Patents

Literature

47results about How to "Large transfer area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

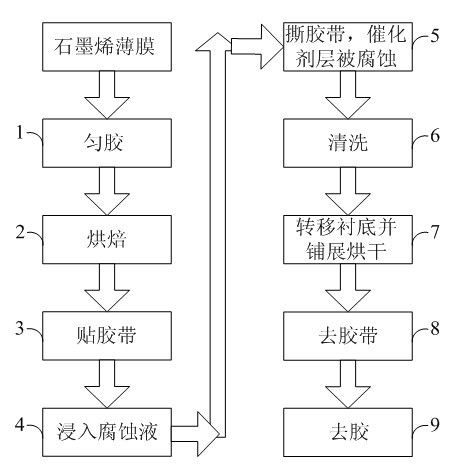

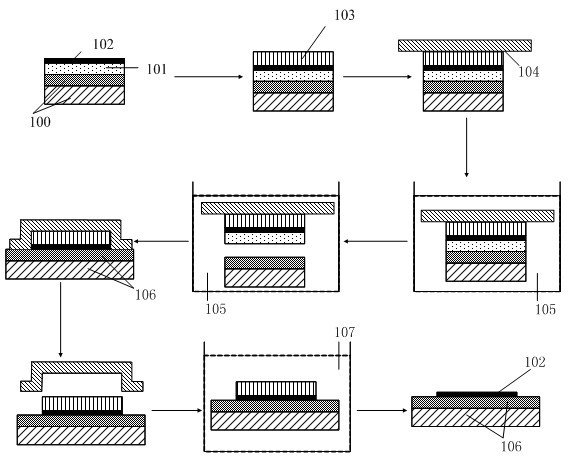

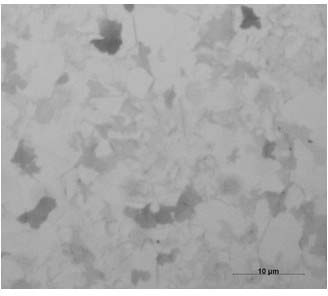

Method for transferring graphene film to substrate

ActiveCN102592964AThe transfer method is simple and easyLarge transfer areaSemiconductor/solid-state device manufacturingCvd grapheneCorrosion

The invention relates to a method for transferring a graphene film to a substrate, belonging to the field of semiconductor film. The method comprises the following steps: spin-coating an organic colloid on the surface of the graphene film, drying and hardening the film; adhering adhesive tape to the surface of the organic colloid; then putting a substrate material adhered the adhesive tape into a corrosive solution to corrode a metal catalyst layer under the graphene film; after the corrosion is finished, taking out the adhesive tape, the organic colloid and the graphene film which are adhered to the adhesive tape from the solution; uniformly spreading onto a target substrate, removing the adhesive tape by using a corresponding method, then dissolving the organic colloid away to finally finish the transfer of the graphene film to the target substrate. The method for transferring the graphene film to the substrate, disclosed by the invention, is simple and easy to implement, and can conveniently transfer the graphene film with a large area to any substrate material without causing a large damage. The method has the advantages of being large in transfer area, simple in processing steps, convenient in operation and can be combined with semiconductor techniques to prepare graphene semiconductor devices.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

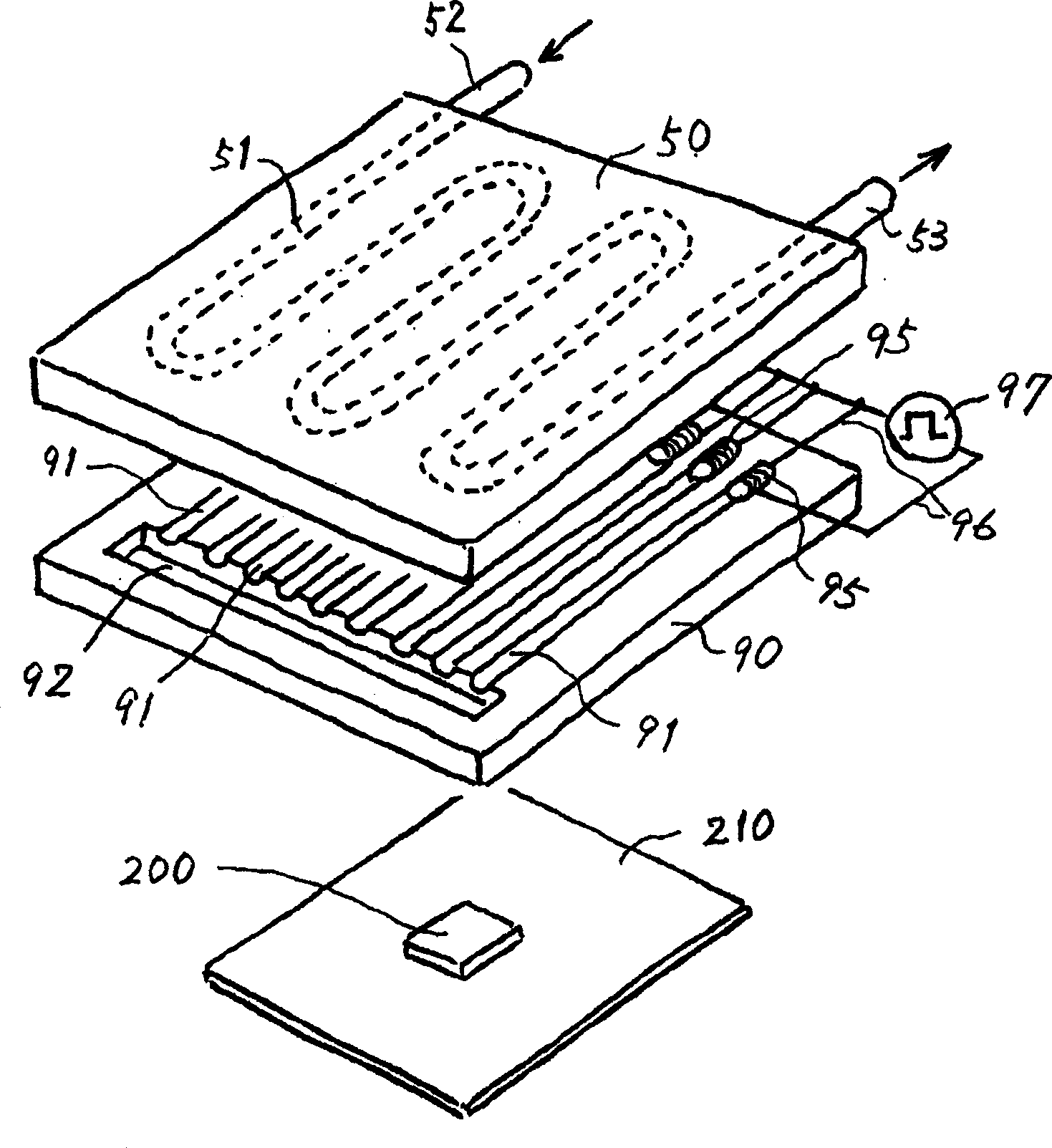

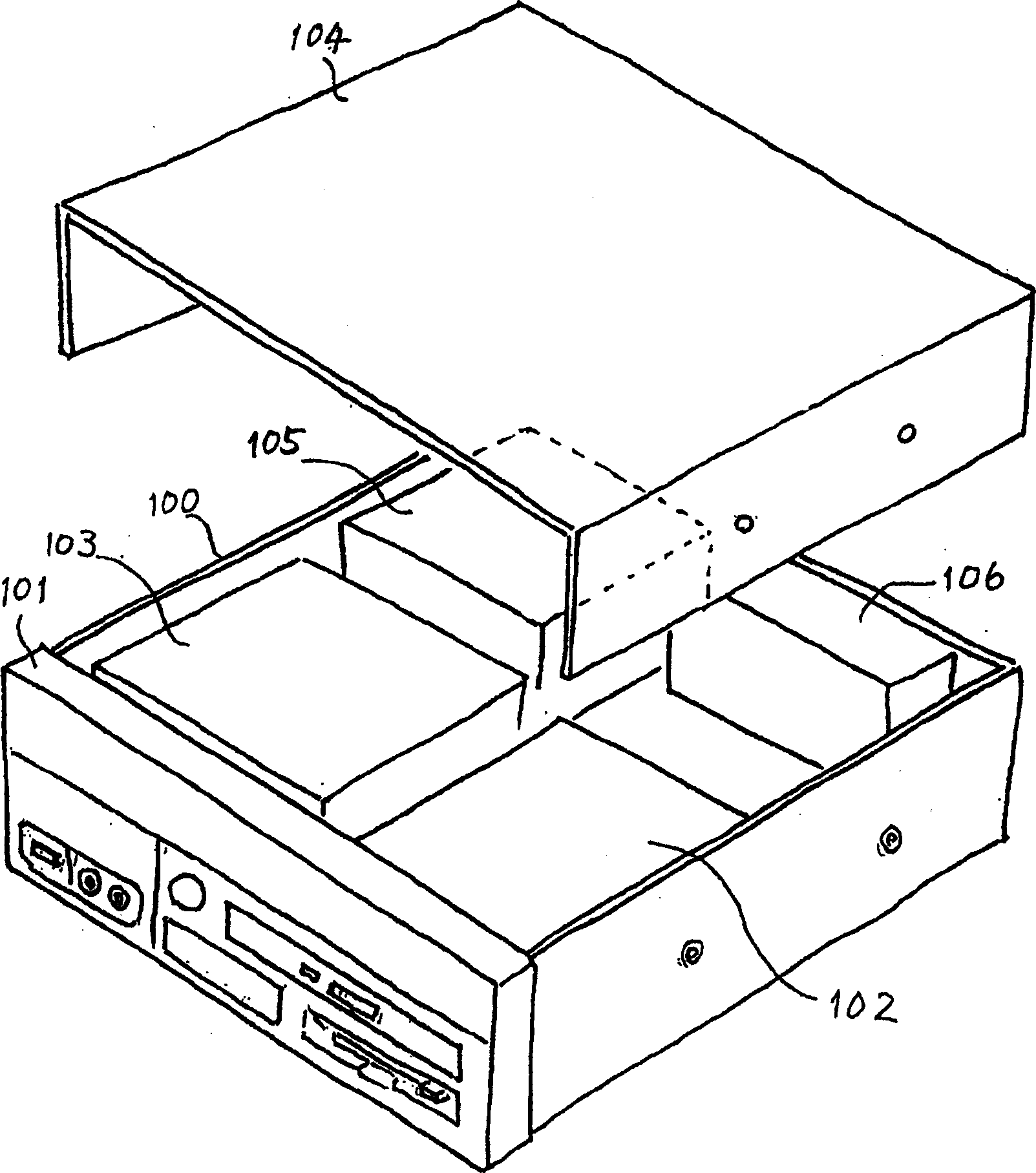

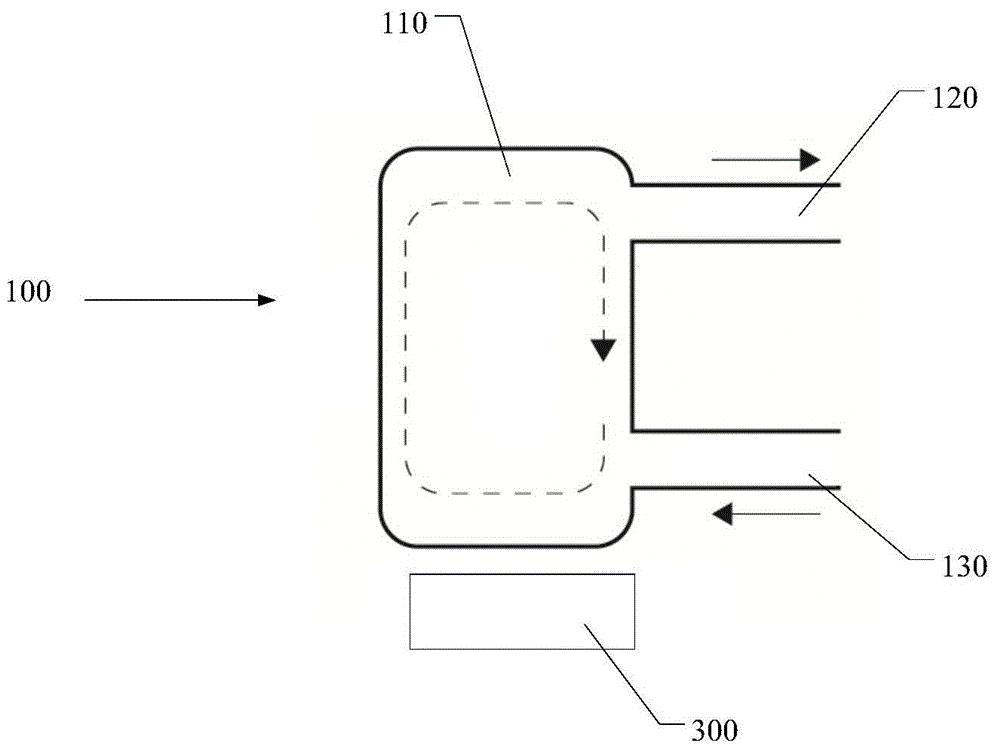

Cooling system for electronic apparatus, and electronic apparatus using the same

InactiveCN1658122AImprove cooling efficiencyLarge transfer areaDigital data processing detailsSemiconductor/solid-state device detailsWorking fluidCoolant flow

An electronic apparatus, such as, personal computers of so-called a desktop type and a notebook type, as well as, a server, etc., having a cooling system being high in cooling efficiency, wherein a CPU 200 in need of cooling is installed within a hosing 100, and the liquid cooling system for cooling the CPU, comprises: a heat-receiving (cooling) jacket 50; a radiator 60; and a circulation pump 70, wherein the heat-receiving (cooling) jacket 50, for transmitting heat generated from a heat-generation element, i.e., the CPU, into a liquid coolant flowing with in an inside thereof, has a heat diffusion plate 90 attached on the lower surface thereof. This heat diffusion plate encloses an operating fluid 94, such as water, within a space, which is hermetically sealed and formed within an inside thereof, and also has heater elements 95, being provided in contact with a portion the operating fluid. To those heater elements 95 are supplied a pulse-like electric power. With this, a portion of the operating fluid repeats forming / extinguishing, to give vibration to the operating fluid, thereby diffusing the heat over the entire of the diffusion plate, as a whole, thereafter the heat is transmitted to the heat-receiving (cooling) jacket. Or, alternatively, it may be connected with a heat radiation fin 300.

Owner:HITACHI LTD

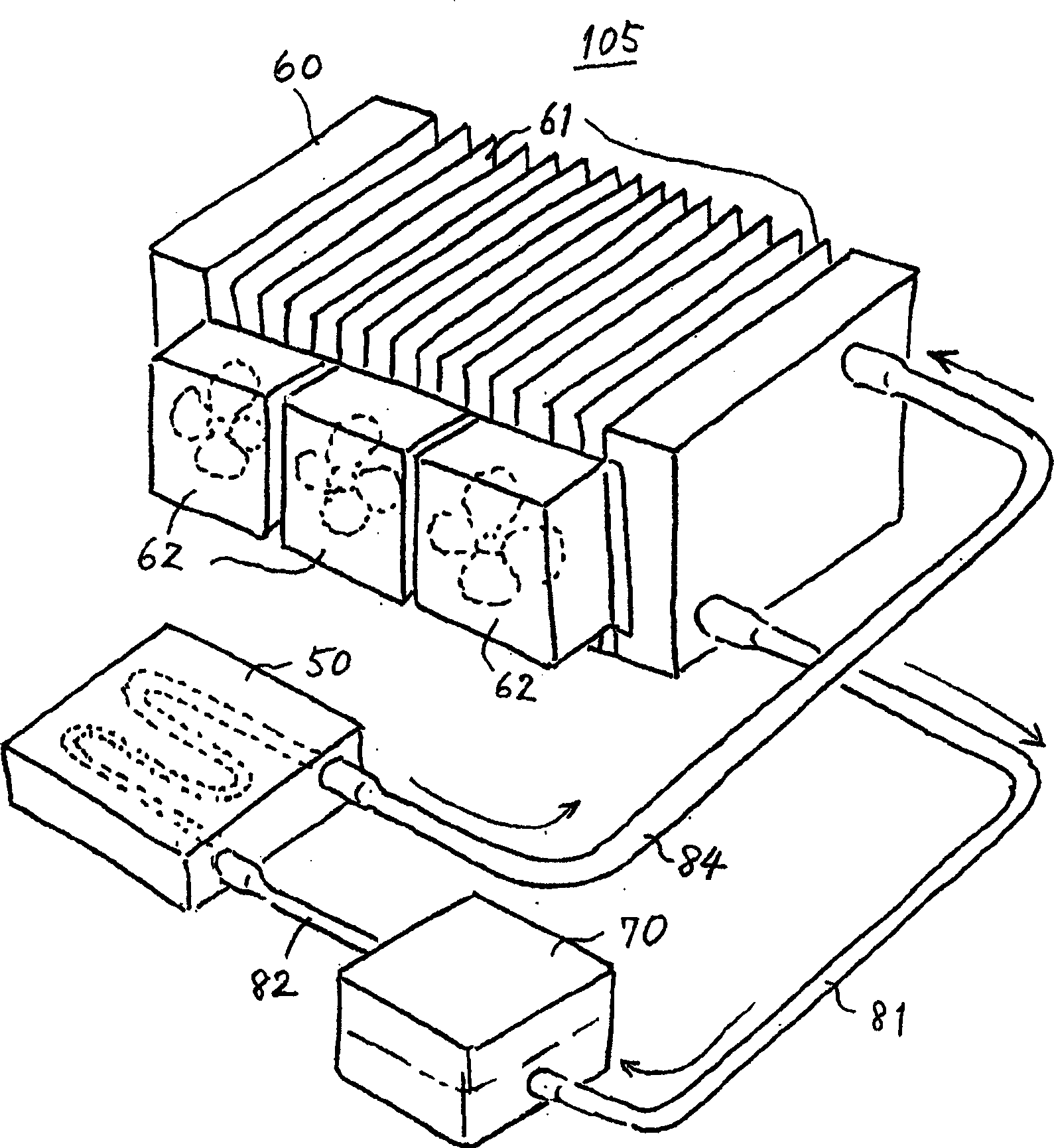

Fluidized-bed normal pressure spray-freezing drying method and device

InactiveCN101191693ANo need to shred againAvoid damageDrying solid materials without heatVoid ratioWater vapor

The present invention relates to a fluidized bed atmospheric spray freeze drying method and a device thereof, and is mainly used for dehydration and preservation of liquid food, medicine, biological products and other products with high added-value; the method is formed by combining a low temperature spray freeze granulating technique and a fluidized bed atmospheric freeze drying technique. Liquid material is atomized and frozen by two liquid atomizers which operate in a low temperature; the fine freezing particles are achieved and collected in the fluidized bed layer of the bottom of the device; then the atmospheric freeze drying medium is used to have partial pressure on the low vapour to satisfy the condition of water sublimation; through the fluidization technology, the freezing particles made by spray freezing are dried in the same device to a high quality qualified powdery product which has high void rate and fluidness and can adjust the granularity distribution; the system is a continuous closed operation; the cost of equipment investment and operation expense is lower than that of vacuum freeze drying; the invention has no pollution on environment.

Owner:李胜

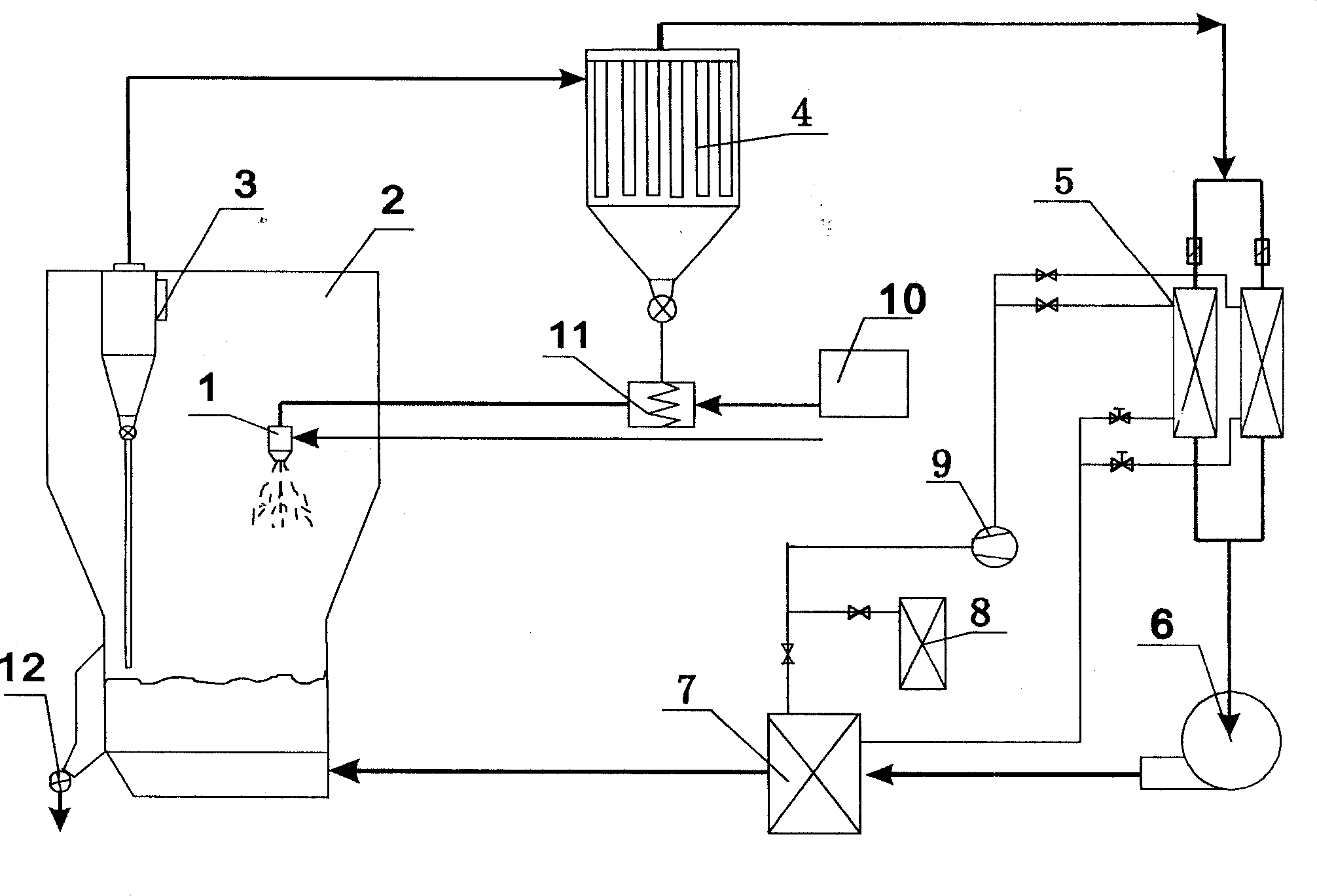

Self-service car washing method based on mobile Internet communication

InactiveCN105869308AImprove efficiencyAdvanced technologyApparatus for meter-controlled dispensingInternet communicationAnti jamming

