Patents

Literature

134results about How to "High degree of homogenization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

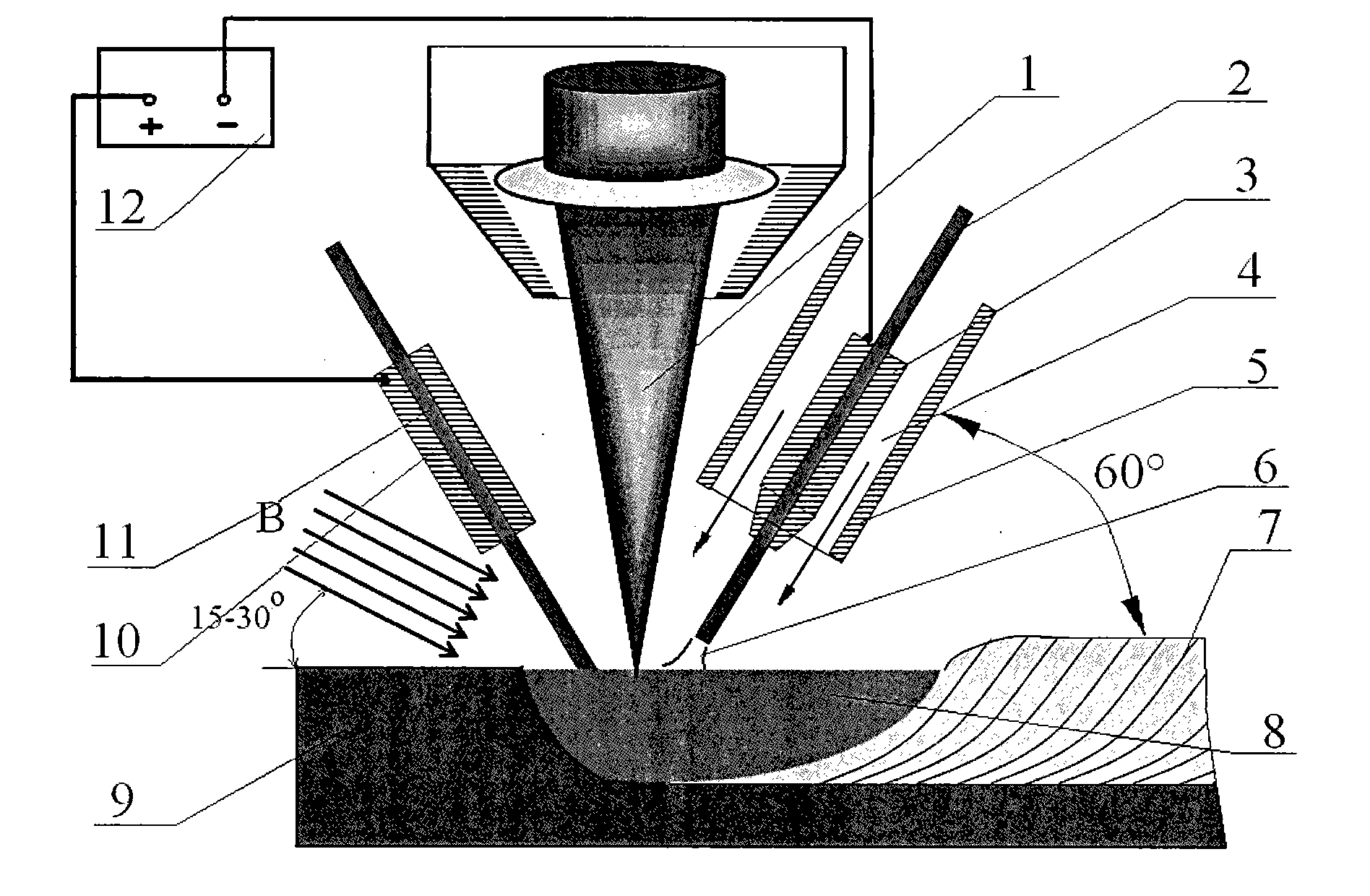

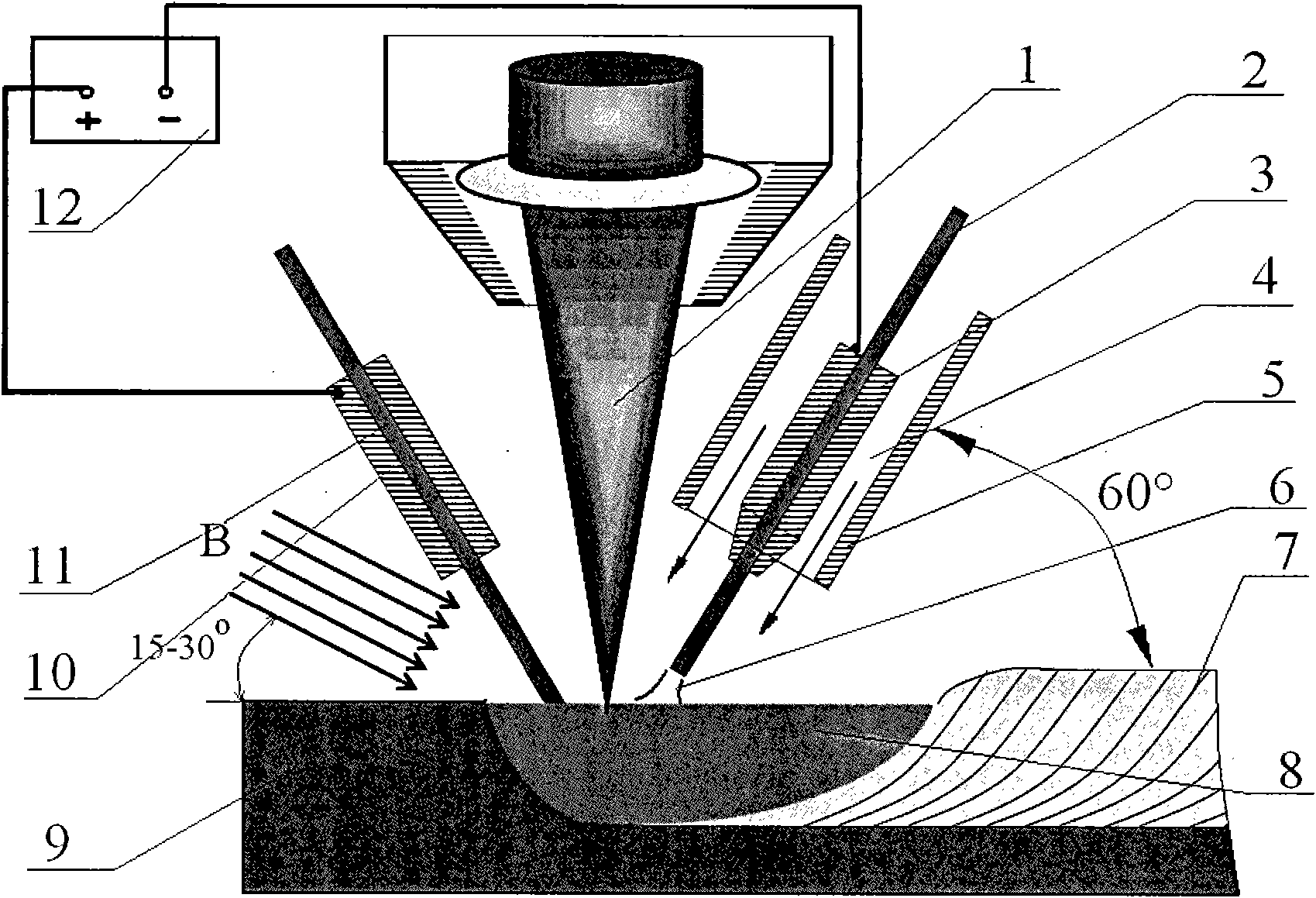

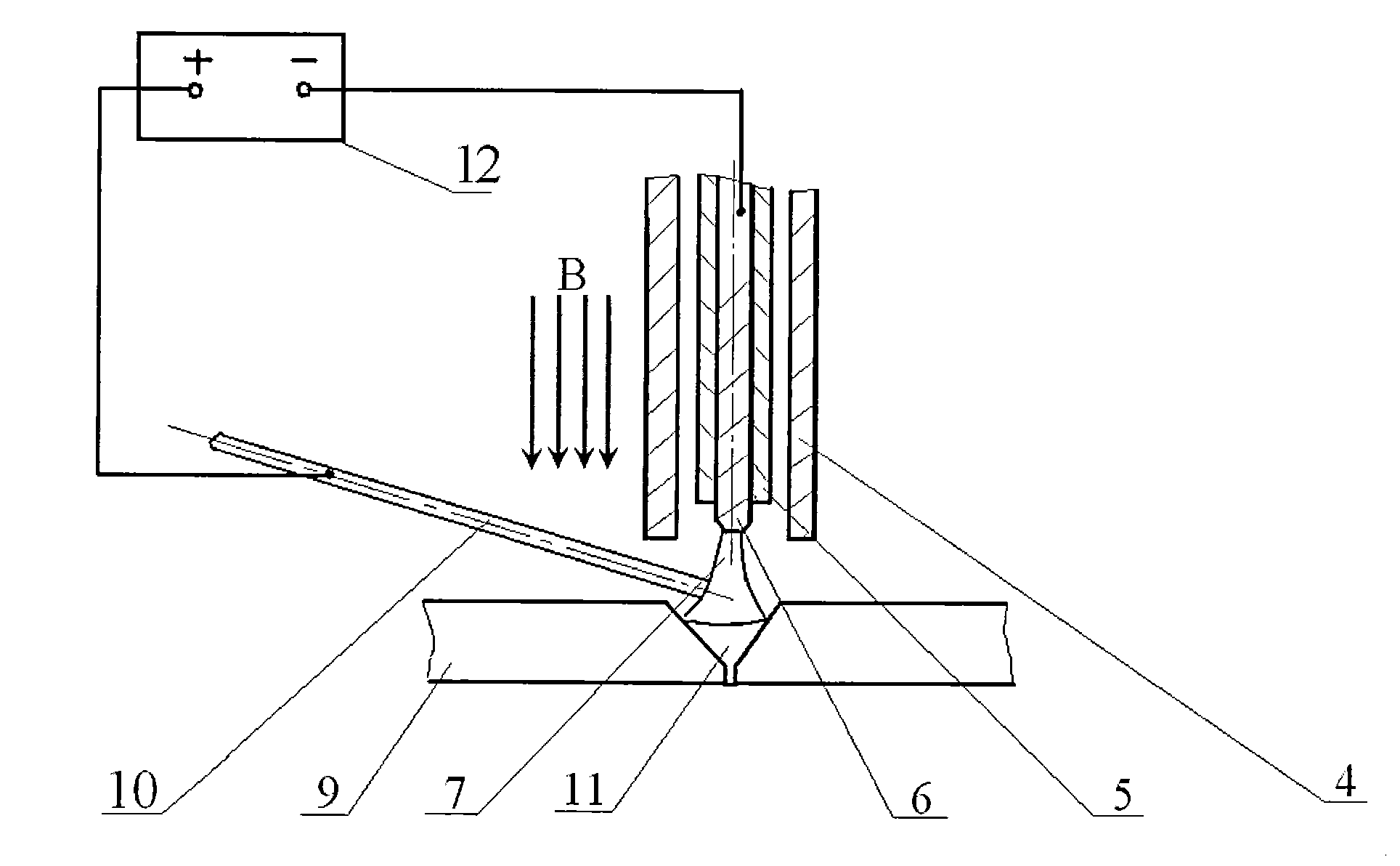

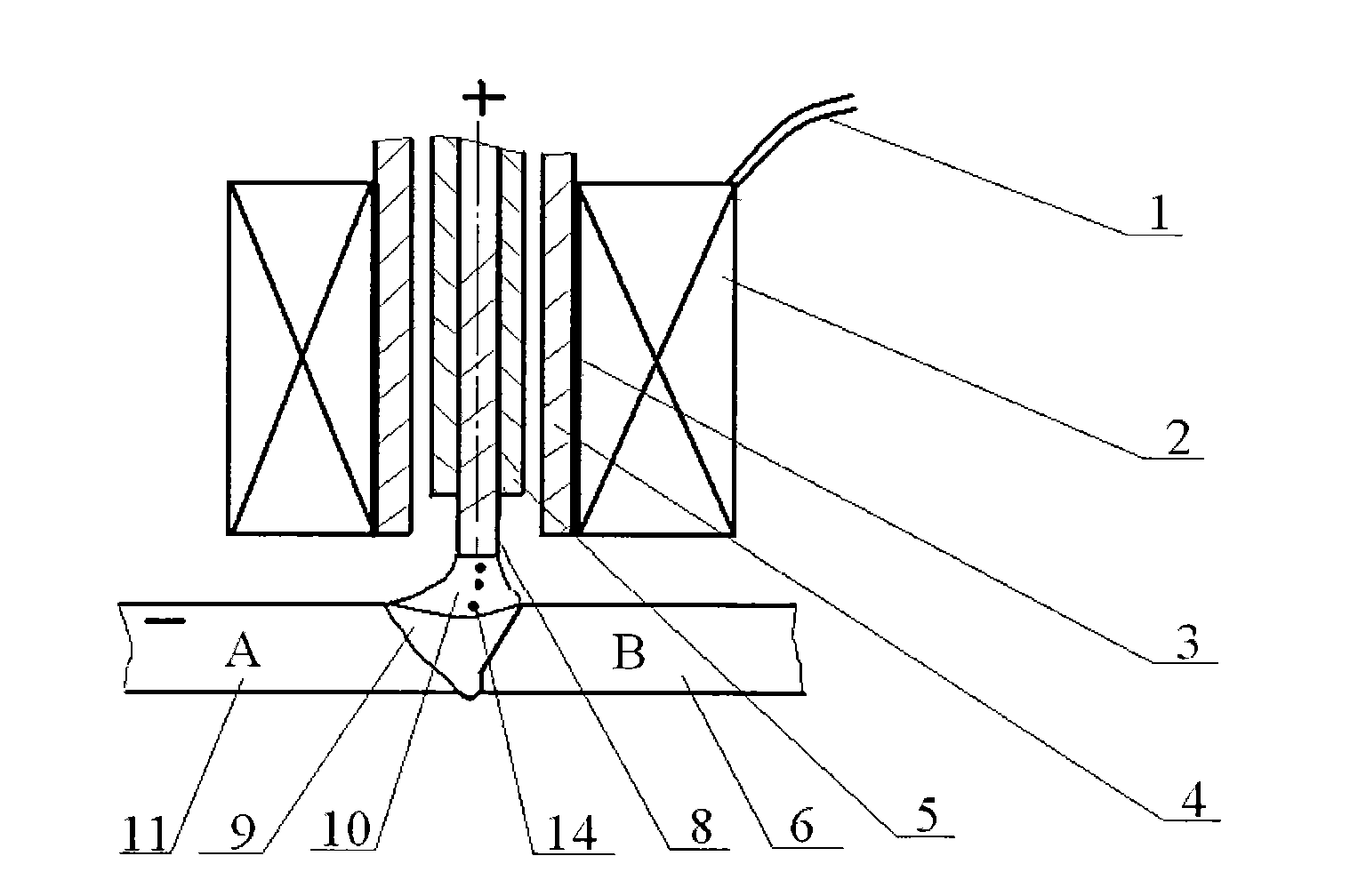

Electromagnetic current coupling field assisted hybrid melting-brazing method for laser-TIG arc and equipment

InactiveCN101862913AImprove connection qualityInhibition formationSoldering apparatusWelding apparatusMetallic materialsWelding defect

The invention discloses an electromagnetic current coupling field assisted hybrid melting-brazing method for a laser-TIG arc and equipment. In addition to the use of the welding zone, an alternating magnetic field is added to control properties of plasma formed through ionization of laser, arc and a raw material metal, thereby improving the laser utilization rate. Under the electric field assisted comprehensive effect, the weld melting depth is increased, and the assistant effect on the melting bath of the liquid-state brazing filler metal for laser-arc melting-brazing is realized through electromagnetic stirring and excitation and enhancement, thereby promoting the orderly flow of the liquid-state brazing filler metal and the rupture, wetting, spreading and proliferation of the liquid-state brazing filler metal on the surface of the high metal material, improving the full mixing of the liquid-state brazing filler metal and the base metal formed by melting the low-melting-point metal material, improving the uniformity of the components of the brazed weld, stabilizing the welding process, reducing welding defects, increasing the welding speed, improving the weld formation, optimizing the structure and performance of the brazed weld, and improving the quality of the brazed joint. Moreover, the equipment has the advantages of simple structure, flexible application, low cost, good effect and easy realization.

Owner:CHONGQING UNIV

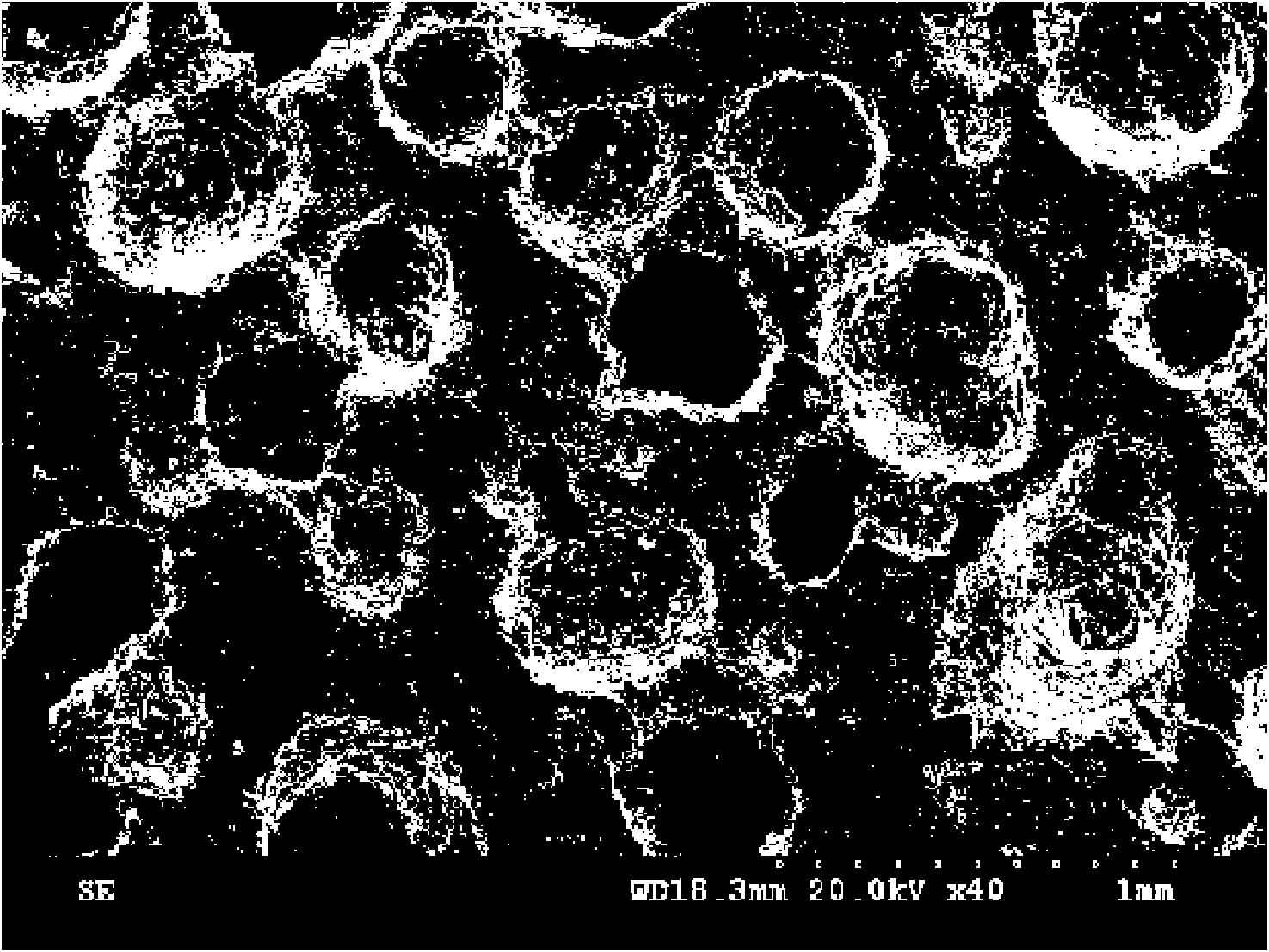

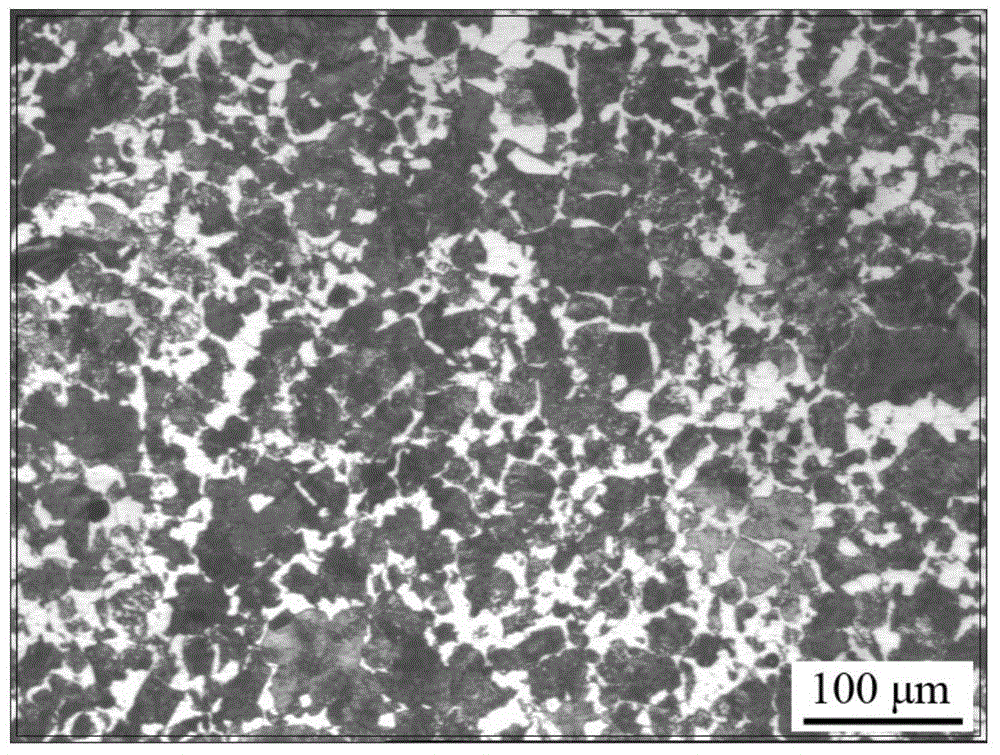

Nano-ceramic particle reinforced aluminum foam matrix composite material and preparation method thereof

A nano-ceramic particle reinforced aluminum foam matrix composite material and a preparation method thereof relates to an aluminum foam matrix composite material and a preparation method thereof. The invention solves the problem that in the preparation method of the ceramic particle reinforced aluminum foam matrix composite material, ceramic particles are micron-sized, the uniform distribution of nano-ceramic particles can not be realized, and the existing ceramic particle reinforced aluminum foam matrix composite material has wide aperture and low compressive yield strength. The aluminum foam matrix composite material of the invention is prepared from aluminum or aluminum alloy powder, CaCO3 and nano-ceramic particles. The preparation method comprises the following steps: using a ball mill to process raw material powder and stearic acid, mixing powder, then placing the mixture in a graphite mould to perform vacuum hot press sintering and obtain a perform, performing forward extruding to obtain a semi-finished product, heating and foaming to obtain the finished product. The aperture of the aluminum foam matrix composite material is less than 1mm, and the compressive yield strength is 50-98MPa which is 2-20 times of that of the existing aluminum foam matrix composite material. By using the method of the invention, the nano-ceramic particles can be uniformly distributed in the aluminum foam matrix composite material.

