Vacuum desalination system and process

A seawater and vacuum technology, applied in the vacuum seawater desalination system and process field, can solve the problems of increased cost of maintenance and repair of seawater pumps, unstable boiling point of seawater, difficulty in increasing freshwater production, etc., to increase the effective area of evaporation and save engineering cost, and the effect of increasing freshwater production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

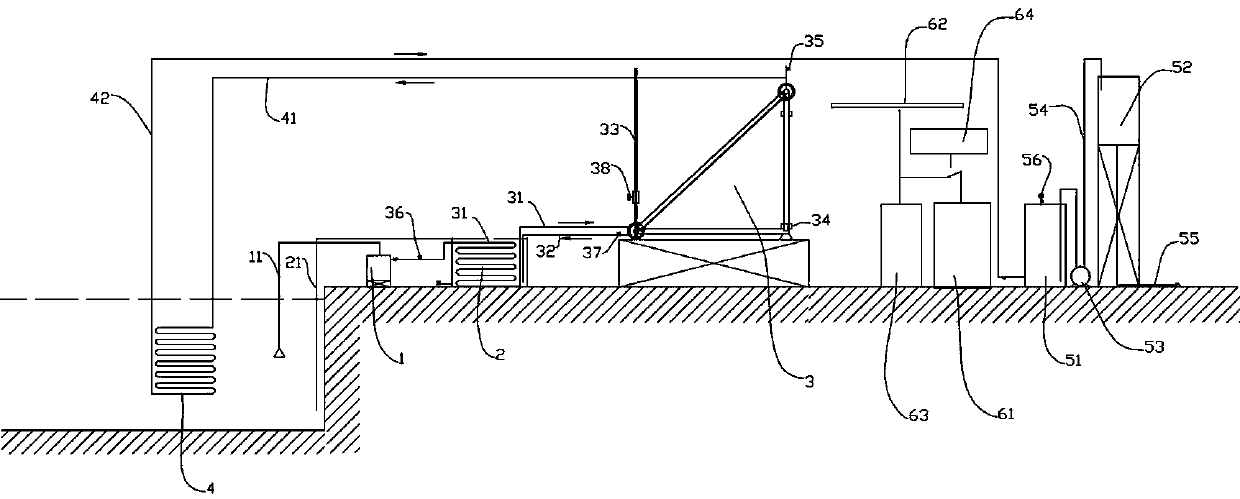

[0034] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

[0035] Such as figure 1 As shown, a vacuum seawater desalination system includes a water intake preheating device, a vacuum distillation device and a fresh water storage device connected in sequence, and a system control device electrically connected with the vacuum distillation device and the fresh water storage device. The water intake preheating device Including a seawater filter 1 and a seawater preheating pool 2, the water inlet of the seawater filter 1 is provided with a water intake pipe 11 to communicate with the sea, and the water outlet is provided with a water supply pipe 31 to connect with the vacuum distillation device; the water supply pipe 31 is pierced The seawater preheating pool 2; the vacuum distillation device includes a seawater heater 3 and a steam condenser 4; the seawater heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com