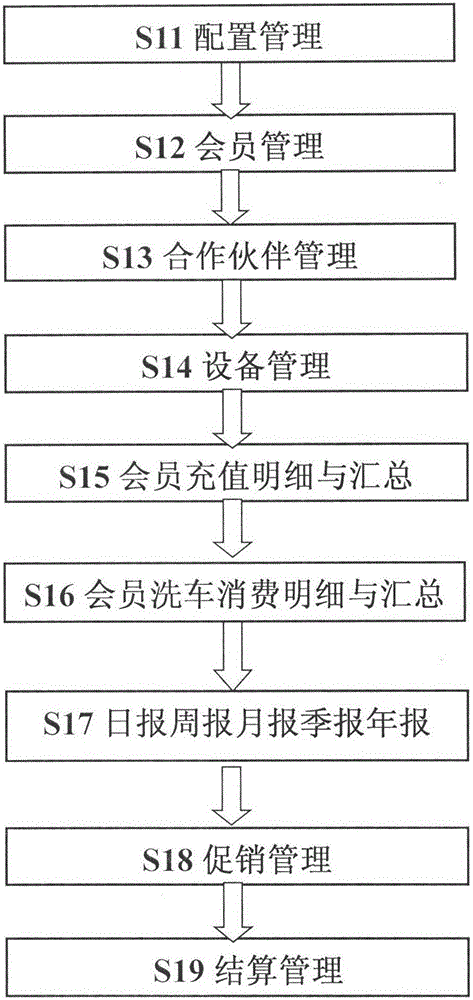

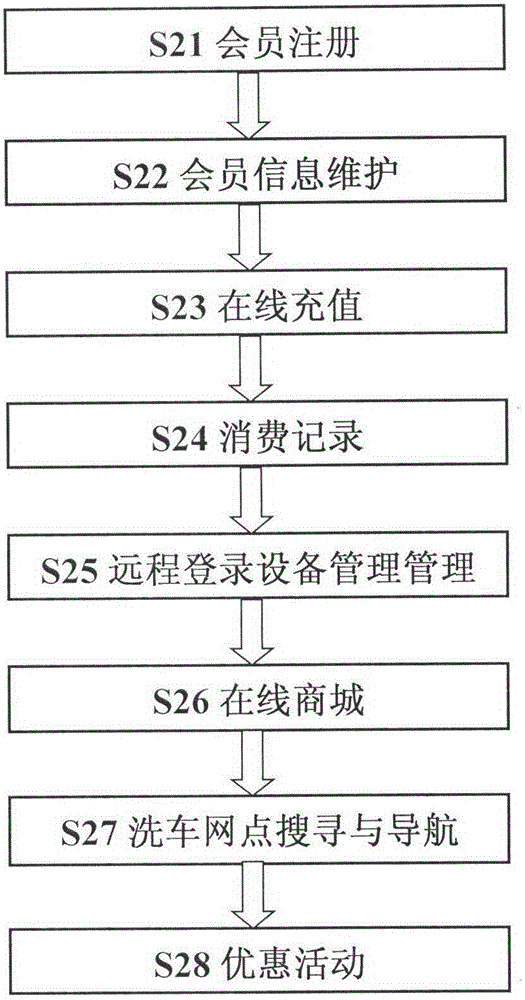

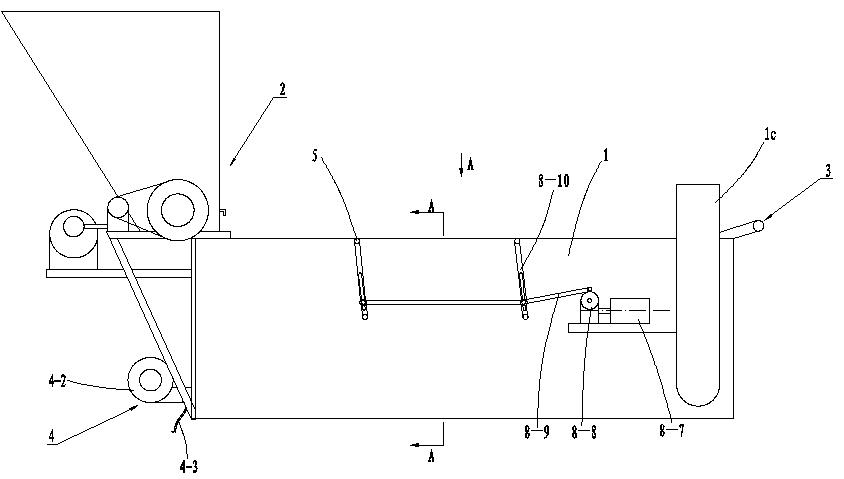

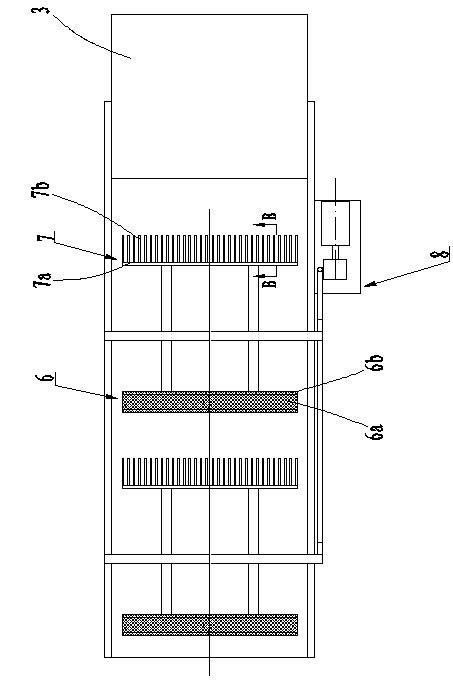

The present invention is a self-service car washing method based on mobile Internet of Things communication, including S1 center control operation management, S2 WeChat application management and S3 self-service terminal car washing management, a total of three levels of management. Among them: S1 is divided into S11, S12, S13 to S19, in order to realize the configuration management, member management, equipment management and settlement management required for the establishment and control of self-service terminal car washing; S2 is divided into S21, S22, S23 to S28, in order Member registration, online recharge, consumption records, etc. required for self-service terminal car washing; S3 is divided into S31, S32, S33 to S38, which sequentially perform member login and timeout management, human-computer interactive operation control, timing and settlement required for self-service terminal car washing , communication management, data upload interface, external equipment self-test, etc. The invention implements self-service terminal car washing based on the use of mobile Internet communication technology, and has the characteristics of wide coverage, large transmission area, strong anti-interference ability, good safety, high reliability, wide application range, and environmental protection.

Owner:袁春林

Method for processing potato chips

Owner:包海荣

Transfer method for holographic anti-counterfeiting molded film

ActiveCN102514414AExtended service lifeImprove transfer efficiencyDuplicating/marking methodsAdhesiveTitanium

The invention relates to the holographic anti-counterfeiting printing industry, in particular to a transfer method for a holographic anti-counterfeiting molded film. The invention provides the transfer method for the holographic anti-counterfeiting molded film, which can replace a pattern transfer method which is used for molding transfer of a film used by a nickel plate to form a molded film. A holographic nickel plate is produced and a titanium nitride layer is formed on a polyethylenetherephtalate (PET) base film through molding transfer and vacuum titanium plating to form a holographic titanium-film mother plate film band; and the mother plate film band and a base film band are abut-pressed at certain temperature and pressure, a coating layer part is softened in advance, ultraviolet (UV) adhesive is used for post-curing to form a holographic film, and then vacuum aluminum plating is performed to form a holographic aluminum-plated film. The transfer method for the holographic anti-counterfeiting molded film has the advantages that the original molding method that the nickel plate is required to be used as a mother plate for molding transfer is changed, the cost can be greatly saved and the molding transfer efficiency is improved.

Owner:武汉宇恩防伪技术有限公司

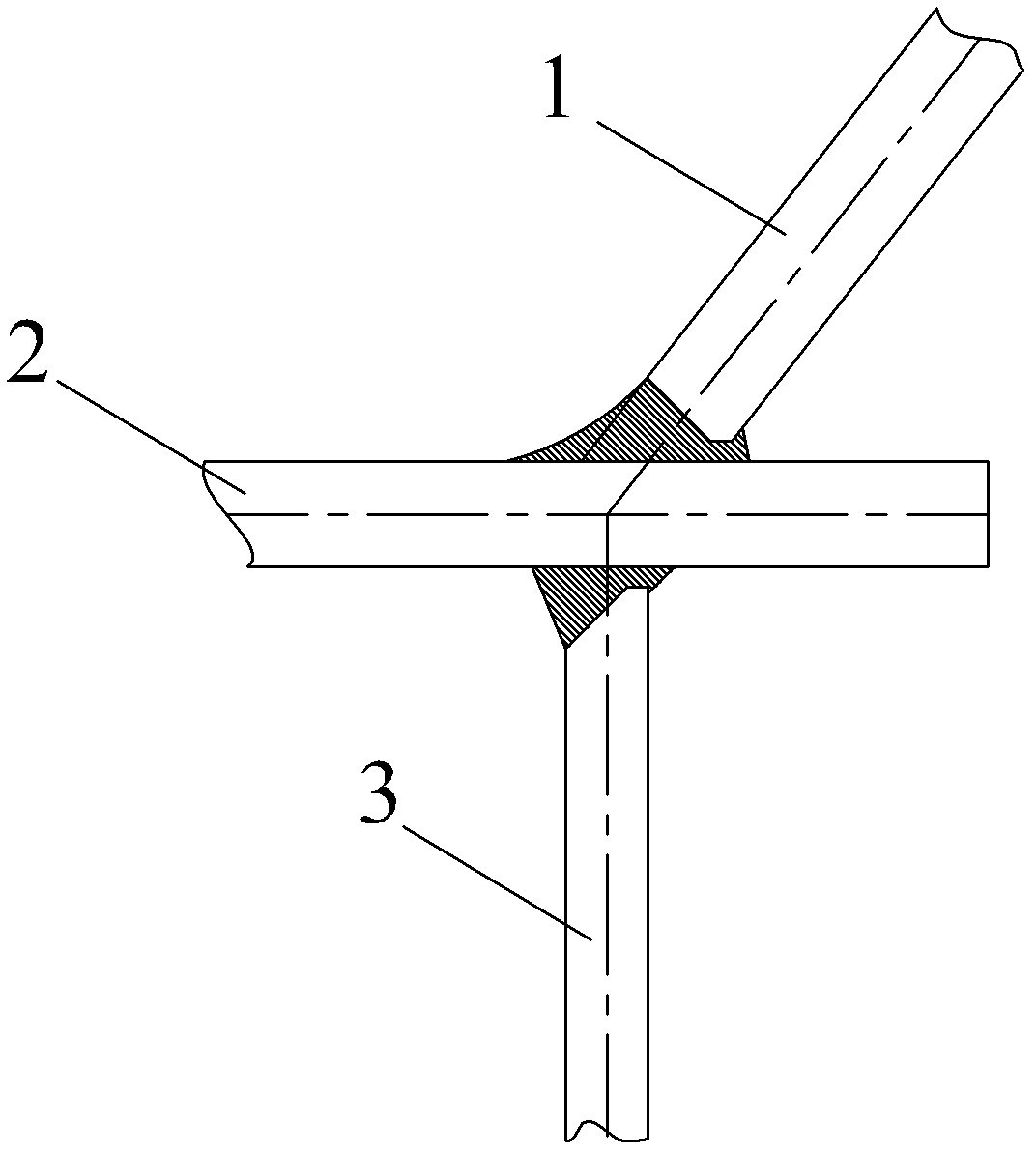

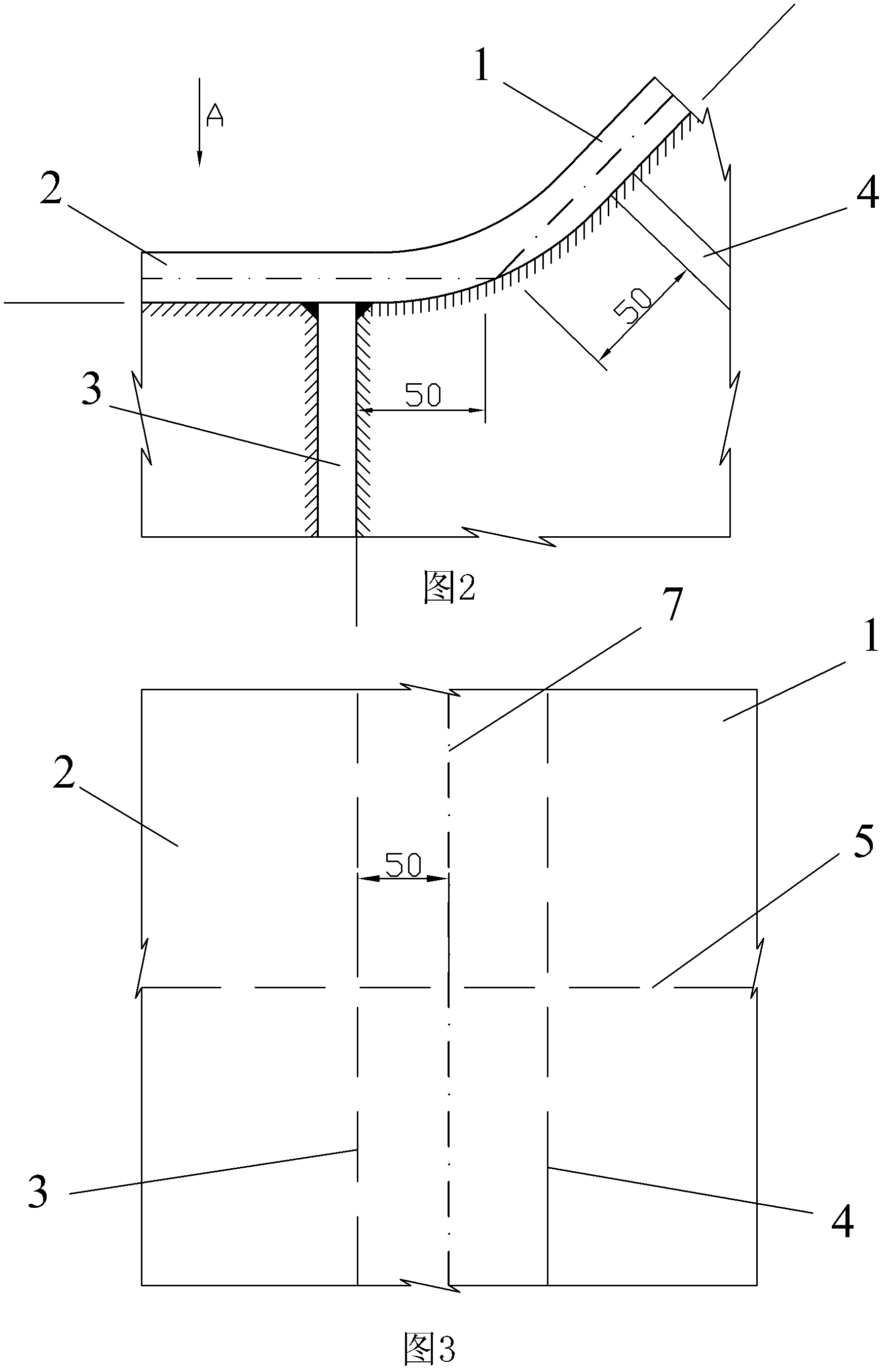

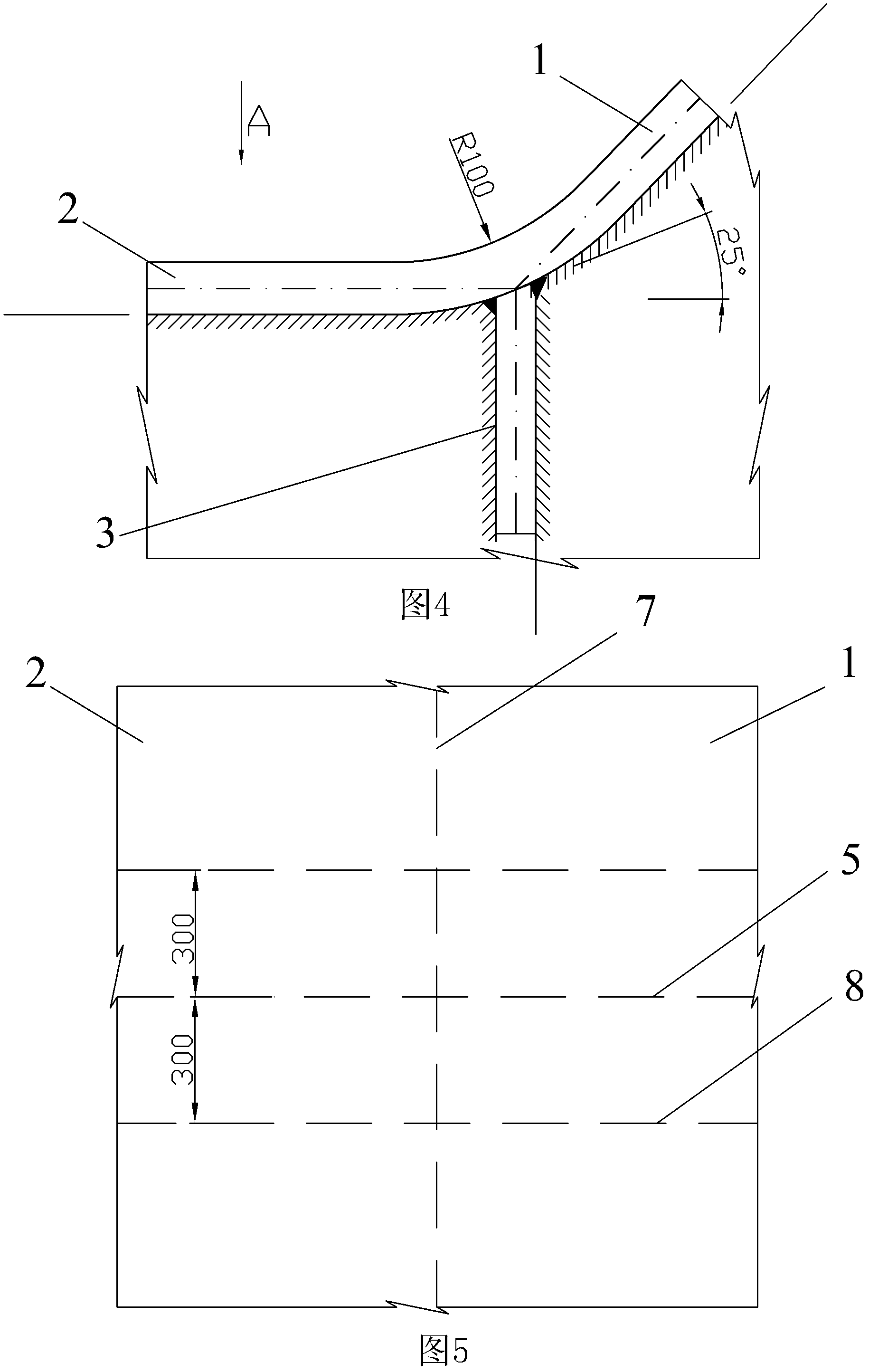

Cargo hold structure

ActiveCN103129699AImprove stress concentrationReduce welding workloadHull bulkheadsMachining processOil tanker

The invention discloses a cargo hold structure which comprises a bottom side tank inclined bottom plate (1), an inner bottom plate (2) and an inner bottom side stringer (3), wherein the lower portion of the inner bottom side stringer (3) is vertically supported. The inclined bottom plate (1) and the inner bottom plate (2) are connected through a board and by utilizing of a bent arc transition mode. The inner bottom side stringer (3) is supported below a knuckle line (7) formed by intersecting of extension planes of the inclined bottom plate (1) and the inner bottom plate (2). The cargo hold structure is especially suitable for an oil tanker cargo hold. A three-line centering and arc transition type connection structure of the bottom side tank inclined bottom plate and the inner bottom plate is mainly designed. According to the cargo hold structure, welding and polishing work load is effectively reduced. Fatigue resistance is effectively improved, at the same time, constructing and machining processes are simplified, work efficiency is improved, and the cargo hold structure has the advantages of being low in cost and high in strength.

Owner:DALIAN SHIPBUILDING IND

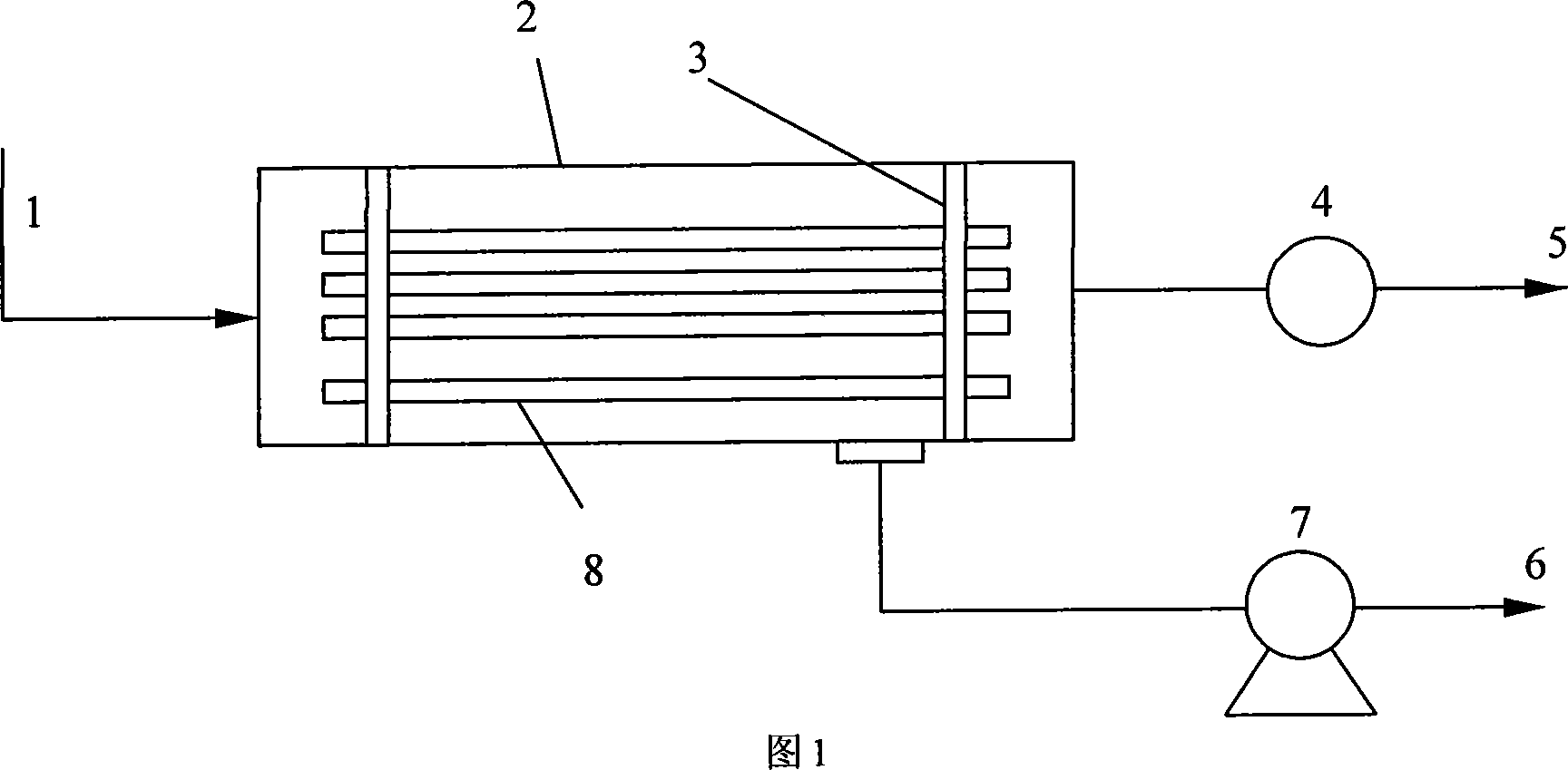

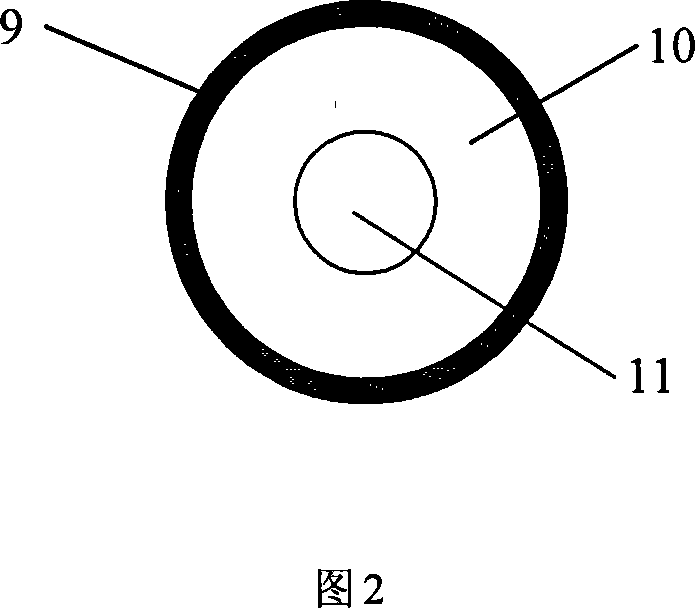

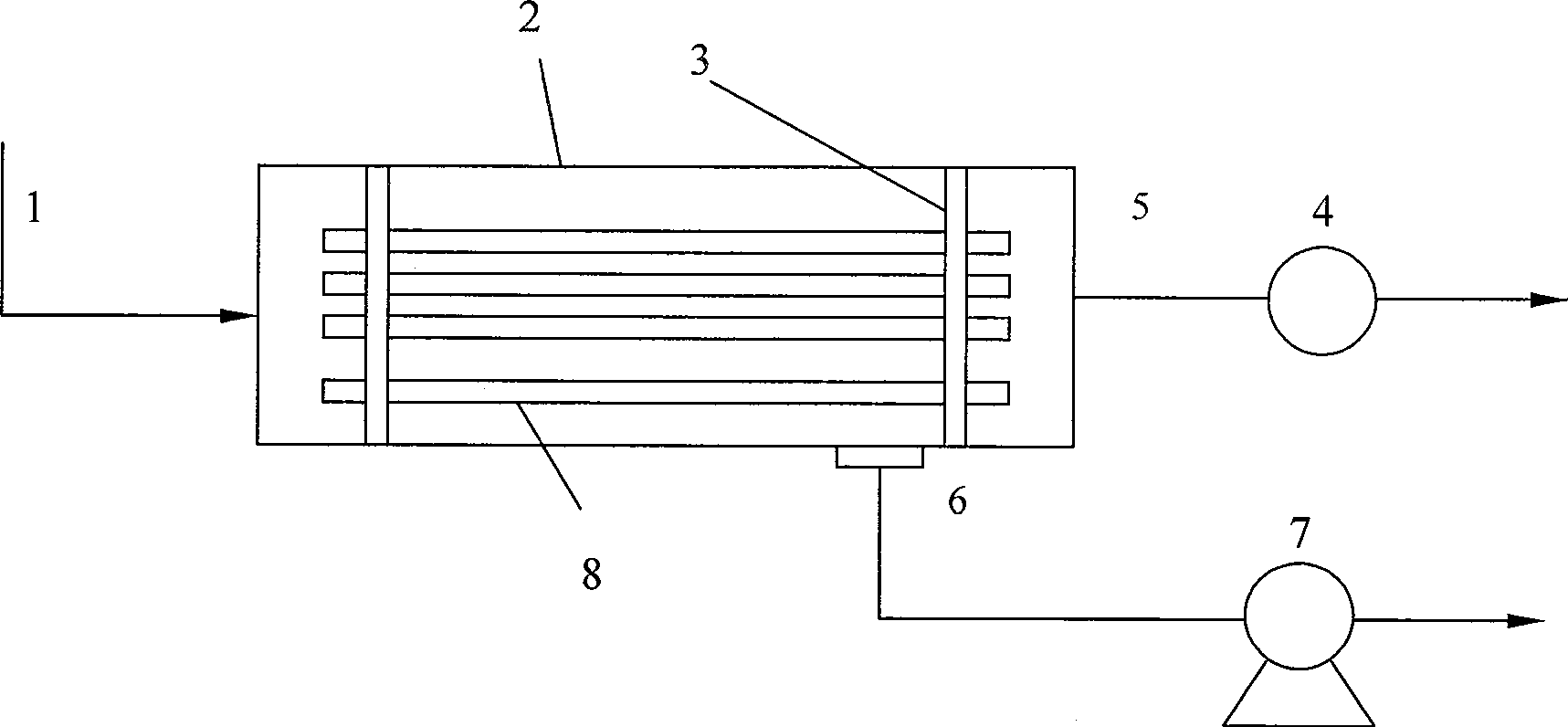

Indoor air purifying device

InactiveCN101058052ADoes not require heating to regenerateReduce energy consumptionDispersed particle filtrationEpoxyFiber

The invention relates to an indoor air purification device that comprises the air inlet, shell, air blower, air exhauster, vacuum pump and volatile organic compound outlet, with hollow fiber inside the shell, epoxide resin roll end separating the hollow fiber into shell and tube, forming into a tubular heat exchanger, the said air inlet connected with one end of the shell, which connects with the vacuum pump, volatile organic compound outlet connected with the vacuum pump, the other end of the wind blower connected with the other end of the shell and connected to the wind blower, indoor volatile organic permeated into the tube and the shell under the drawing force of the vacuum pump, exhausting the said volatile organic compound through its outlet. It can effectively remove most of the volatile organic compound with efficiency over 80%. It is more efficient, energy economical and environmental protective.

