Polishing pad, method of producing same, and polishing method

Inactive Publication Date: 2005-01-27

NIHON MICRO COATING

View PDF16 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

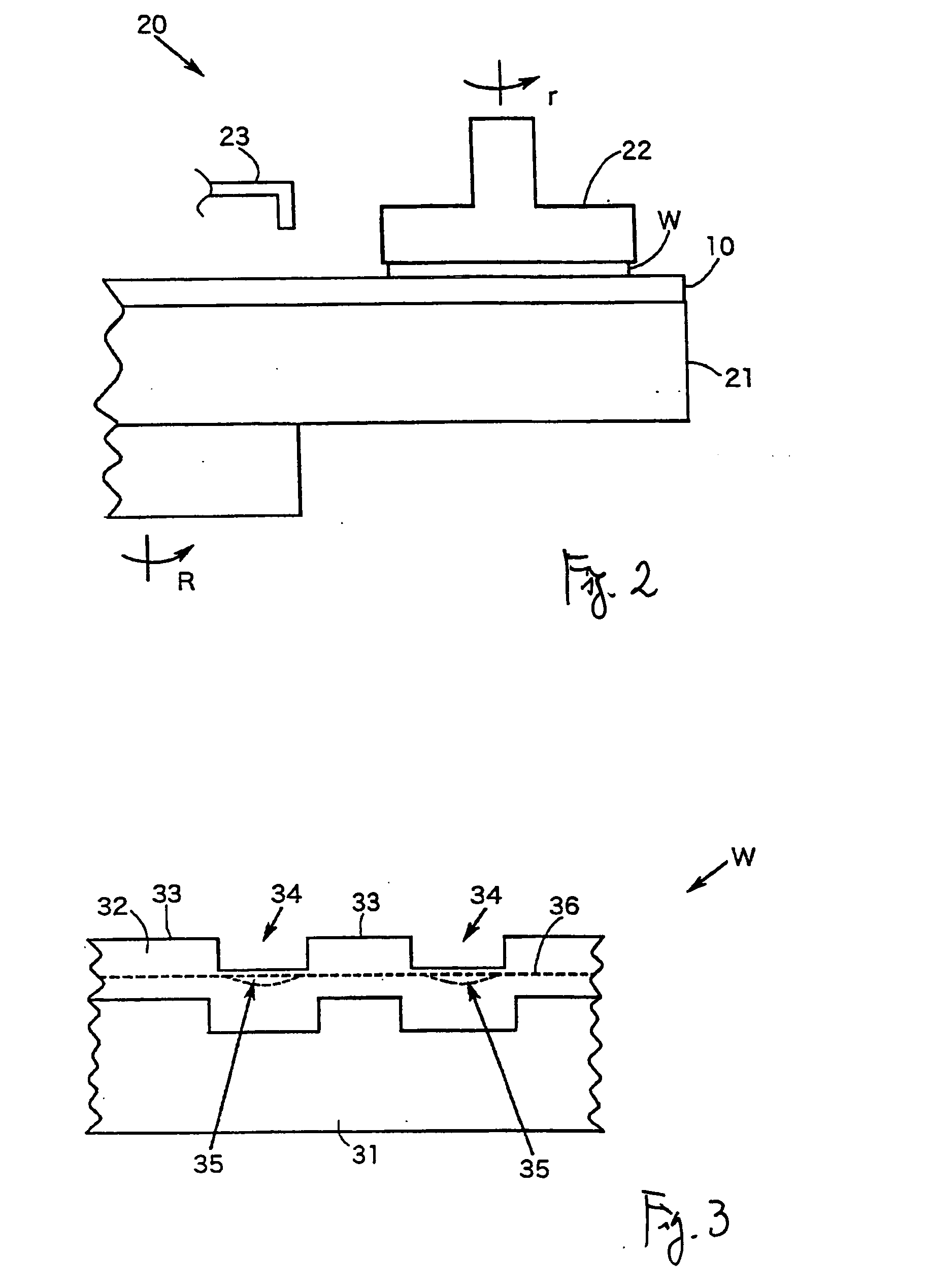

Grooves are formed on the surface of the polishing pad of this invention for collecting polluting or contaminating objects such as debris generated during the polishing operation such that such objects can be discharged ou

Problems solved by technology

If a conventional flexible and elastic polishing pad is used to polish the surface of such a top layer, a gentle unevenne

