Heat treatment method of nickel-based single-crystal superalloy

A heat treatment method and superalloy technology, applied in the field of superalloys, can solve the problems of increasing the manufacturing cost of the fourth-generation single crystal blade, reducing the degree of uniformity of the alloy structure, affecting the diffusion of alloy elements, etc., achieving good application prospects, improving comprehensive performance, Low segregation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1. preparation single crystal test bar

[0049] Master alloys were prepared using the single crystal synthesis compositions shown in Table 1 below, and then single crystal test rods were drawn.

[0050] Table 1. DD476 alloy composition (wt.%)

[0051]

[0052] After the DD476 master alloy was smelted in a high vacuum induction furnace, the single crystal test rod for the test was drawn at 1550 °C at a rate of 3 mm / min by the spiral crystal selection method.

Embodiment 2

[0053] Embodiment 2. Research and testing of properties and microstructure of the alloy

[0054] 2.1 Alloy differential scanning calorimetry analysis

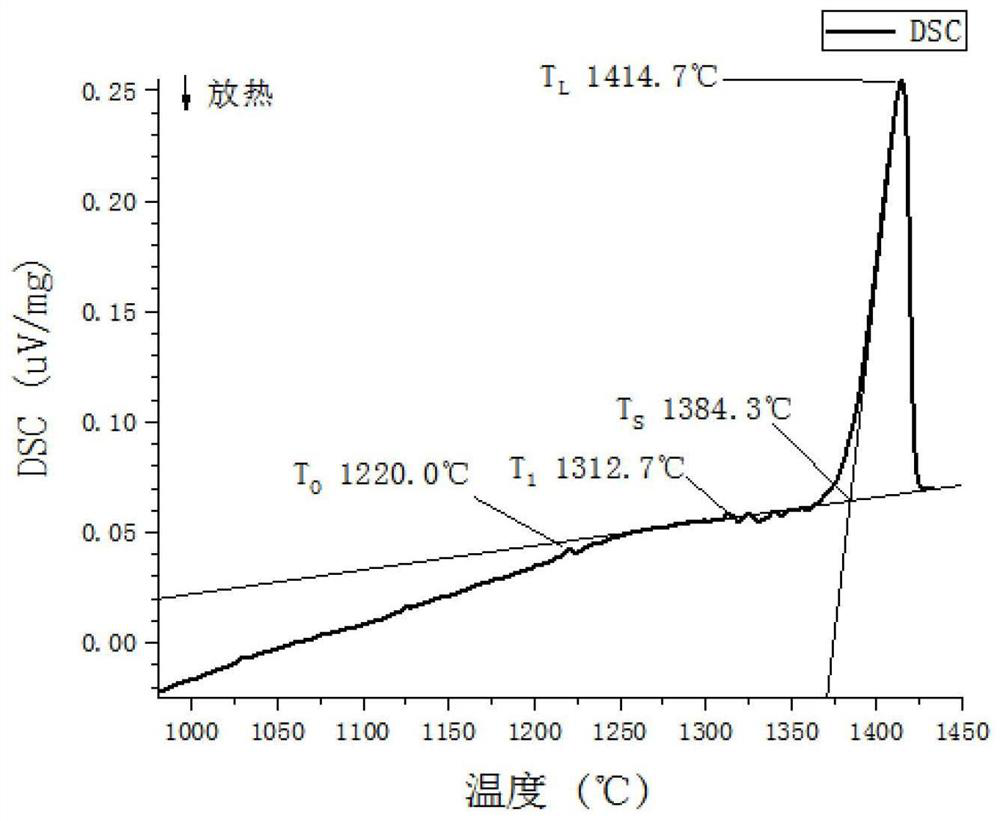

[0055] Carry out DSC curve analysis to the alloy of the present invention, heating rate is 10 ℃ / min, is heated from room temperature to 1450 ℃ and is lowered to room temperature by the same rate, and alloy endothermic curve is as follows figure 1 shown.

[0056] According to the figure, it can be seen that the temperature at which the interdendritic γ’ starts to dissolve is T 0 (1220°C), γ / γ' eutectic transition temperature T 1 (1312.7°C), liquidus T L (1414.7°C), the extrapolated solidus temperature is T S (1384.3°C).

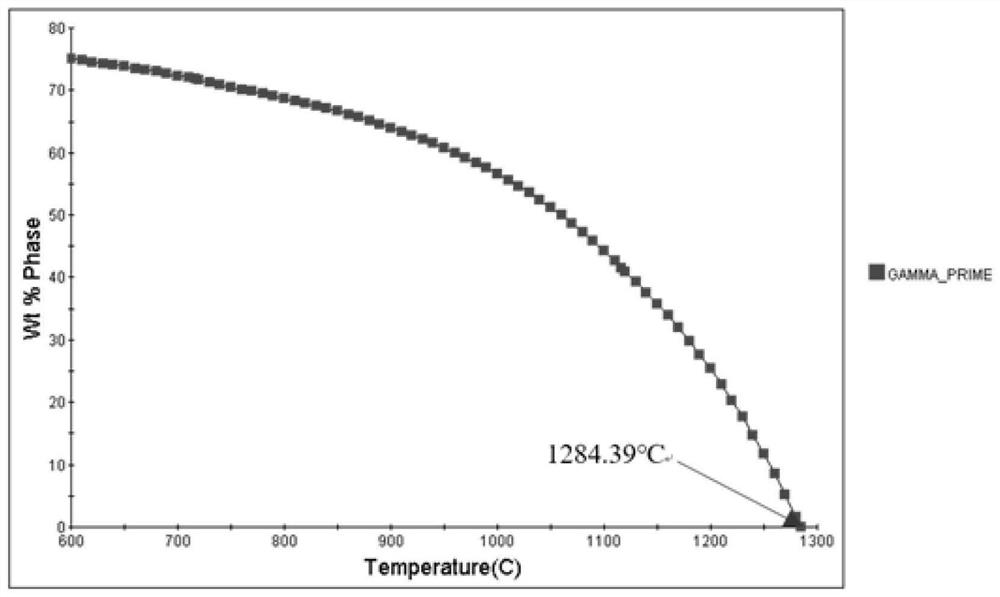

[0057] 2.2 γ' solid solution temperature

[0058] According to JmatPro simulation calculation, the γ' solid solution temperature of DD476 single crystal is about 1284.39°C (see figure 2 ), so three heat treatment regimes were set up to explore the actual solution temperature of the alloy γ’. The three ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com