Owner:SOUTH CHINA UNIV OF TECH

Direct energy storage type refrigerating and heating device

ActiveCN102410659ARapid coolingHeating up fastMachines using electric/magnetic effectsCooling fluid circulationProcess engineeringRefrigerated temperature

The invention discloses a direct energy storage type refrigerating and heating device, which comprises a main body, wherein a temperature adjusting unit for containing beverage and an enclosed energy storage chamber for loading energy storage liquid are arranged on the main body; the temperature adjusting unit is separated from the enclosed energy storage chamber; the enclosed energy storage chamber is arranged around the temperature adjusting unit; and a semiconductor dynamic refrigerating / heating device for heating or refrigerating the energy storage liquid in the enclosed energy storage chamber is arranged on the main body. Therefore, when the direct energy storage type refrigerating and heating device is used, the beverage only needs to be directly or indirectly arranged in the temperature adjusting unit through a container, cold energy or hot energy stored in the energy storage liquid can be in directly contact with the beverage, the energy storage liquid is continuously refrigerated or heated by cooperatively utilizing the semiconductor dynamic refrigerating / heating device, so that the beverage is rapidly cooled or heated, therefore, refrigerating or heating efficiency on the beverage is effectively improved, and equipment, such as a refrigerator, an electric heater and the like are unnecessarily required; and the direct energy storage type refrigerating and heating device is very convenient to use.

Owner:开平精锐电子有限公司

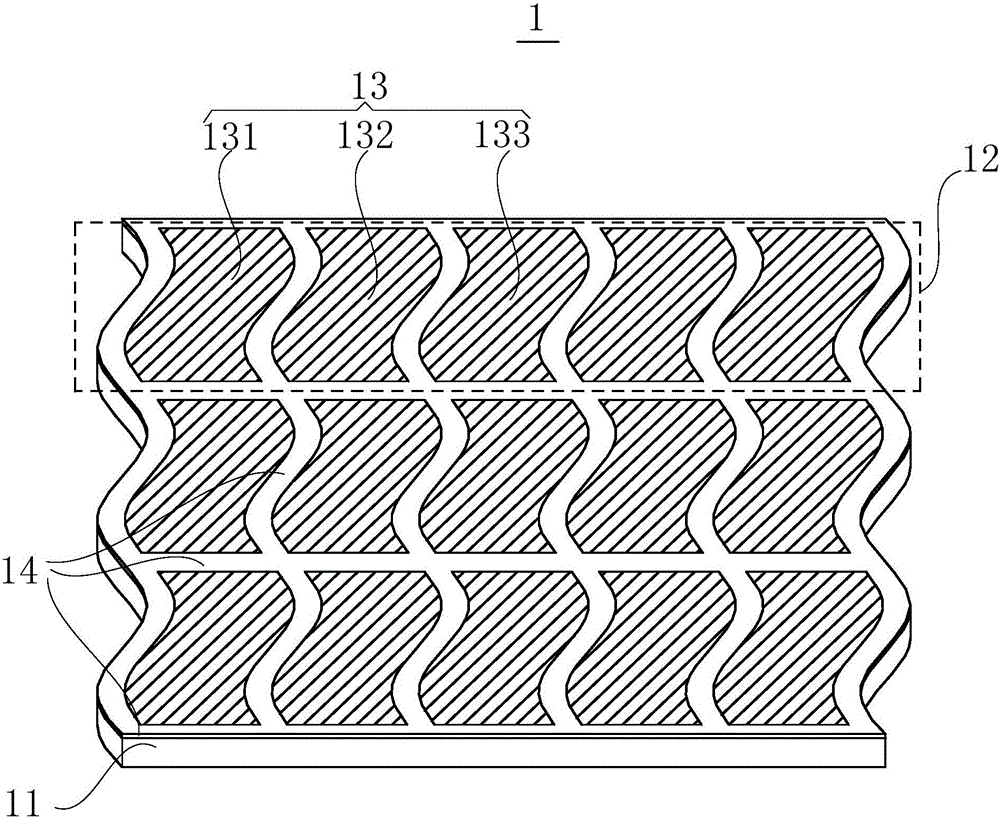

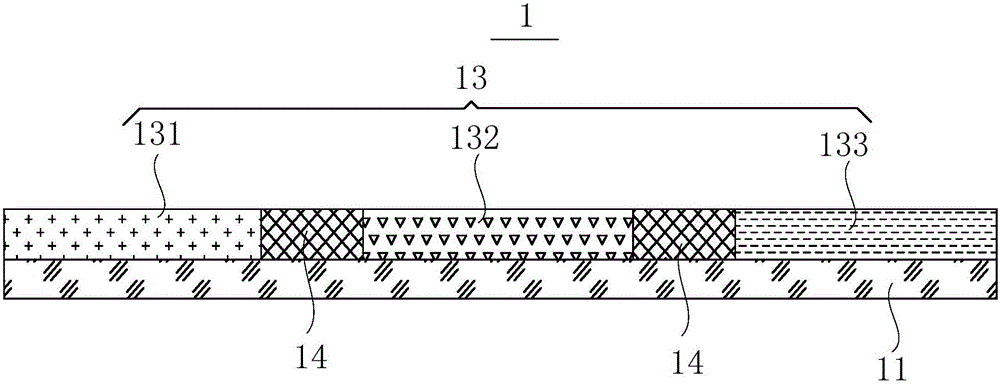

Color film substrate, array substrate, display panel and display device

InactiveCN105700220ALarge transfer areaImprove fidelityOptical filtersNon-linear opticsColor filmDisplay device

The invention discloses a color filter substrate, an array substrate, a display panel and a display device, and belongs to the technical field of displays. The color filter substrate includes: a first substrate, and at least one row of color filter layers arranged on the first substrate; each row of color filter layers includes a plurality of filters arranged side by side, and each filter is curved Structure; any two adjacent color filters in the same row of color filter layers have different colors and there is a light-blocking strip edge with a curved structure between the two adjacent color filters. The color filter substrate includes a plurality of optical filters arranged side by side on the first substrate, and the shape of the optical filters is a curved structure, and the light section formed on the optical filter is a curved structure, so that for each color Light, the intersection area between this color light and its adjacent color light is larger, which improves the color mixing effect.

Owner:BOE TECH GRP CO LTD +1

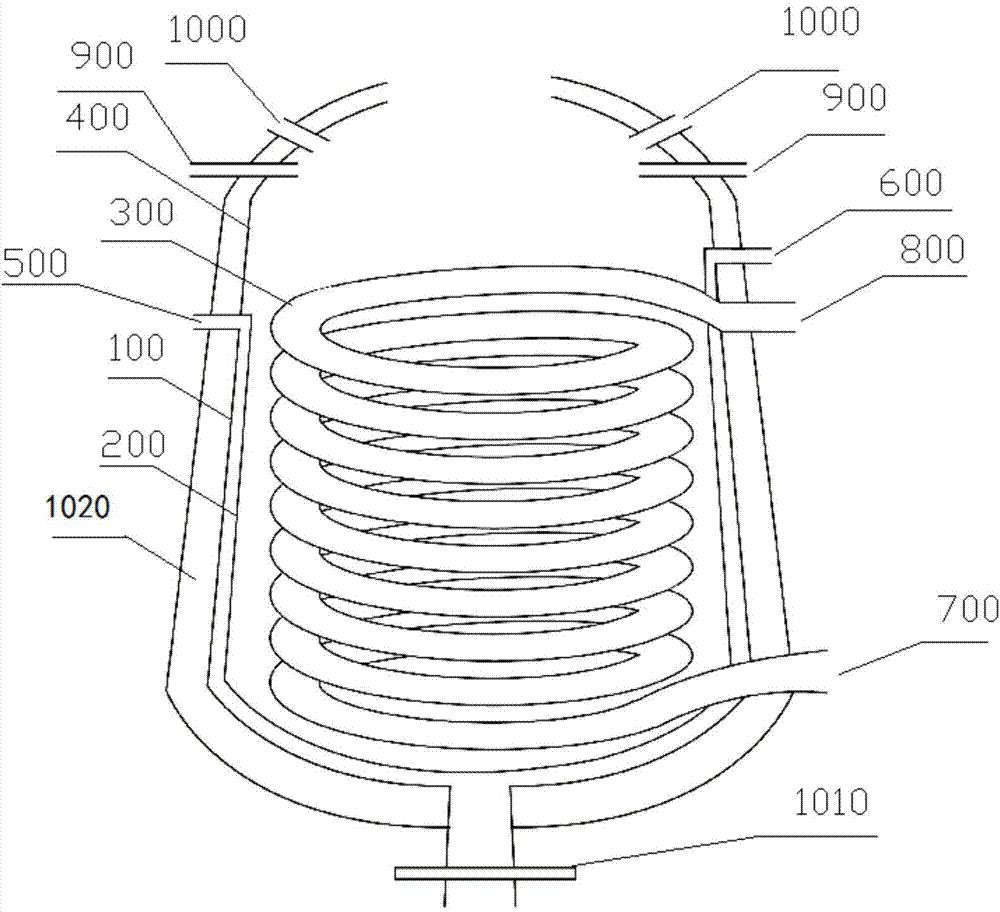

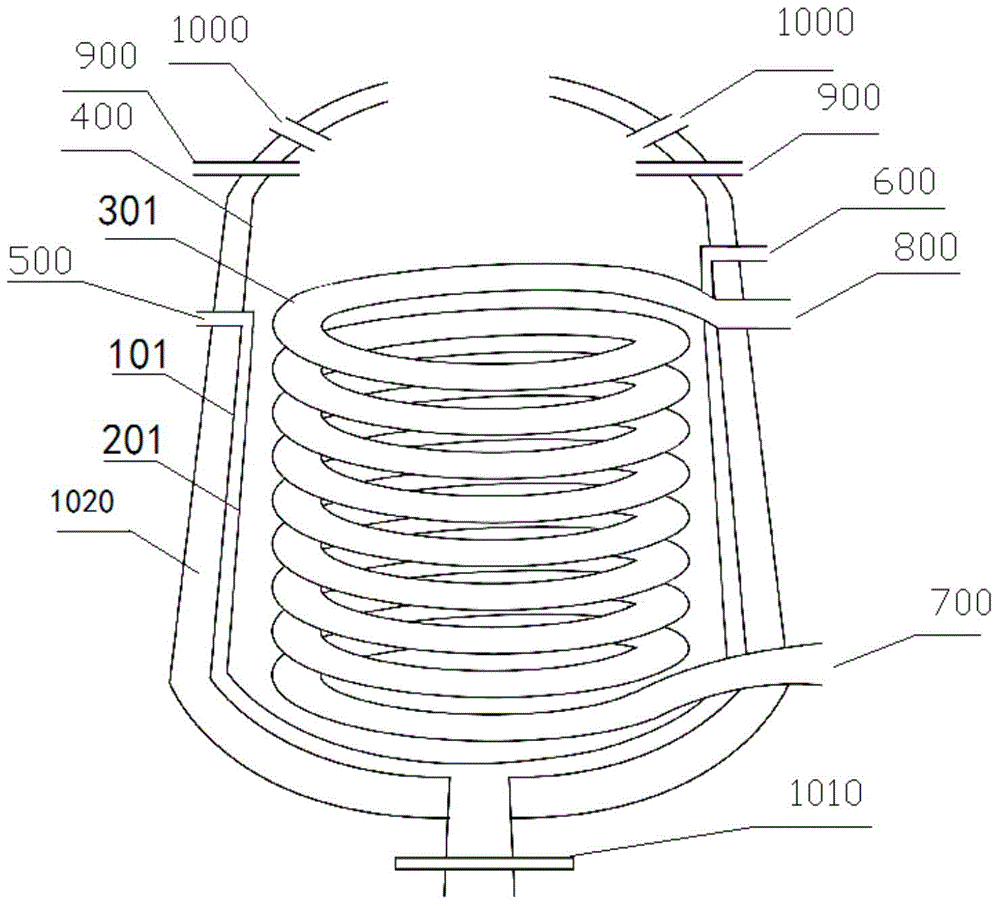

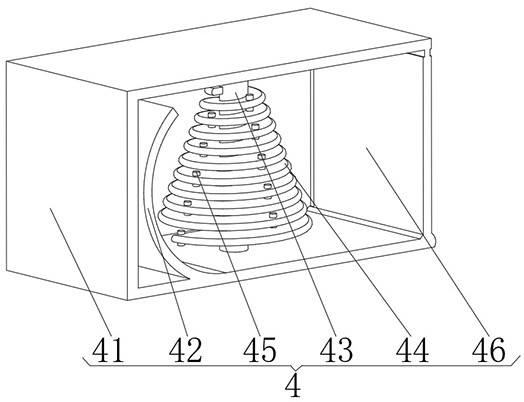

Heating device

InactiveCN104492352ALarge transfer areaHeating evenlyDistillation in boilers/stillsChemical/physical/physico-chemical processesEngineeringFractional distillation

The invention discloses a heating device. The heating device comprises a fractional distillation kettle body, a first jacket layer, a second jacket layer and a coiled pipe, wherein the first jacket layer, the second jacket layer and the coiled pipe are arranged inside the fractional distillation kettle body, the first jacket layer and the second jacket layer commonly form a hollow cavity for containing conduction oil, two ends of the hollow cavity are provided with a conduction oil inlet and a conduction oil outlet respectively, the oil inlet and the oil outlet penetrate out of the fractional distillation kettle body and are fixed on the fractional distillation kettle body, the oil outlet is higher than the oil inlet in position, two ends of the coiled pipe are provided with a conduction oil inlet and a conduction oil outlet, the conduction oil inlet and the conduction oil outlet penetrate out of the fractional distillation kettle body and are fixed on the fractional distillation kettle body, and the conduction oil outlet is higher than the conduction oil inlet in position. Compared with the bottom heating mode, the heating device has large heat transfer area and can heat uniformly.

Owner:云南华香源香料有限公司

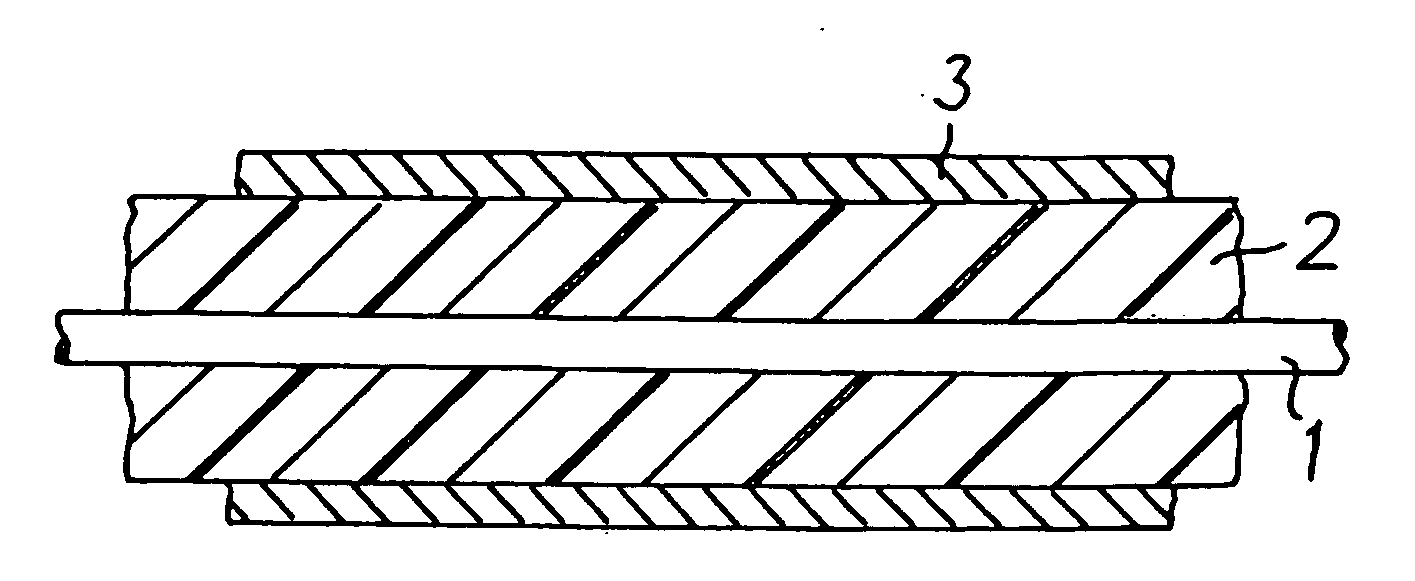

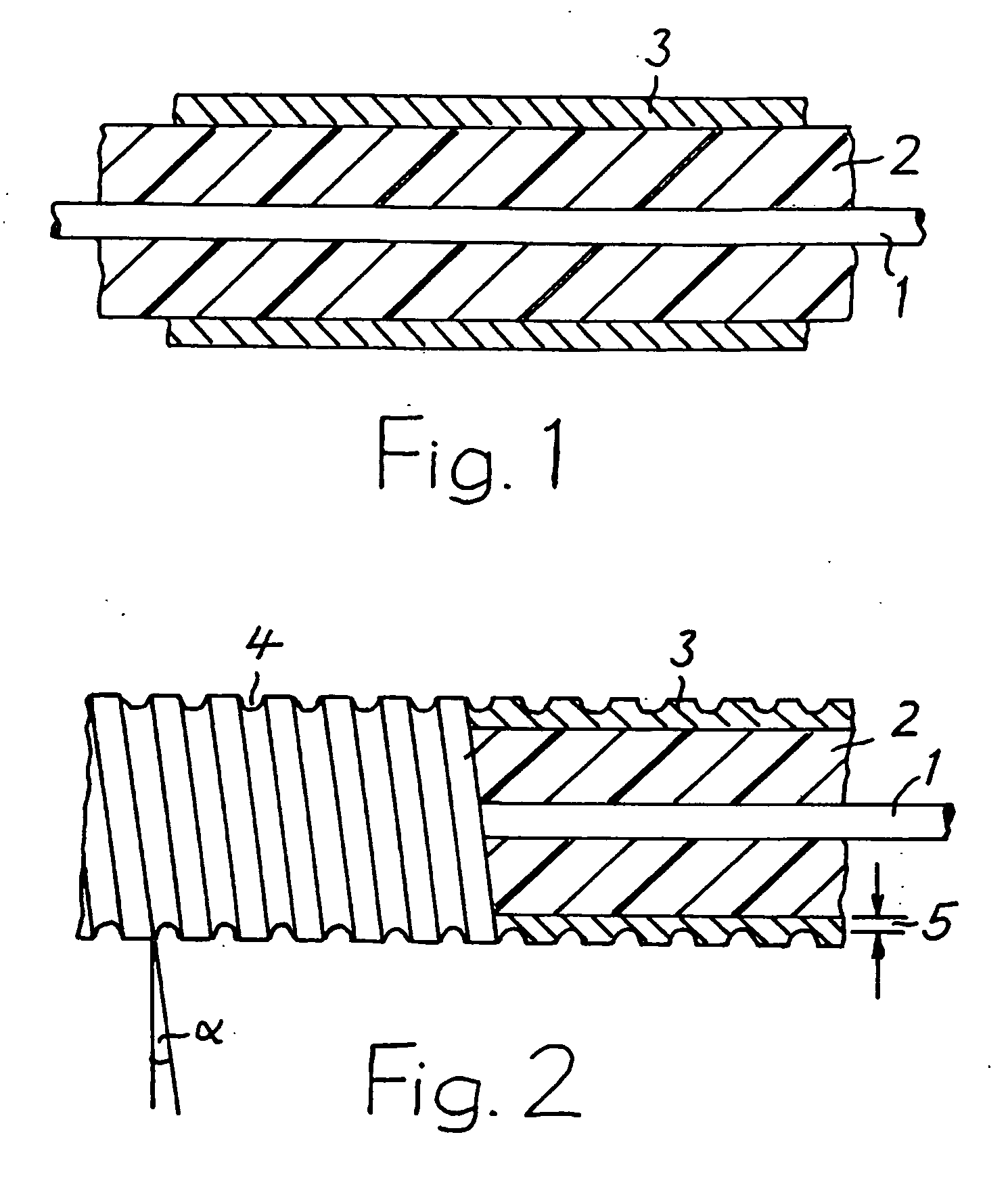

Temperature-resistant electrical line

InactiveUS20090183892A1Ensure stabilityHigh transverse stabilityPower cables with screens/conductive layersInsulated cablesEngineeringElectrical conductor

A temperature-resistant electrical line comprises at least one central electrical conductor, an insulation, which is made from a mineral material and surrounds the electrical conductor completely, and a metallic outer tube, which bears against the insulation. The outer tube (3) has, over its entire length, a helical notch (4), which is open to the outside, and which is produced once the line is finished by means of a metal-removing tool and whose depth is at least 50% of the wall thickness of the outer tube (3), with a residual wall thickness (5) which ensures the stability thereof.