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Login to View More

Abstract

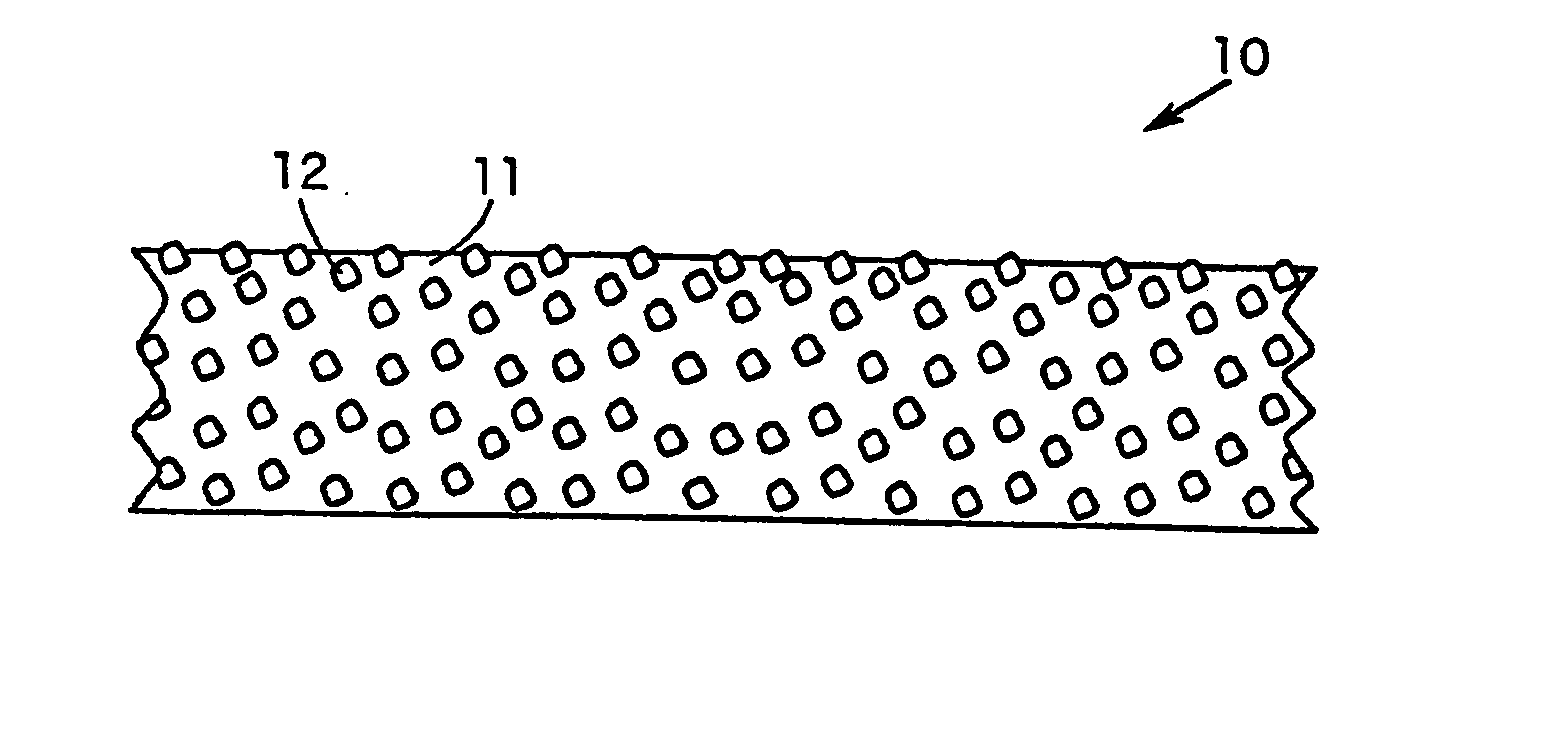

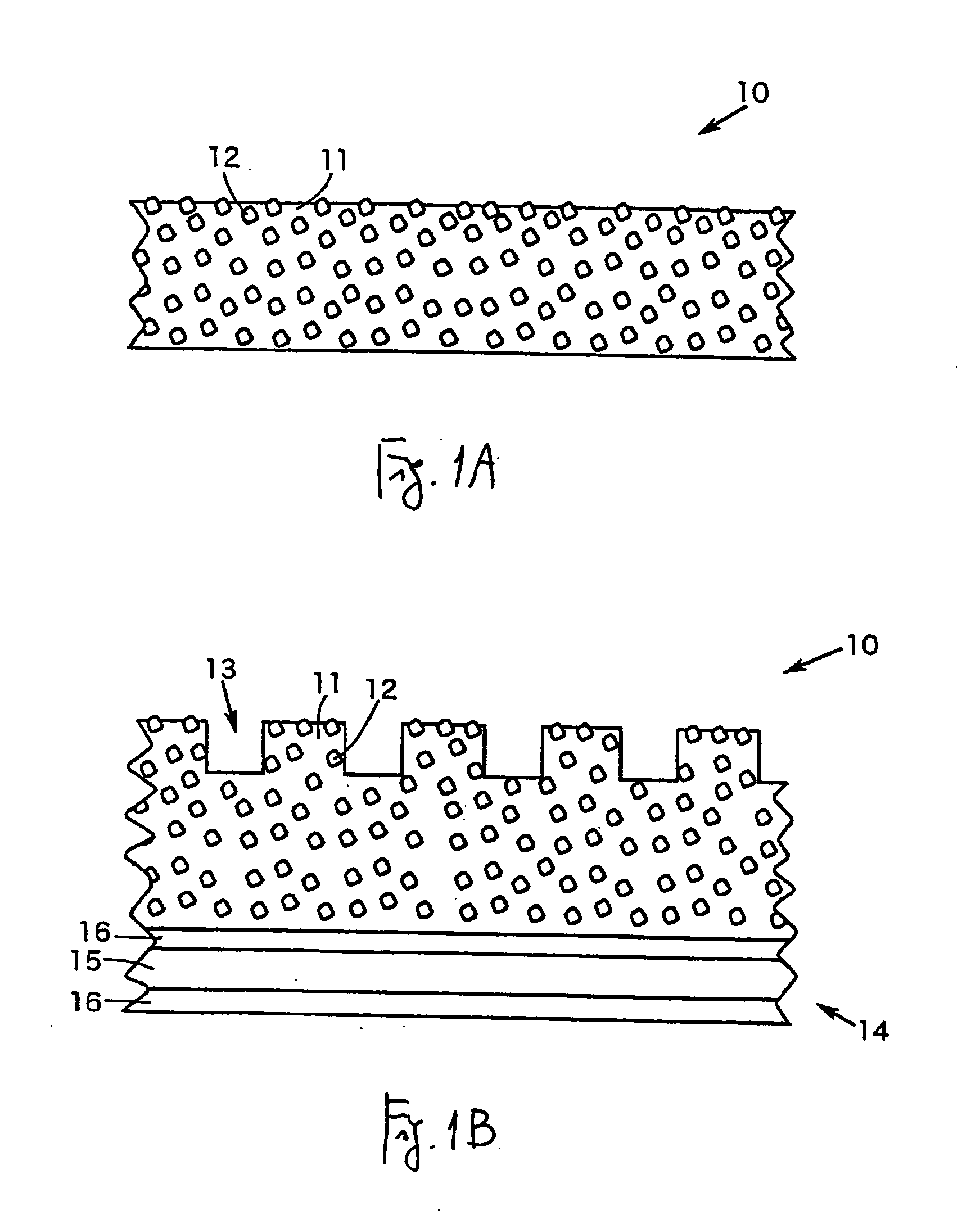

A polishing pad is formed with a non-foamed member shaped as a plate having a flat surface and abrading particles affixed inside and on the surfaces of this non-foamed member. Its average surface roughness is in the range of 0.5 μm-10 μm, and its Shore D hardness is within the range of 50-85. Grooves are formed on the surface of the polishing pad for collecting debris generated during the polishing operation and serving also as flow routes of a polishing liquid for distributing it uniformly over the surface of the polishing pad.

Description

Priority is claimed on Japanese Patent Application 2003-174258 filed Jun. 19, 2003. BACKGROUND OF THE INVENTION This invention relates to a polishing pad to be used for polishing the surface of a workpiece made of a metallic material, ceramics or glass, as well as a method of producing such a polishing pad. In particular, the invention relates to such a polishing pad used for polishing the surface of a workpiece such as a semiconductor wafer, a semiconductor device wafer, a liquid crystal display element, a thin-film imaging device, a magnetic disk substrate and an optical disk substrate, a method of producing such a polishing pad and a method of polishing. Semiconductor devices and magnetic disks are used as principal electronic components of electronic apparatus such as telephones, cameras and computers in order to control their functions and to store or display data. A workpiece such as a semiconductor wafer used in such an electronic component is made into a product after hav...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B24D3/00B24D7/02B24D3/28B24D3/30B24D7/00H01L21/304

CPCB24D3/30B24B37/26

Inventor SAITO, MITSURUTAMURA, JUNIZUMI, TOSHIHIROKOBAYASHI, TOSHIHIRONAGAMINE, TAKUYAMILLER, CLAUGHTON

Owner NIHON MICRO COATING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com