Apparatus for injecting tail gas and inflow hot air in vacuum cabin of ramjet

A technology for ramjets and vacuum chambers, which is used in the testing of engines, measuring devices, and testing of machine/structural components. Test site, compact structure, high vacuum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0025] The best implementation mode of the present invention is as follows:

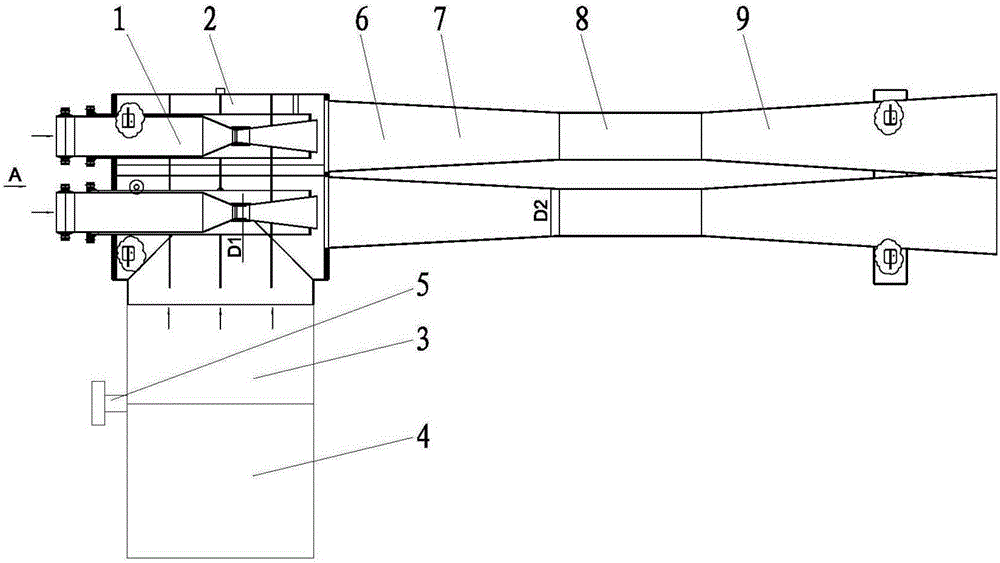

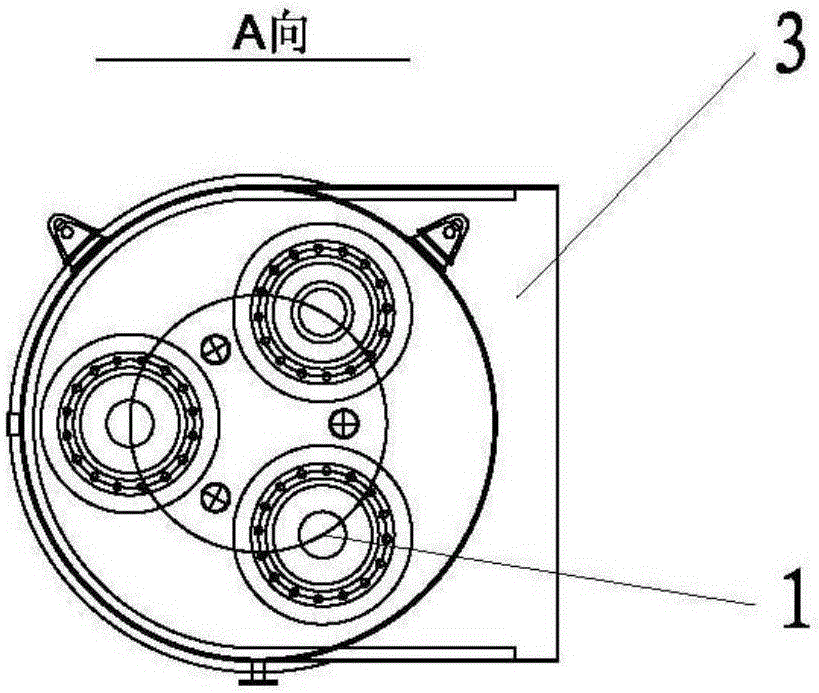

[0026] see figure 1 with figure 2 As shown, in the exhaust gas and incoming hot air injection device in the vacuum chamber of the ramjet, three injection nozzles 1 are inserted into the receiving chamber 2 at intervals of 120°, and the side of the receiving chamber 2 is connected to the vacuum pipe 3, and the vacuum pipe 3 is connected to the vacuum of the ramjet. The cabins 4 are connected, separated by a vacuum butterfly valve 5 in the middle, and the outlets of the three injection nozzles 1 are respectively connected with the three throttling pipes 6 (the three throttling pipes all include the mixing chamber 7, the connecting pipe 8 and the diffusion chamber 9 connected in sequence. ); Before the engine is ignited, the steam first passes into three injection nozzles 1, and because the cross-sectional area of the flow passage decreases, a negative pressure is generated at the outlet of the inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com