Owner:HARBIN INST OF TECH

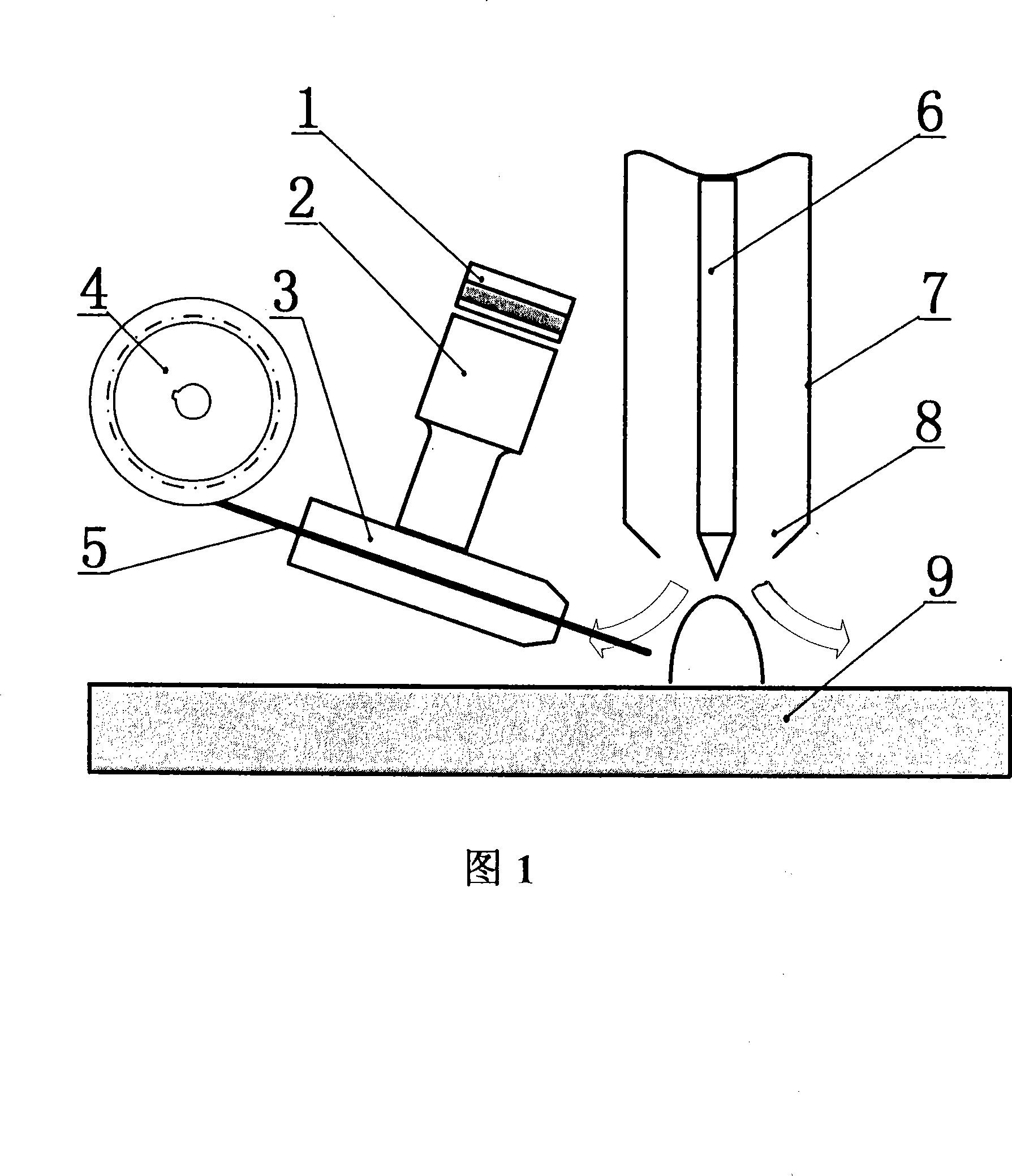

Ultrasonic vibration and welding stick feeding system compound welding method and device thereof

InactiveCN101239415AControl transitionAchieve welding productionArc welding apparatusMelting tankCavitation

The invention discloses an ultrasonic vibration and welding wire feed system composite welding method and a device thereof which are provided with a stable welding process, high quality of welding seams, controllable welding pool grain growth phenomenon after welding, and high welding quality in normal welding surroundings. The objective is achieved by following steps: transmitting cavitation effect and vibration effect to the welding pool during the welding wire and welding pool contacting process by broadcasting the ultrasonic in the welding wire feed system. The melt drop size at the terminal of the welding wire is controlled effectively by ultrasonic action during welding process, transition from melt drop to welding pool is more stable, and welding seam quality is further improved. Since ultrasonic is applied in the welding feed system during welding process, welding wire melt drop transition condition is affected, energy distribution status during welding process is improved, thereby refinement and homogenization degree of the joint, and mechanical property such as intensity are further enhanced.

Owner:HARBIN INST OF TECH

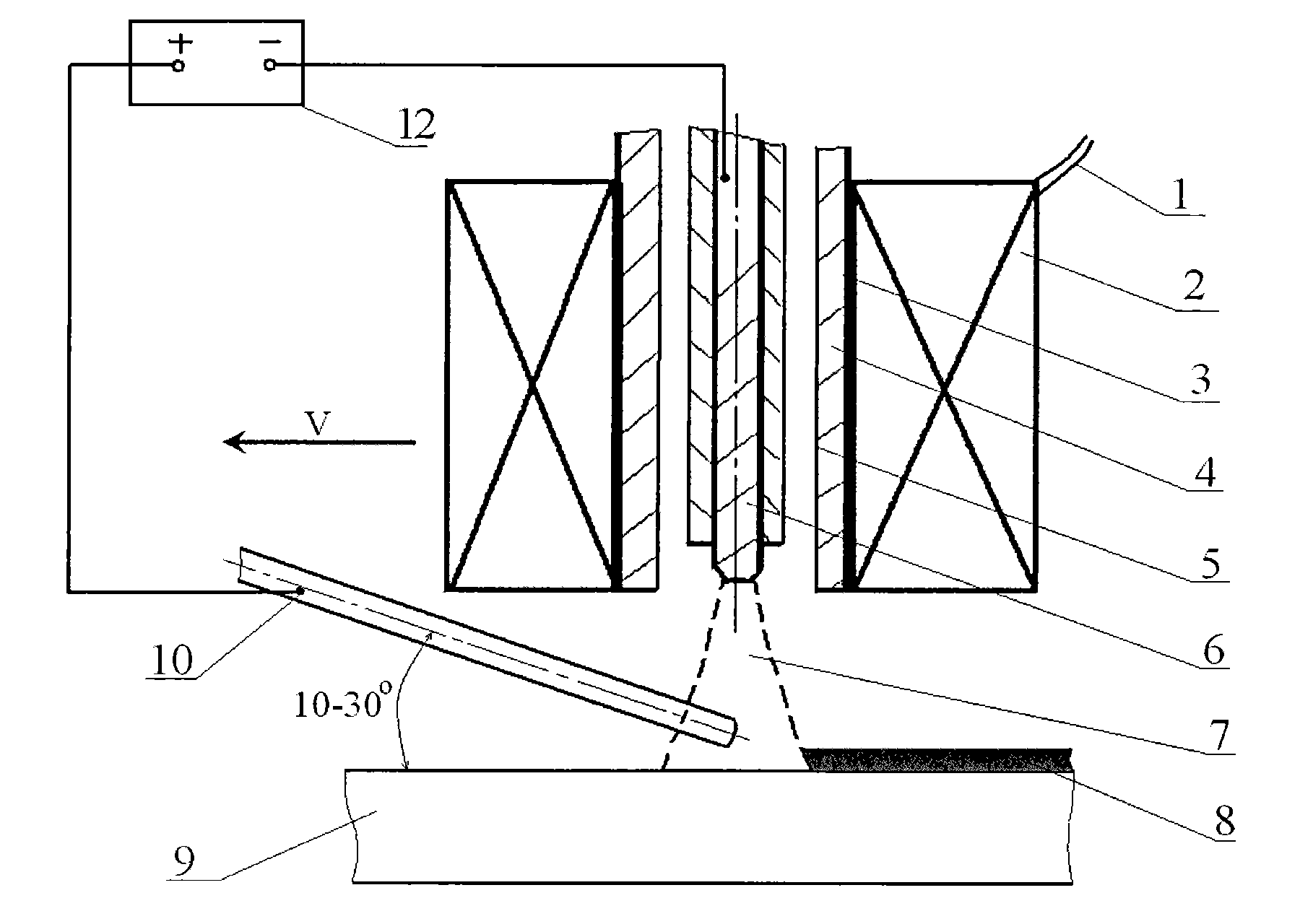

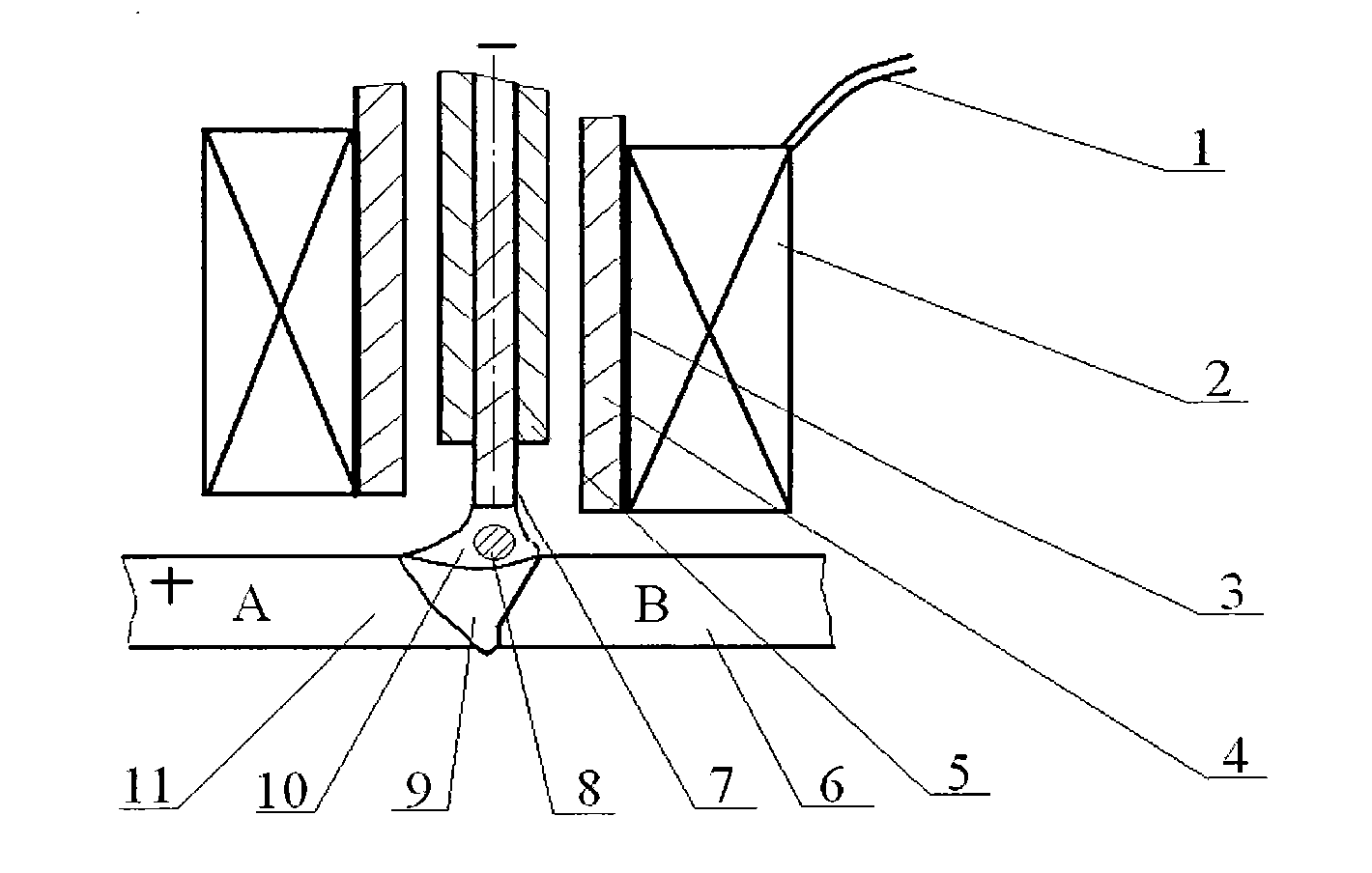

Electromagnetic excited TIG arc melting-brazing hybrid welding method and equipment

InactiveCN101862873AAvoid severe burnsLow heat inputSoldering apparatusMetal working apparatusMetallic materialsWelding defect

The invention discloses an electromagnetic excited TIG arc melting-brazing hybrid welding method and equipment. In addition to the use of the welding zone, an alternating magnetic field is added to control properties of a welding arc, and the assistant effect on the melting bath of the liquid-state brazing filler metal for arc melting-brazing is realized through electromagnetic stirring and excitation and enhancement, thereby promoting the orderly flow of the liquid-state brazing filler metal and the rupture, wetting, spreading and proliferation of the liquid-state brazing filler metal on the surface of the high metal material, improving the full mixing of the liquid-state brazing filler metal and the base metal formed by melting the low-melting-point metal material, improving the uniformity of the components of the brazed weld, reducing welding defects, increasing the welding speed, improving the weld formation, optimizing the structure and performance of the brazed weld, and improving the quality of the brazed joint. Moreover, the equipment has the advantages of simple structure, flexible application, low cost, good effect and easy realization.

Owner:CHONGQING UNIV

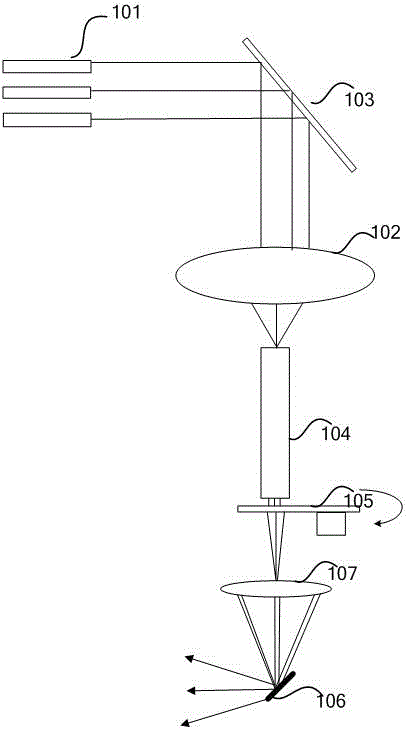

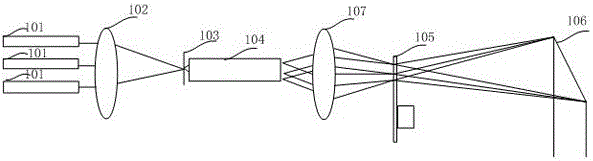

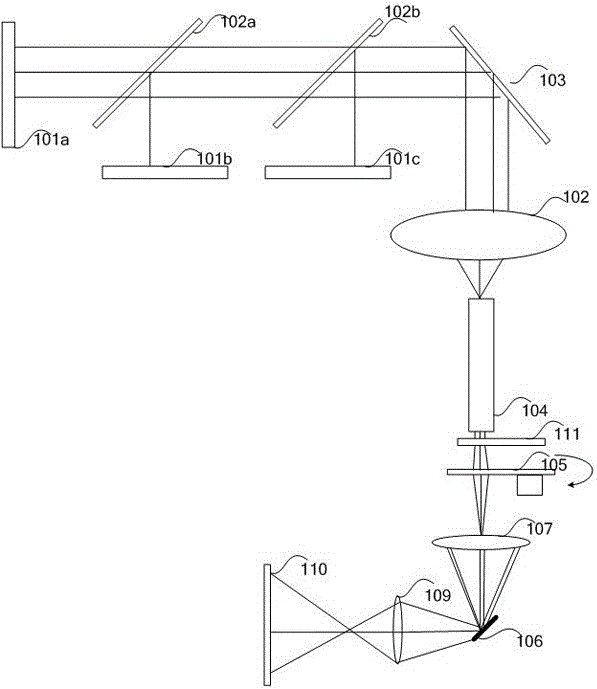

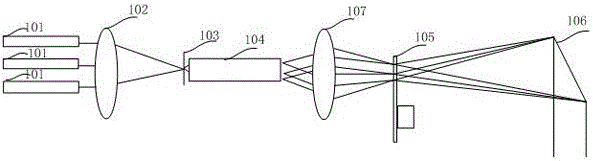

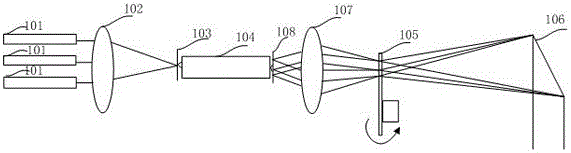

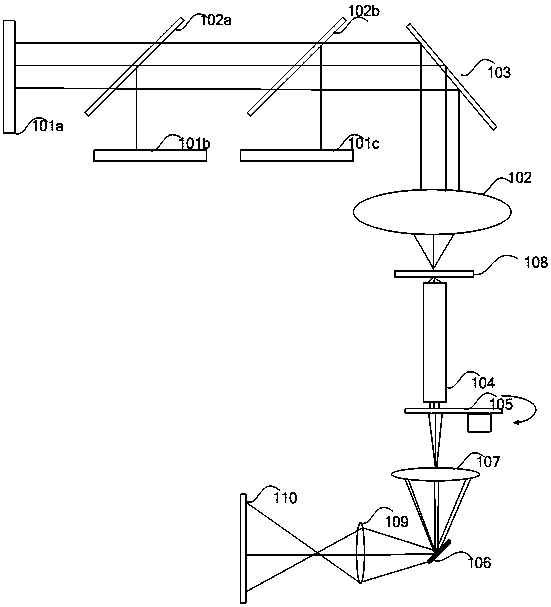

Laser projection system

InactiveCN106707671AVariety of divergence anglesImprove display qualityProjectorsOptical elementsDivergence angleLight beam

The invention discloses a laser projection system comprising a laser light source which emits laser beams of at least one color. The transmission light path of the laser beams includes a light homogenizing part which is used for receiving and homogenizing the laser beams; a light valve which is used for receiving the laser beams homogenized by the light homogenizing part and modulating the laser beams; a diffuse scattering phase plate which is arranged at the light incident surface side of the light homogenizing part and can increase the divergence angle of the beams; and a moving diffuser which is arranged at the light emergent surface side of the light homogenizing part and can greatly enhance the generation number of random phases, wherein the position of the moving diffuser is the object plane position of the light valve and the human eye integration effect is performed on the generated random phases so that the speckle effect of the projection frame can be weakened or eliminated to the greatest extent, and thus the speckle elimination effect and the display quality of the projection frame can be greatly enhanced.

Owner:HISENSE

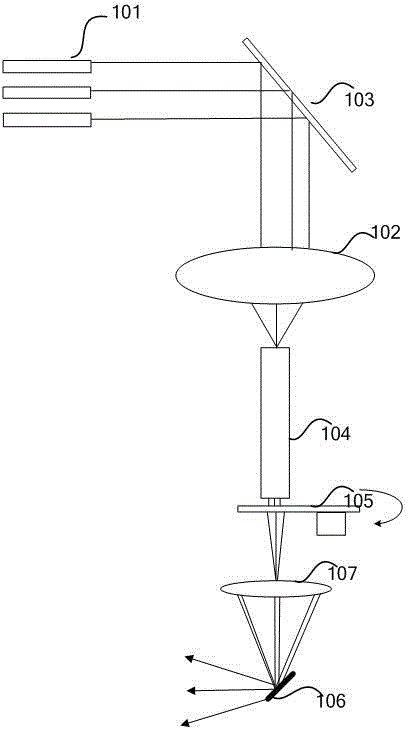

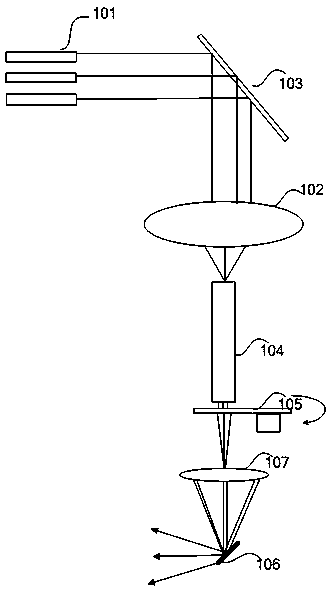

Laser projection system

InactiveCN106647127AVariety of divergence anglesImprove display qualityProjectorsOptical elementsIntegral actionProjection image

The invention discloses a laser projection system, comprising a laser light source which is used for emitting laser beams of at least one color; a light homogenization component which is used for receiving and homogenizing the laser beams; a light valve which is used for receiving the laser beams homogenized by the light homogenization component and modulating the laser beams; a vibrating reflection-type phase plate which is arranged on a light incident surface side of the light homogenization component; and a motion diffuser which is arranged on a light emergent surface side of the light homogenization component. A position at which the motion diffuser is located is an object plane position of the light valve. The number of produced random phases can be greatly increased, according to the random phases, through integral action of human eyes, the speckle effect of a projection image can be reduced or eliminated to the greatest extent, and the speckle eliminating effect and the display quality of the projection image can be greatly improved.