Owner:ZIEMEK CABLE TECH

Recycling heat transfer system

InactiveCN104390353ALarge transfer areaHeating evenlyStorage heatersFractionationPetroleum engineering

The invention discloses a recycling heat transfer system comprising a heat-transfer oil furnace and a heat-transfer oil utilization device. The heat heat-transfer oil furnace comprises a heat-transfer oil containing unit, a hot oil outlet pipe and a cold oil inlet pipe. The hot oil outlet pipe and the cold oil inlet pipe are connected with the heat-transfer oil containing unit. The heat-transfer oil utilization device comprises a fractionation still body, a first jacket layer, a second jacket layer and a coil. The first jacket layer, the second jacket layer and the coil are arranged in the fractionation still body. A hollow chamber is formed in a place between the first jacket layer and the second jacket layer, with an oil inlet nozzle and an oil outlet nozzle provided in two ends thereof. The oil inlet nozzle and the oil outlet nozzle penetrate and are fixed onto the fractionation still body. A heat-transfer oil discharge outlet is arranged upon a heat-transfer oil feed inlet. Two ends of the coil are formed into a heat-transfer oil inlet nozzle and a heat-transfer oil outlet nozzle which penetrate the fractionation still body to be fixed onto the same. The heat-transfer oil outlet nozzle is arranged upon the heat-transfer oil inlet nozzle. The heat-transfer oil feed inlet and the heat-transfer oil inlet nozzle are connected with the hot oil outlet pipe. The heat-transfer oil discharge outlet and the heat-transfer oil outlet nozzle are connected with the cold oil inlet pipe. By the use of the recycling heat transfer system, efficiency is improved.

Owner:云南华香源香料有限公司

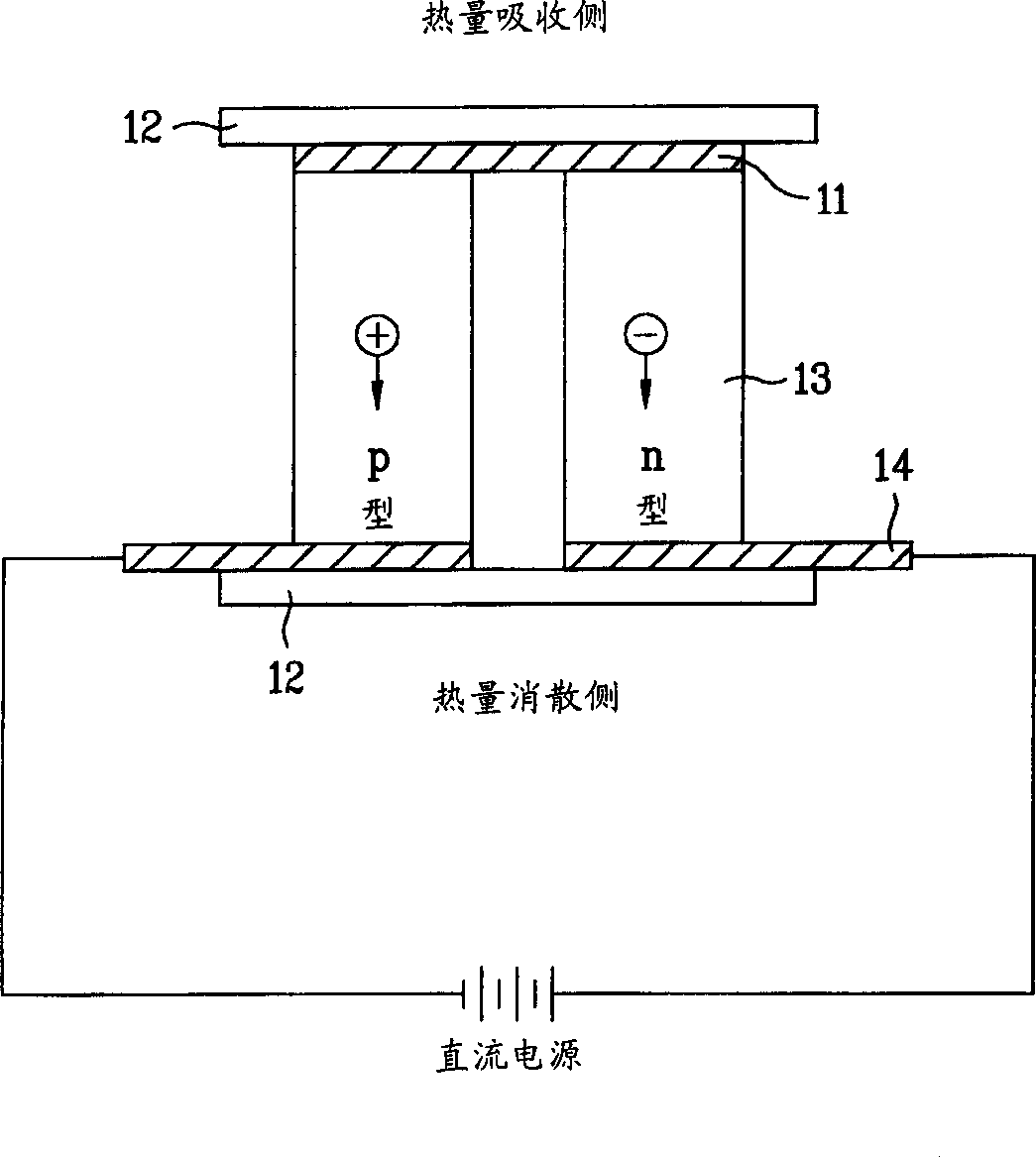

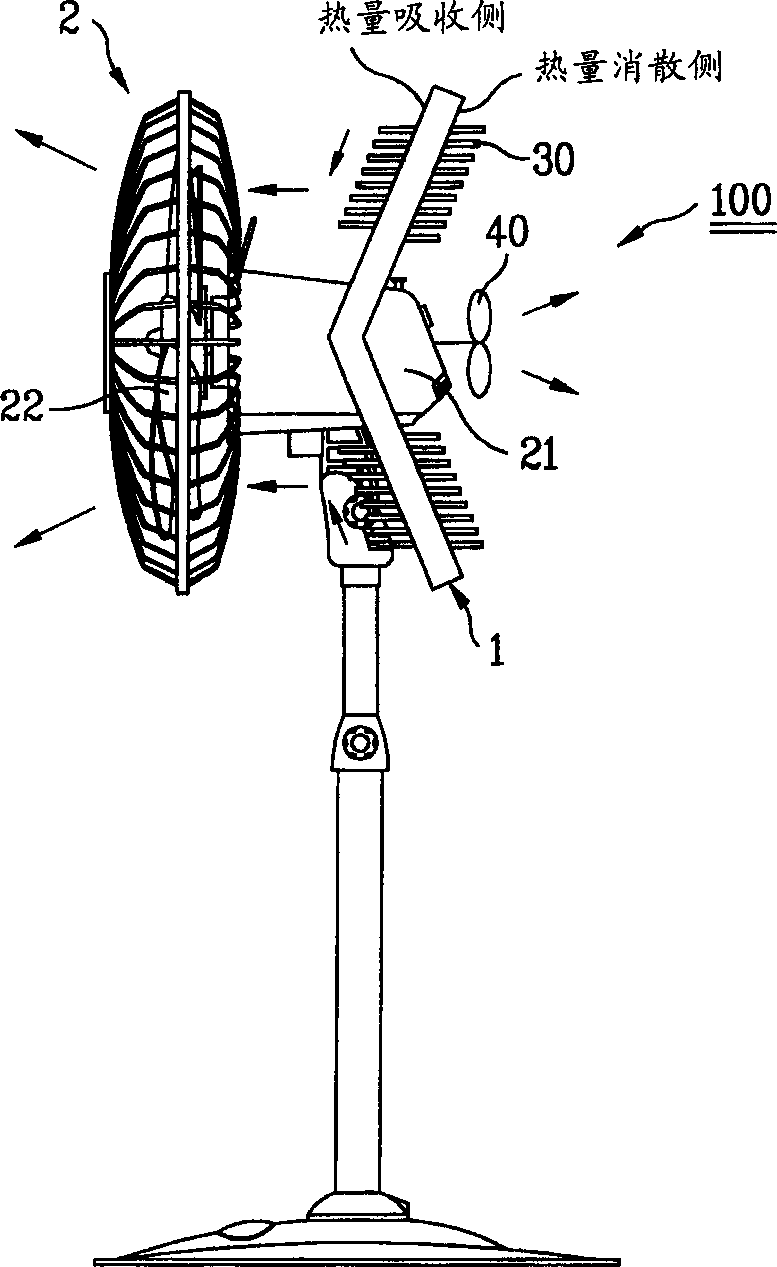

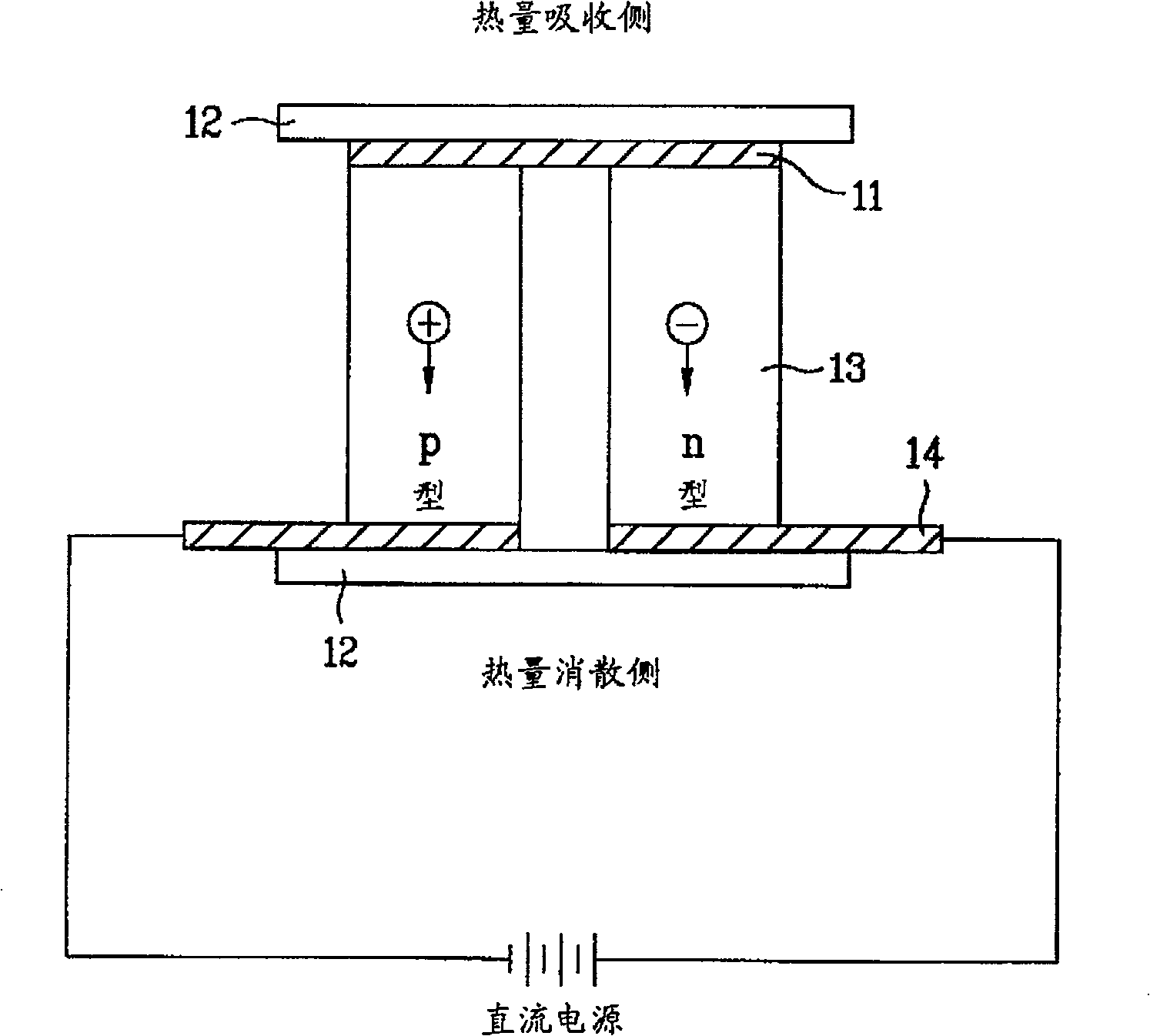

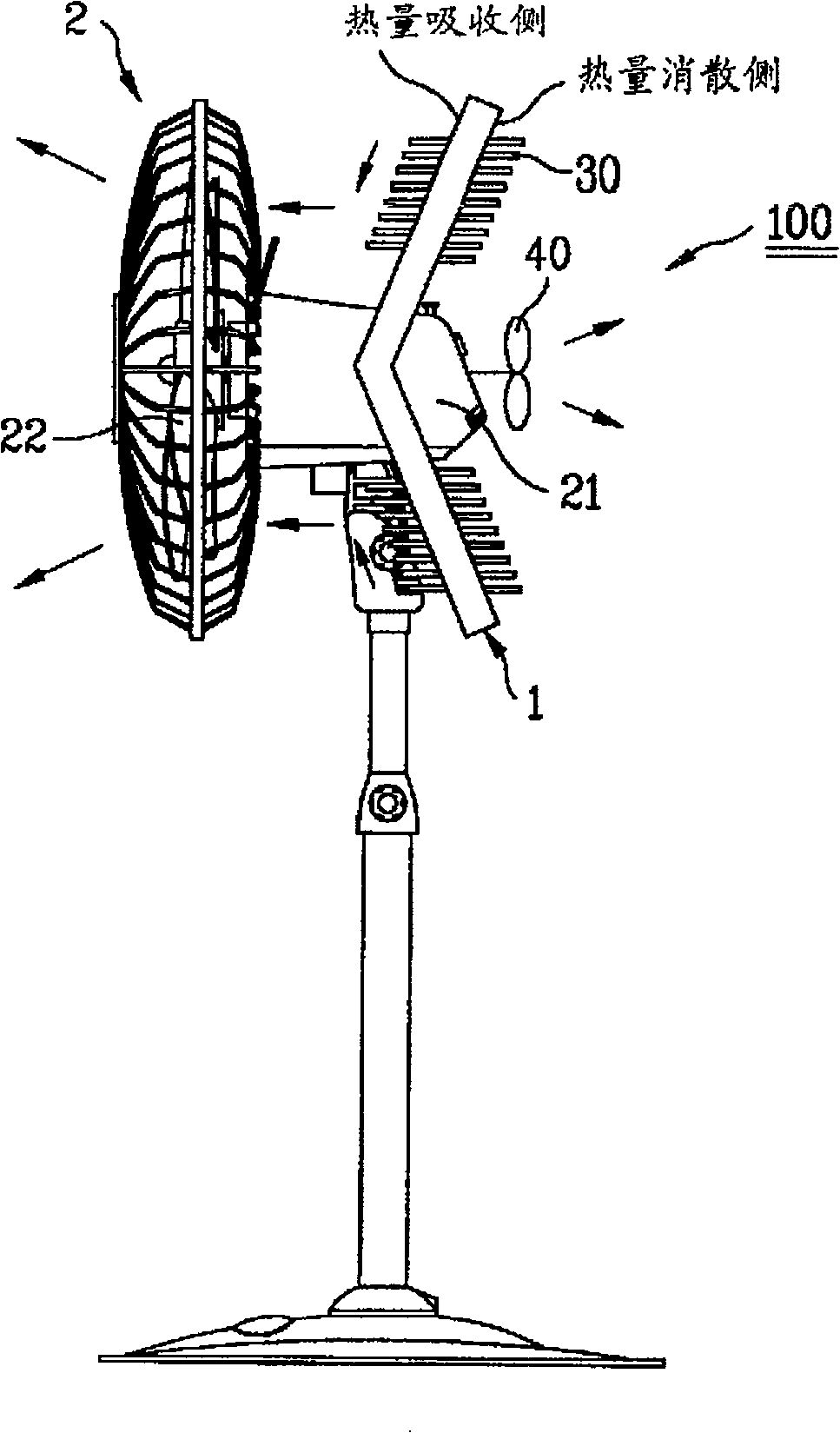

Thermoelectric cooler

InactiveCN1364994AImprove cooling efficiencyReduce manufacturing costPump componentsIndirect heat exchangersThermoelectric coolingLow noise

The present invention relates to a thermoelectric cooler, and more particularly, to a thermoelectric cooler, in which a thermoelectric module is applied to a blow system of a fan blade set and a motor, for converting a current blow system into a blow system having a cooling function with a low noise. To do this, the present invention provides a thermoelectric cooler including a thermoelectric module having thermoelectric elements each for absorbing or dissipating a heat at a junction of two different metal depending on a direction of a current flowing through the junction, a fan blade set for blowing air cooled at a heat absorption side of the thermoelectric module to a desired place, and a motor for giving a rotating force to the fan blade set.

Owner:LG ELECTRONICS INC

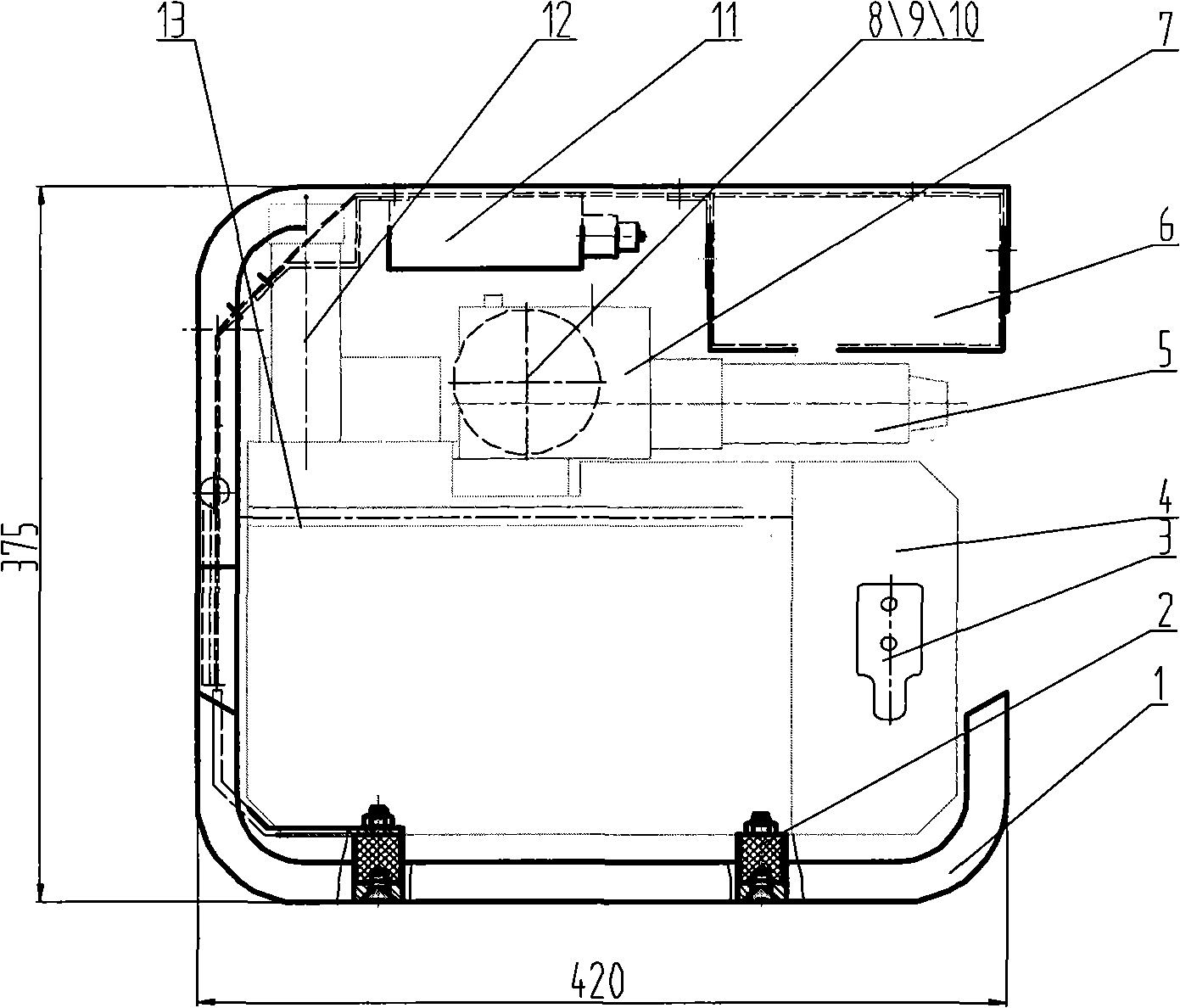

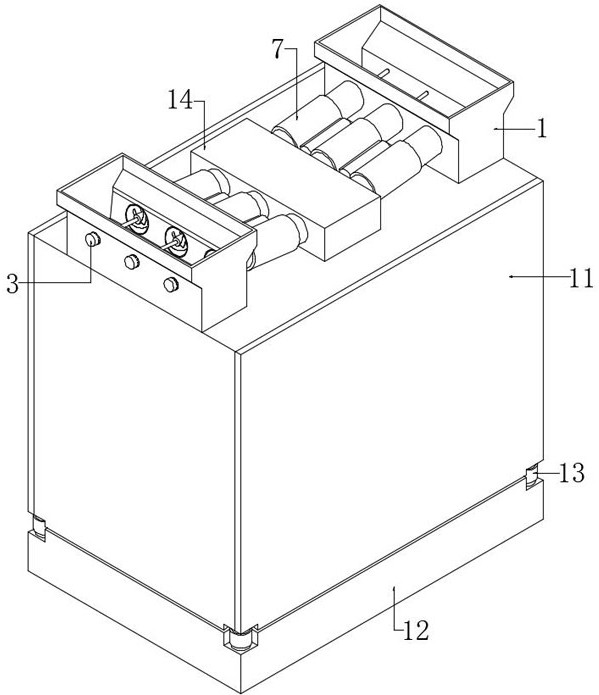

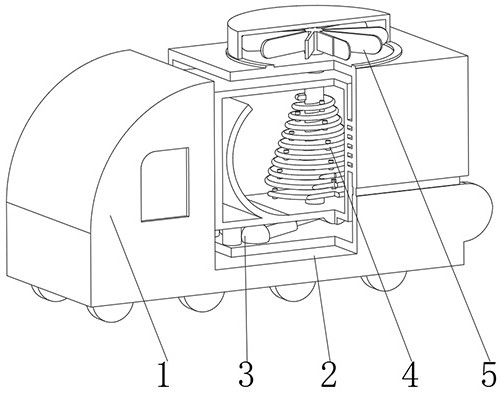

Hydraulic electric pump station

InactiveCN101539161AImprove lubrication conditionsExtended service lifeServomotorsUltra high pressureMachine parts

The invention provides an ultra-high pressure hydraulic electric pump station which consists of an electric motor (4), a hydraulic pump (13), a rack (1), an anti-vibration pad (2), an oil filling tube (12), a hydraulic manifold block (7 ), a filter (8), a pressure regulating valve (9), an unloading valve (10), a pressure gauge (11), an electrical box (6), a solenoid directional valve (5) and an operating handle (3); and the machine parts have excellent performance and good cooling effect and can work for a long term.

