Construction technology of asphalt mixture pavement with ultra-thin wearing layer

An asphalt mixture and construction technology technology, applied in roads, roads, road repair and other directions, can solve the problems of equipment impact, endanger the safety of driving equipment and personnel, increase the overall inertia of equipment, etc., to avoid deposition, ensure use quality, Avoid severe effects of delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

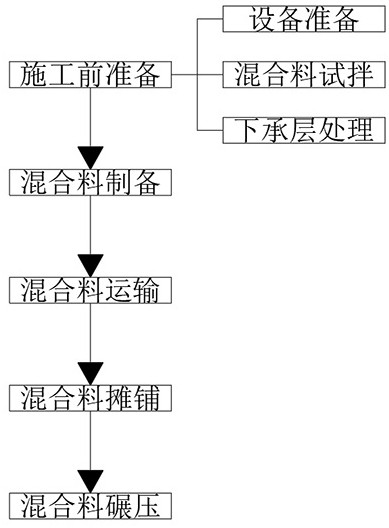

[0042] see figure 1 , the present invention provides a technical solution: an ultra-thin wearing layer asphalt mixture pavement construction process, comprising the following steps:

[0043] Step 1: Preparation before construction: Prepare construction equipment, test mix and test the mixture, and thoroughly deal with the quality defects of the underlying layer, remove dust and debris in the gaps and refill the gaps, and then use high-pressure fans to clean the road surface and keep the road clean;

[0044] Step 2: Preparation of the mixture: the mixture is mixed by a batch asphalt mixer, the mixing capacity is not less than 240t / h, the temperature is controlled as follows: the heating temperature of the stone is 180°C-190°C, the heating temperature of the asphalt is 165°C-175°C, and the mixing The temperature is 170℃~180℃, the dry mixing time is 8~10s, then add asphalt and mineral powder, and wet mix for 40~45s, the temperature of the mixture is 180±5℃;

[0045] Step 3: Tra...

Embodiment 2

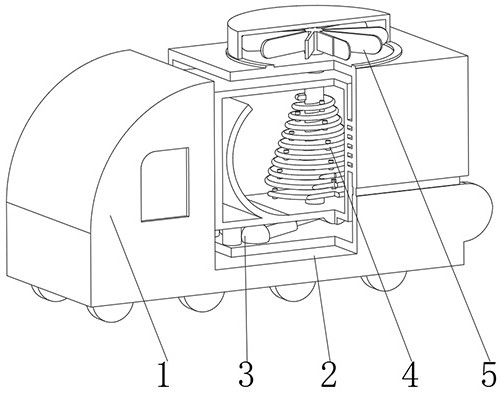

[0049] see Figure 2-6 , the present invention provides a technical solution: transportation equipment, specifically comprising:

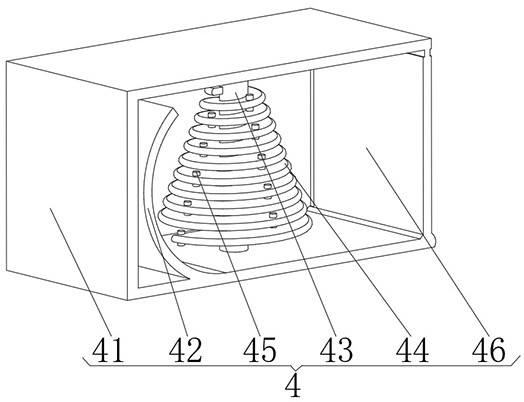

[0050] Transport locomotive head 1, the transport lorry head 1 has a box-shaped main body, a carrying vehicle body 2 installed on the right side of the box-shaped main body, and a carrying device 3 installed on the top of the carrying vehicle body 2, and is installed on the carrying device 3 away from the carrying vehicle body 2 The transportation device 4 in the middle position on one side, and the protective device 5 arranged on the outside of the transportation device 4, the transportation device 4 includes:

[0051] Transport box 41, the transport box 41 has a doorless box body, and an arc-shaped return plate 42 installed on the bottom of the doorless box inner cavity close to the side of the transport vehicle head 1, the mixture is guided by the setting of the arc-shaped return plate 42, To avoid the impact of the mixture on the transport box...

Embodiment 3

[0063] see Figure 2-6 , on the basis of Embodiment 2, the present invention provides a technical solution: a method for using transport equipment, comprising the following steps,

[0064] Step 1: open the opening and closing box door 46 and pour the mixture into the inside of the transport box 41, and then close the opening and closing box door 46 of the transport box 41;

[0065] Step 2: Start the transport vehicle head 1 to drive the overall equipment to move until it reaches the destination;

[0066] Step 3: During the transportation of the overall equipment, start the electric ring rail 56 in the protective device 5, so that the angle of the shielding cover body 57 is adjusted along the electric ring rail 56, so that the air flow drives the wind plate 55 to rotate, so that the spiral movement The material plate 44 conveys the mixture from bottom to top;

[0067] Step 4: The rotation of the pneumatic plate 55 drives the central shaft column 54 and the transmission shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com