Vacuum pumping running maintaining system of newly-built power plant condenser and running method of vacuum pumping running maintaining system

An operation method and condenser technology, which are used in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of large floor space, high energy consumption, waste of equipment resources, etc., to reduce operating energy consumption, overcome the The effect of high energy consumption and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with specific embodiments.

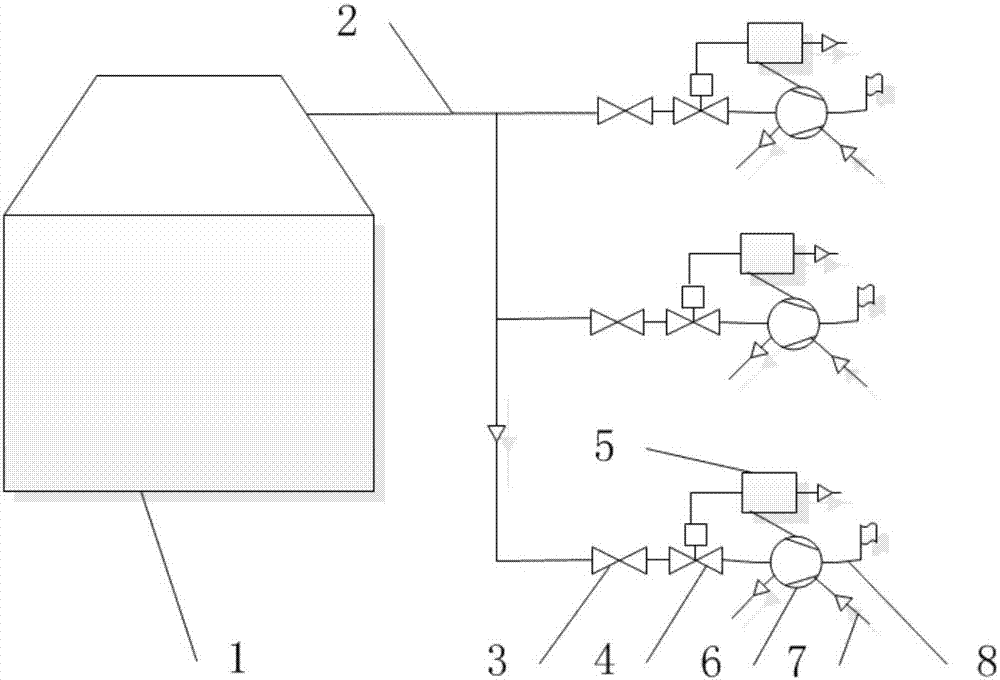

[0020] A new power plant condenser vacuum pumping operation maintenance system, including a number of parallel vacuum pump subsystems connected to the outlet end of the power plant condenser 1 through the inlet pipeline 2; the number of vacuum pump subsystems is based on the operating capacity of the new power plant Requires construction, three sets of vacuum pump subsystems are set up in this embodiment, such as figure 1 shown.

[0021] Each set of vacuum pump subsystem is equipped with intake manual valve 3, intake quick-closing pneumatic valve 4, dry screw vacuum pump 6 and control device 5; among them, intake manual valve 3, intake quick-closing pneumatic valve 4 and dry Type screw vacuum pump 6 is connected by pipeline, the air inlet end of air intake manual valve 3 is connected to the air outlet end of air intake pipeline, and the air outlet end of dry scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com