Owner:北京海泰斯工程设备股份有限公司

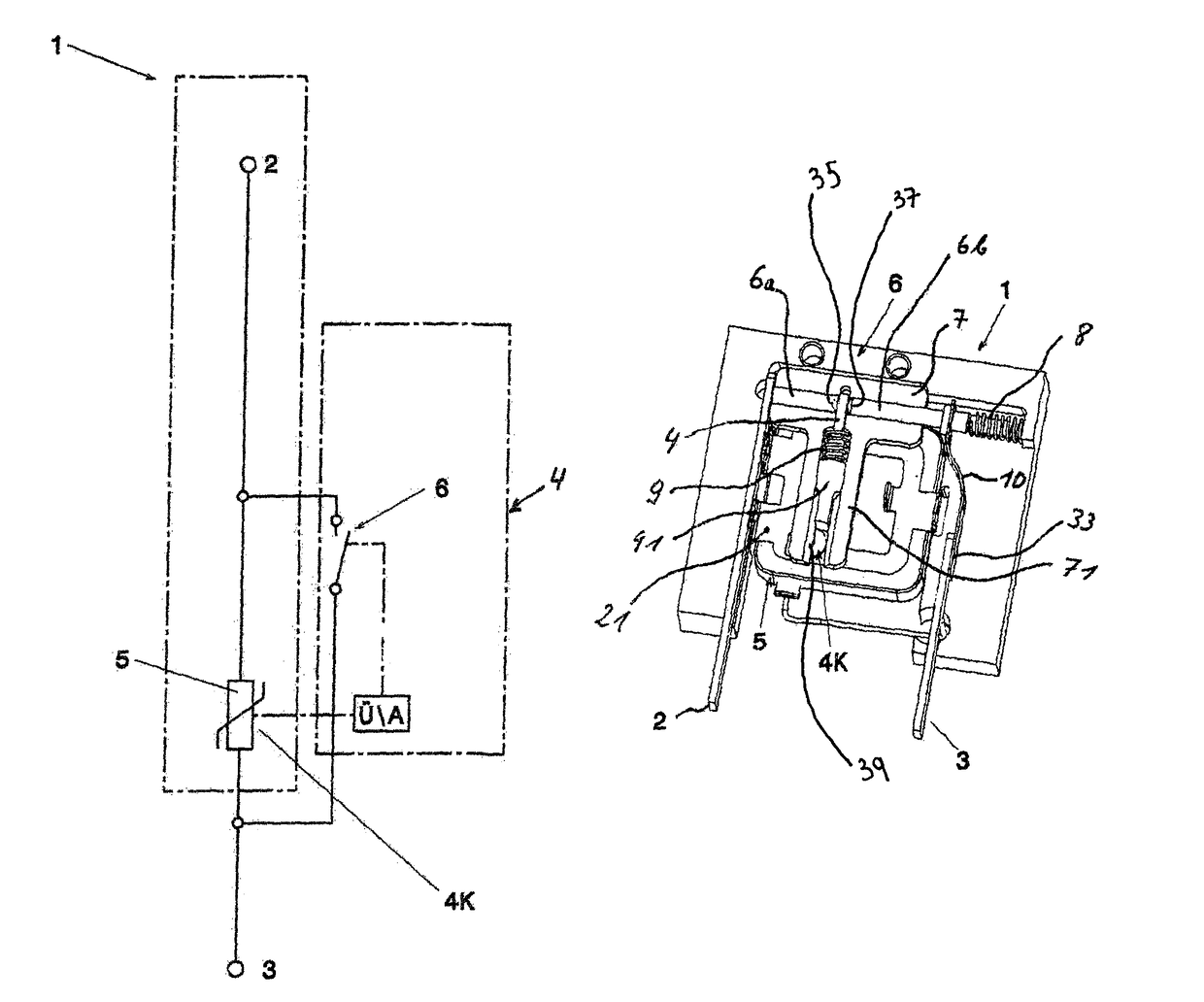

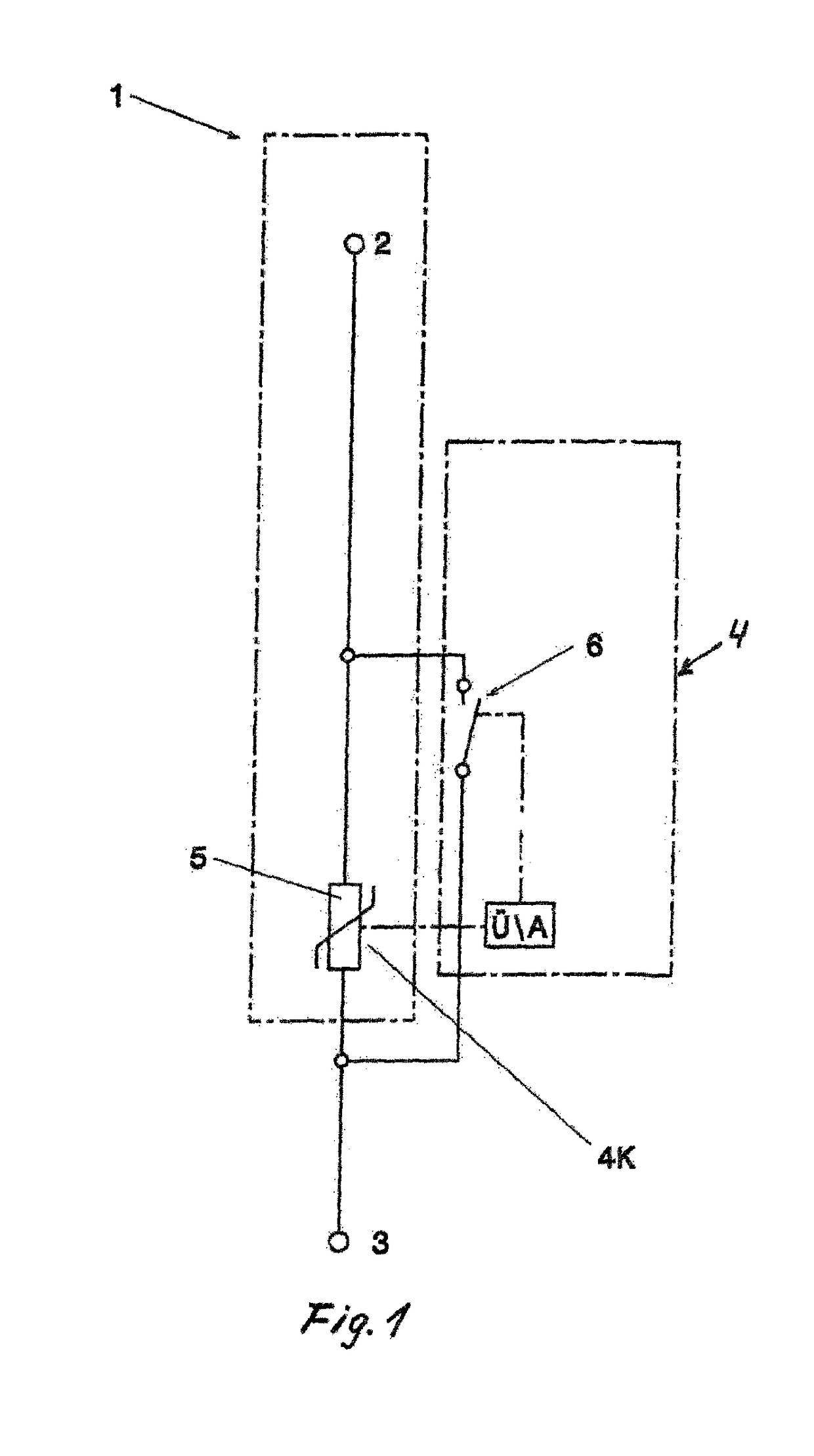

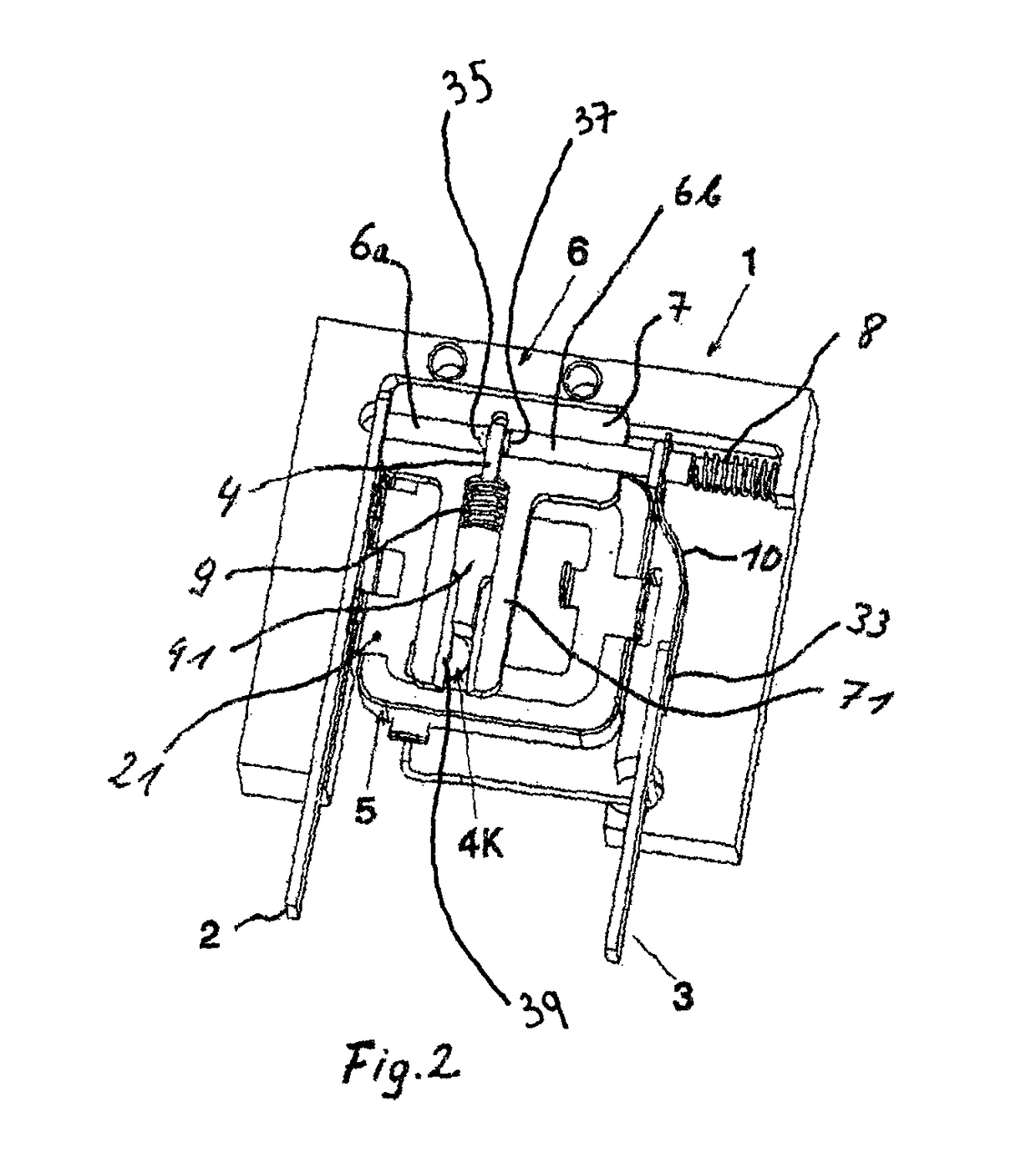

Surge protection device, comprising at least one surge arrester and one short-circuit switching device which is connected in parallel with the surge arrester, can be thermally tripped and is spring-pretensioned

ActiveUS10014098B2Enlarge current transfer areaReduce transmission resistanceSpark gap detailsSwitch operated by excess voltagePower flowPhysical unit

The invention relates to a surge protection device, comprising at least one surge arrester and one short-circuit switching device which is connected in parallel with the surge arrester, can be thermally tripped and is spring-pretensioned, wherein the abovementioned means form one physical unit. The thermal tripping means is arranged in the region where heating of the surge arrester is expected when it is overloaded, and operating or surge current does not flow through said thermal tripping means. The thermal tripping means is in the form of a stop part which releases an unlocking slide of the switching device in the event of thermal overload. The switching device has two opposite contact pieces, wherein at least one of the contacts is of moveable design and is under spring pretension in the closing direction of the switching device. The opening state of the switching device is maintained by the unlocking slide, which is released by the thermal tripping means to close the switching device.

Owner:DEHN SOHNE GMBH CO KG

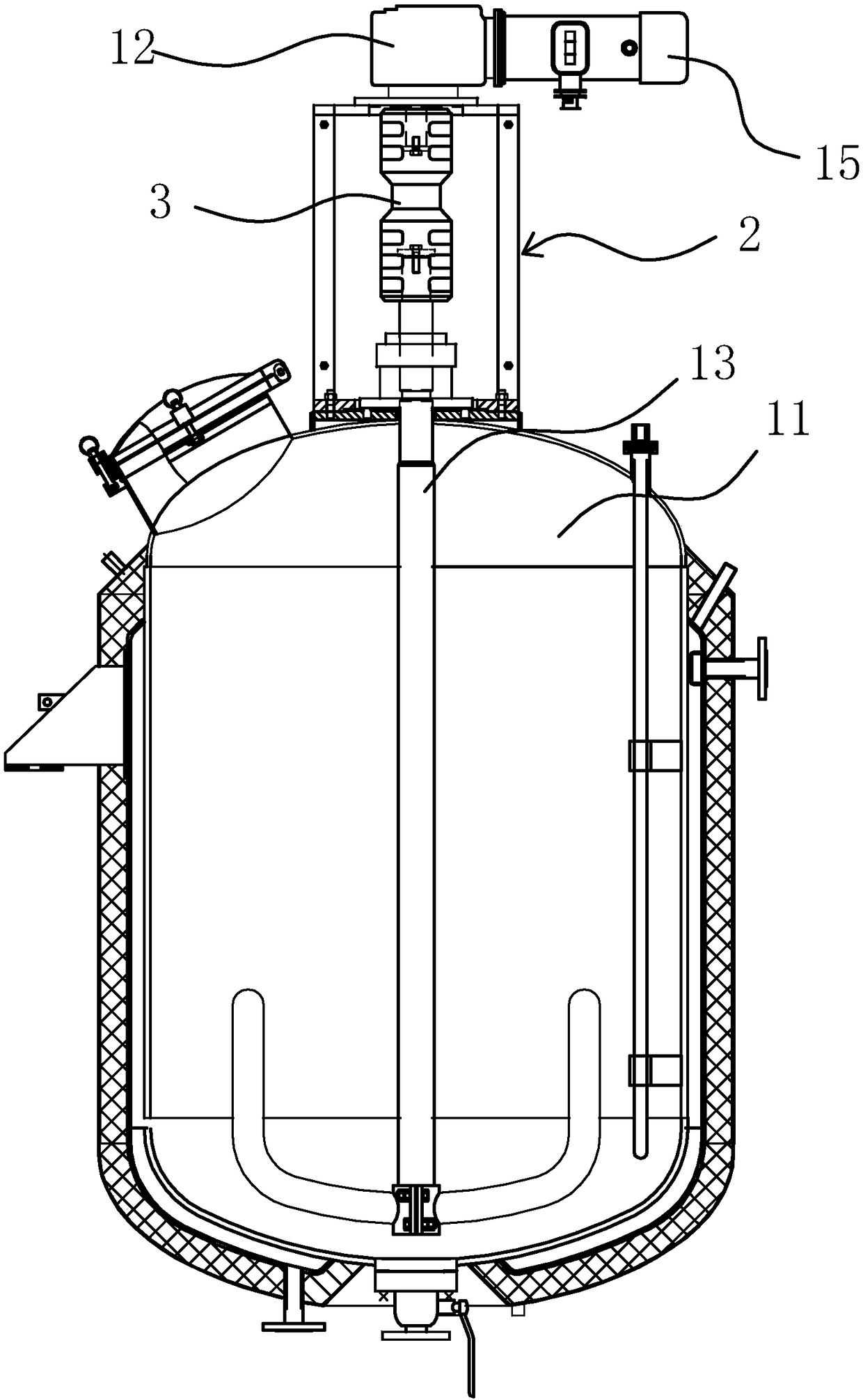

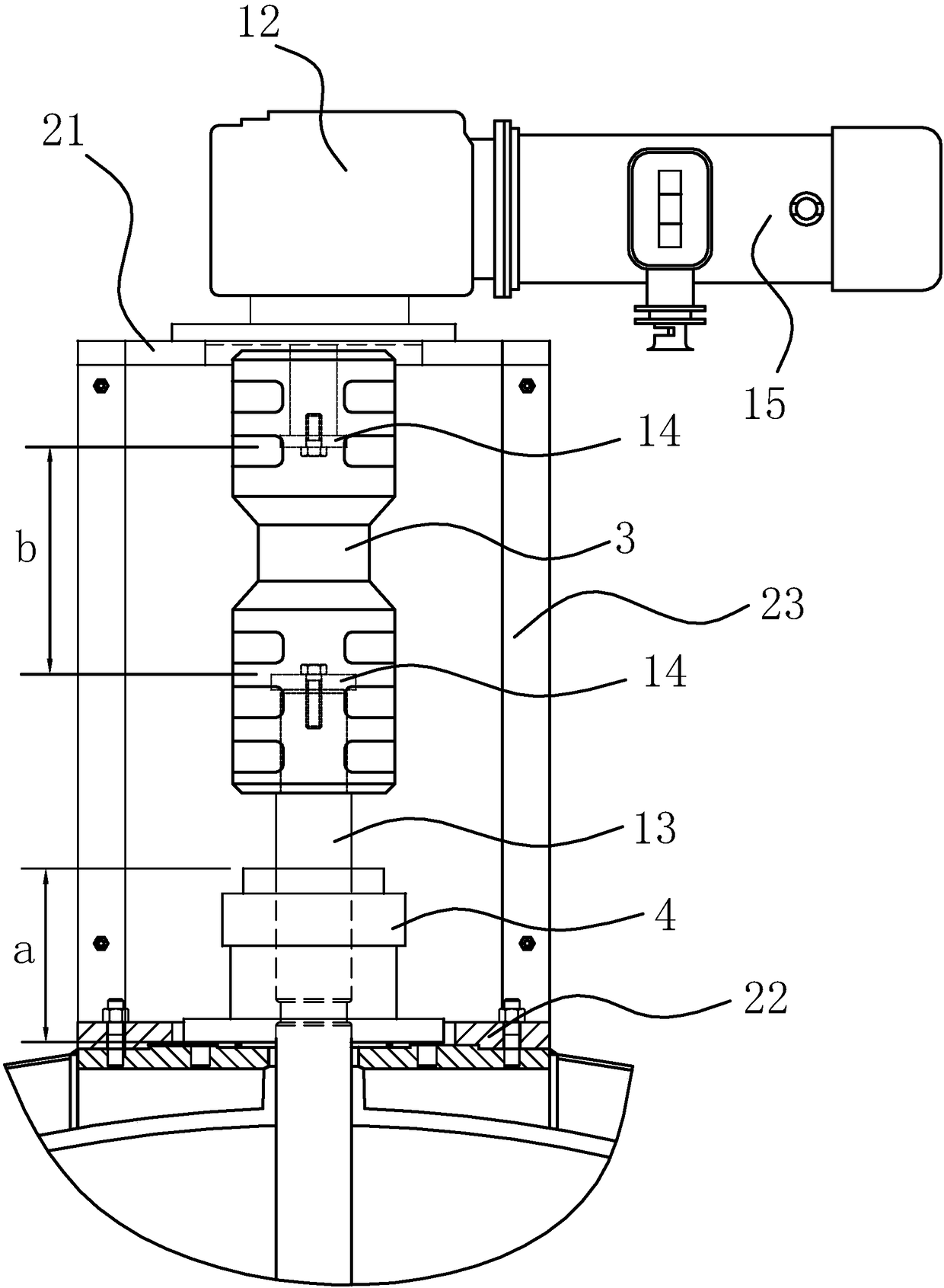

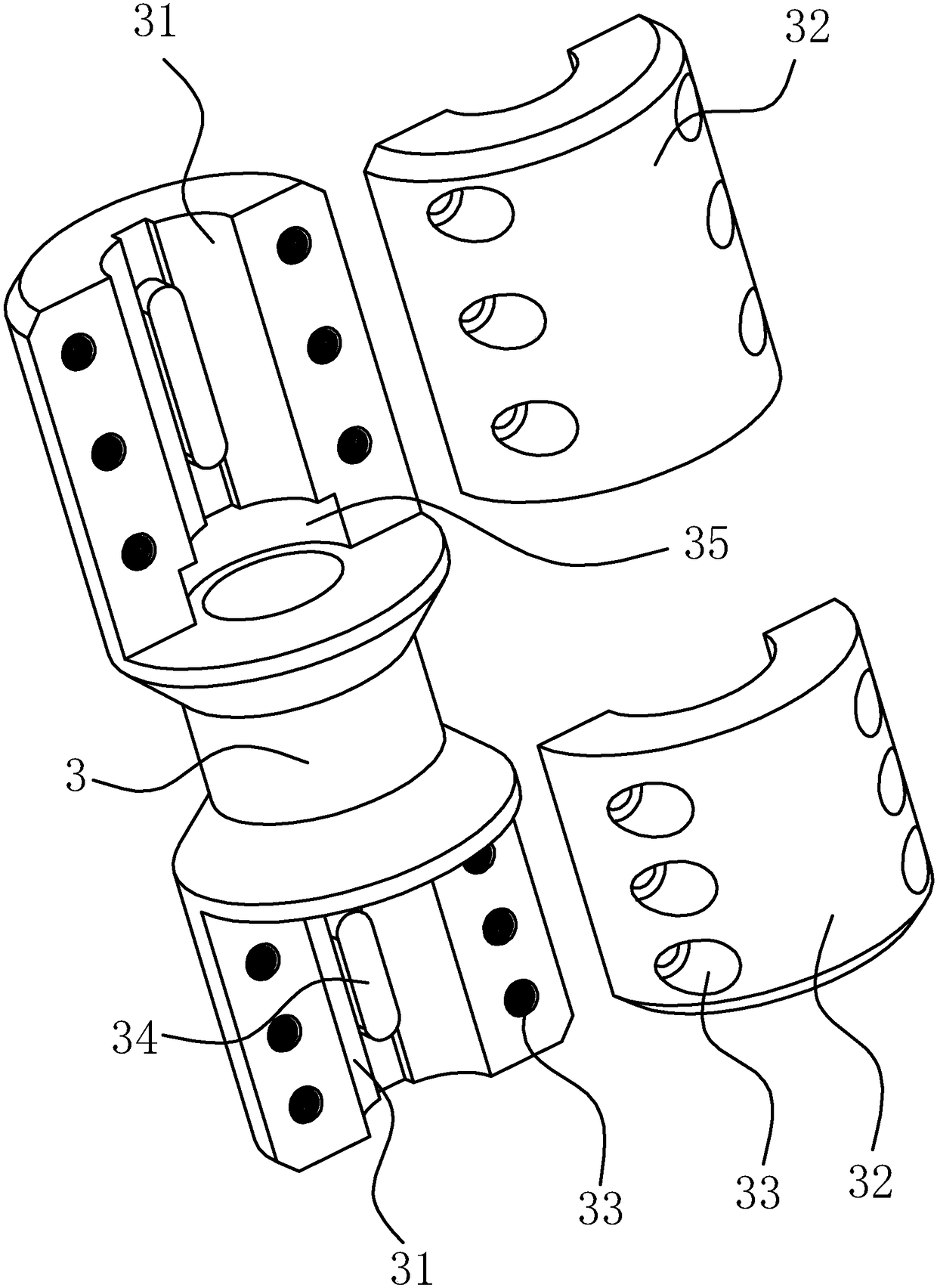

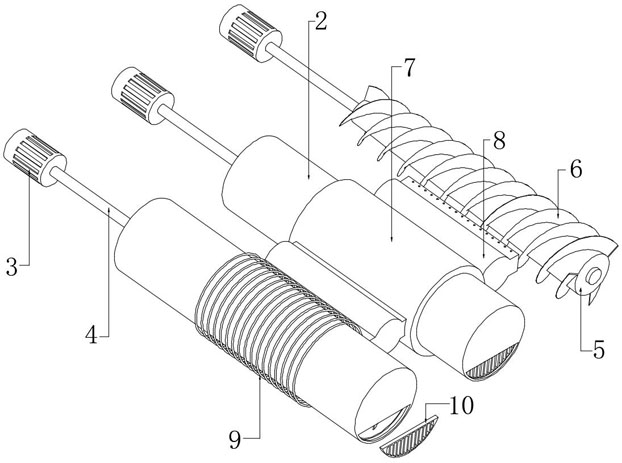

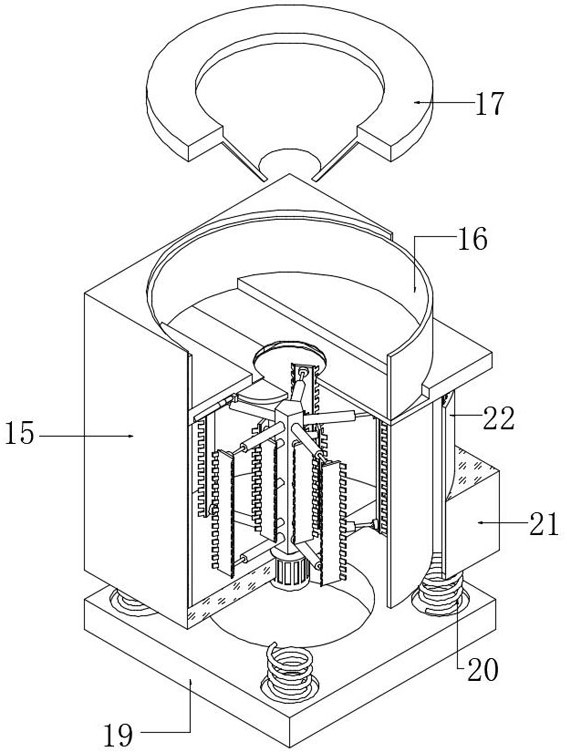

Agitating kettle with mechanical seal convenient to change

PendingCN108479596ALarge transfer areaStable structureRotary stirring mixersTransportation and packagingReducerEngineering

The invention provides an agitating kettle with a mechanical seal convenient to change, which belongs to the technical field of machinery and solves the technical problem of inconvenient replacement of existing mechanical seals. The agitating kettle comprises a kettle body, wherein a machine frame is arranged on the kettle body, a speed reducer is arranged on the machine frame, a stirring shaft isarranged on the kettle body in a penetrating manner, and a gap with width larger than the thickness of the mechanical seal is formed between the end part of the stirring shaft and the output end of the speed reducer, a connecting member is arranged between the end part of the stirring shaft and the output end of the speed reducer, a first clamping portion and a second clamping portion, which aredetachably connected with each other, are arranged at each end of the connecting member, and the first clamping portion and the second clamping portion at one end of the connecting member radially clamp the end part of the stirring shaft and form axial and radial clamping connection. In the process of taking out the mechanical seal, the speed reducer and the like do not need to be disassembled byvirtue of the connecting member, so that the power transmission can be stable while the mechanical seal is easily disassembled, and the connection position does not need to be periodically changed.