Owner:HISENSE

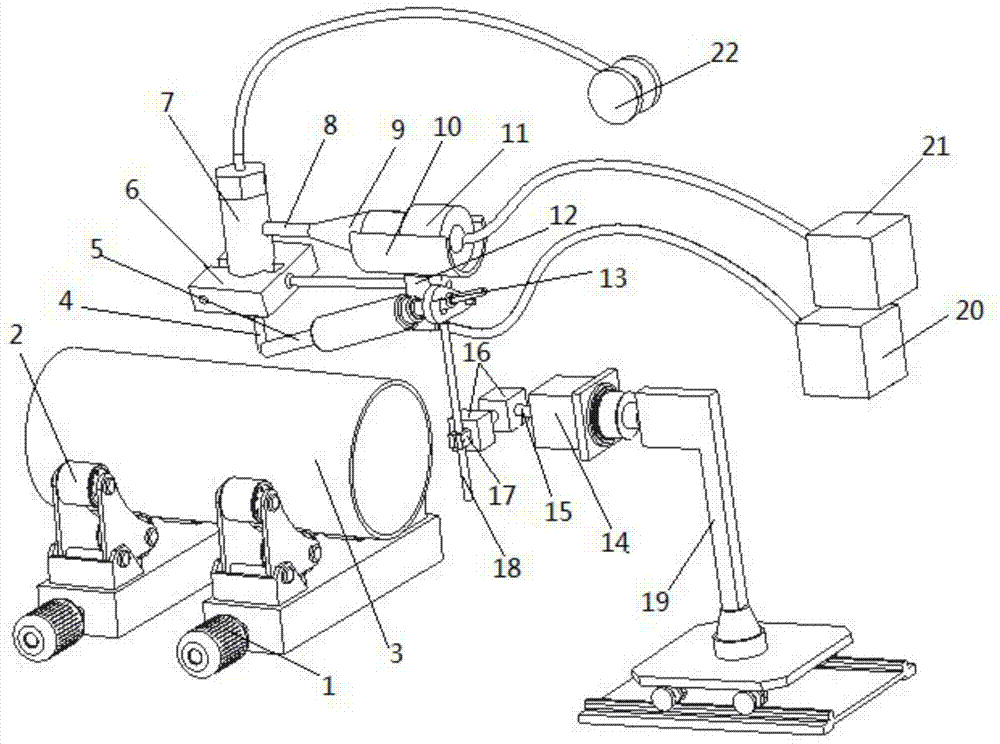

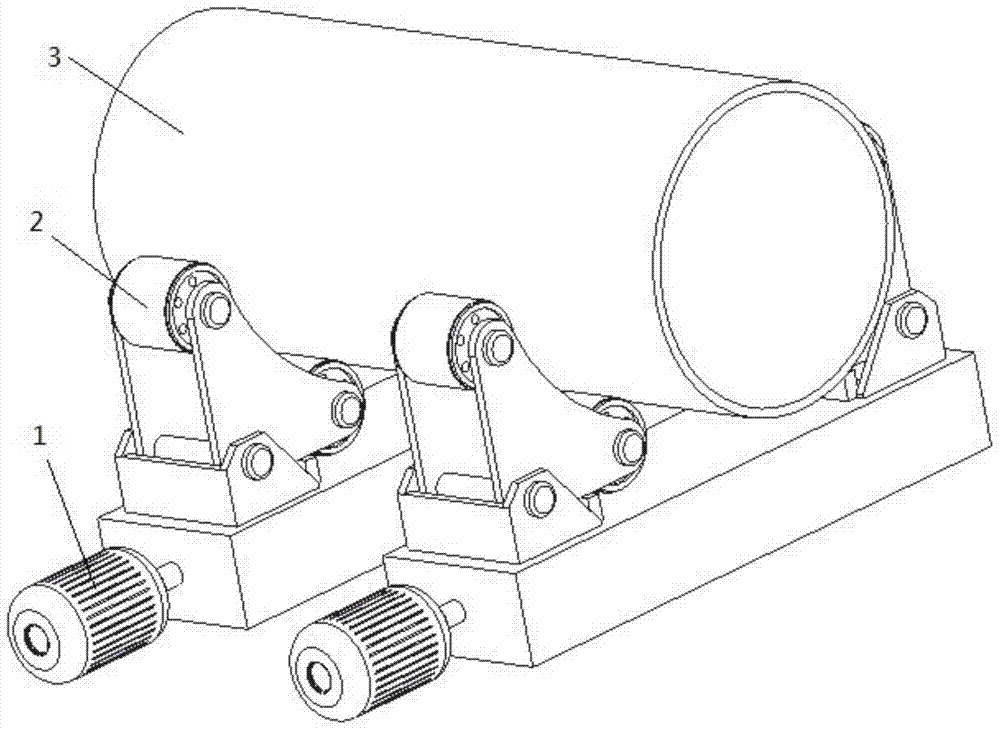

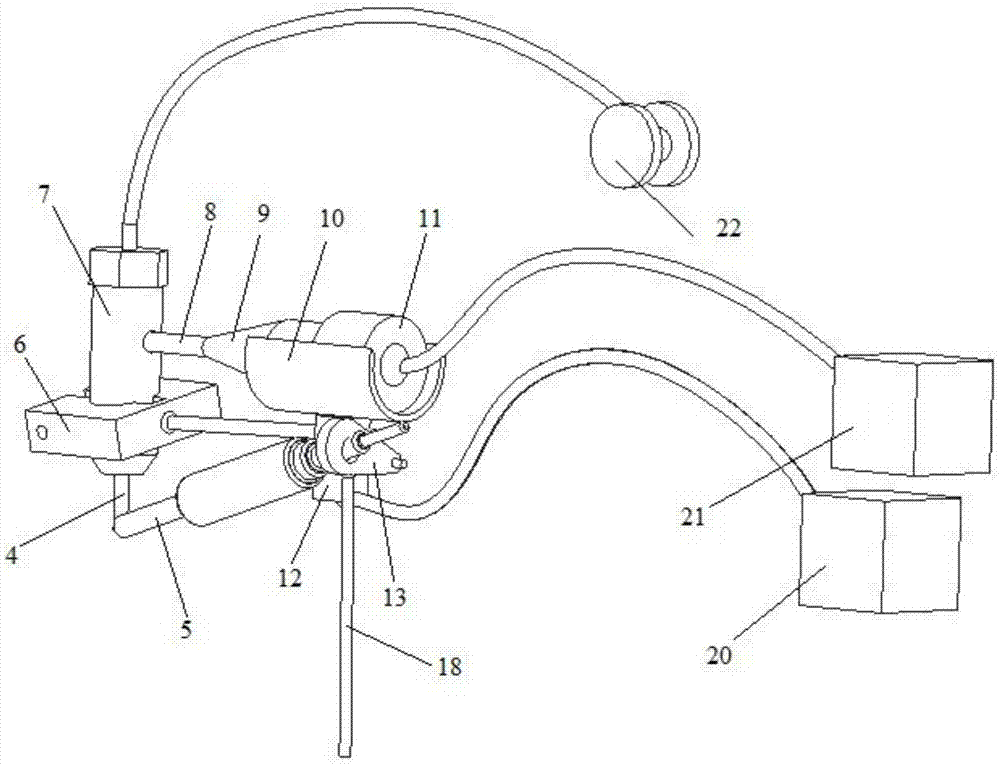

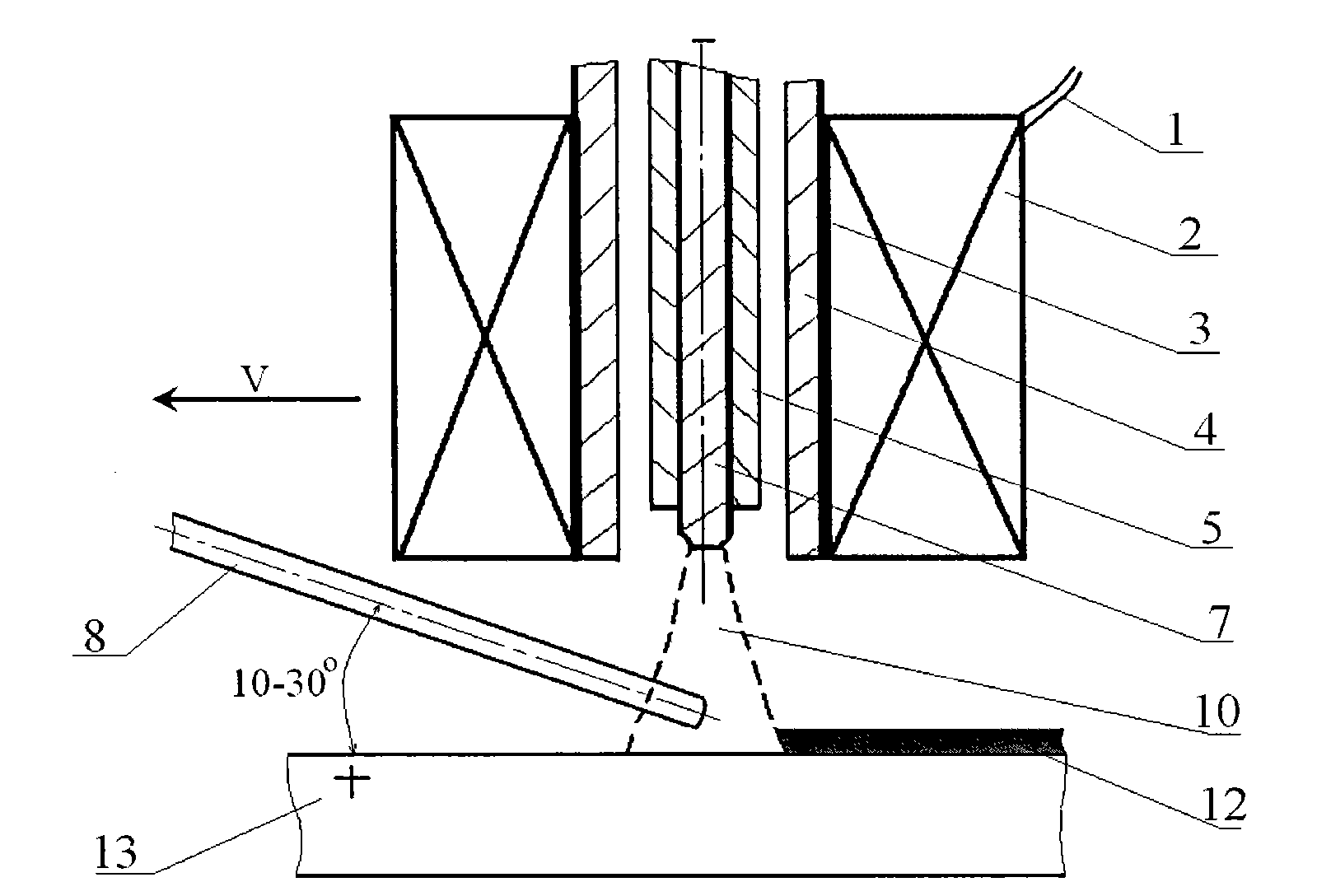

Device and method for welding high steel grade and large wall thickness pipeline steel

The invention discloses a device and a method for welding high steel grade and large wall thickness pipeline steel. The device for welding the high steel grade and large wall thickness pipeline steel is mainly composed of a work platform controller 1, an idler wheel support 2, a work piece 3, a welding gun 5, a wire feeding nozzle 7, an ultrasonic tool head 8, an amplitude variation pole 9, an ultrasonic transducer 11, a welding power source 20, an ultrasonic generator 21, a wire feeding mechanism 22, an oscillator 14, a transmission shaft 15, an angle adjustor 16 and the like. The method for welding the high steel grade and large wall thickness pipeline steel includes: (1) placing the work piece on the idler wheel support, and starting the work platform controller; (2) setting welding voltage and a welding current, turning on the welding power source, and starting the ultrasonic generator after an electric arc is stabilized; (3) adjusting angles of the welding gun through the angle adjustor; (4) starting the oscillator, and driving the welding gun to swing back and forth through entrance and exiting movements of the transmission shaft; (5) starting the wire feeding mechanism, and staring automatic welding. The device and the method for welding the high steel grade and large wall thickness pipeline steel achieve high welding quality, good weld joint formation, and a high welding joint microstructure constituent homogenization degree, and have a broad market application prospect.

Owner:SOUTHWEST PETROLEUM UNIV

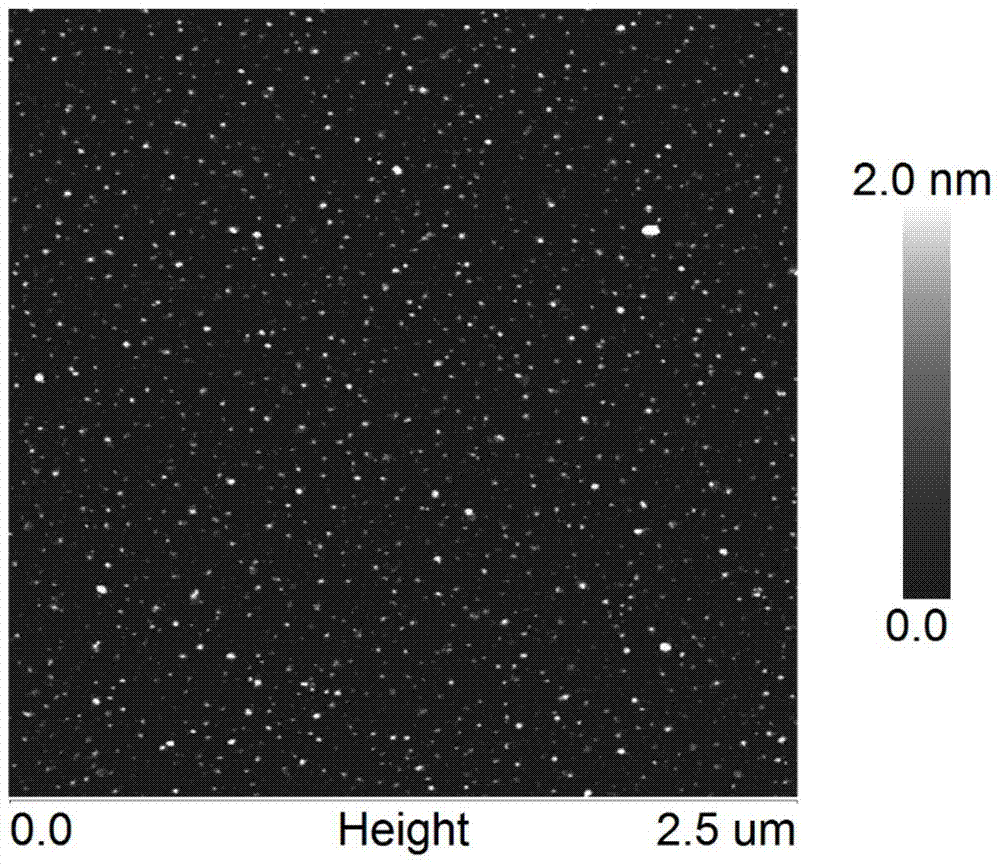

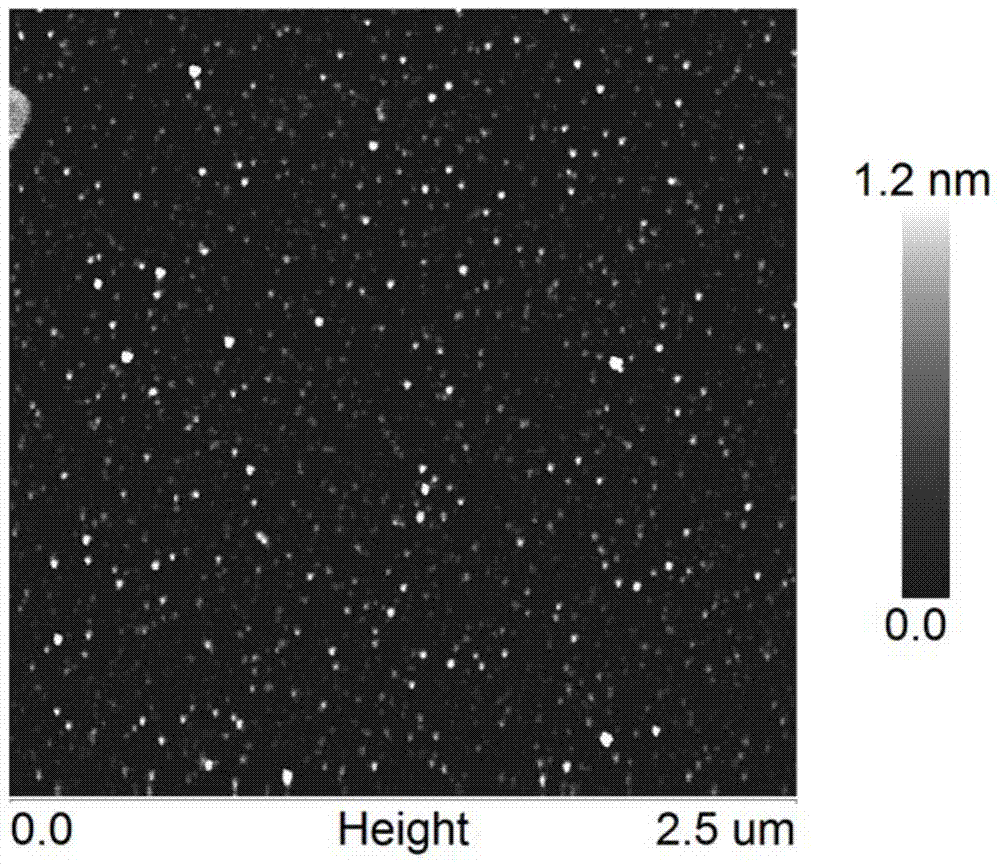

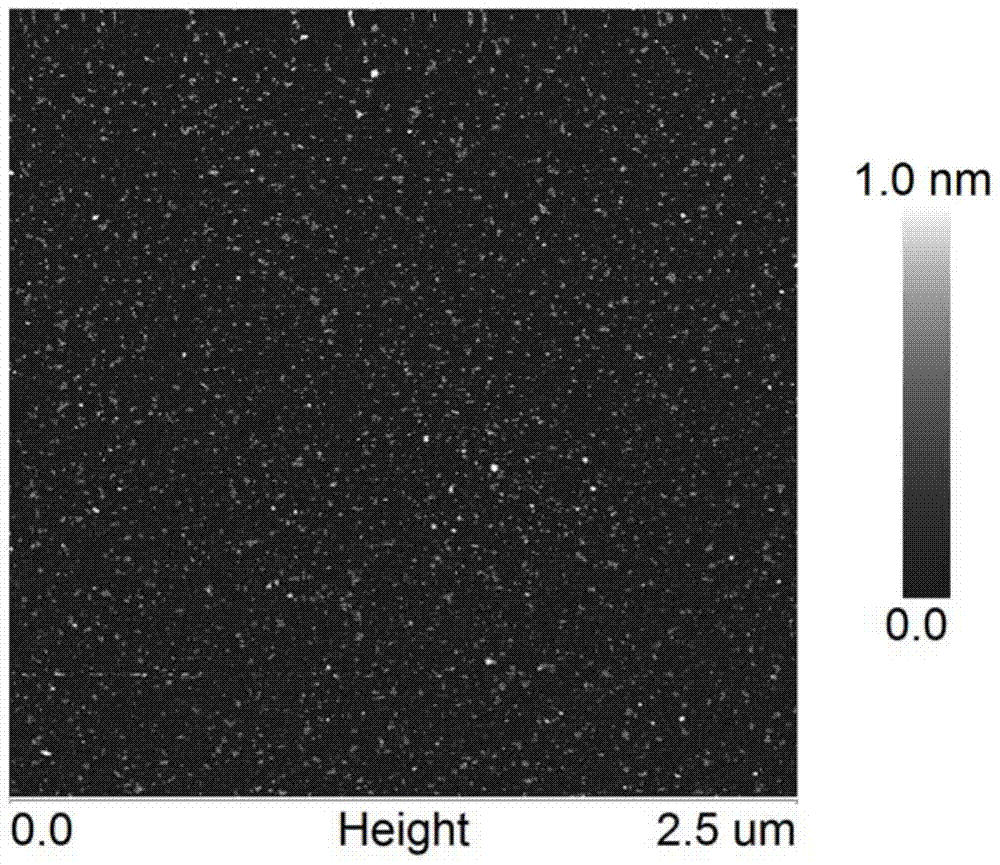

Method for batch preparation of graphene quantum dots

The invention discloses a method for batch preparation of graphene quantum dots. The method is characterized by comprising the following steps: using graphite powder as a raw material; quickly obtaining large-batch unoxidized graphene quantum dots by liquid nitrogen impregnation ultralow temperature pretreatment and ultrasonic chemical stripping. According to the method disclosed by the invention, a liquid nitrogen impregnation ultralow temperature pretreatment technology is introduced and is combined with conventional ultrasonic processing, so that large-batch preparation of the graphene quantum dots is realized; according to the method, the condition that the graphene quantum dots are oxidized can be effectively avoided, and the activities such as conductivity of the graphene quantum dots is ensured to the maximum extent; in addition, by using the method, large-batch preparation of high-concentration graphene quantum dots can be realized; the method has the advantages of simple process, convenience in operation and low preparation cost.

