Magnetostatic moving field magnetorheological polishing mechanism test device and processing method thereof

A test device, magnetorheological technology, applied in grinding drive devices, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as loss of polishing pressure, loss of workpiece pressure and polishing effect, and difficulty in ensuring workpiece uniformity. , to achieve the effect of low cost, good surface quality, no surface and sub-surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

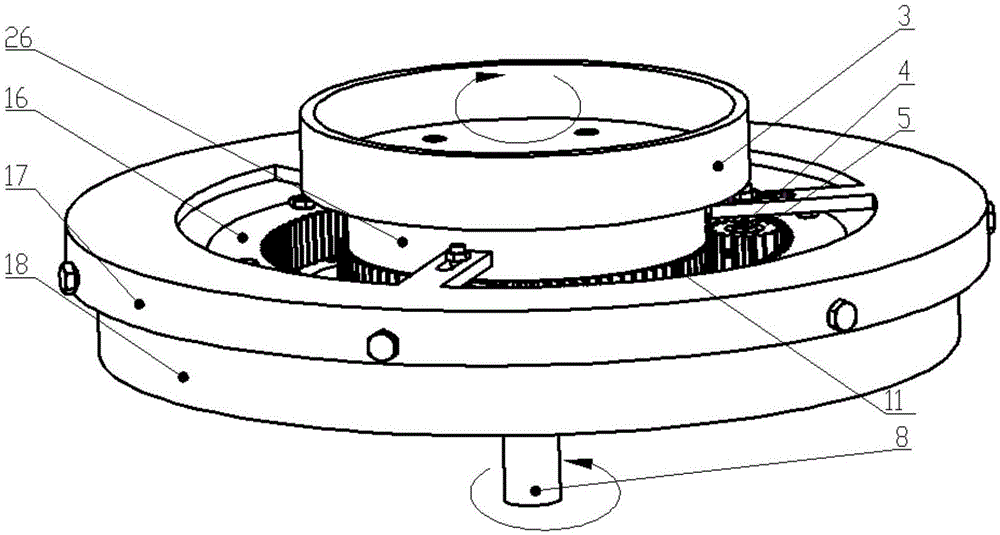

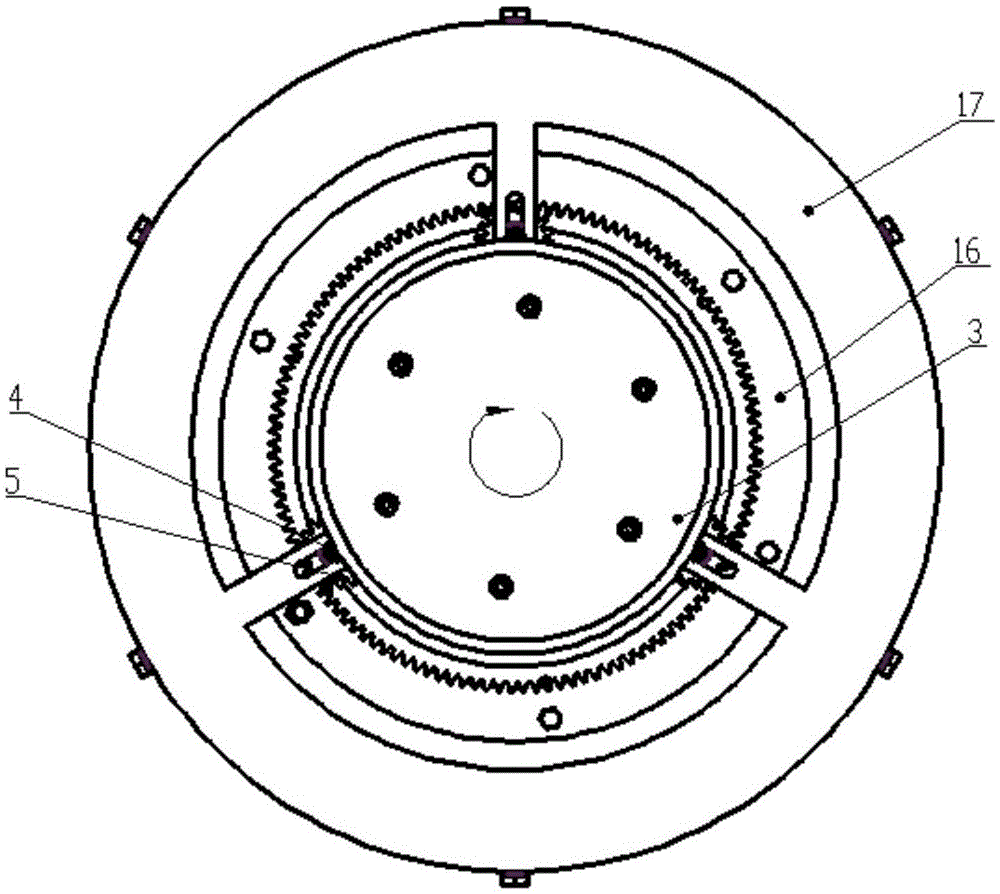

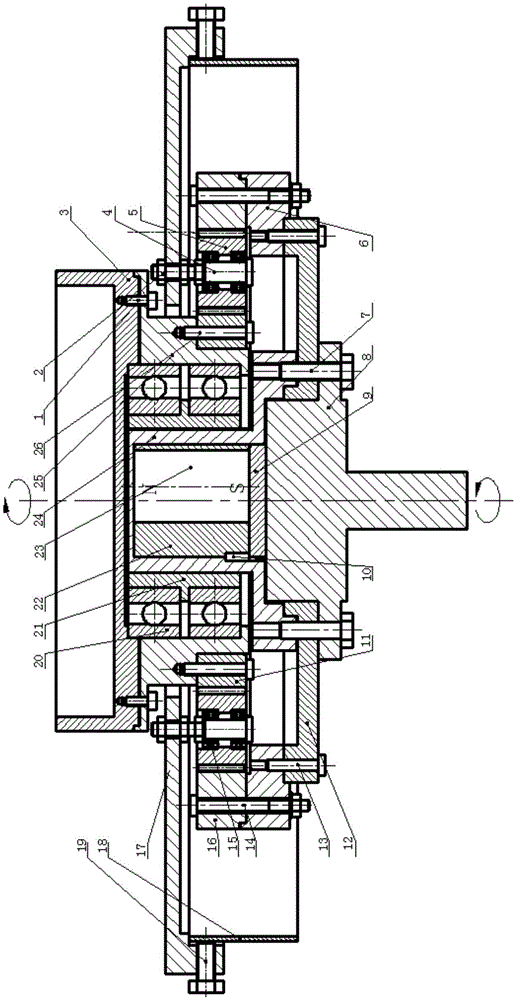

[0027] Such as Figure 1 ~ Figure 3As shown, the magnetostatic dynamic field magneto-rheological polishing mechanism test device of the present invention includes a magneto-rheological abrasive semi-fixed flexible micro-grinding head generator, a static-magnetic dynamic field eccentric conversion device, a polishing disc reverse rotation device, and a magneto-rheological abrasive. The semi-fixed flexible micro-grinding device includes a base 8, a permanent magnetic pole 23, a fixed sleeve 24, a turntable 12, and a polishing disc 3. The static-magnetic dynamic field eccentric conversion device includes a gasket 9, an eccentric sleeve 22, an inner positioning ring 21, The angular contact ball bearing 20, the outer positioning ring 25, the base 8 are clamped on the machine tool table, the turntable 12 is set on the outside of the base 8, the fixed sleeve 24 is installed on the upper part of the base 8, and the turntable 12 and the fixed sleeve 24 are connected with the base 8 con...

Embodiment 2