Owner:ZHEJIANG CHENGXIN PHARMA & CHEM EQUIP

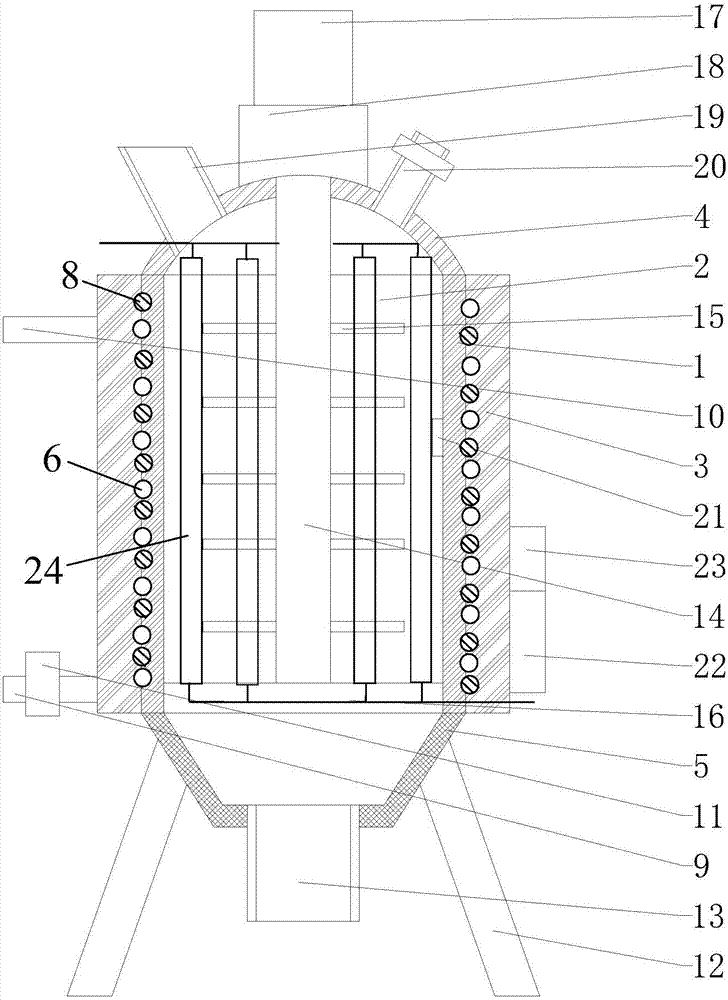

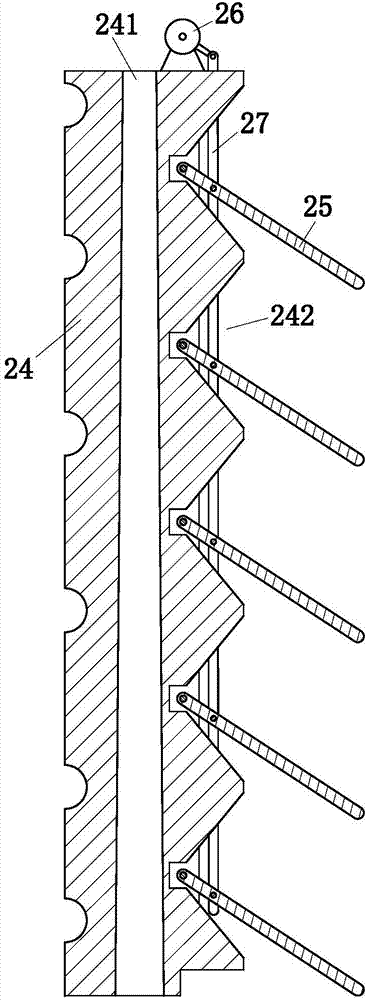

Chemical reaction kettle convenient for temperature adjustment

ActiveCN107456941AIncrease contact areaLarge transfer areaChemical/physical/physico-chemical stationary reactorsDrive motorEngineering

The invention relates to a reaction kettle, and particularly relates to a chemical reaction kettle convenient for temperature adjustment. A plurality of adjustment modules are arranged on the inner wall of a kettle body, can be used for heating, cooling and stirring chemical raw materials, and include heat conductive seats which are arranged along the vertical direction, fins for cooling and heating and drive motors for reciprocating the fins; cooling water holes running through the heat conductive seat are formed in the heat conductive seats; one end of each fin is hinged on the heat conductive seat when a heat resistor is used for heating in chemical reaction; a plurality of fins are uniformly distributed along the length direction of the heat conductive seat; the drive motor is arranged at the top of the heat conductive seat, and is used for driving the fins to swing through connecting rods. According to the chemical reaction kettle, stirring of reacting substances and quick transferring of heat can be realized due to the swing type fins, the reacting substances can be heated, cooled and stirred, so that the temperature of reacting substances can be controlled.

Owner:安徽省福泰精细化工有限责任公司

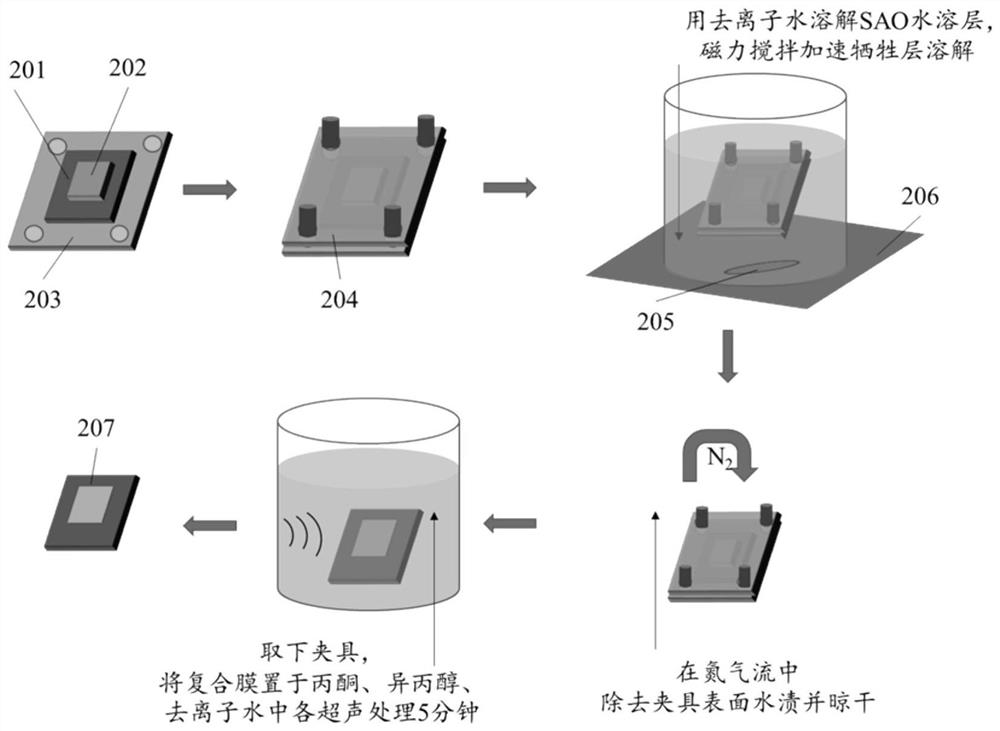

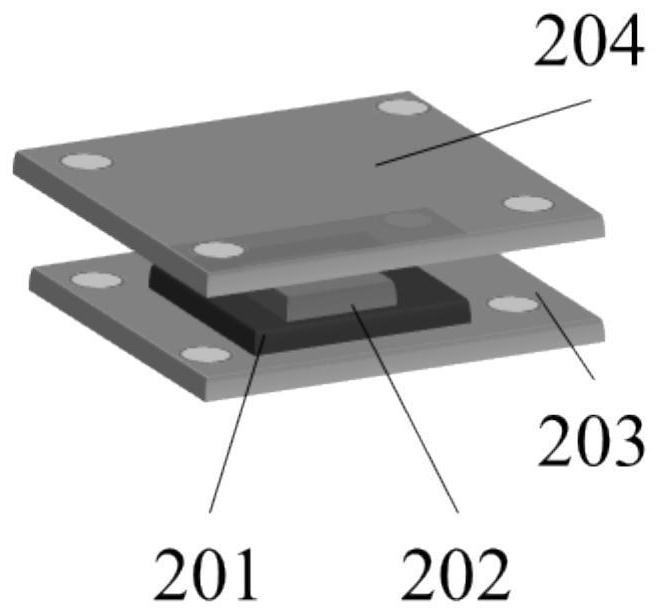

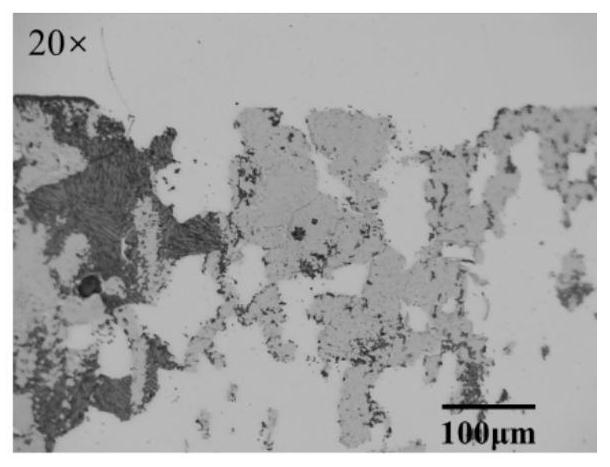

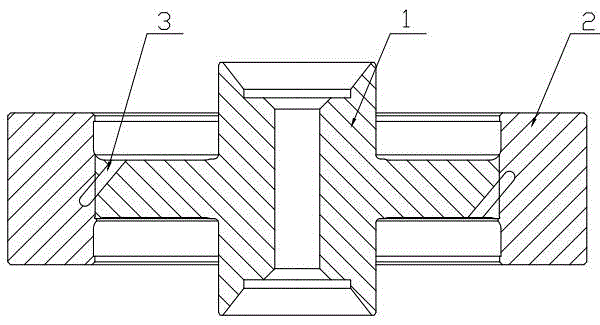

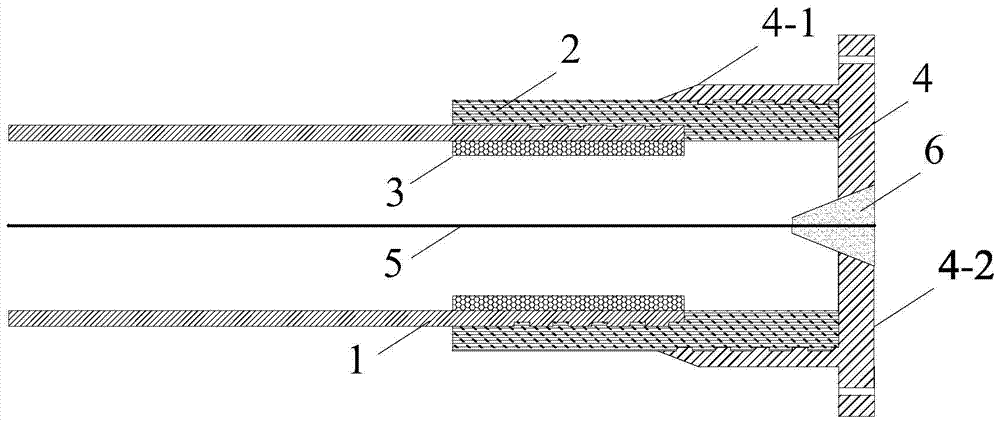

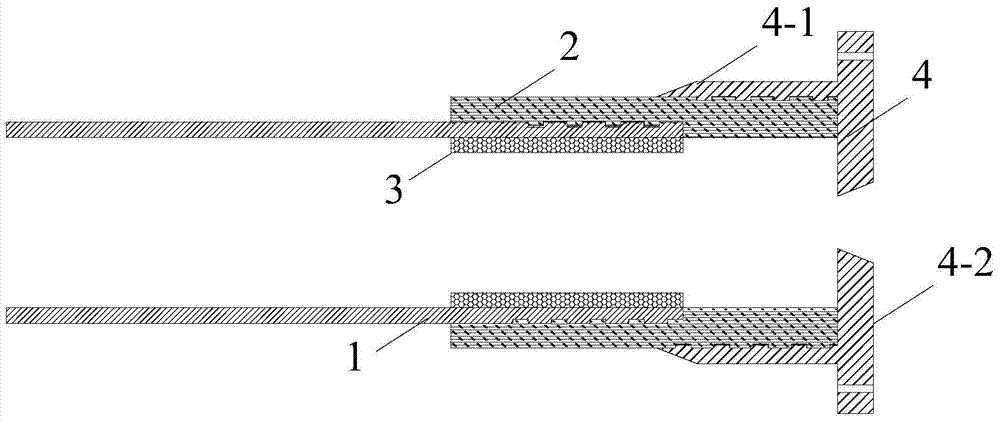

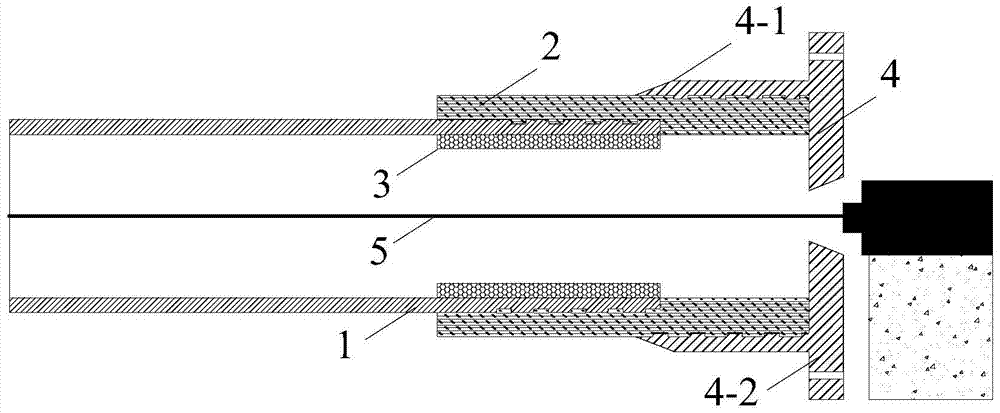

Transfer method for achieving smooth self-supporting film through external pressure and self-supporting film

InactiveCN113564519ALarge transfer areaEfficient removalSolid-state devicesVacuum evaporation coatingStrontium titanateBarium titanate

The invention discloses a transfer method for achieving smooth self-supporting film through external pressure and a self-supporting film obtained through the method. The transfer method of the self-supporting film comprises the steps: a target substrate and a to-be-transferred film are clamped through an aluminum clamp, adequate attachment of the to-be-transferred film and a target contrast is achieved, then the clamp is soaked in deionized water, and the self-supporting film adsorbed on the target substrate is obtained; the clamp is placed in nitrogen flow, and water stains near the clamp and the target substrate are removed; and the clamp is detached, the obtained self-supporting film attached to the target substrate is subjected to ultrasonic treatment in acetone, isopropanol and deionized water, and the self-supporting film is obtained. According to the two-dimensional ultrathin perovskite thin film, a strontium titanate substrate is adopted, the film is barium titanate, and the target substrate is a silicon substrate; and according to the method, the smoothness of the self-supporting film can be improved, and the transfer area of the self-supporting film is greatly increased.

Owner:NANJING UNIV

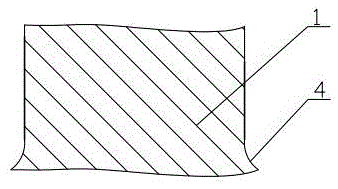

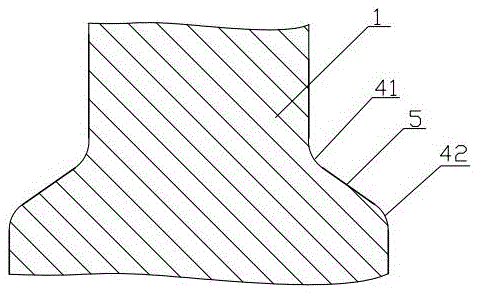

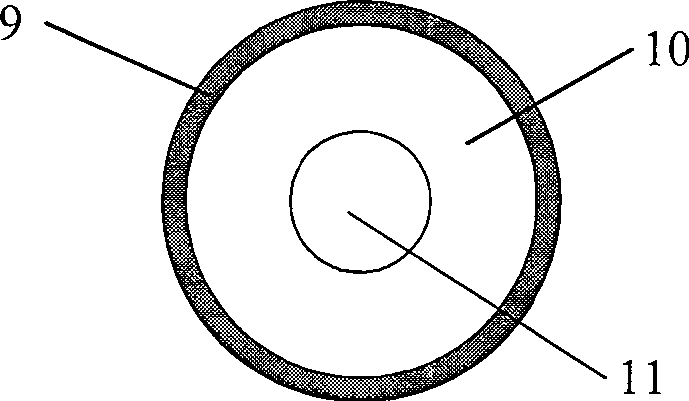

Combined type vertical roller ring

InactiveCN105478480ASolve the strength problemSolve wear resistanceRollsAuxillary arrangementsManufacturing technologyAdhesive

The invention relates to a combined type vertical roller ring applied to H-section steel and belongs to the technical field of manufacturing of a roller. The combined type vertical roller ring comprises a ring sleeve made from a semi-steel material and a central spindle made from a forged steel material, wherein the ring sleeve and the central spindle are fixedly connected by a connecting part; the safety coefficient of the vertical roller ring after connection is larger than or equal to 5.0; the connecting part is a positioning pin, a positioning key or an adhesive; the edge and corners of the central spindle are all in circular arc transition; the radius R of each circular arc is 5mm to 20mm; the circular arcs include a circular arc I and a circular arc II; an oblique line is smoothly connected between the circular arc I and the circular arc II; the included angle of the oblique line and the horizontal line is 45 to 65 degrees. The vertical roller ring disclosed by the invention is relatively high in strength, relatively high in wear resistance, small in stress after being connected, high in safety coefficient which is larger than or equal to 5.0, and capable of totally satisfying the rolling requirements.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

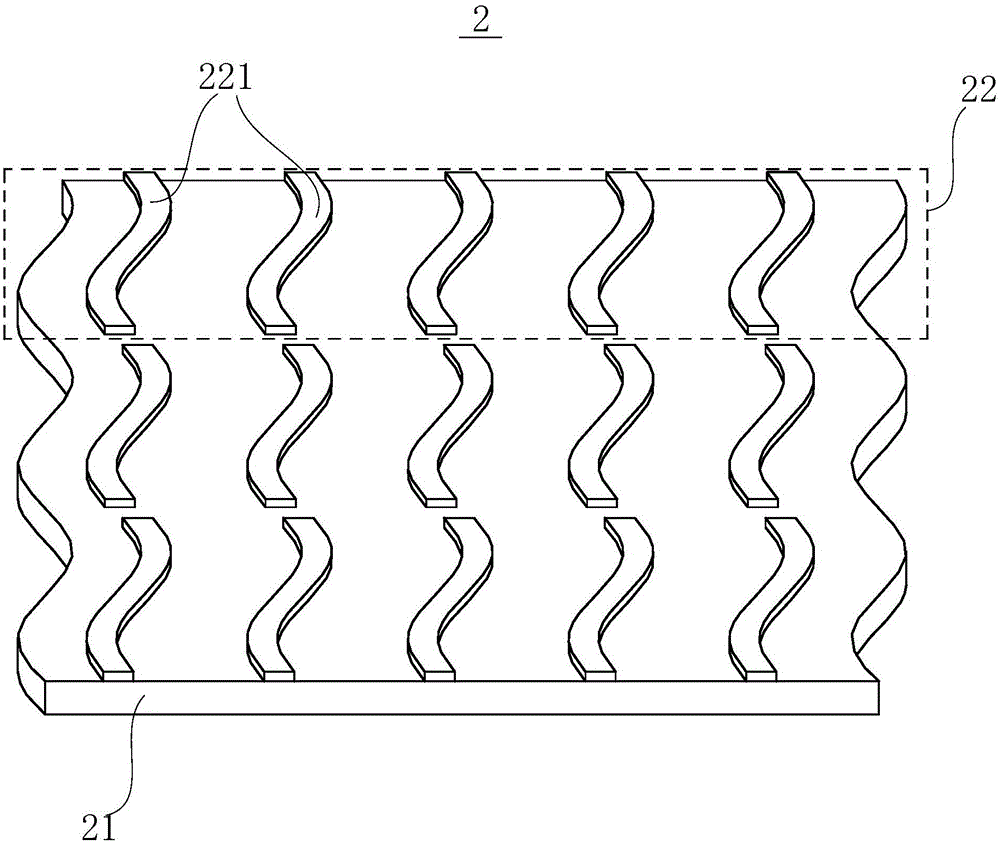

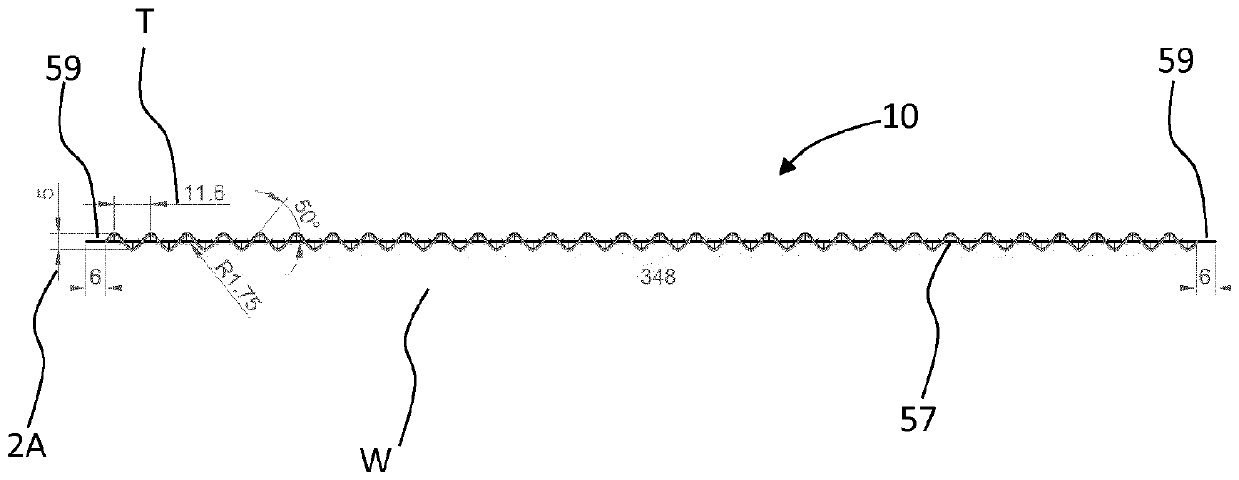

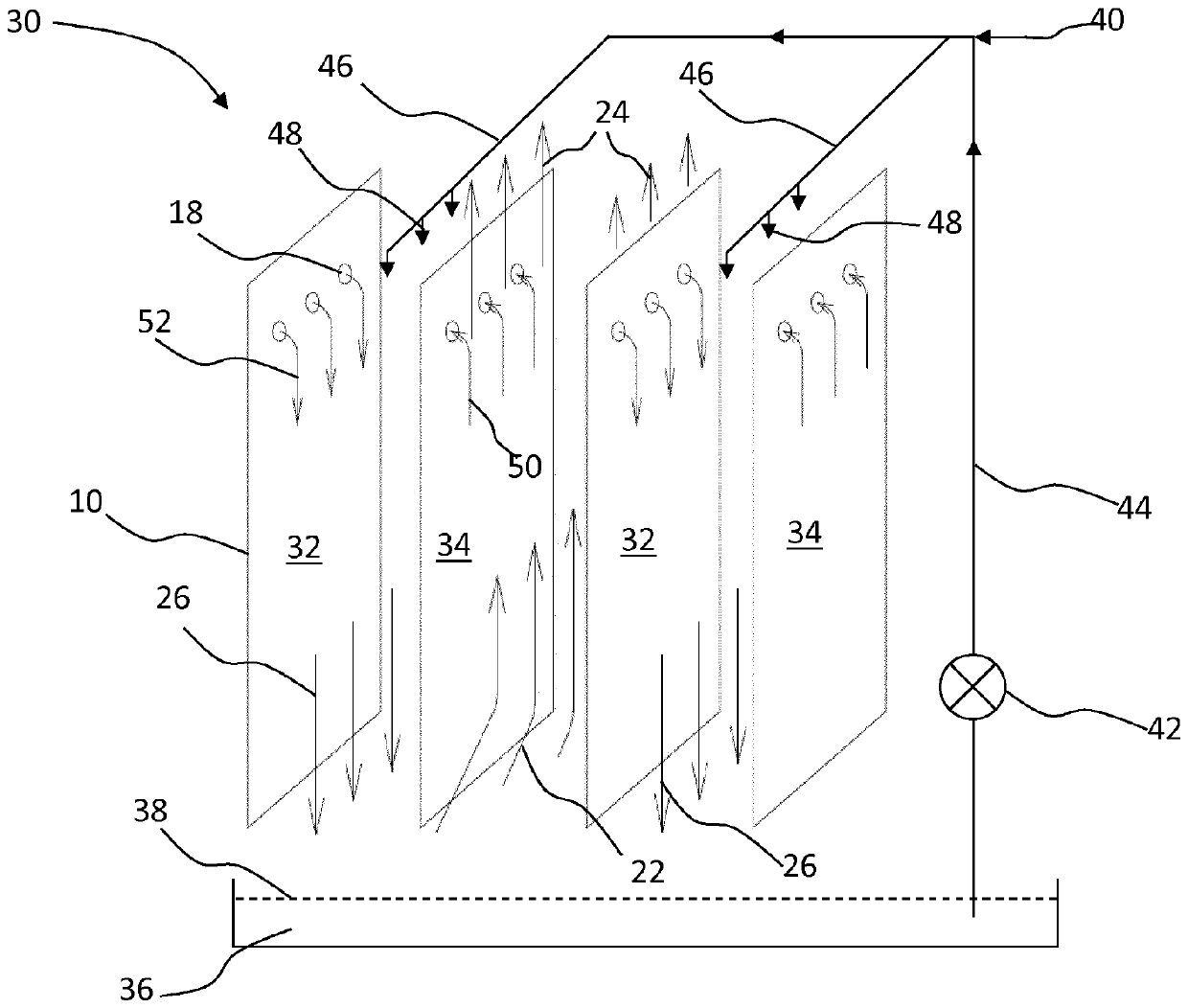

Heat exchanger apparatus

PendingCN109952486AIncrease flow rateImprove cooling efficiencySafety devices for heat exchange apparatusEfficient regulation technologiesPolyvinyl alcoholMicrobial agent