Owner:HEFEI UNIV OF TECH

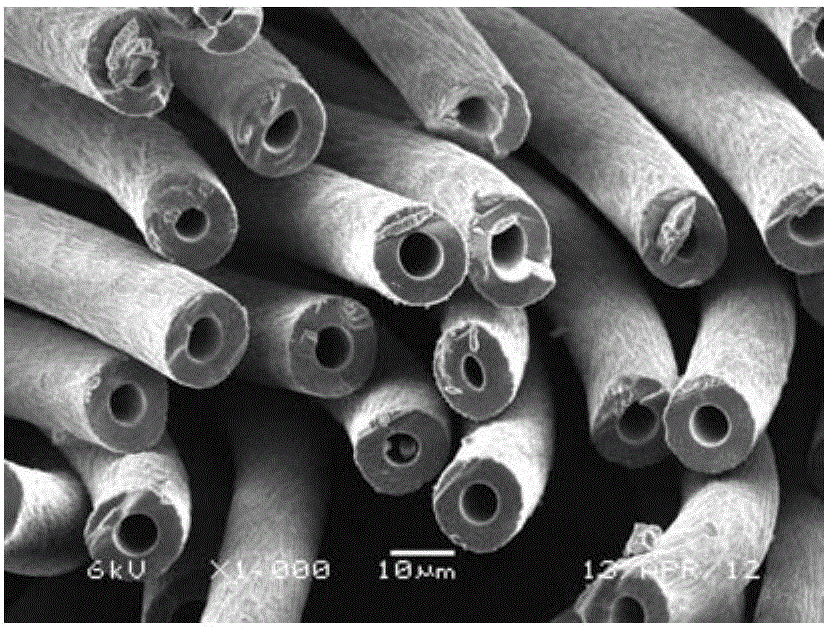

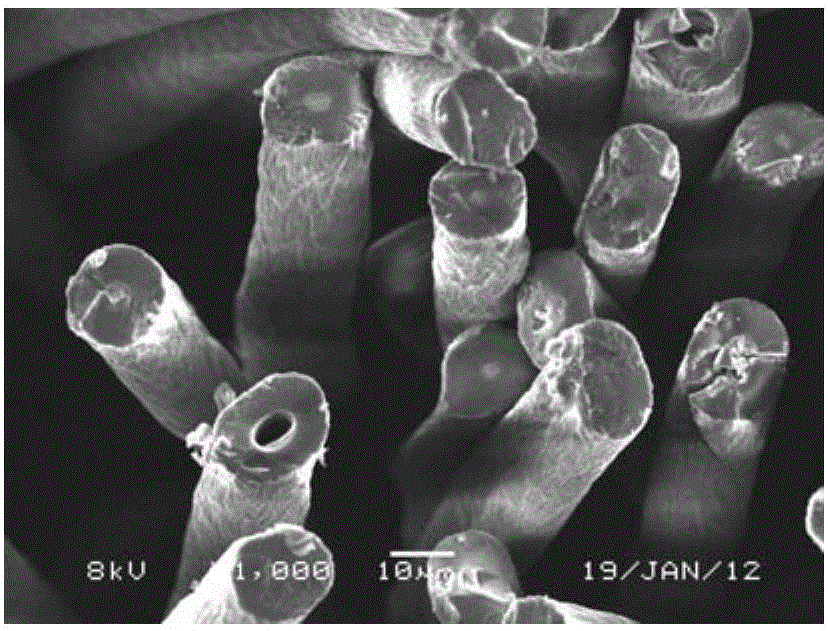

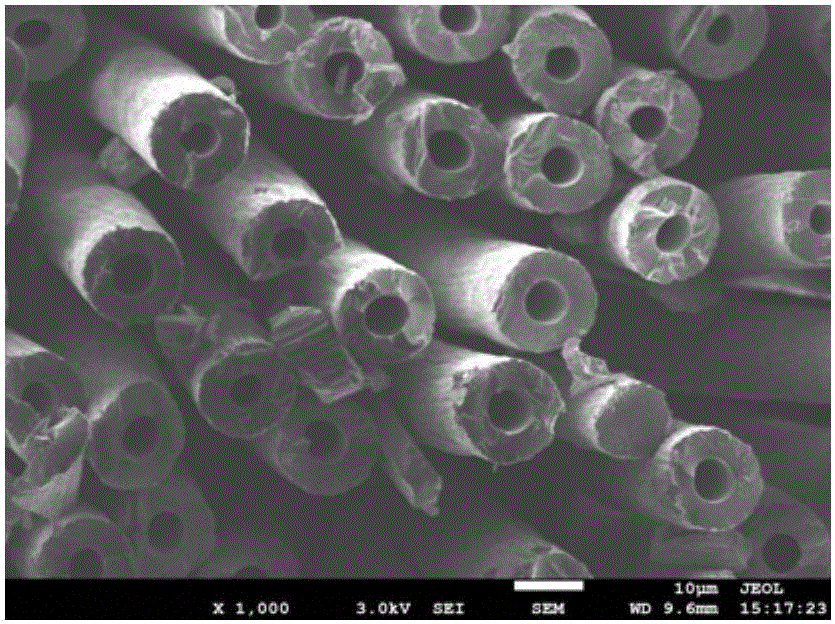

Prepn. of polyacrylonitrile-base high-performance raw carbon fiber

InactiveCN1167838CReduce gel particlesReduce intensityFibre chemical featuresItaconic acidMineralogy

The present invention relates to the preparation of high-performance polyacrylonitrile-based carbon fiber. Acrylonitrile, itaconic acid and methyl methacrylate in a certain weight proportion are reacted to obtain spinning dope, and the spinning dope is made into greign fiber of high-performance carbon fiber through filtering, solidification, water washing, drafting in hot water, oiling, drying and densifying, re-oiling, drying and densifying for the second time, steam drafting and drying setting. The present invention has the advantages of high drafting rate, homogeneous fibre structure, and small mechanical performance variation coefficient.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

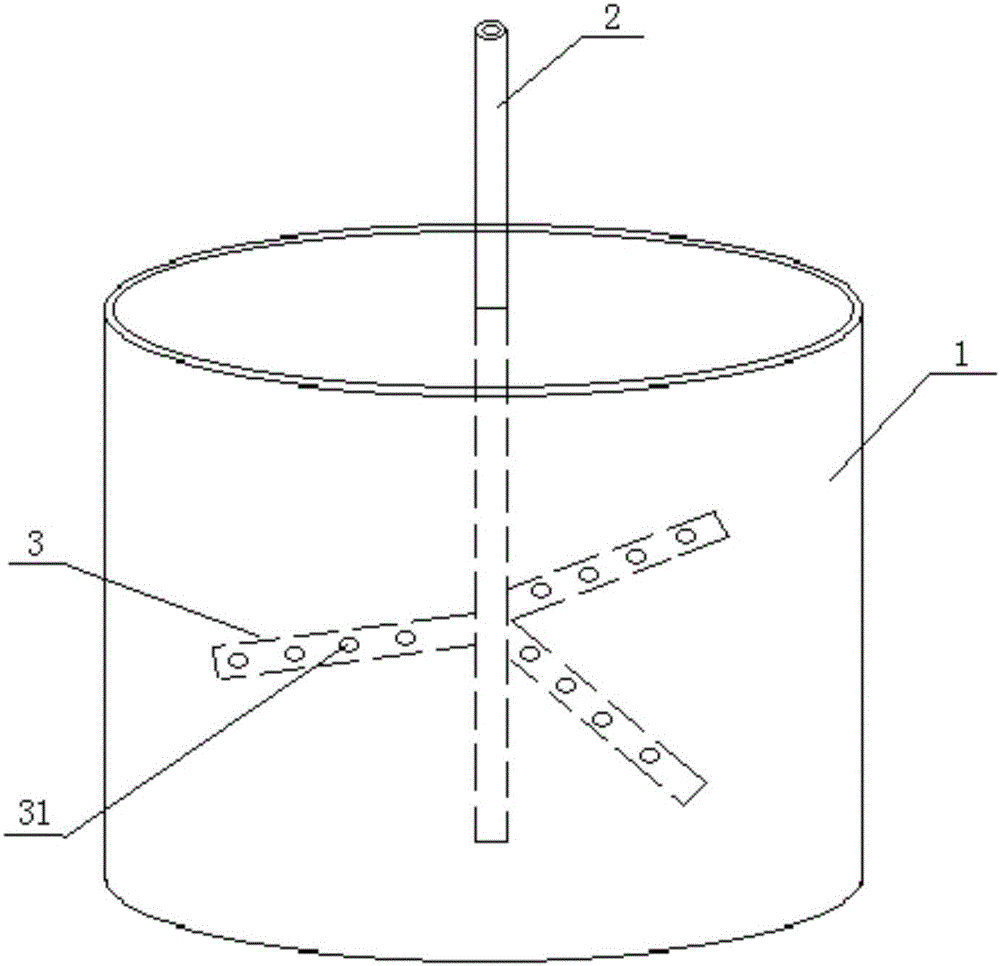

Stirring device

ActiveCN104984681AStir wellWater evenlyRotary stirring mixersClay mixing apparatusEngineeringCavity wall

The invention discloses a stirring device. The stirring device comprises a box body with an opening in the upper end, a stirring shaft and a stirring paddle, wherein the stirring shaft is connected with the stirring paddle, the stirring shaft comprises a first hollow cavity, and a water injection port is formed in the cavity wall of the first hollow cavity; the stirring paddle comprises a second hollow cavity, the second hollow cavity is communicated with the first hollow cavity, and a plurality of water outlet holes are formed in the cavity wall of the second hollow cavity. The stirring device disclosed by the invention can greatly improve the stirring uniformity.

Owner:ZHANJIANG JIANKE ENG QUALITY TESTING CENT CO LTD

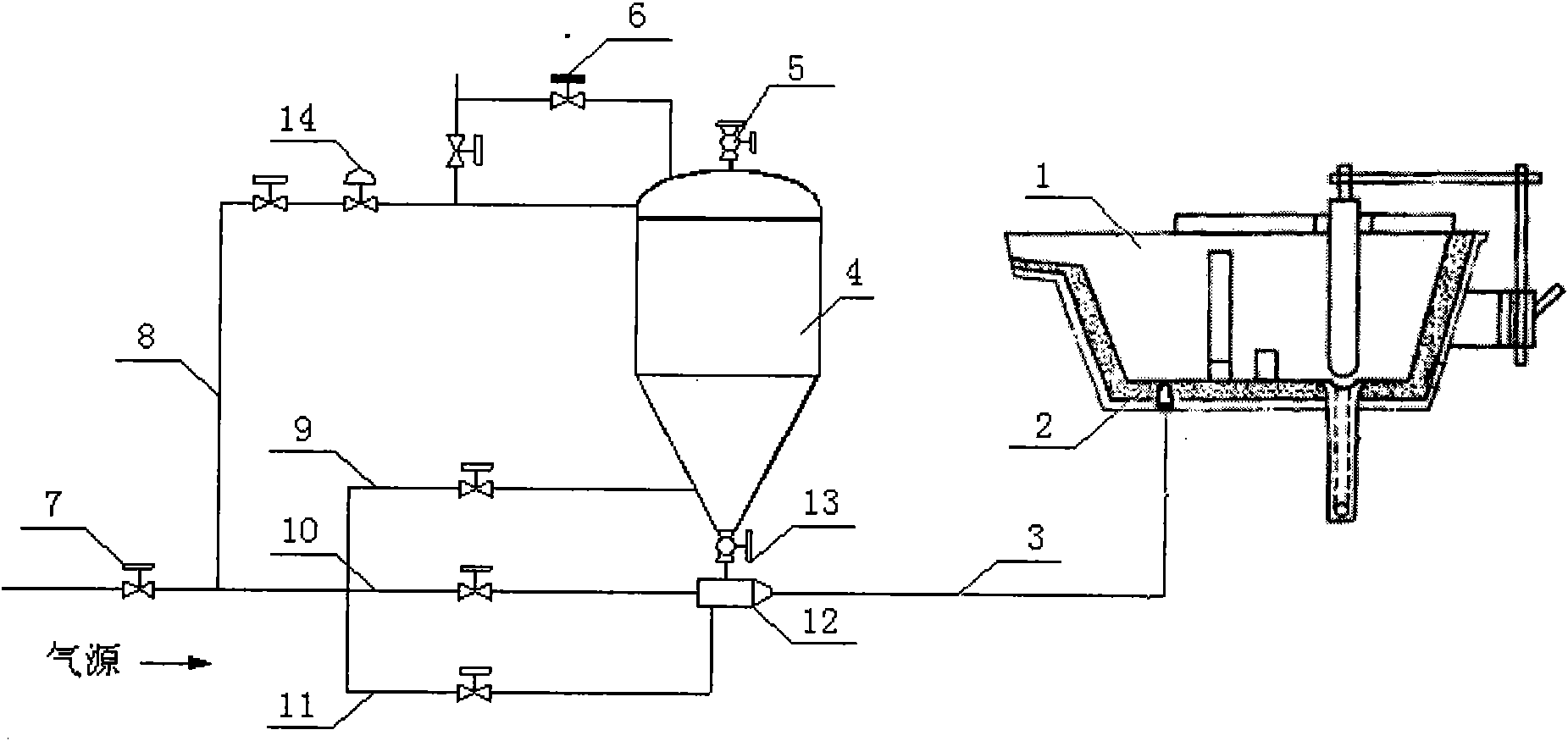

K2O-Na2O-Nb2O5-SiO2-B2O3 system glass ceramic material used for energy storage, and preparation method thereof

The invention relates to a K2O-Na2O-Nb2O5-SiO2-B2O3 system glass ceramic material used for energy storage, and a preparation method thereof. The method comprises the following steps: mixing K2CO3, Na2CO3, Nb2O5, SiO2, H3BO3 and BaF2 according to a molar ratio of 15:15:30:4.2:(2-5), fusing, molding, annealing, and crystallizing to prepare the material. Alkali metal oxides in raw materials exist in the glass system as a network modifier to destroy the network structure of glass, so the formula of the glass is simplified, the cost is reduced, and the quantity of kinds of precipitated impure phases is fundamentally reduced; a fusion technology is adopted, so the raw materials highly and uniformly react, and the experiment operation is simple; annealing can effectively eliminate internal stress; and segment heat insulation is adopted in the crystallization treatment process, so a crystal phase completely grows, crystal precipitation is thorough, and obtaining of glass ceramic with fine internal crystal grins, high homogenization degree and high energy storage density is facilitated.

Owner:SHAANXI UNIV OF SCI & TECH

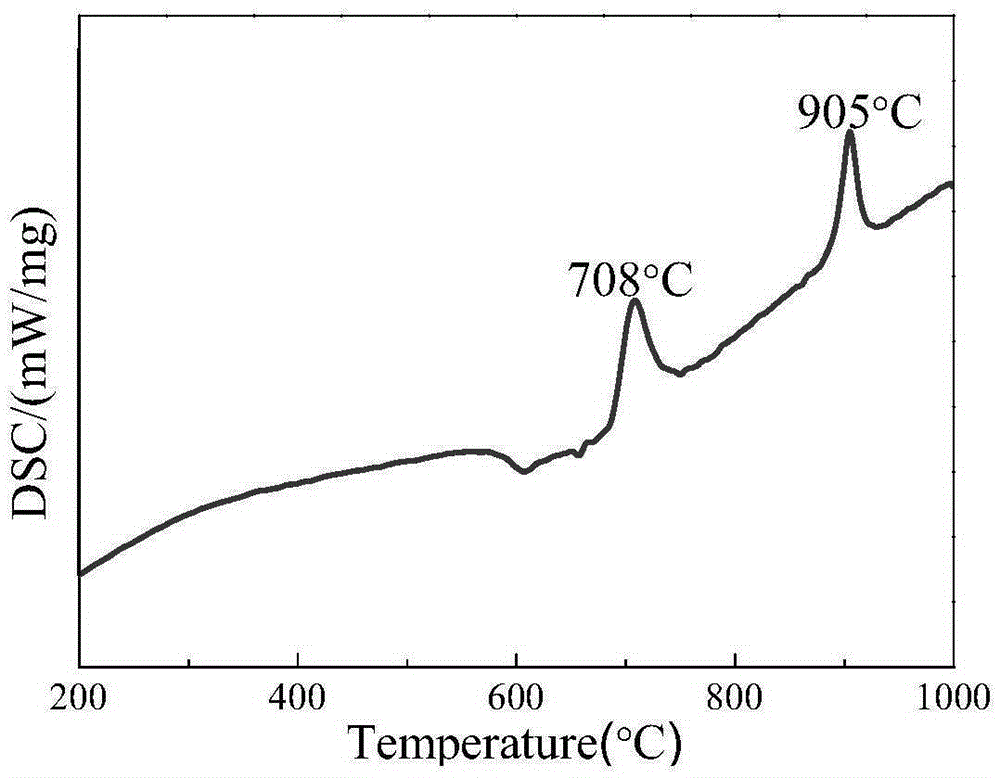

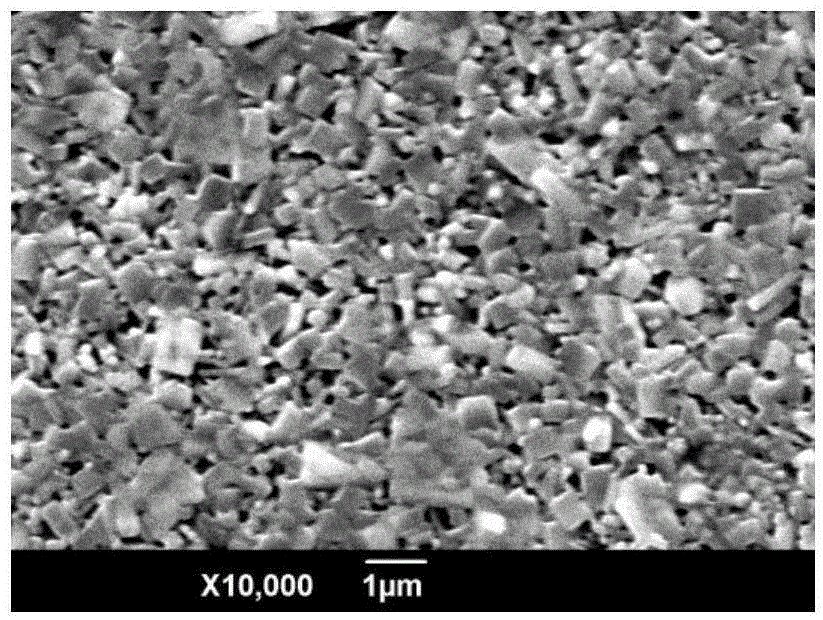

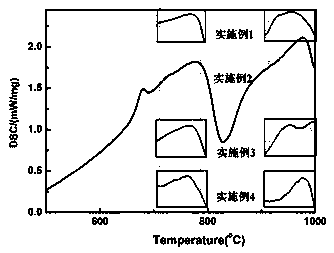

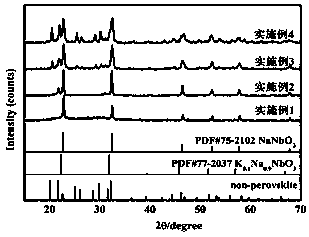

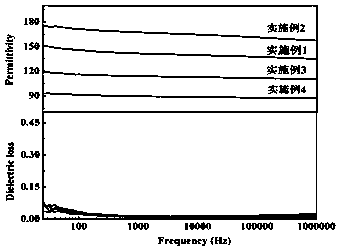

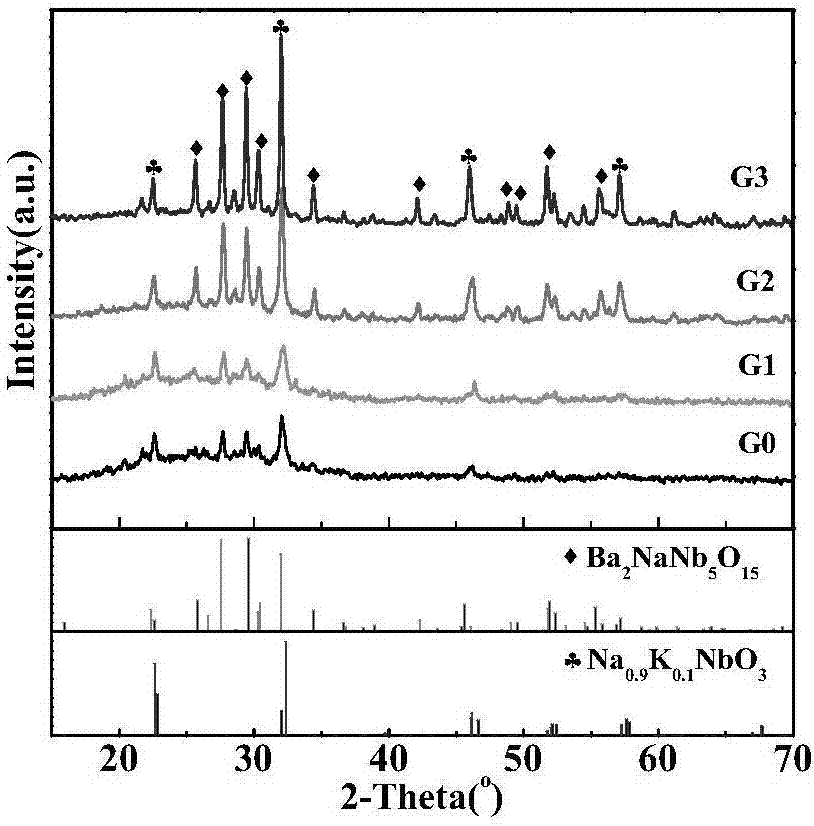

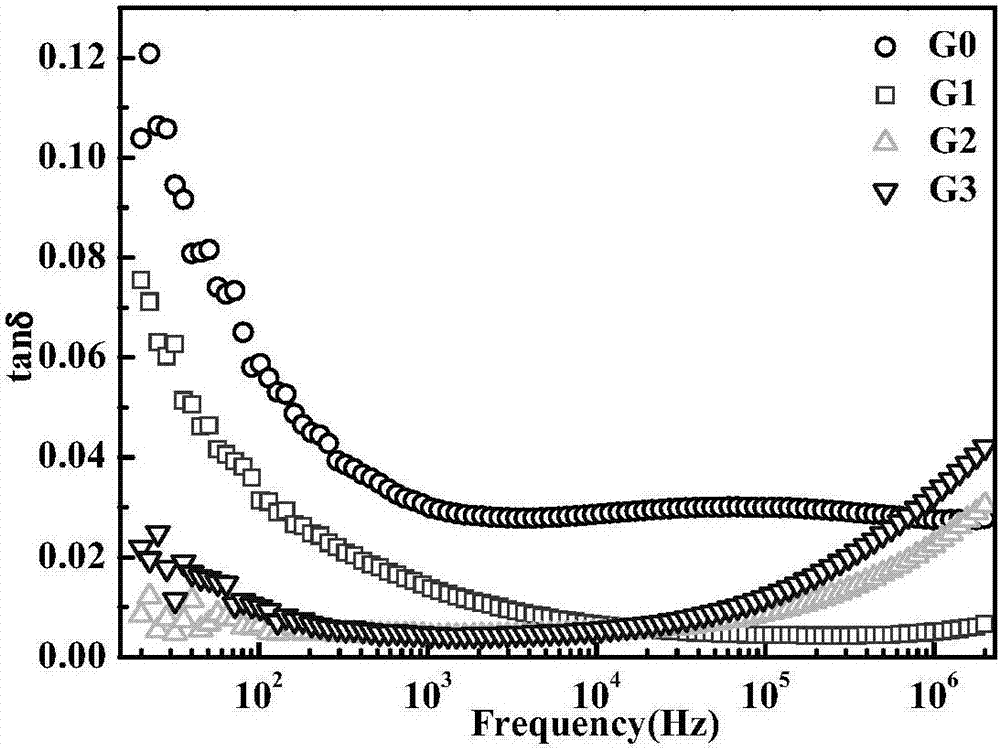

NaNbO3 phase containing Na2O-K2O-Nb2O5-SiO2 low dielectric loss energy storage glass ceramic

The invention relates to a NaNbO3 phase containing Na2O-K2O-Nb2O5-SiO2 low dielectric loss energy storage glass ceramic material, the microcrystal glass material is prepared by mixing a glass phase and a crystal phase, fusing, cooling and molding, annealing, and conducting crystallization heat treatment; wherein the glass phase accounts for 20% according to mole percent, and the balance is the crystal phase; the crystal phase is prepared by heating and fusing Na2CO3, K2CO3 and Nb2O5 at the molar ratio of x:(1-x):1, wherein x is more than or equal to 0.7 and less than or equal to 1. The dielectric loss of the prepared potassium-sodium niobate based energy storage microcrystal glass material is low; the added Na2CO3 not only has an effect on regulating the composition of the crystal phase ofa potassium-sodium niobate system, but also has a certain effect on promoting the crystallization process, the NaNbO3 phase favorable for the high energy storage density is formed, and the high energy storage density glass ceramic material is finally obtained.

