Indoor air purifying device

A technology for indoor air and purification devices, applied in the field of air purification, can solve the problems of poor air purification effect, low packing density of flat membrane, poor separation effect, etc., and achieve compact and compact equipment, high mass transfer efficiency and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

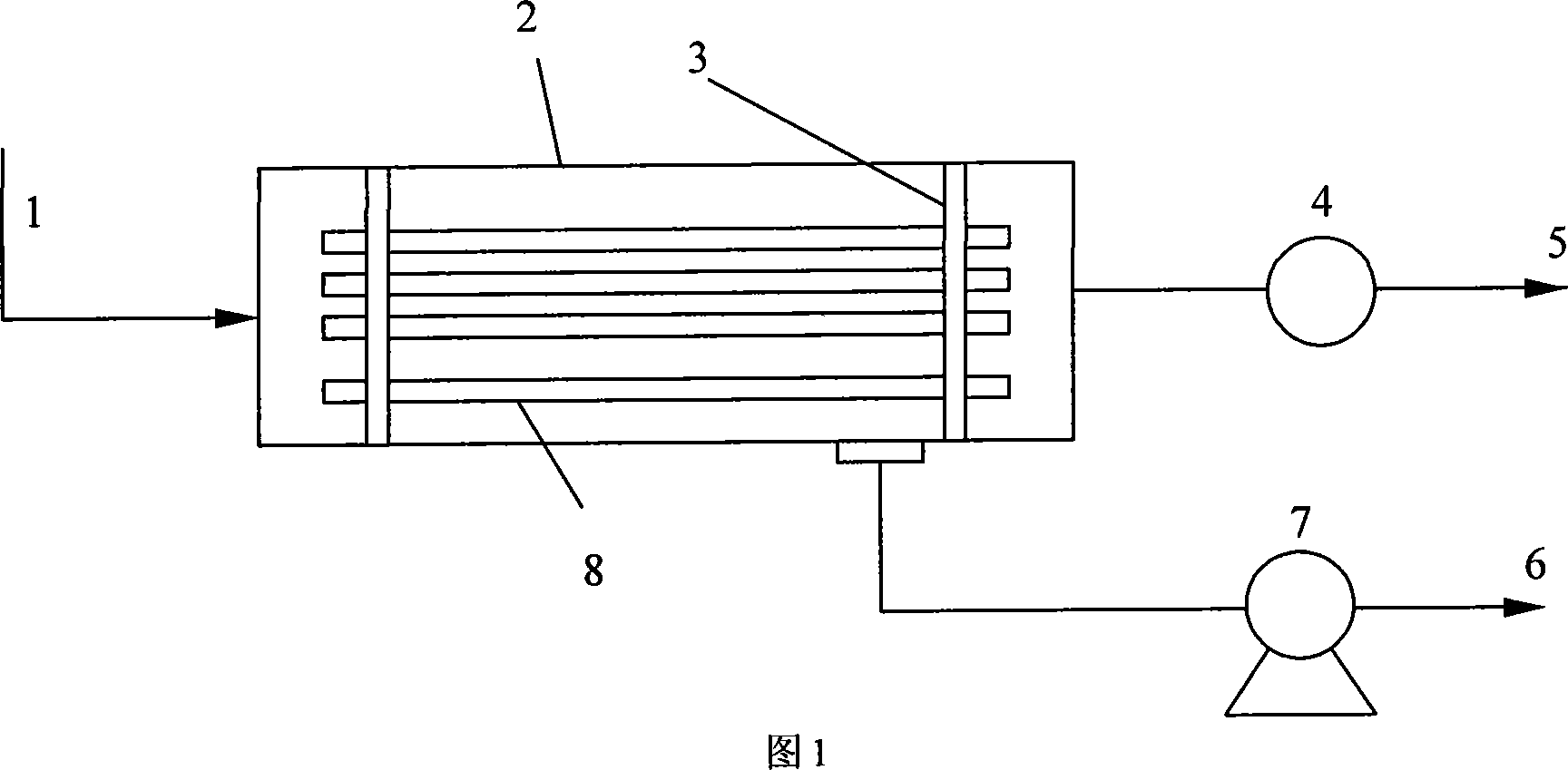

[0024] The indoor air purification device of the present invention is shown in Figure 1, and the device includes an air inlet 1, a housing 2, an epoxy resin head 3, a fan 4, an air outlet 5, a VOCs outlet 6, a vacuum pump 7, and a hollow fiber 8. The air inlet 1 is connected to one end of the housing 2, the housing 2 is connected to the vacuum pump 7, and the volatile organic compound outlet 6 is connected to the vacuum pump 7; the fan 4 is connected to the other end of the housing 2 and is connected to the air outlet 5 The epoxy resin head 3 seals the hollow fiber 8 into a shell side and a tube side, the hollow fiber 8 and the head 3 are sealed and airtight, and the space between the head 3 and the shell 2 is also sealed and airtight; Driven by the fan 4, the indoor air enters the shell 2 through the air inlet 1 and flows through the hollow fiber tube, the VOCs in it enter the shell side through the wall of the hollow fiber, and the clean air after removing the VOCs flows out ...