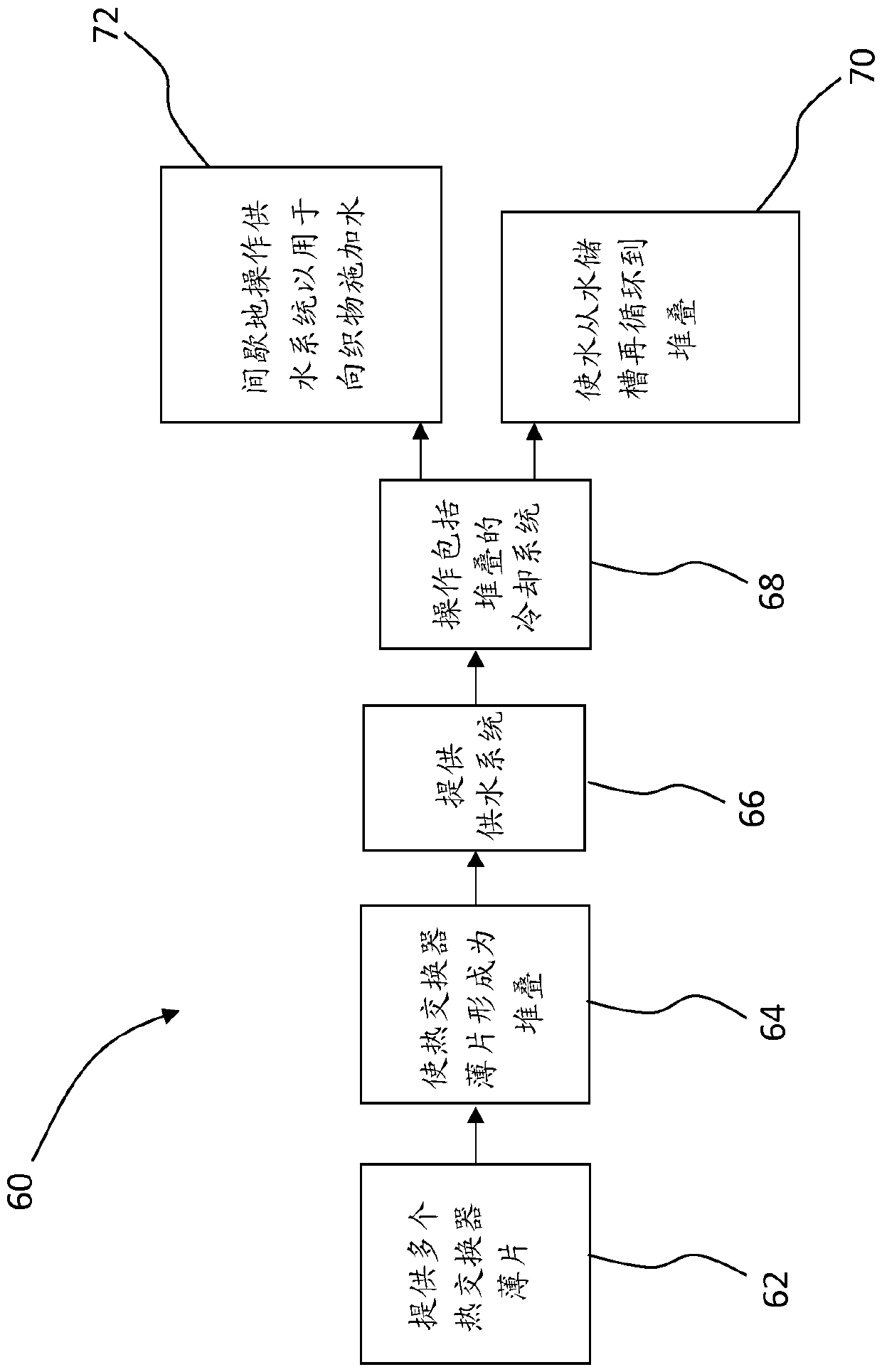

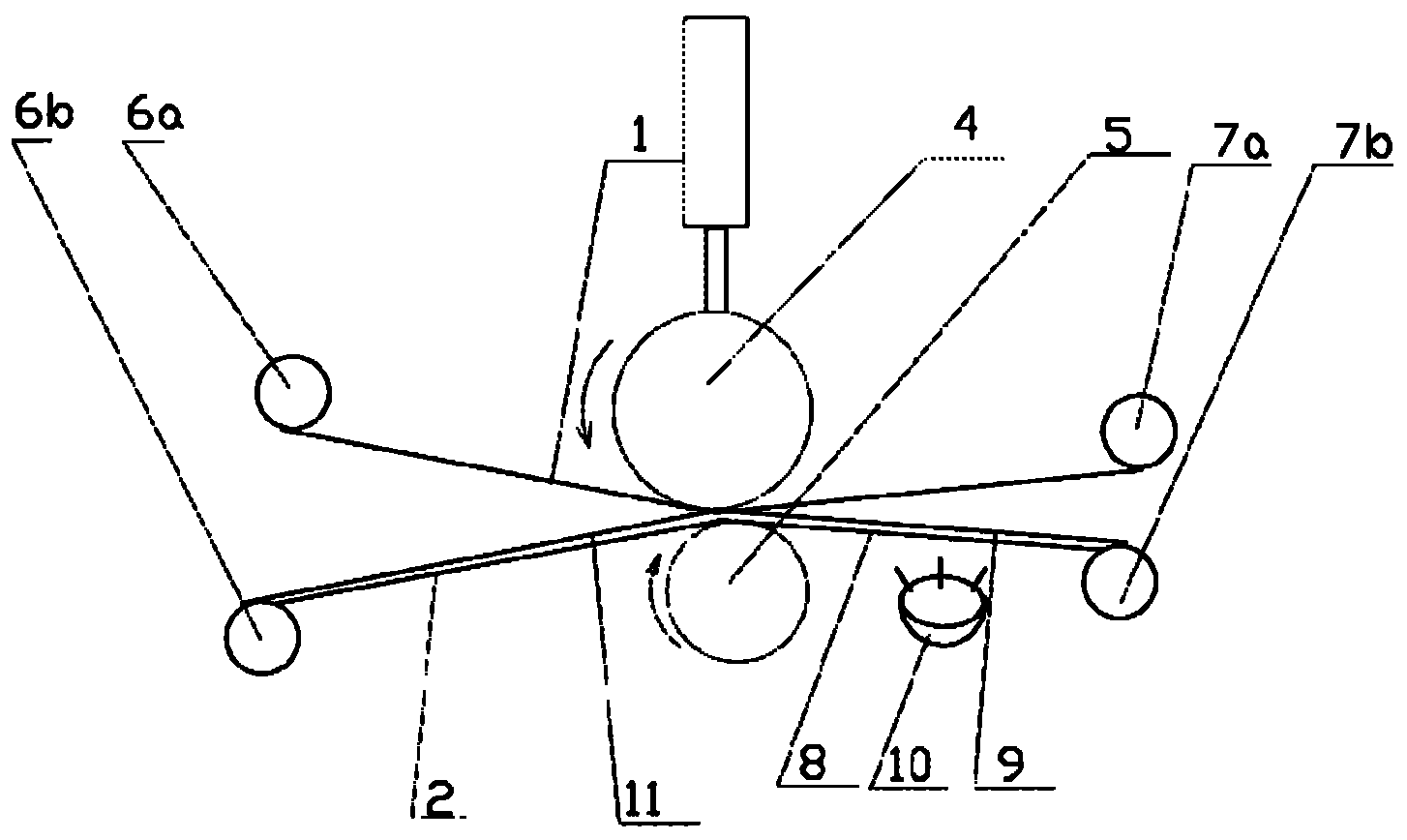

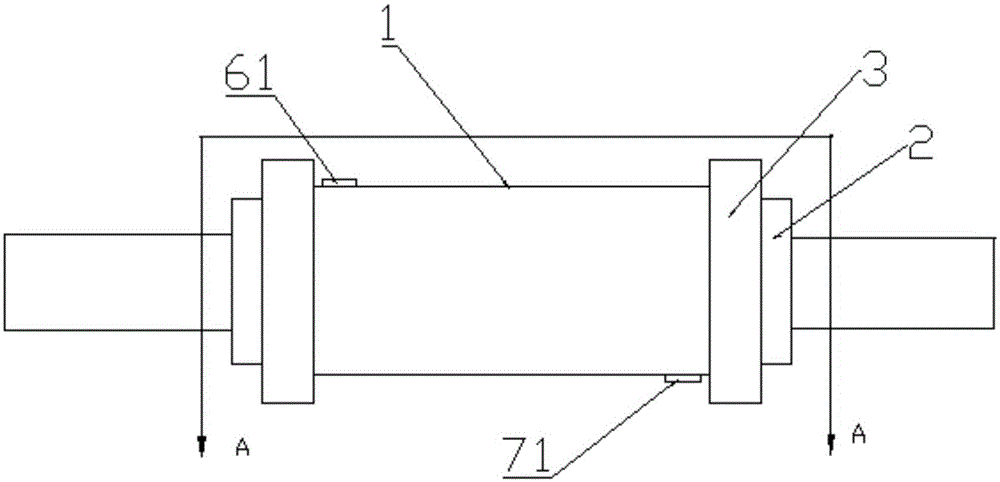

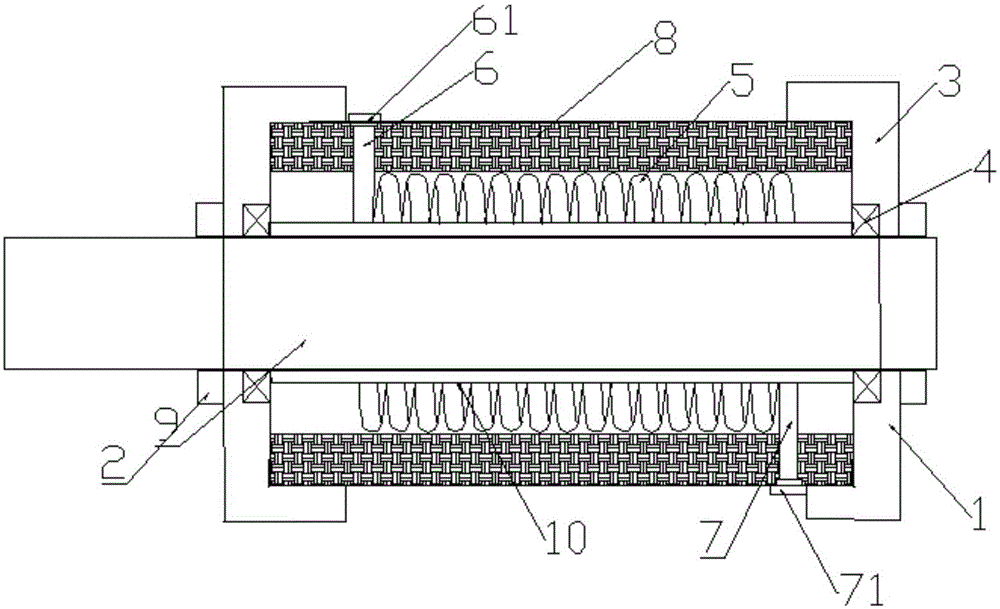

The invention relates to a heat exchanger apparatus comprising at least one metal sheet (10) (e.g. aluminium), and preferably a plurality in a stack. Each metal sheet (10) has a corrugated surface, with fabric covering at least a portion of one surface of the metal sheet to promote evaporation. A wetting agent (e.g. LiCl / Polyvinyl-Alcohol (PVA) solution) is provided in the fabric to promote wetting of the fabric, and also acts as an anti-microbial agent. The fabric preferably covers all of the corrugated surface, and two planar portions are provided above and below the corrugated surface respectively. In use, the heat exchanger apparatus is disposed with a long side vertical and the corrugated surface is disposed on a middle portion, the upper planar portion is contiguous with an air outlet, and / or the lower planar portion is contiguous with an air inlet. In a preferred embodiment, the corrugated surface has in cross-section a profile of a periodic waveform, wherein the peak-to-peak distance is 11.6 mm, the amplitude is 2.5 mm, and corrugations intersect the plane of the heat exchanger apparatus at an angle to that plane of 50 degrees. Also disclosed are a cooling system incorporating the heat exchanger apparatus and methods of operating the cooling system, involving intermittently operating a water supply system for the application of water to the fabric, and / or, recirculatingwater from a water sump using the water supply system.

Owner:UNIVERSITY OF HULL

Transfer method for holographic anti-counterfeiting molded film

ActiveCN102514414BExtended service lifeImprove transfer efficiencyDuplicating/marking methodsAdhesiveTitanium

The invention relates to the holographic anti-counterfeiting printing industry, in particular to a transfer method for a holographic anti-counterfeiting molded film. The invention provides the transfer method for the holographic anti-counterfeiting molded film, which can replace a pattern transfer method which is used for molding transfer of a film used by a nickel plate to form a molded film. A holographic nickel plate is produced and a titanium nitride layer is formed on a polyethylenetherephtalate (PET) base film through molding transfer and vacuum titanium plating to form a holographic titanium-film mother plate film band; and the mother plate film band and a base film band are abut-pressed at certain temperature and pressure, a coating layer part is softened in advance, ultraviolet (UV) adhesive is used for post-curing to form a holographic film, and then vacuum aluminum plating is performed to form a holographic aluminum-plated film. The transfer method for the holographic anti-counterfeiting molded film has the advantages that the original molding method that the nickel plate is required to be used as a mother plate for molding transfer is changed, the cost can be greatly saved and the molding transfer efficiency is improved.

Owner:武汉宇恩防伪技术有限公司

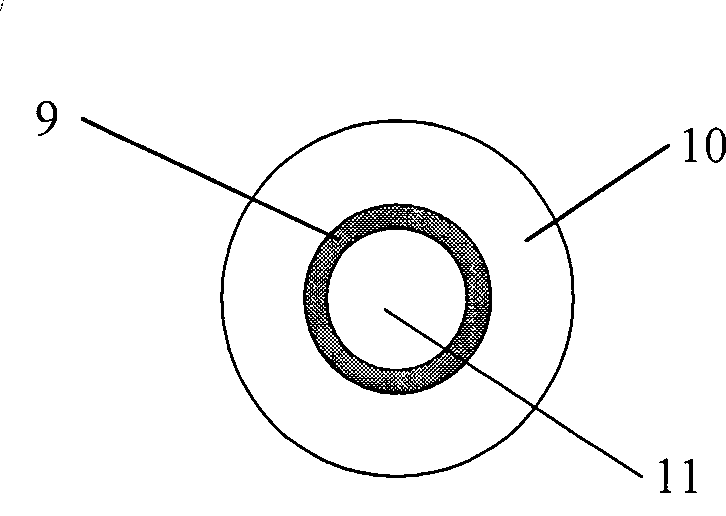

Draught fan bearing pedestal

InactiveCN105134641AAchieve coolingLarge transfer areaPump componentsPumpsThermal insulationRing type

The invention provides a draught fan bearing pedestal. The draught fan bearing pedestal comprises a base body, end covers located at the two ends of the base body, bearing chambers inside the end covers, bearings located in the bearing chambers, and through holes for a rotating shaft to penetrate through in the axial direction of the base body. The draught fan bearing pedestal is characterized in that a circular ring type heat conduction plate is arranged in the base body, a spiral water pipe surrounds the heat conduction plate, a water inlet pipe and a water outlet pipe are arranged at the two ends of the water pipe respectively, the water inlet pipe extends to the outer surface of the base body upwards, the water outlet pipe extends to the outer surface of the base body downwards, and thermal insulation cotton is arranged between the water pipe and the inner wall of the base body. By means of the draught fan bearing pedestal, the rotating shaft can be cooled, the heat transfer area is enlarged through the water pipe arranged in a spiral mode, heat of a draught fan is prevented from being transmitted to a motor through the rotating shaft and burning down the motor, and the service life of the motor and the draught fan is ensured.