Owner:SHAANXI UNIV OF SCI & TECH

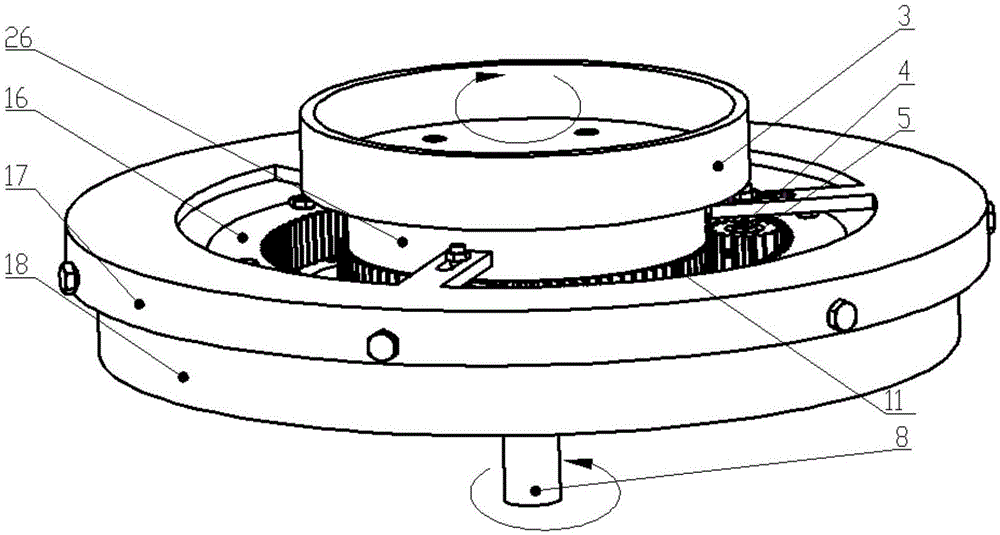

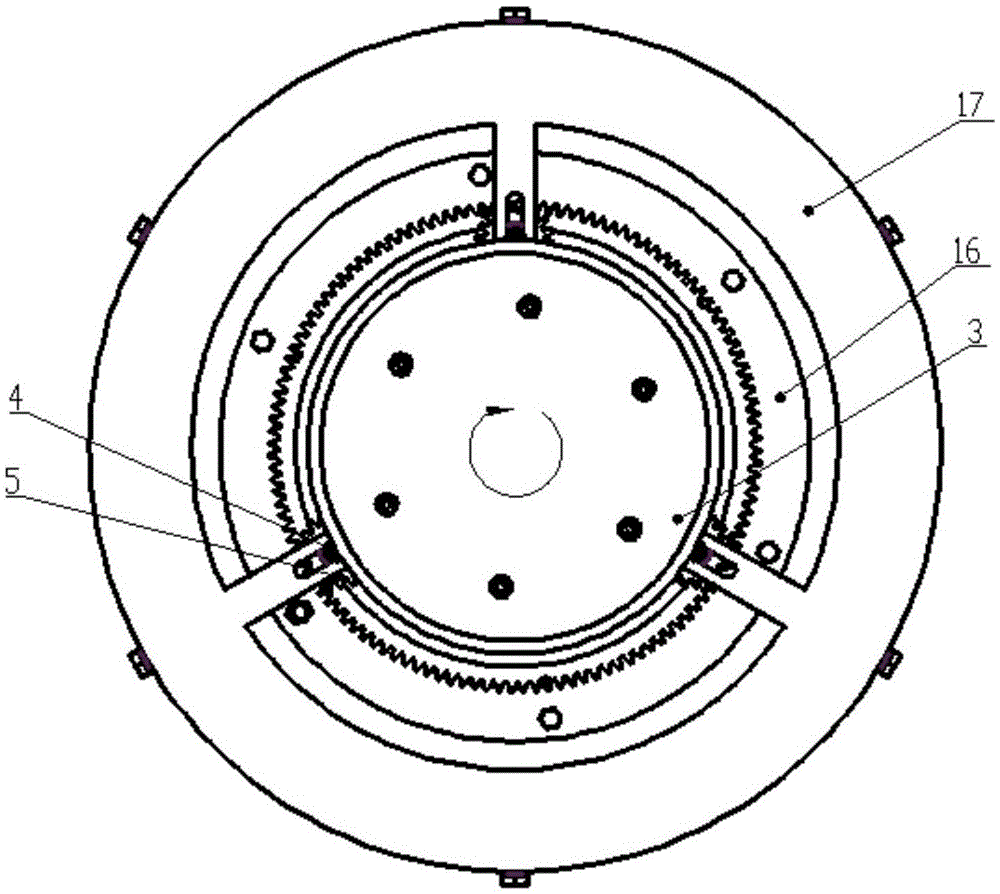

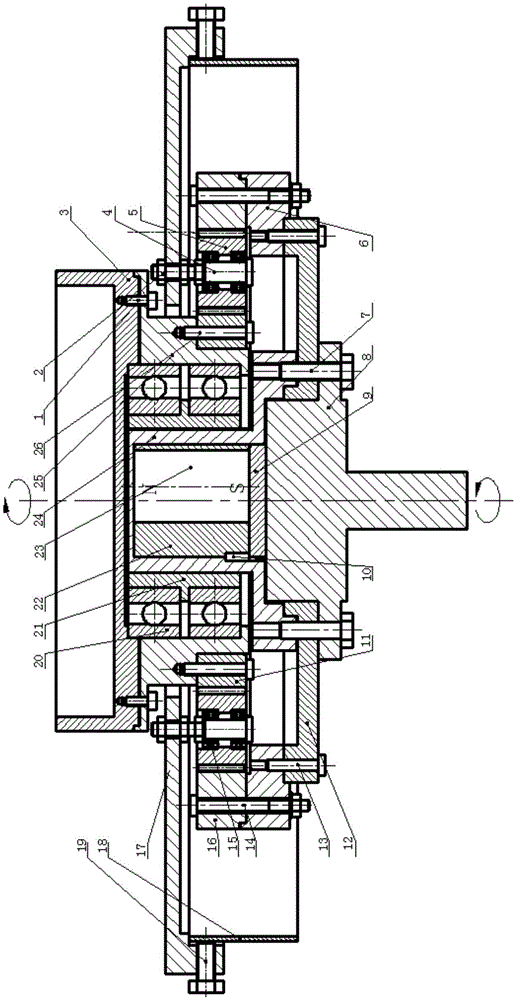

Magnetostatic moving field magnetorheological polishing mechanism test device and processing method thereof

ActiveCN105458840APolished evenlyImprove polishing efficiencyGrinding drivesGrinding machinesBall bearingMagnetic poles

The invention relates to a magnetostatic moving field magnetorheological polishing mechanism test device and a method. The device comprises a magnetorheological abrasive semi-fixed flexible micro-grinding head generation device, a magnetostatic moving field eccentric conversion device and a polishing disc reverse rotating device; the magnetorheological abrasive semi-fixed flexible micro-grinding head generation device comprises a base, a permanent magnetic pole, a fixed sleeve, a turntable and a polishing disc; the magnetostatic moving field eccentric conversion device includes a gasket, an eccentric sleeve, an inner positioning ring, an angle contact ball bearing and an outer positioning ring; and the polishing disc reverse rotating device comprises an outer gear, a planet gear, an inner gear, a support piece, a fixed disc, a deep groove ball bearing, a mounting shaft and a static piece. The device realizes high-efficiency and constant-pressure ultrasmooth magnetorheological polishing of workpieces under the condition of not updating magnetorheological liquid; the surfaces quality of obtained workpieces is good; the processing efficiency and precision are high; the workpieces have no surface and sub-surface damage; the uniformity degree is high; the material consumption is low; the cost is low; and the device can be applied to processing of various optical elements and semiconductor substrates.

Owner:GUANGDONG UNIV OF TECH

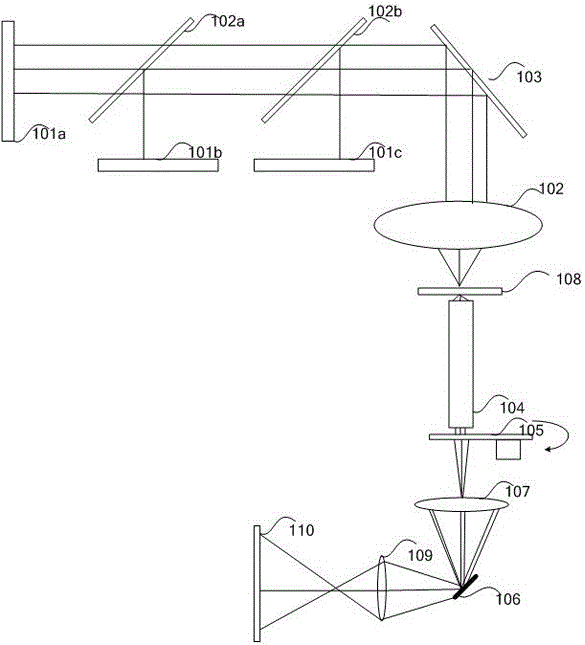

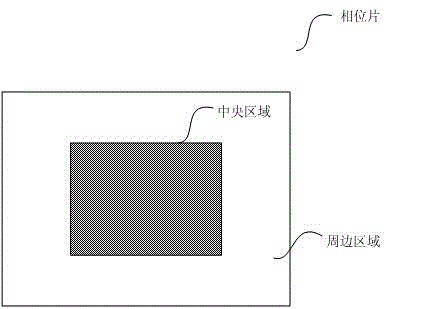

Laser projection system

InactiveCN106773485AVariety of divergence anglesAmplitude of small scatterProjectorsOptical elementsIntegral actionDivergence angle

The invention discloses a laser projection system which comprises a laser light source, a light homogenizing component, a light valve, a first phase plate and a motion diffuser, wherein the laser light source emits laser beams of at least one color; the light homogenizing component, the light valve and the first phase plate are included in a transmission light path of the laser beams; the light homogenizing component is used for receiving and homogenizing the laser beams; the light valve is used for receiving the laser beams homogenized by the light homogenizing component and modulating the laser beams; the first phase plate is arranged on the incident side of the light homogenizing component; the center area of the first phase plate is larger than a divergence angle of the laser beams in a surrounding area; the motion diffuser is arranged on the emergent side of the light homogenizing component and is capable of greatly improving the quantity of generated random phases; the position where the motion diffuser is positioned is conjugated to the light valve surface. Due to the human eye integral actions at the random phases, a spot dissipating effect of a projected picture can be weakened or eliminated to the greatest degree, so that the spot dissipating effect and projected picture display quality are greatly improved.

Owner:HISENSE

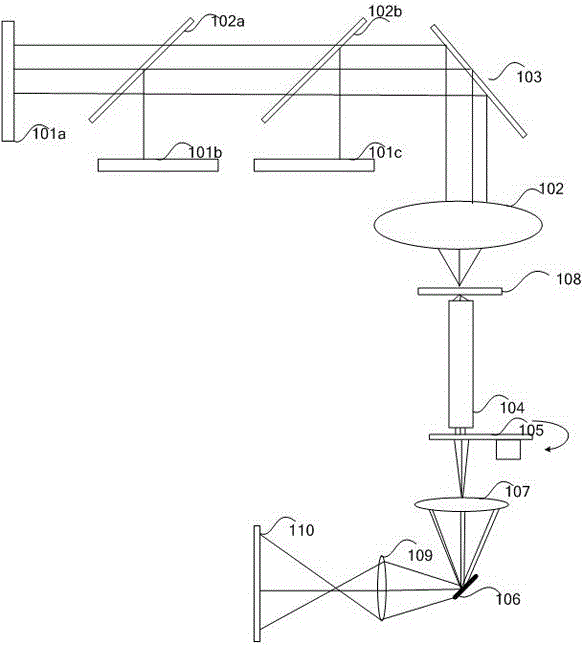

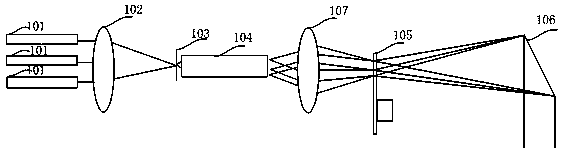

Laser projection system

InactiveCN109884851AVariety of divergence anglesEasily damagedProjectorsOptical elementsLight beamOptoelectronics

The invention discloses a laser projection system. The laser projection system comprises a laser light source, which respectively emits a first color laser, a second color laser, and a third color laser; before a laser beam emitted by the laser light source enters a light valve, the laser beam further passes through a light homogenizing part, which is used for receiving and homogenizing the laserbeam; the light valve used for receiving the laser beam homogenized by the light homogenizing part and modulating the laser beam; a fixed phase plate arranged on the light-entering surface side of thelight homogenizing part; and a rotary diffusion sheet arranged on the light-emitting surface side of the light homogenizing part, and the position of the rotary diffusion sheet is conjugated with thelight valve surface. The laser projection system provided by the invention can weaken or eliminate the speckle effect of a projected picture to the maximum extent, thereby greatly improving the speckle removing effect and the display quality of the projected picture.

Owner:HISENSE

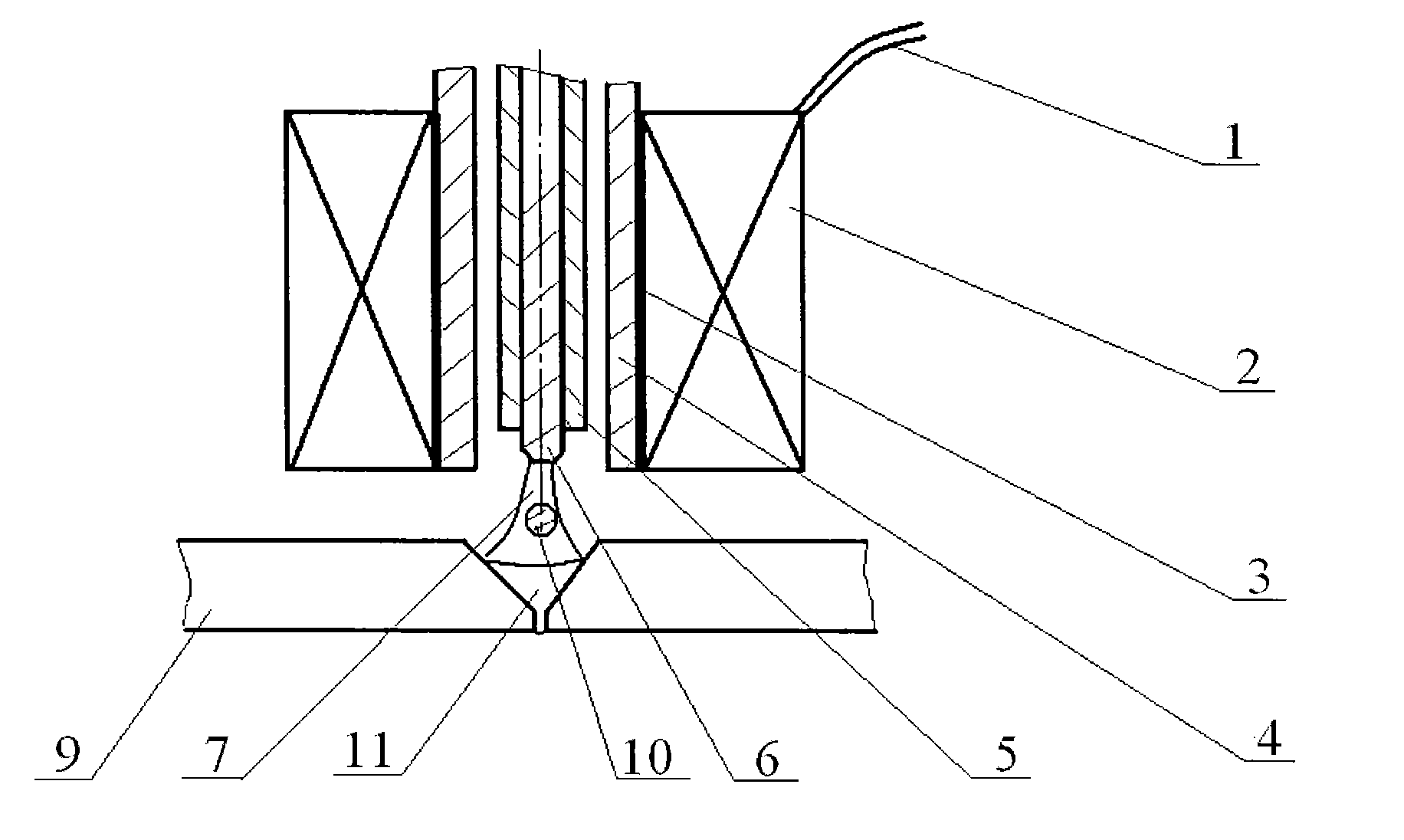

Method and device for performing electric magnetization arc welding-braze welding compounding on dissimilar materials

InactiveCN101844259AImprove connection qualityInhibition formationSoldering apparatusMetal working apparatusMetallic materialsMagnetization

The invention discloses a method and a device for performing electric magnetization resistance welding-braze welding compounding on dissimilar materials. In the process of performing arc welding-braze welding on the dissimilar metal material, a brazed liquid solder molten pool is subjected to the reinforced booster action of electromagnetic stirring and electric magnetization by using the characteristic that a magnet exciting coil generates an external applied alternating magnetic field in a welding area to control a welding arc so as to promote ordered flow of the liquid solder, and rupture of membranes, wetting, spreading and diffusion of the liquid solder on the surface of the metal material with a higher melting point, promote the liquid solder and a base metal which is molten by the metal material with a lower melting point to be mixed fully, improve uniformity of compositions of a soldered seam, reduce the weld defects, optimize the compositions and the performance of the soldered seam, and improve the soldered joint; and the device has the advantages of simple structure, flexible application, lower cost, good effect, and easy implementation.

Owner:CHONGQING UNIV

Complex nitride and boride synergetic enhancement self-protection bead weld flux-cored wire

ActiveCN106001995ARefined organizationVarious ingredientsWelding/cutting media/materialsSoldering mediaHardnessWeld bead

The invention discloses a complex nitride and boride synergetic enhancement self-protection bead weld flux-cored wire. A mild-carbon steel strip is adopted as skin, a flux core is prepared from, by mass, 6%-45% of high carbon ferro-chrome, 3%-10% of TiN, 3%-10% of BN, 3%-10% of B4C, 3%-10% of TiB2, 3%-10% of ZrB2, 1%-3% of graphite, 0.5%-1% of 60-mesh cellulose powder, 0.5%-1% of 200-mesh cellulose powder, 1%-3% of 60-mesh aluminum magnesium alloy, 1%-3% of 200-mesh aluminum magnesium alloy, 2%-5% of 60-mesh silicomanganese, 2%-5% of 200-mesh silicomanganese and the balance iron powder, and flux core powder accounts for 50% to 54% of the total weight of the wire. According to the complex nitride and boride synergetic enhancement self-protection bead weld flux-cored wire, flux core components different in grain size are added, so that the good welding process performance is guaranteed; the flux core components and other alloy powder are reasonably matched, so that complex nitride and boride are dispersed through the wire in the welding process, the advantages of being high and even in hardness, good in wear resistance and the like are achieved, no slag basically exists on the surface of a weld bead, and slag removal is not needed during multilayer welding.