[0052]The structure of the present invention is the same as that of Embodiment 1, except that the permanent magnet pole 23 is a cylindrical permanent magnet with a diameter of 20mm, the magnetic induction intensity of the end face is 2500GS, the eccentric distance of the eccentric sleeve 22 is 2mm, and the rotating speeds of the workpiece and the permanent magnet pole 23 are respectively 800rpm and 300rpm, the workpiece 31 yaws 15mm from the center to the left and right along the X installation axis.

[0053] The present invention prepares the magnetorheological fluid 30 by the following method: add silicon carbide abrasives with a concentration of 4 to 8% and a particle size of 1 to 5 microns in deionized water, and micron-sized carbonyl iron powder with a concentration of 18%, with a mass percentage of 3 % glycerin, 4% anti-rust agent, fully stirred and vibrated by ultrasonic wave for 15 minutes. When the magnetorheological fluid 30 enters the top of the annular polishing di...

Embodiment 3

[0059] The structure of the present invention is the same as that of Embodiment 1, except that the permanent magnet pole 23 is a cylindrical permanent magnet with a diameter of 15 mm, the end surface magnetic induction is 2000 GS, the eccentricity of the eccentric sleeve 22 is 3 mm, and the rotating speeds of the workpiece and the permanent magnet pole 23 are respectively At 1000rpm and 200rpm, the workpiece 31 is processed along the line cutting track.

[0060] The present invention prepares the magnetorheological fluid 30 through the following method: adding aluminum oxide abrasives with a concentration of 2 to 6% and a particle size of 1.5 to 5 microns in deionized water, and micron-sized carbonyl iron powder with a concentration of 20% and a mass percentage of 4 % glycerin, 5% anti-rust agent, fully stirred and vibrated by ultrasonic wave for 20 minutes. When the magnetorheological fluid 30 enters the top of the annular polishing disc 3 , under the action of the magnetic f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com