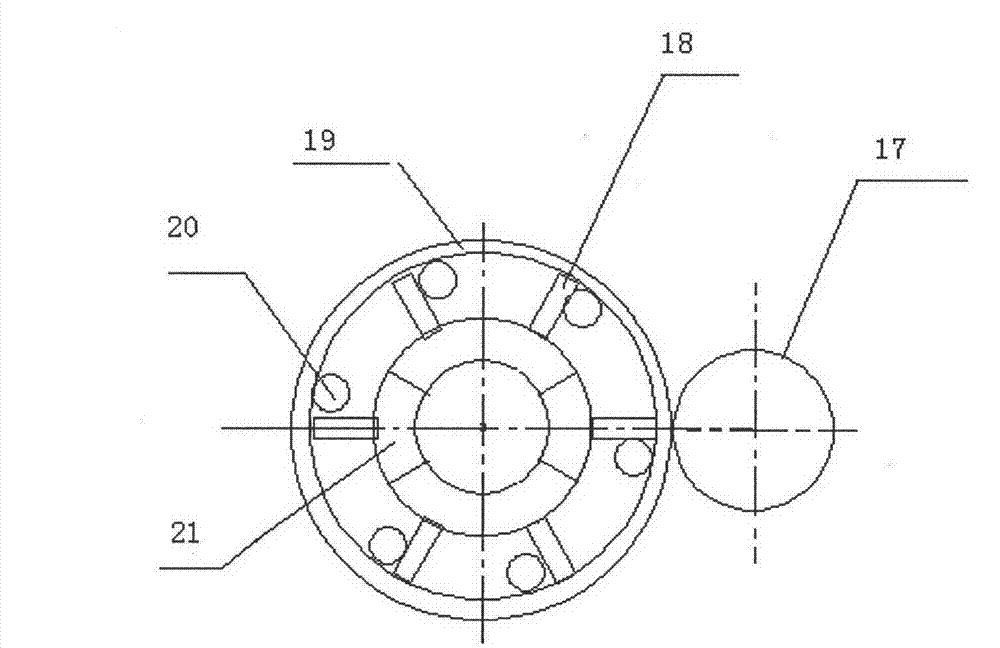

[0034] figure 1 and figure 2 As shown, it is a schematic structural view of disposing two different types of throat devices according to the present invention, and the body 2 is cross-sectionally shown in the figure. In the figure, the bottom of the vessel body 2 is cone-shaped, and the concentric diameter-reducing throat device of the condenser is connected below the cone-dipper. This throat device can have two types: or a concentric diameter-reducing valve 1 ( Such as figure 1 ), or a set of replaceable conical bucket-shaped concentric variable-diameter throat combination (such as figure 2, this set of detachable conical bucket-shaped concentric variable-diameter throat assembly consists of two parts: the fixed throat lining 1-1, and the movable one can be replaced by a cone-shaped bucket-shaped throat lining 1-2 with different inner diameters) . The drain tailpipe 16 is connected below the throat device, and the center of the body 2 is provided with a sealed water c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com