Owner:JIANGSU UNIV OF SCI & TECH

Zirconium-containing copper silver titanium solder alloy

InactiveCN102699567AReduce manufacturing costExcellent brazeabilityWelding/cutting media/materialsSoldering mediaTitaniumUltimate tensile strength

The invention discloses a zirconium-containing copper silver titanium solder alloy. The zirconium-containing copper silver titanium solder alloy comprises the following components by mass percent: 10-45% of Ag, 1-4% of Ti, 0.5-5% of Zr and Cu for the rest. A vacuum melting and argon shield casting mode is adopted, silver and copper are molten at first and then titanium and zirconium are added. The zirconium-containing copper silver titanium solder alloy can be used for directly soldering copper alloys, iron steel, ceramics and diamonds. The zirconium-containing copper silver titanium solder alloy has the advantages as follows: the cost is low; a connector is high in mechanical strength, has smooth surface, is stable in quality and is good in uniformity after the copper alloys are soldered by the zirconium-containing copper silver titanium solder alloy; and the joint clearances can be fully filled up. The zirconium-containing copper silver titanium solder alloy can replace the conventional copper silver titanium solder and is suitable for large-scale industrial application.

Owner:CENT SOUTH UNIV

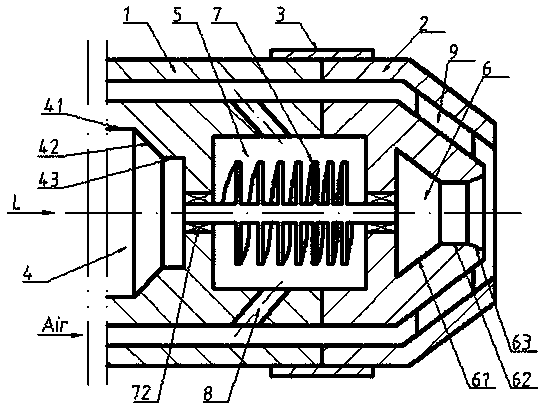

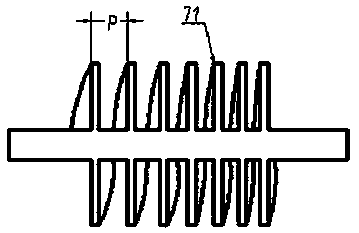

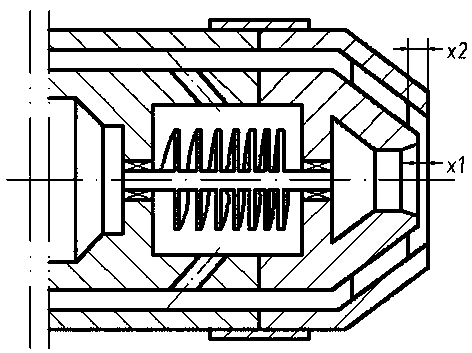

Glazing device for tile production equipment

ActiveCN109940746ACollision uniformCollision stabilizationCeramic shaping apparatusSpray nozzleEngineering

The invention discloses a glazing device for tile production equipment. The glazing device for tile production equipment comprises a spray gun, wherein the spray gun is provided with a nozzle; the nozzle comprises a first body (1), a second body (2), a connecting element (3), a fluid channel (4), a mixing oscillation cavity (5), an outlet part (6), a spiral rotor (7), a gas channel, wherein the fluid channel, the mixing oscillation cavity and the outlet part are sequentially arranged in the fluid flow direction, the glazing device is characterized in that the mixing oscillation cavity (5) is internally provided with the spiral rotor (7), the spiral rotor comprises spiral blades (71) and a rotating shaft, the spiral blades are arranged on the periphery of the rotating shaft, the two ends ofthe rotating shaft are connected with guide frames (10) through bearings (72), the two guide frames are positioned on the first body and the second body respectively. Through the design of the spiralrotor and air inlet holes, the glaze liquid / the liquid is atomized into smaller atomized spray in the mixed oscillation cavity, the atomization refinement degree is high, the atomization is uniform and stable, the glaze spraying yield is improved, and the raw material utilization rate is improved.

Owner:JIANGXI CIMIC CERAMICS +1

Method for regulating and controlling homogenization degree of polyacrylonitrile preoxidized fiber

InactiveCN106637520AImprove modification effectHigh degree of homogenizationFibre typesFibre chemical featuresChemistryUltrasonic oscillation

The invention relates to a method for regulating and controlling the homogenization degree of a polyacrylonitrile preoxidized fiber. The method comprises the steps of dipping a polyacrylonitrile fiber into xylene at the room temperature, carrying out oscillation for 5-15 minutes in an ultrasonic oscillation instrument, removing an oil agent from the surface of the PAN fiber, carrying out dipping modification on the polyacrylonitrile fiber by virtue of a 0.5%-4% boric acid solution for 0.5 second to 6 minutes, heating the boric acid-modified polyacrylonitrile fiber in air from the room temperature to 260-340 DEG C at a heating speed of 5 -9 DEG / min, and carrying out pre-oxidation for 10-30 minutes. The method has the advantages that the homogenization degree of the PAN preoxidized fiber can be regulated and controlled and the strength of carbon fibers can be increased.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

High-strength and high-plasticity hollow aluminum profile and preparation method thereof

InactiveCN110453111AAvoid overheatingImprove mechanical propertiesAnodisationElectrophoretic coatingsMechanical propertyToughness

The invention discloses a high-strength and high-plasticity hollow aluminum profile and a preparation method thereof, and belongs to the field of aluminum profile preparation. The high-strength and high-plasticity hollow aluminum profile comprises the following raw materials of, in percentage by weight (wt%), 2.0-4.0 of Mg, 2.0-4.0 of Cu, 0.4-0.8 of Si, 0.4-1.0 of Gu, 0.8-1.0 of As, 0.2-0.6 of Ti,0.4-1.0 of Mn, 1.0-3.0 of Fe, 0.4-0.6 of Cr, 0.4-0.6 of Zn, 0.6-0.8 of Li, and the balance aluminum and inevitable impurities. By controlling the content of elements in aluminum alloy components, strengthening phases such as Al2Cu, Al2CuMg, Mg2Si and MgZn2 are formed in an aluminum alloy, the strengthening phases act synergistically, so that the effects of deoxidizing and refining grains are achieved, the obvious strengthening effect on the aluminum profile is achieved, the cracking sensitivity of a material is effectively reduced, the mechanical properties such as plasticity, toughness and fatigue resistance of the aluminum profile and the good machining performance are improved, and the performance requirement of the aluminum profile for alternate transportation can be met.

Owner:ANHUI XIN FA ALUMINUM PROD

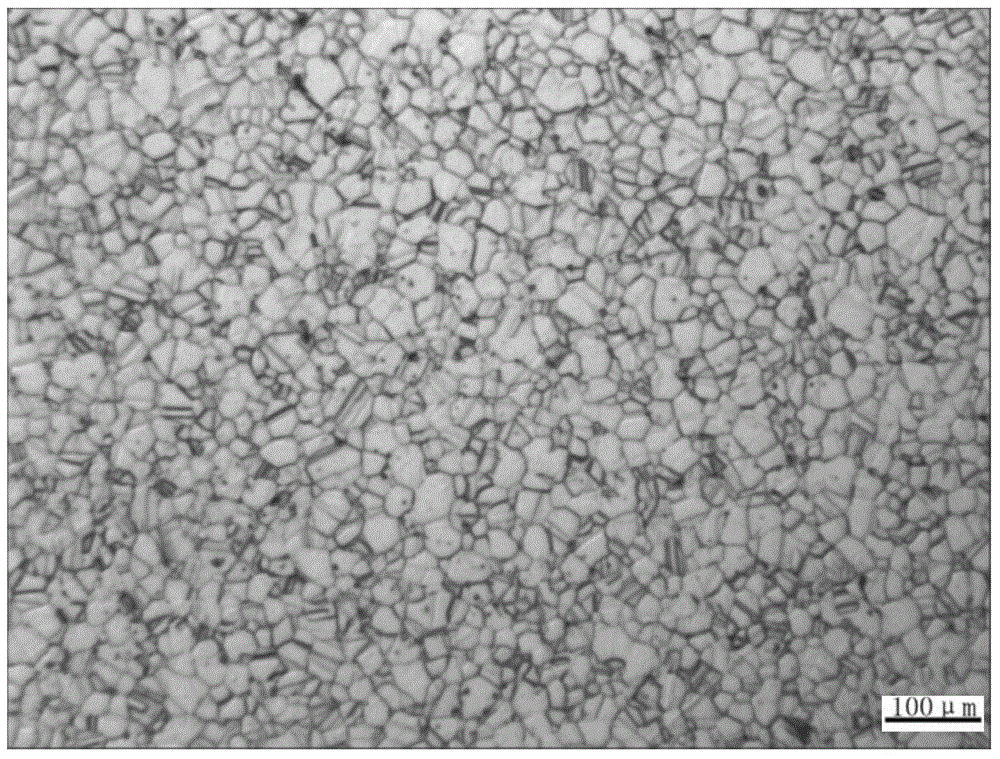

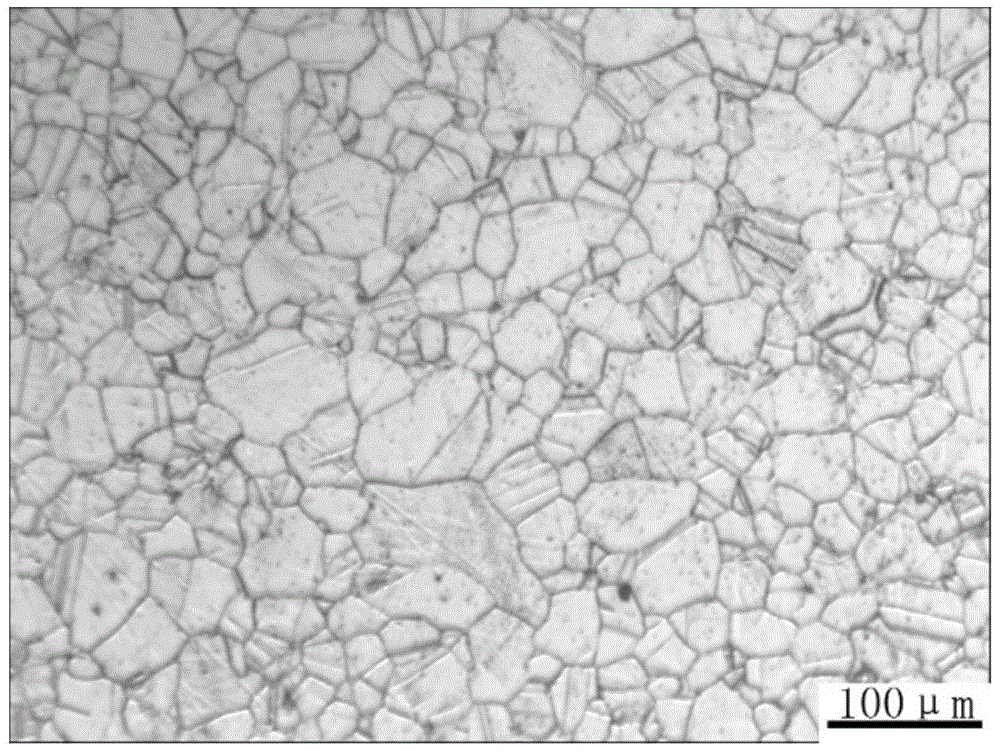

GH4738 alloy fine-grain blank manufacturing method for supercritical power station steam turbine blade

ActiveCN105195541AAvoiding the Insufficiency of Free Forging Billet TechnologyEasy to shapePower stationSteam turbine blade

The invention discloses a GH4738 alloy fine-grain blank manufacturing method for a supercritical power station steam turbine blade and aims at existing technical states that a temperature field and the deformation rate are difficult to meet high requirements of alloy deformation parameter sensitivity degree, and microstructures are low in homogenization degree in a process of blank manufacturing by hammer forging a GH4738 alloy ingot. According to the method, an extrusion method for blank manufacturing is used for replacing an original hammer forging manner for blank breakdown. The GH4738 alloy ingot is heated to the recrystallization temperature or more so as to be subjected to extrusion deformation; the moulding of the alloy ingot can be improved by using a three-direction pressure state in the extrusion deformation, so that the moulding deformation can be played to the greatest extent; the fine grain is improved by adopting the deformation with a large extrusion ratio; a coating and sleeving technology is used for reducing the temperature drop during transfer and extrusion deformation of the alloy, so that the extrusion ratio is controlled accurately; a temperature rising effect is adopted for enabling the alloy to be subjected to heat deformation in the appropriate temperature field all the time, so that alloy bars having the fine grain and the high microstructure homogenization degree are manufactured.

Owner:UNIV OF SCI & TECH BEIJING

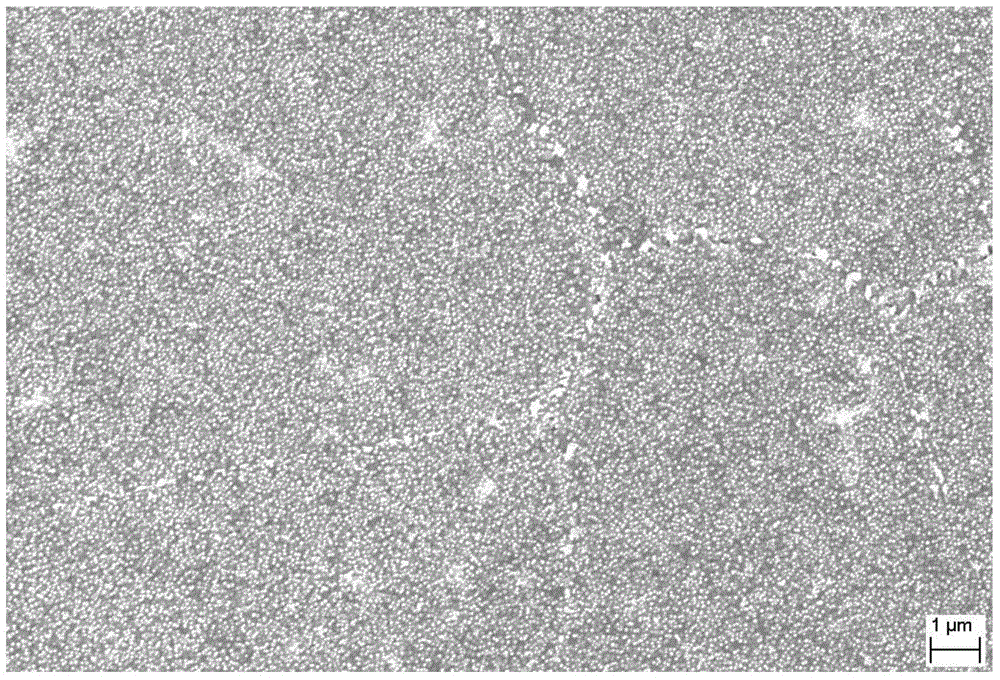

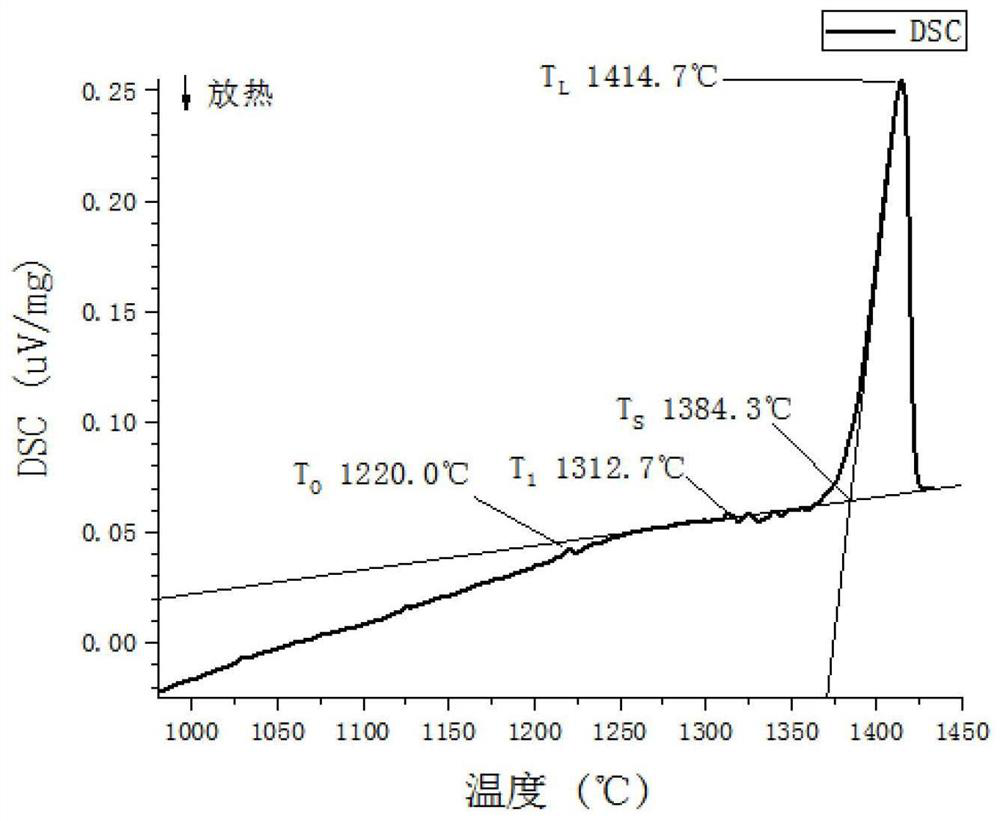

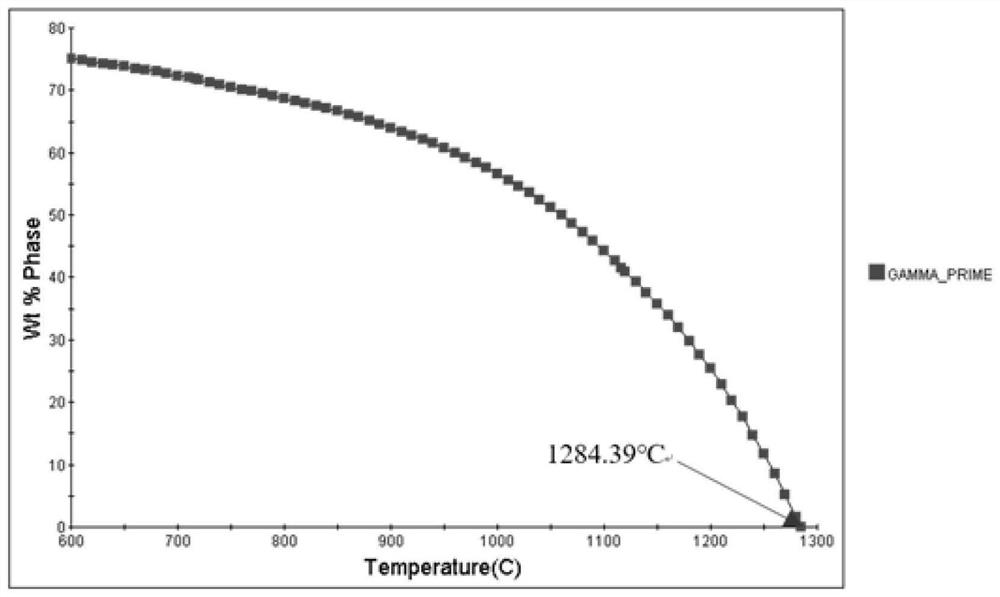

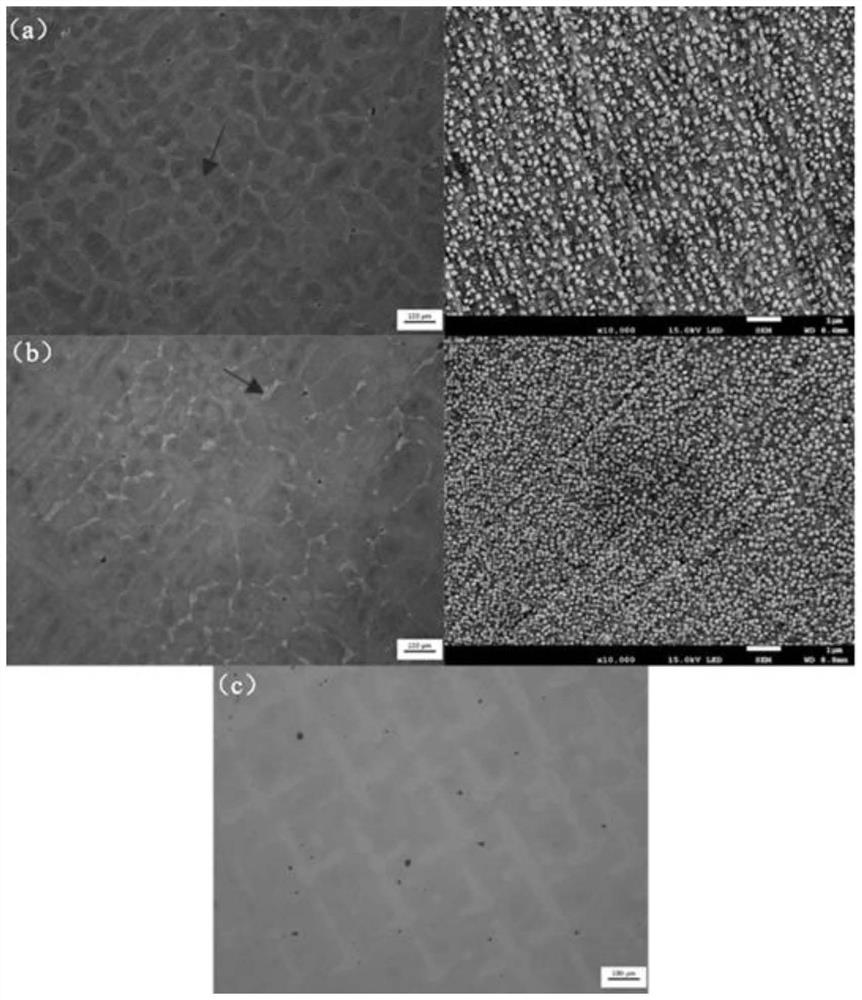

Heat treatment method of nickel-based single-crystal superalloy

ActiveCN113528993AIncreased maximum heat treatment temperatureImprove stabilityPolycrystalline material growthAfter-treatment detailsSingle crystal superalloySingle crystal

The invention provides a heat treatment method of a nickel-based single-crystal superalloy, and relates to the technical field of superalloys. The heat treatment method comprises the following steps that a nickel-based single-crystal superalloy casting is subjected to first-stage heat treatment at 1280-1300 DEG C, then subjected to second-stage heat treatment at 1330-1350 DEG C, heated to 1360-1380 DEG C, subjected to third-stage heat treatment and finally subjected to cooling treatment. According to the method, the upper limit temperature of a heat treatment window of the alloy is increased to 1380 DEG C from 1340 DEG C through a three-stage heat treatment system, the solid solution heat treatment window of the alloy is expanded, the highest heat treatment temperature of solid solution heat treatment is increased, the homogenization degree of all elements (especially Re, W and other elements) of the DD476 alloy is greatly improved, and the performance of a single-crystal alloy is improved.