Owner:天津尼特风机有限公司

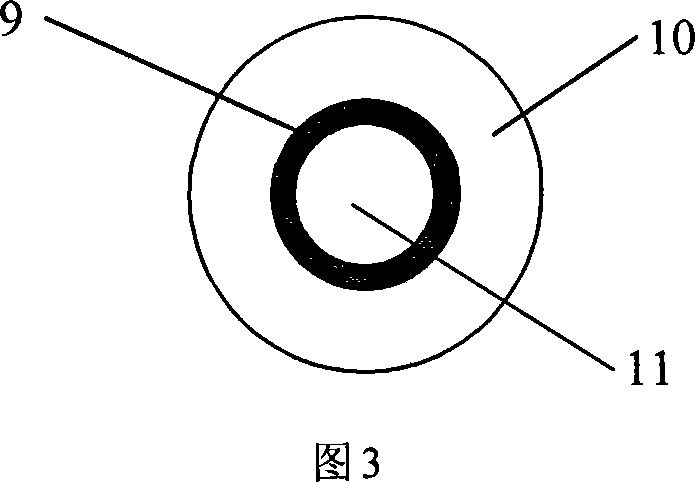

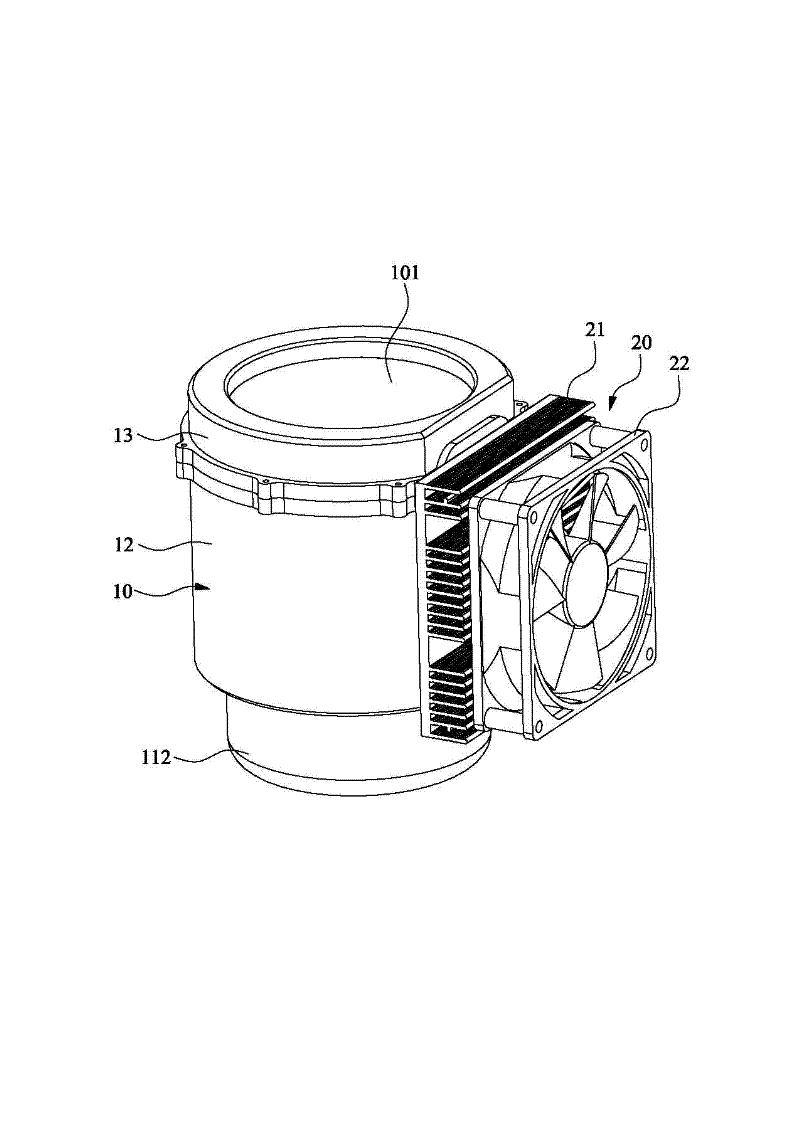

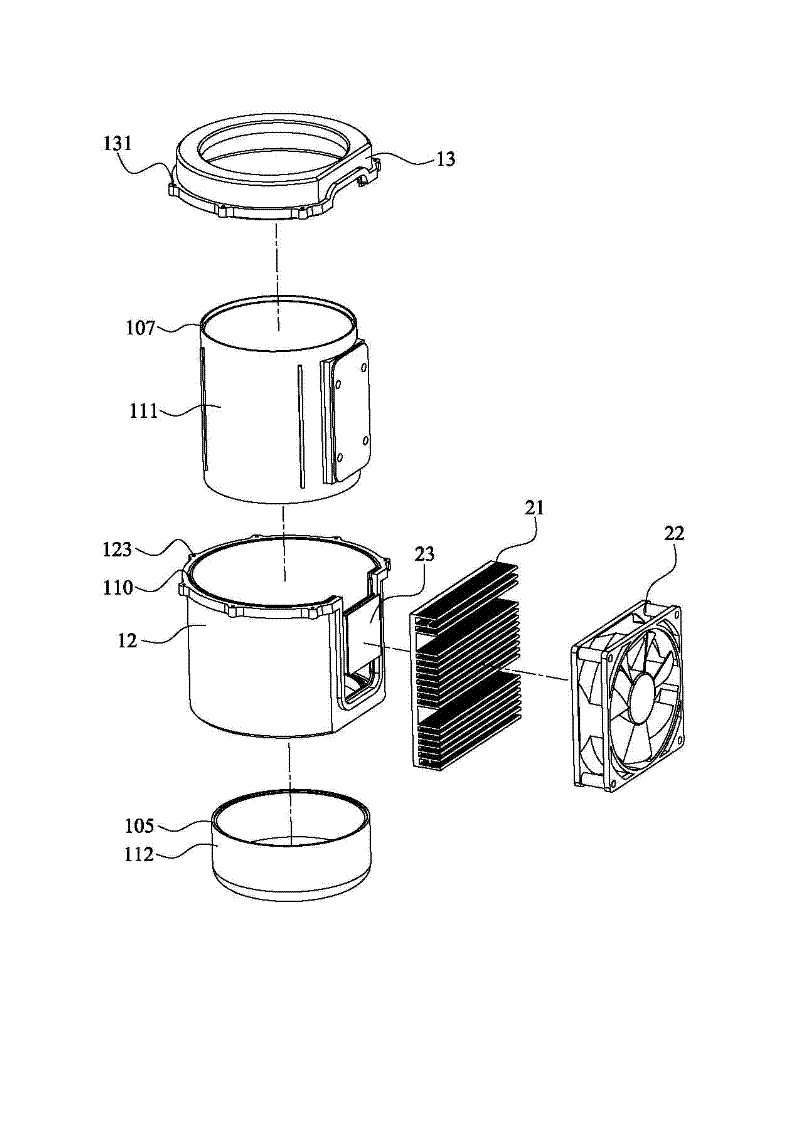

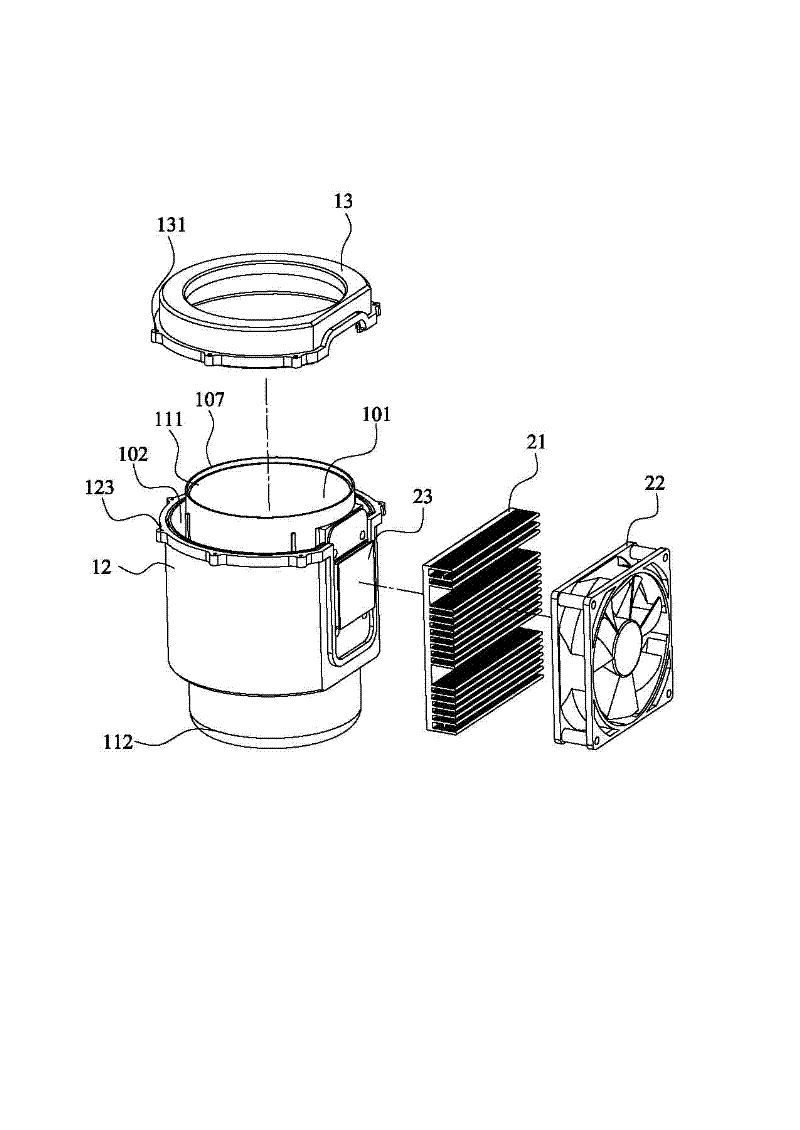

Thermoelectric cooler

InactiveCN100414217CLarge transfer areaImprove cooling efficiencyPump componentsIndirect heat exchangersThermoelectric coolingLow noise

Owner:LG ELECTRONICS INC

Indoor air purifying device

InactiveCN100500262CDoes not require heating to regenerateReduce energy consumptionDispersed particle filtrationEpoxyFiber

The invention relates to an indoor air purification device that comprises the air inlet, shell, air blower, air exhauster, vacuum pump and volatile organic compound outlet, with hollow fiber inside the shell, epoxide resin roll end separating the hollow fiber into shell and tube, forming into a tubular heat exchanger, the said air inlet connected with one end of the shell, which connects with the vacuum pump, volatile organic compound outlet connected with the vacuum pump, the other end of the wind blower connected with the other end of the shell and connected to the wind blower, indoor volatile organic permeated into the tube and the shell under the drawing force of the vacuum pump, exhausting the said volatile organic compound through its outlet. It can effectively remove most of the volatile organic compound with efficiency over 80%. It is more efficient, energy economical and environmental protective.

Owner:SOUTH CHINA UNIV OF TECH

A slurry mixing device for shoe and hat processing

ActiveCN113522146BIncrease temperatureEligible for mixingShaking/oscillating/vibrating mixersMixing materials pretreatmentCircular coneProcess engineering

The invention belongs to the technical field of textile processing, in particular to a slurry mixing device for processing shoes and hats. Aiming at the agglomeration phenomenon due to temperature changes before the slurry is added into the mixing container, the weight of the agglomeration will increase when the slurry is directly added to the mixing container. However, if it sinks into the bottom, it will be difficult to stir thoroughly during mixing, which will affect the overall mixing effect of the slurry. The following scheme is proposed now, including two charging boxes, and the two charging boxes are placed symmetrically. There are three round holes, the inner wall of the round hole is fixedly connected with the processing cylinder, and three equidistant grooves are opened on the two feeding boxes, and the inner wall of the groove is fixedly connected with the first motor. In the present invention, the processing cylinder is used to heat the added slurry to increase the temperature of the slurry, and then the frustum-shaped crushing shaft and the spiral crushing blade are used to squeeze and crush the slurry, so that the slurry meets the mixing conditions and avoids the presence of Agglomeration affects subsequent mixing operations.

Owner:JIANGSU ZHONGSHI HOME TECH CO LTD

Composite pipe connection joint using prestressed cables and method of use thereof

ActiveCN105114412BImprove bearing capacityImprove the force characteristicsRod connectionsInterference fitEngineering

Owner:PLA UNIV OF SCI & TECH

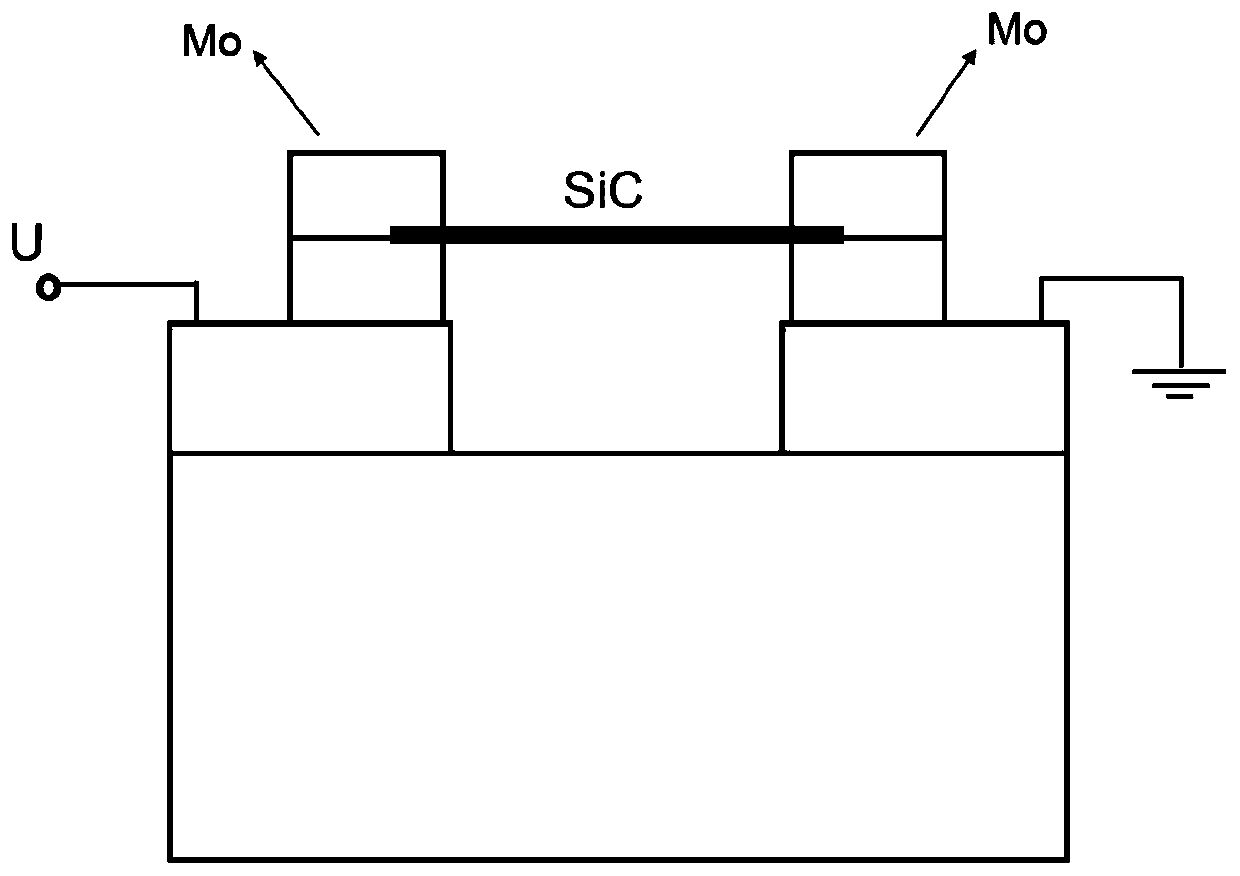

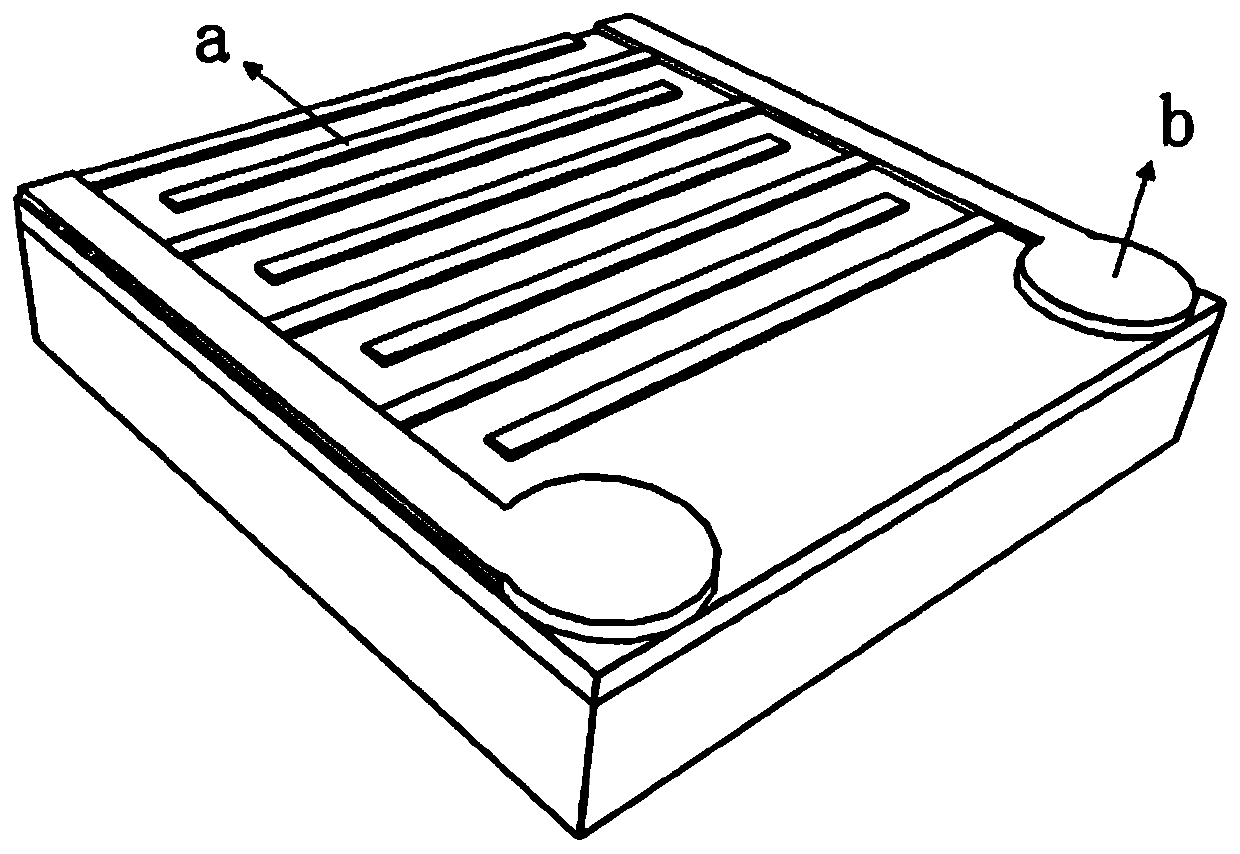

A kind of preparation method of msm structure 4h-sic ultraviolet photodetector

ActiveCN108231953BImprove detection efficiencyEasy to prepareFinal product manufactureSemiconductor devicesEtchingInsulation layer

The invention discloses a method for preparing a 4H-SiC ultraviolet photoelectric detector of an MSM structure and relates to the preparation of ultraviolet photoelectric detectors. The method comprises the following steps: performing epitaxial growth of a semi-insulation layer on an n-shaped 4H-SiC substrate, cutting a material sample into a rectangular strip-shaped sample, cleaning the surface by adopting a standard RCA program, further adopting an electrothermal decomposition growth method, controlling the environmental conditions, temperature and growth time, electrifying two ends of the rectangular strip-shaped sample by using a DC direct current power supply, directly performing thermal growth of a multi-layer graphene film on the Si surface of the 4H-SiC epitaxial layer, optimizingthe growth technology conditions, and preparing an interdigital electrode for the MSM structure on the device surface by combining ICP etching by virtue of photolitho-pattern; combining sputtering deposition and a metal bonding pad, and covering and growing a dense SiO2 layer to serve as a passivation layer on the sample surface by virtue of plasma-enhanced chemical vapour deposition; and removingthe SiO2 in the circular bonding pad area by using lithography and etching, thereby obtaining the product.

Owner:XIAMEN UNIV

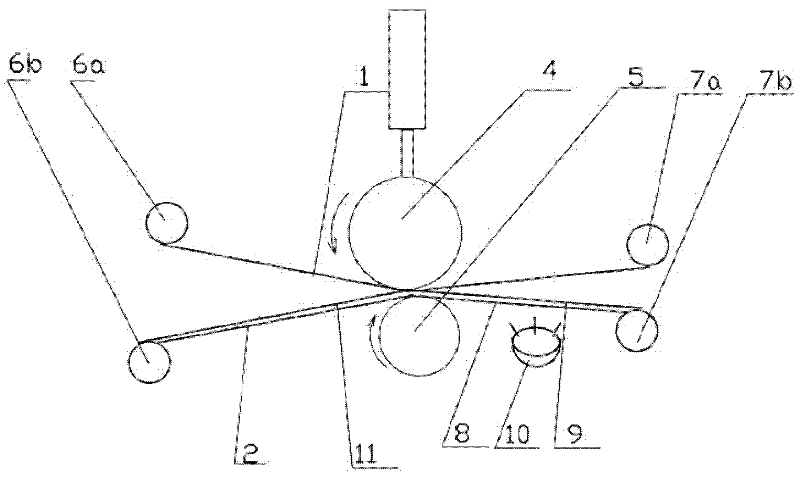

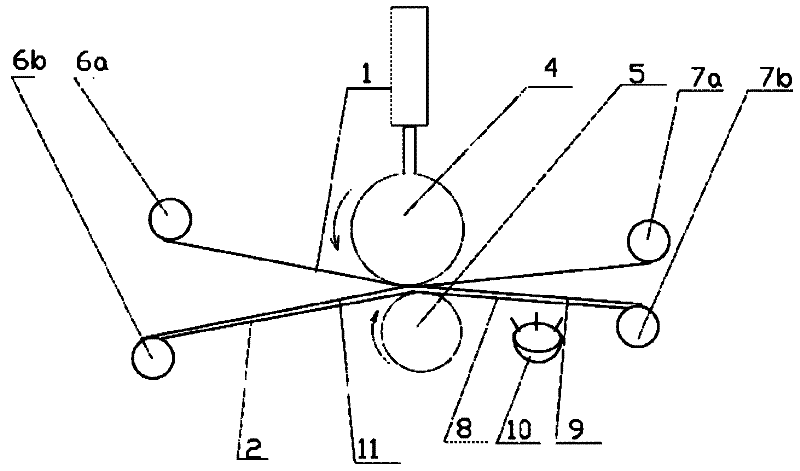

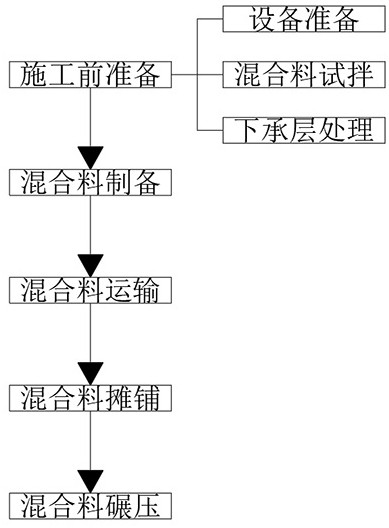

Construction technology of asphalt mixture pavement with ultra-thin wearing layer

The invention discloses an ultra-thin wearing layer asphalt mixture pavement construction process, comprising the following steps: Step 1: preparation before construction: preparation of construction equipment, trial mixing and testing of the mixture, and thorough treatment of the quality of the underlying layer Defects, remove the dust and debris in the gaps and refill the gaps; Step 3: Mixed material transportation: Use the mixed material transportation equipment to transport the mixed material; Step 5: Mixed material rolling: The initial rolling temperature should not be lower than 150°C, the temperature of the final pressure gauge is not lower than 120°C; Step 6: testing after forming, the present invention relates to the technical field of road engineering. The mixed material is guided by the arc-shaped return plate to avoid the impact of the mixed material on the transport box due to inertial factors when the deceleration occurs during transportation. The arc-shaped return plate is used to guide the mixed material to return to the transport box. Protection to prevent the mixture from destroying the transport box and causing harm to the transport vehicle.

Owner:广州公路工程集团有限公司

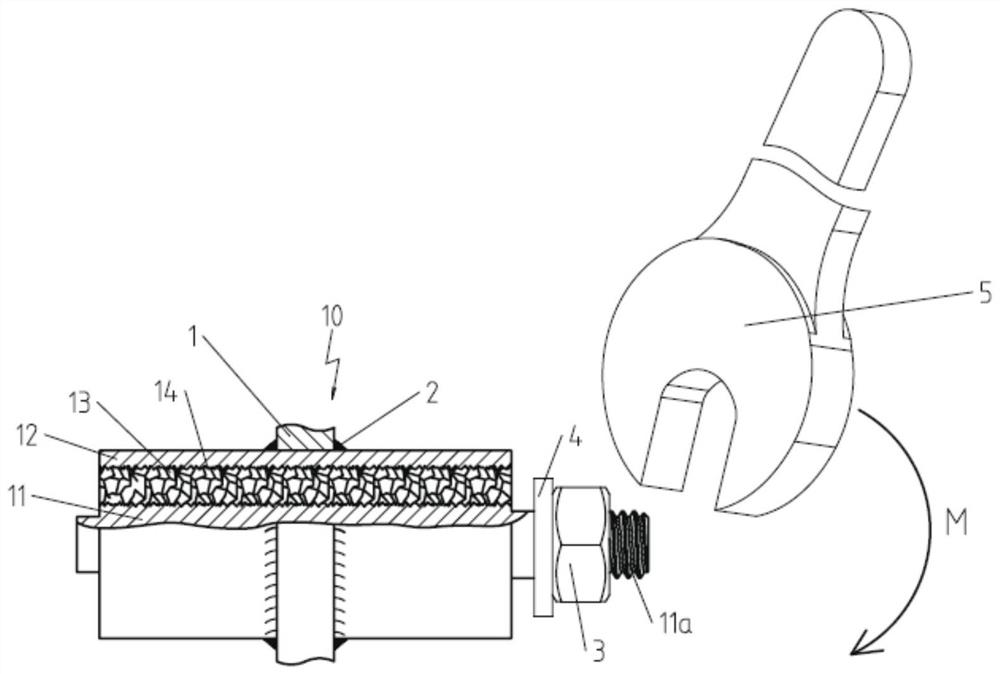

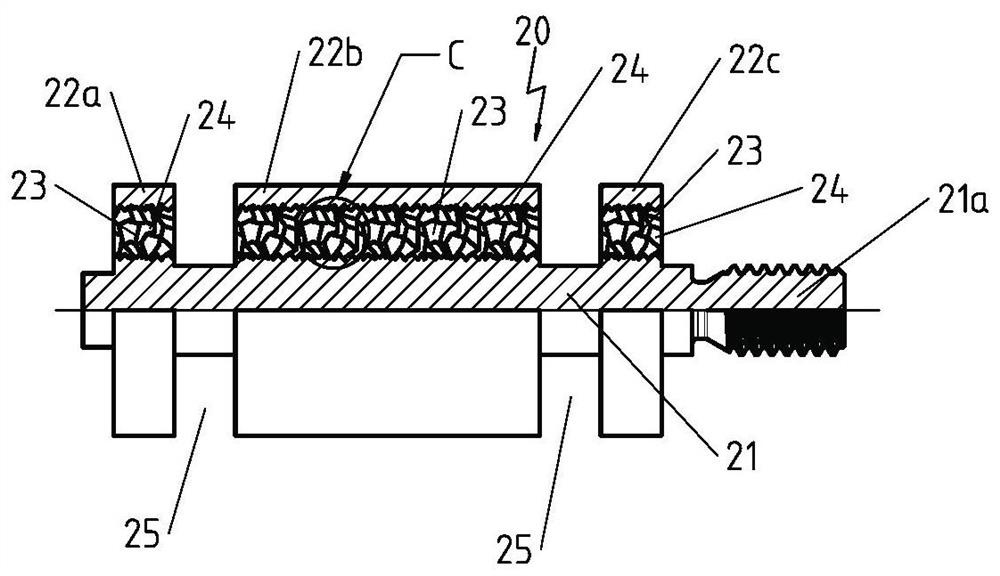

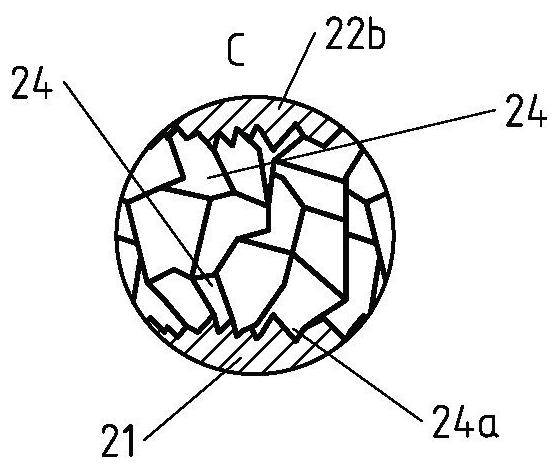

Device with an internal conductor and method for manufacturing such a device

The invention provides a device (10, 20, 30) and a method for manufacturing the device. A device is disclosed with an internal conductor (11, 21, 31), which is arranged within the tube interior of a tubular metal sheath (12, 22a, 22b, 32) and is electrically insulated from this sheath with a compacted, electrically insulating material (13, 23, 33), in which the compacted electrically insulating material is a compacted magnesium oxide granulate made from magnesium oxide grains (14, 24, 34) of different sizes with edges and projections (24a, 34a), and that sections, especially edges and projections of magnesium oxide grains are pressed, under local deformation of the internal conductor and / or the tubular metal sheath, into the internal conductor or into the tubular metal sheath.

Owner:塔克及海林阁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com