Embodiment 2

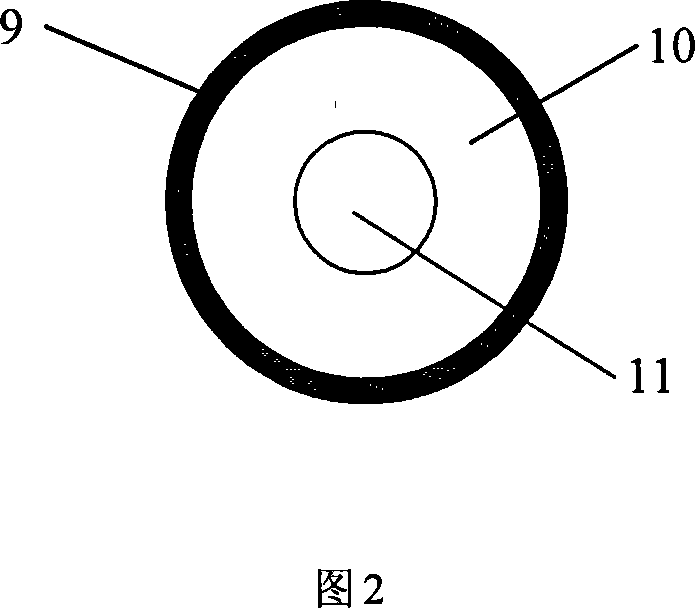

[0027] The specific structure of the hollow fiber of the present invention is shown in Figure 2, the dense skin layer 9 is located outside the hollow fiber, and the porous support layer 10 is located inside the hollow fiber. As can be seen from Figure 2, the indoor air goes through the pipe 11, and the porous support layer 10 of the hollow fiber is a porous support body with a thickness of 100-200 μm, including polyvinylidene fluoride (PVDF), polyetherimide (PEI) , any one of polyacrylonitrile (PAN), polypropylene (PP), polysulfone (PSU) etc., its pore diameter is 0.4-2.0 μm; the thickness of the dense cortex 9 is 0.2-5 μm, non-porous, and its material includes poly Any of dimethylsiloxane (PDMS), polyether block amide (PEBA), etc.

Embodiment 3

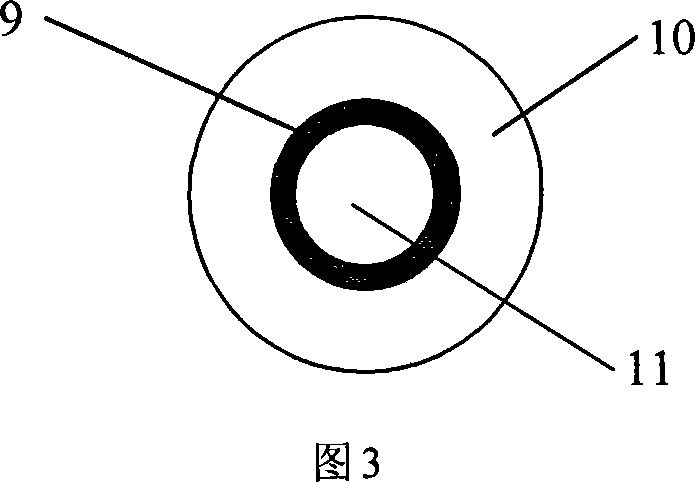

[0029] Another structure of the hollow fiber of the present invention is shown in FIG. 3 , the dense skin layer 9 is located inside the hollow fiber, and the porous support layer 10 is located outside the hollow fiber. As can be seen from Fig. 3, the indoor air goes through the pipe 11, and the porous support layer 10 of the hollow fiber is a porous support body with a thickness of 100-200 μm, including polyvinylidene fluoride (PVDF), polyetherimide (PEI) , any one of polyacrylonitrile (PAN), polypropylene (PP), polysulfone (PSU) etc., its pore diameter is 0.4-2.0 μm; the thickness of the dense cortex 9 is 0.2-5 μm, non-porous, and its material includes poly Any of dimethylsiloxane (PDMS), polyether block amide (PEBA), etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com