Owner:HEBEI GANGYAN DEKAI TECH CO LTD

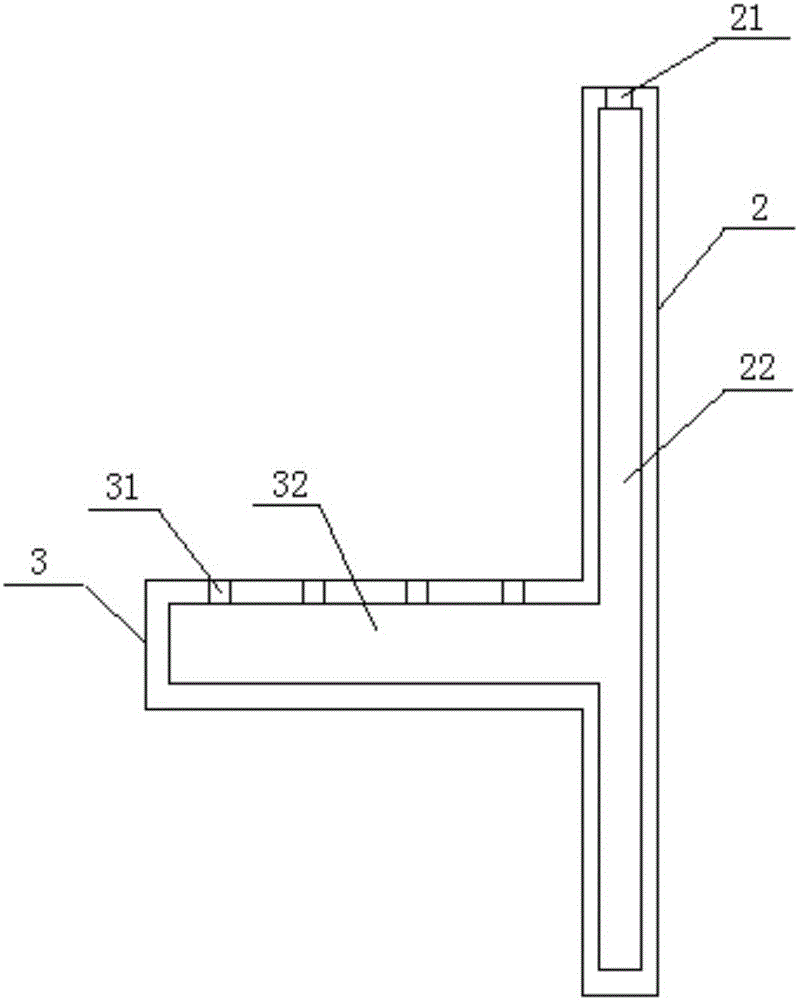

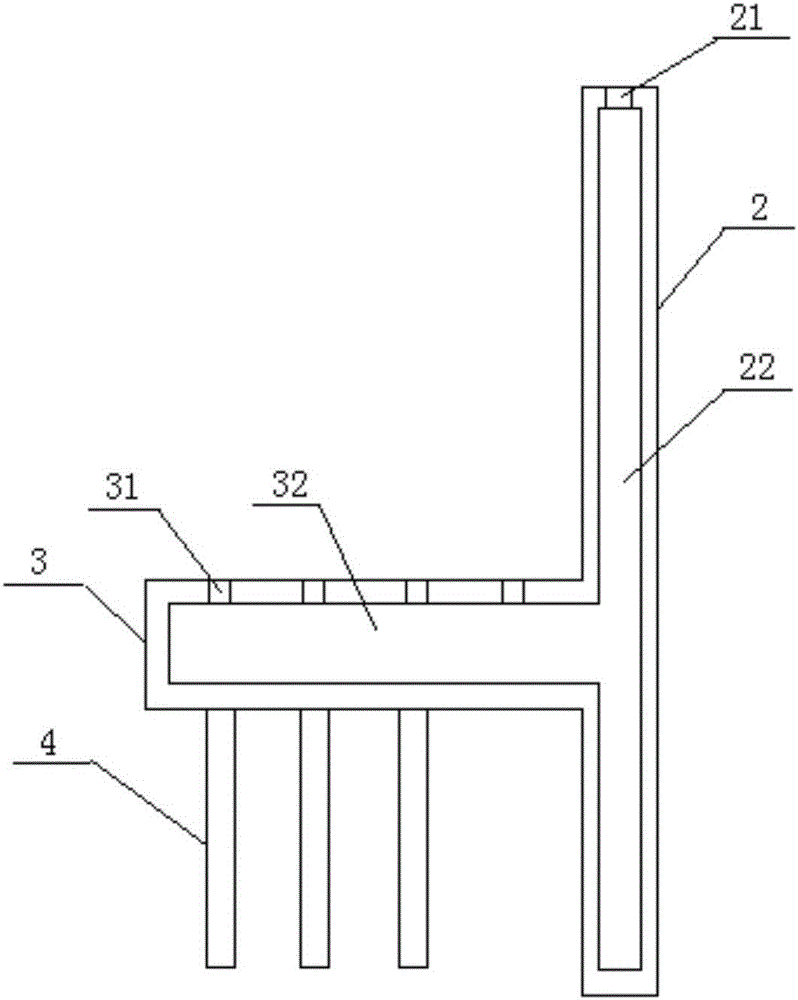

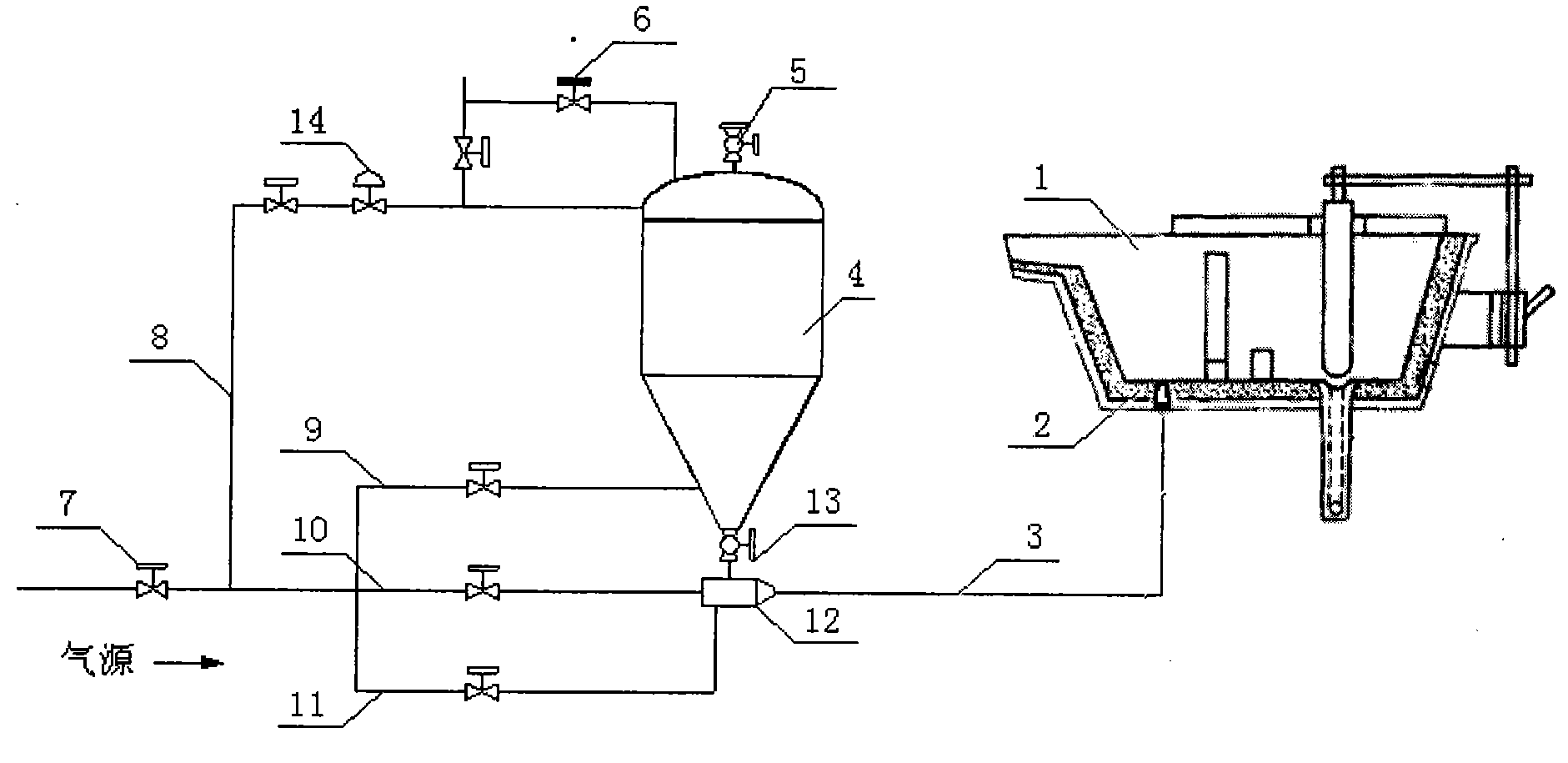

System device for adding rare earth into continuous casting tundish and adding method

InactiveCN101811180AImprove dynamic conditionsHigh degree of homogenizationRare-earth elementTundish

The invention relates to a system device for adding rare earth into a continuous casting tundish and an adding method, belonging to the field of ferrous metallurgy. In the invention, a powder spraying tube is arranged between a tundish and a powder spraying pot, one end of the powder spraying tube is connected with a powder spraying pot, the other end is arranged at the slit of a slit-type air brick arranged at the lower part of the tundish, and argon is adopted to spray rare earth powder to the slit of the air brick by the powder spraying tube and then enters the tundish. In the invention, high-pressure powder airflow is utilized to intensively stir molten steel, thus shortening alloying time, greatly improving dynamical condition of metallurgy reaction, promoting homogenized degree of rare earth elements in steel, improving yield of alloy, having strong reproducibility and accurate sprayed elements, and controlling the components of smelt steel within a narrow range. The invention also solves the problem of environmental pollution, and has the advantages of saved investment, portable equipment, easy operation and the like.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

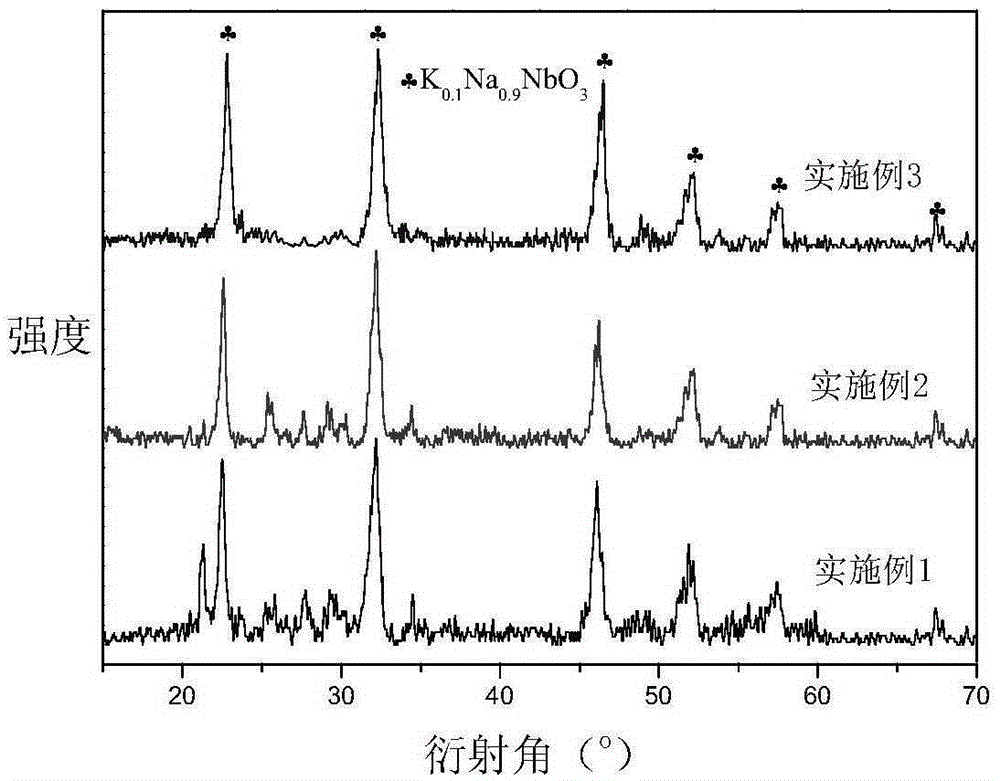

KNN-based (sodium potassium niobate-based) energy storage microcrystalline glass material with ultralow dielectric loss and preparation method

The invention relates to a KNN-based (sodium potassium niobate-based) energy storage microcrystalline glass material with ultralow dielectric loss and a preparation method. The microcrystalline glass material is prepared from a glass phase and a crystal phase through mixing, fusing, cooling and molding, annealing, carrying out crystallization heat treatment, wherein according to mol percent, the glass phase accounts for 20 percent to 50 percent and the balance is the crystal phase; the crystal phase is composed of K2CO3, Na2CO3, Nb2O5 and BaCO3 at a mol ratio of (3-x) to (3-x) to 6 to 2x and x is more than 0 and less than or equal to 2.5. The KNN-based energy storage microcrystalline glass material prepared by the preparation method has extremely low dielectric loss; BaO is introduced, has the effect of adjusting the composition of the crystal phase of a sodium potassium niobate system and also has a certain promotion effect on a devitrification process and devitrification is accelerated by rare-earth metal ions; the BaO can also generate a pinning effect, and adverse impacts, caused by interface polarization, on breakdown and worsening are weakened; finally, the microcrystalline glass material with a high dielectric constant is obtained.

Owner:SHAANXI UNIV OF SCI & TECH

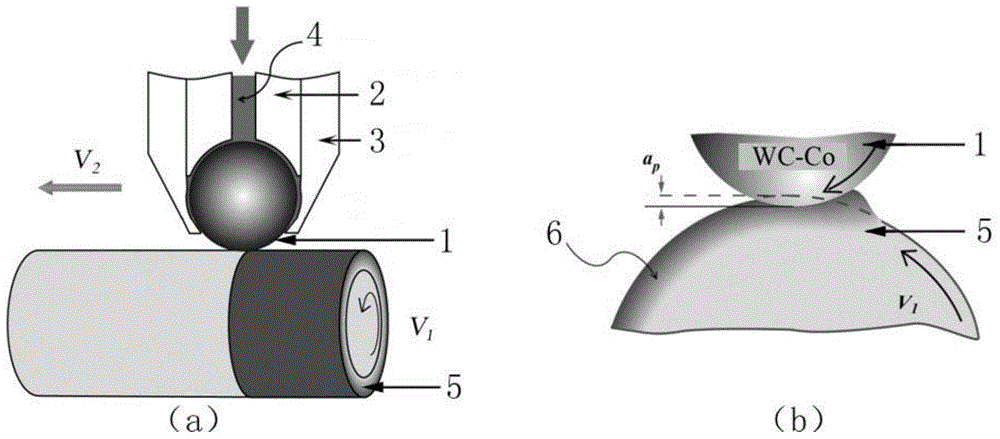

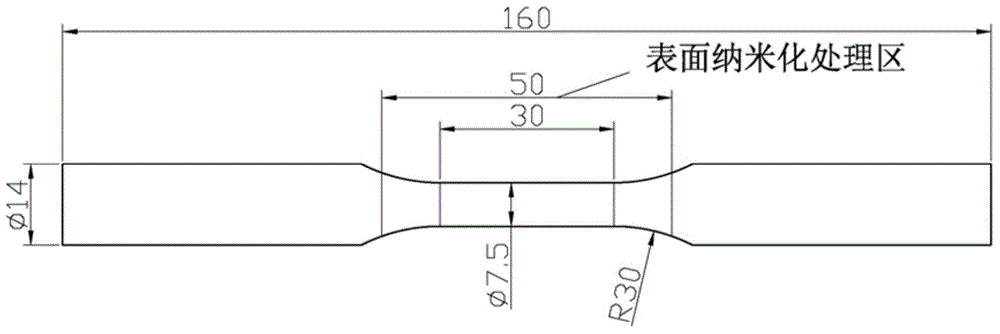

Method for improving rotating bending fatigue performance of locomotive axle steel

ActiveCN105441651ADoes not involve issues such as recyclingEasy to implementNumerical controlNano structuring

The present invention discloses a method for improving rotating bending fatigue performance of locomotive axle steel, and belongs to the technical field of metal material surface nanocrystallization. The method uses surface mechanical rolling treatment technology for surface nanocrystallization of locomotive axle LZ50 steel, and the treatment process is performed on a numerical control surface nanocrystallization treatment system. After the surface nanocrystallization treatment, a LZ50 steel surface structure is transformed into a gradient nano structure, the outermost layer crystal grain size is 10-50nm, the grain size gradually increases with the increase of the layer depth to the original grain size; the LZ50 steel surface nanocrystallization treatment state surface hardness is in a gradient distribution state, the outermost layer microhardness value is greater than 3.0GPa, and is significantly improved compared with the matrix hardness value; and the LZ50 steel surface nanocrystallization treatment state surface roughness is less than 0.4mum, and is significantly improved compared with the turning sate surface roughness. The rotating bending fatigue performance of the locomotive axle LZ50 steel is significantly improved by the surface nanocrystallization treatment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

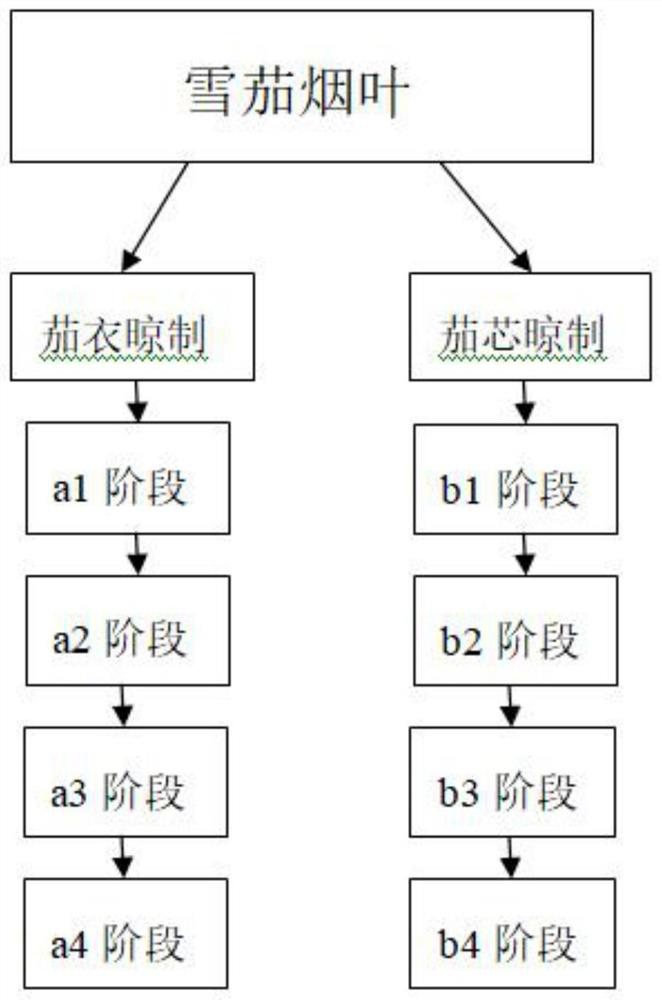

Cigar tobacco air-curing method

The invention discloses a cigar tobacco air-curing method, which comprises cigar coating tobacco leaf air-curing and cigar core tobacco leaf air-curing, and is characterized in that the cigar coating tobacco leaf air-curing comprises the following steps: weaving fresh cigar coating tobacco leaves on an air-curing rod, putting the air-curing rod into an air-curing room, air-curing in four stages, and after ventilation and moisture regaining are conducted till the cigar coating tobacco leaves are soft and not broken, removing from the air-curing rod to obtain the cigar coating tobacco leaves, and the cigar core tobacco leaf air-curing comprises the following steps: weaving fresh cigar core tobacco leaves on an air-curing rod, putting the air-curing rod into an air-curing room, air-curing in four stages, and after ventilation and moisture regaining are conducted till the cigar core tobacco leaves are soft and not broken, removing from the air-curing rod to obtain the cigar core tobacco leaves. According to the invention, high-quality cigar coating tobacco leaves and cigar core tobacco leaves are obtained through four stages of airing, so that the quality of cigars can be remarkably improved.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

