Double-seal internally-closed thimble vacuum valve

A technology of internally closed and vacuum valves, which is applied in the direction of lifting valves, valve devices, engine components, etc., can solve the problems of not being able to guarantee the vacuum degree in the cavity for a long time, stably and reliably, and achieve the purpose of maintaining the vacuum degree, expanding the application range, The effect of shrinking the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

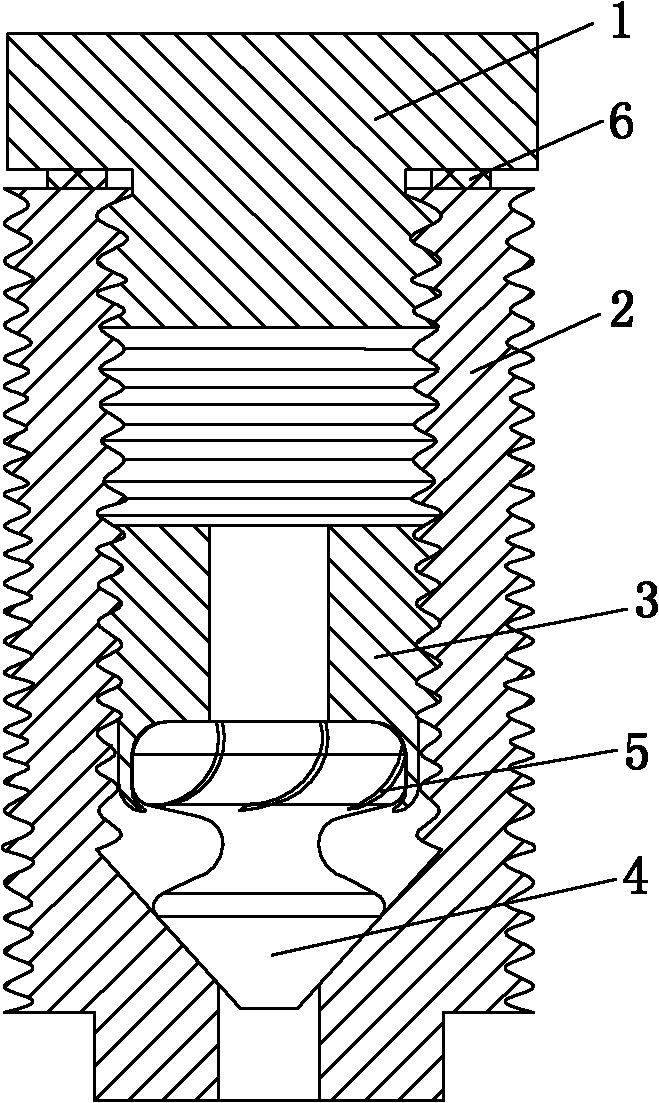

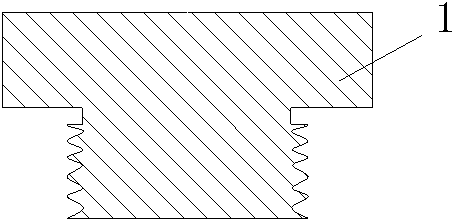

[0020] Such as Figure 1 to Figure 10 As shown, the double-sealed inner-closed thimble vacuum valve of the present invention is mainly composed of a screw cap 1, a casing 2 with internal and external threads, a thimble 3 with external threads, and a thimble plug 4, and the thimble plug 4 is placed in the casing 2 The internal bottom end of the thimble plug 4 is provided with an air extraction hole 5; the external thread of the thimble 3 matches the internal thread of the shell 2, and the thimble 3 is placed inside the shell 2 and is located on the top of the thimble plug 4; the screw cap 1 Connected to the top of the shell 2 by threads.

[0021] There is at least one air extraction hole 5, and there may be six, which are evenly distributed on the circumference of the top of the side wall of the thimble plug 4 for vacuuming.

[0022] The above-mentioned thim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com