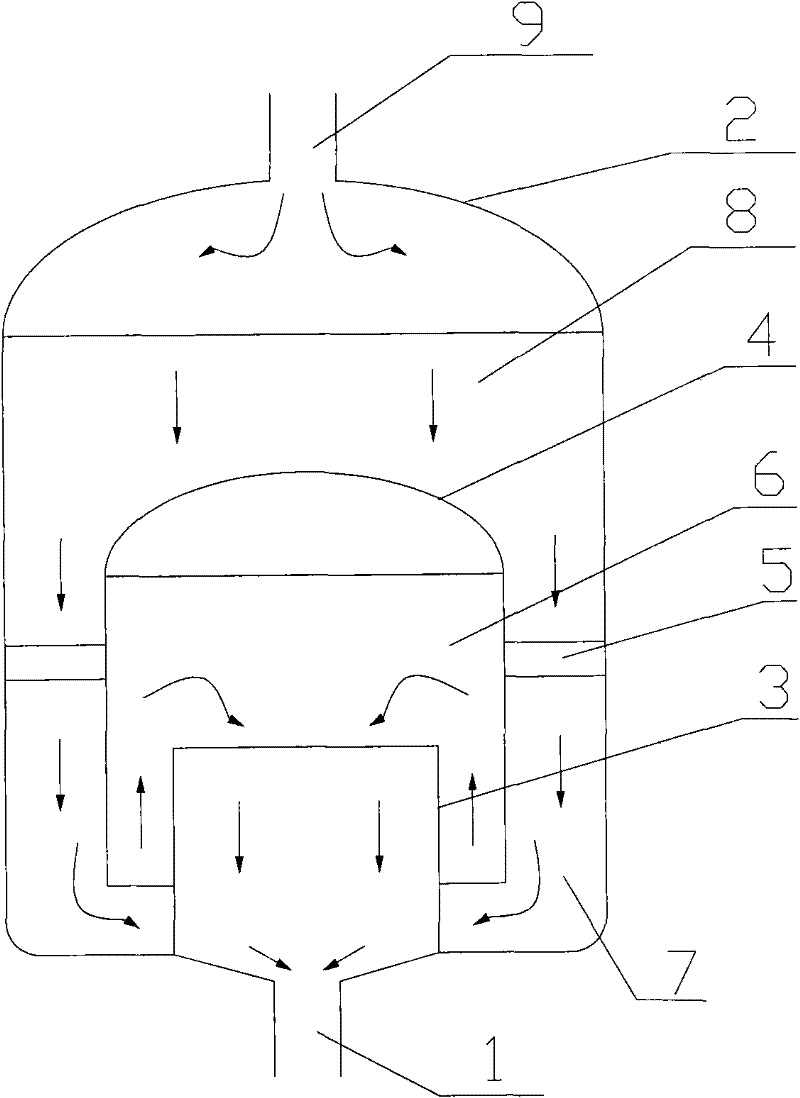

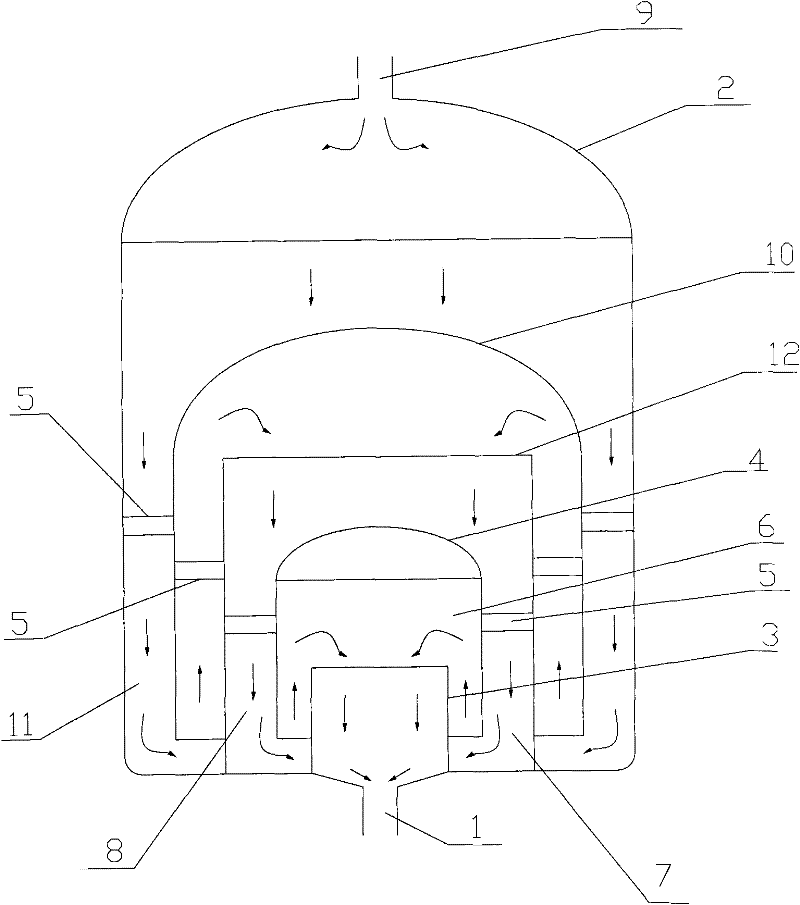

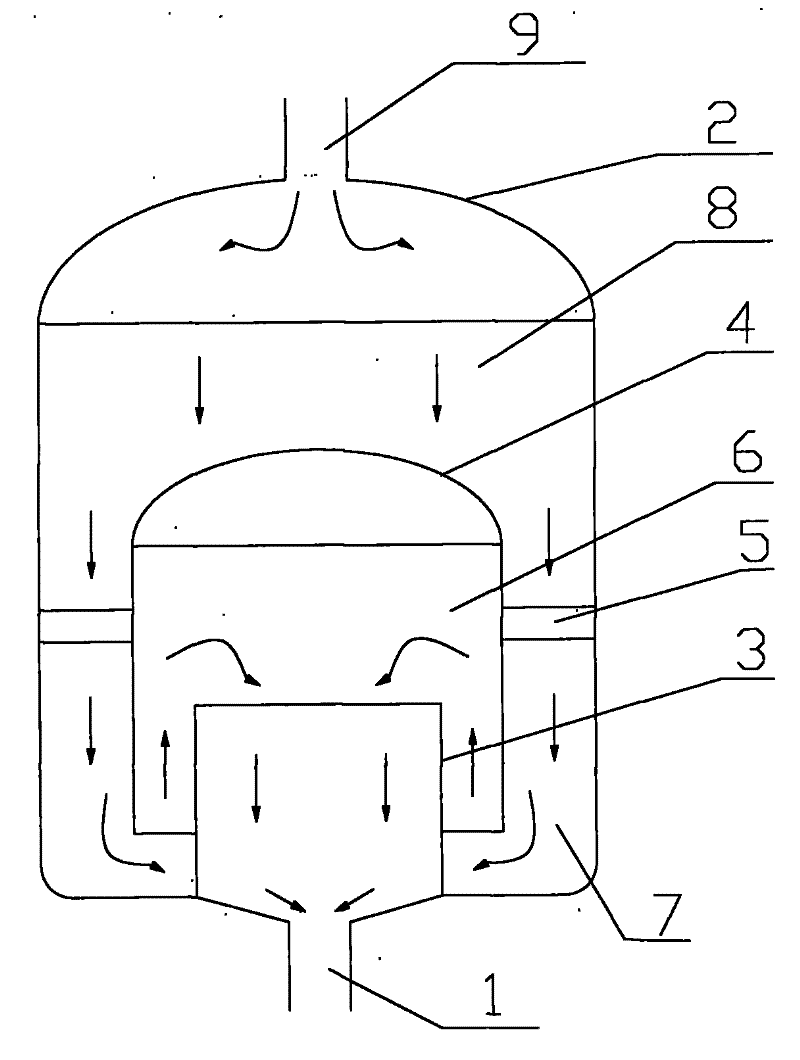

Homogenizer

InactiveCN101745331ASimple structureReduce processing costsFlow mixersEmulsificationEngineeringHomogenizer

The invention relates to a homogenizer comprises at least n first cylinders and at least n-1 second cylinders, which are sleeved together at intervals. The inmost cylinders and the outmost cylinders are both first cylinders; the top of the outmost first cylinder is closed and is provided with an opening which is communicated with the outside, and the bottom is provided with an opening which is communicated with the inside of the innermost first cylinder; the tops of other first cylinders are open; all the first cylinders share the bottom of the same homogenizer; the second cylinders are sleeved outside the first cylinders which are adjacent to the second cylinders at intervals; the tops of the second cylinders are open, and the bottoms are closed, thus a space in the homogenizer, where all the first cylinders are communicated with all the second cylinders, is formed; and the first cylinders and the second cylinders are fixed mutually by connecting parts.

Owner:NANJING HAOYANG CHEM EQUIP

Powder feeding device capable of realizing powder gradient change and for laser cladding

ActiveCN108754493ASolve the problem of "group powder"Solve the problem of clogging pipes or even clogging laser cladding headsIncreasing energy efficiencyMetallic material coating processesMetallurgyLaser

The invention provides a powder feeding device capable of realizing powder gradient change and for laser cladding. The powder feeding device comprises a top end cover, a powder mixing bin, a powder storage bin, a powder storage bin base and a fixing seat, wherein the top end cover is provided with a plurality of powder feeding holes and arranged at one end of the powder mixing bin, and a rotatingpowder mixing device is arranged in the powder mixing bin. The rotating powder mixing device is connected to a motor through the top end cover, and a first powder feeding portion and a first powder discharging hole are formed in the powder storage bin base. A first powder disk arranged on the fixing seat is connected to a second powder disk through a hollow tube, a second powder feeding hole formed in the first powder disk is connected to the first powder feeding portion, and a second powder discharging hole formed in the second powder disk is connected with the first powder discharging hole.The first powder feeding portion communicates with the bottom of the powder storage bin, a first screen is arranged at the bottom of the first powder feeding portion, and a micro oscillator is arranged on the first screen. The powder feeding device capable of realizing powder gradient change and for laser cladding can solves the problems that in existing powder feeding, clogging of a powder feeding pipe and a laser cladding head is prone to occurring, the powder utilization rate is low, and real-time gradient change of various kinds of powders cannot be realized in the cladding process.

Owner:FUJIAN UNIV OF TECH

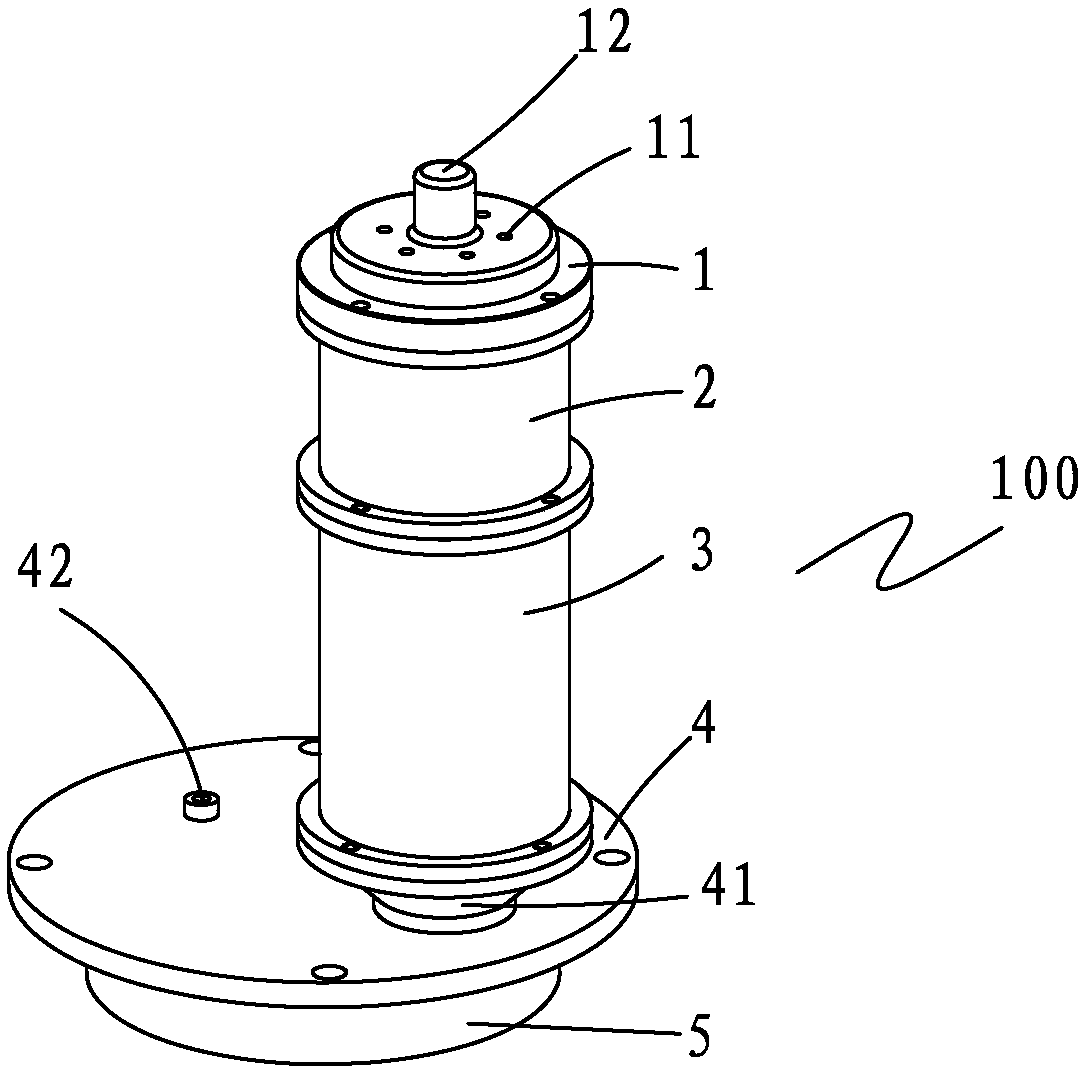

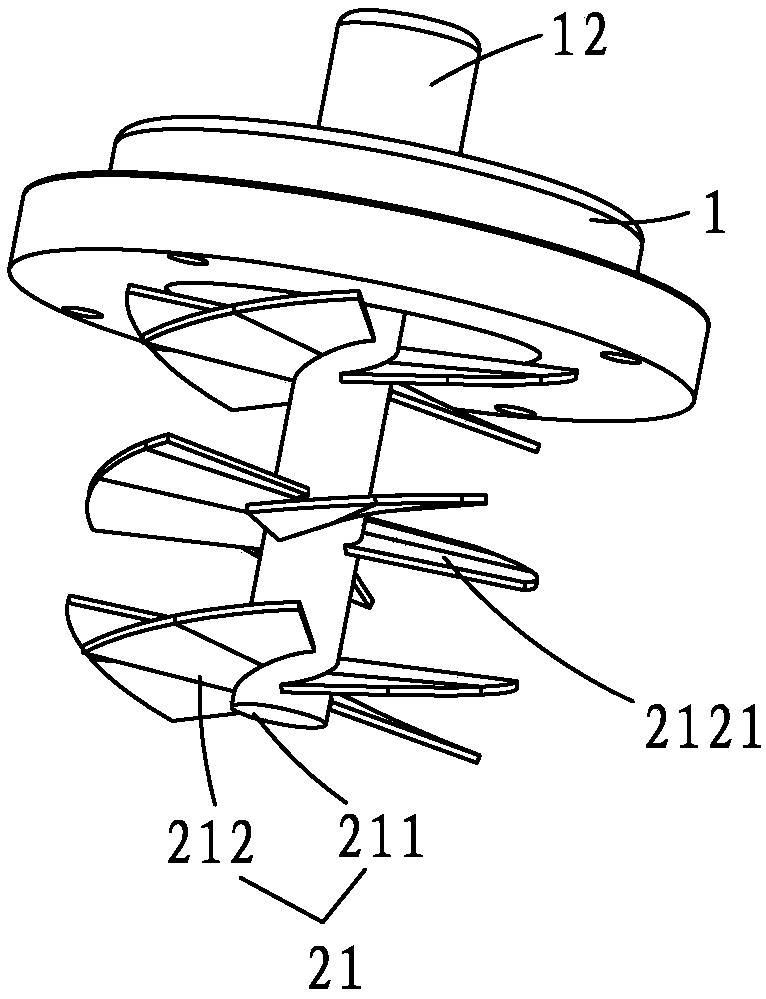

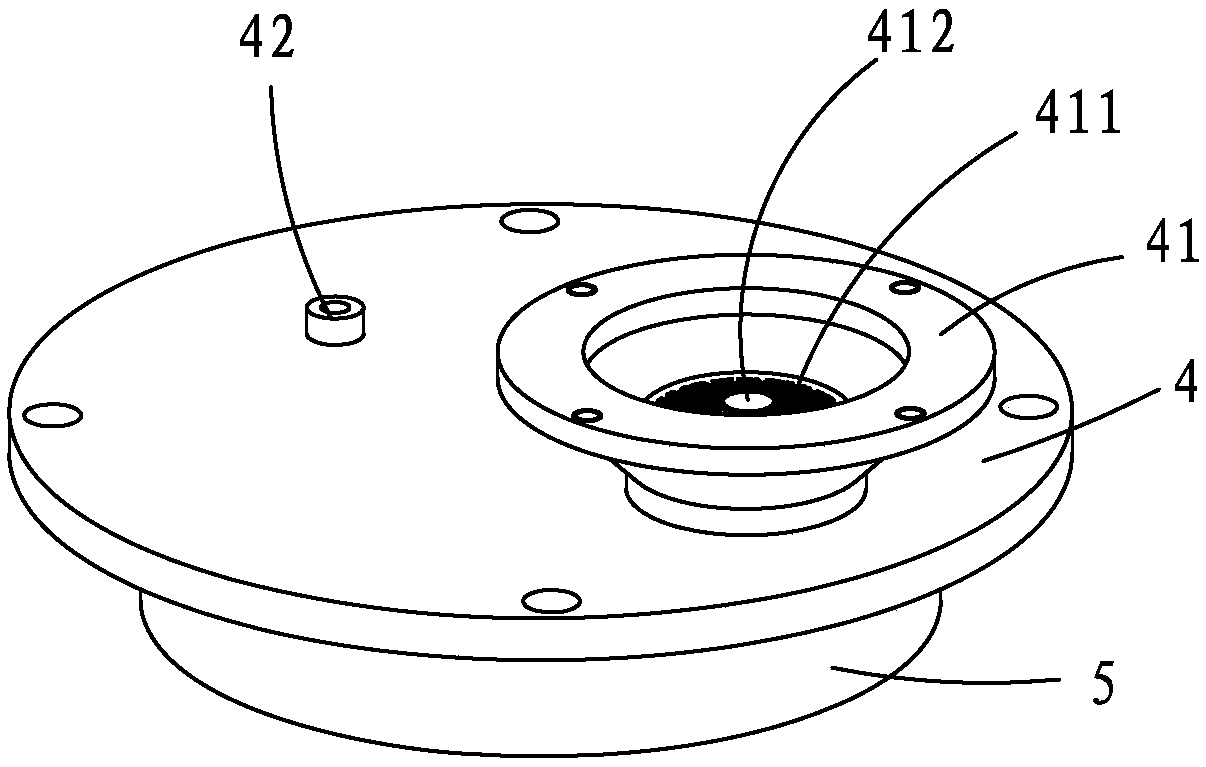

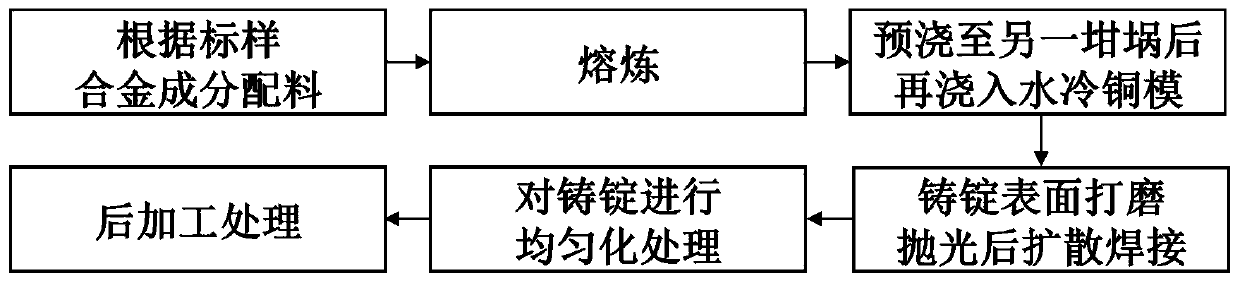

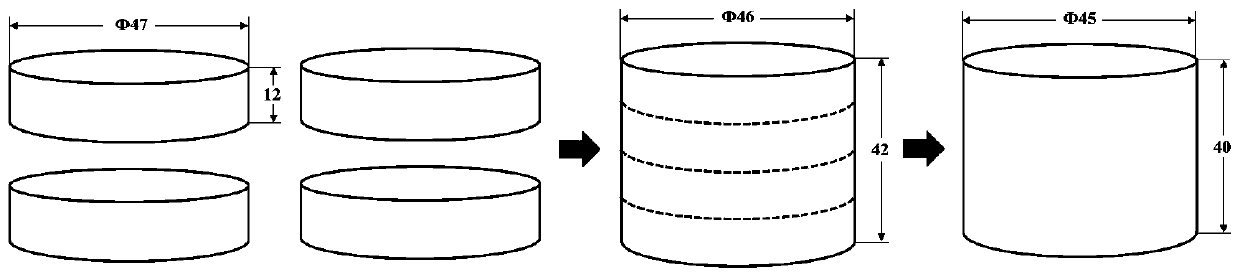

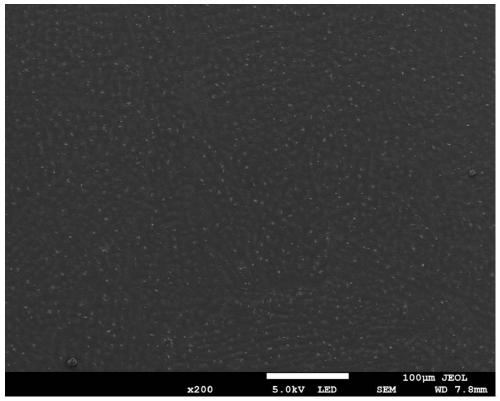

Preparation method of magnesium-rare earth series alloy spectral standard sample

InactiveCN110029259AWell mixedHigh degree of homogenizationPreparing sample for investigationColor/spectral properties measurementsIngotMachining

The invention relates to a preparation method of a magnesium-rare earth series alloy spectral standard sample. The preparation method is characterized in that firstly homogeneous magnesium-rare earthalloy ingots with small sizes are prepared by solidifying under the condition of rapid cooling and are connected by diffusion welding to obtain a sample meeting the shape and size requirements, then the homogenization degree of the sample is increased through homogenization heat treatment, and finally the sample is finished to obtain the spectral standard sample. The preparation method specifically comprises the following steps that S1, a magnesium-rare earth alloy is smelted and cast to obtain a plurality of ingots with the same size; S2, the ingots are machined, the upper surfaces and the lower surfaces of the ingots are bonded and put in a vacuum diffusion furnace for the diffusion welding to obtain the sample; S3, the sample is placed into a heat treatment furnace for homogenization treatment; and S4, the homogenized sample is subjected to finish machining into the standard sample size, and marked with a number to obtain the spectral standard sample. The homogeneous magnesium-rareearth alloy standard sample can be prepared, the preparation period is short and the preparation cost is low.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com