Cigar tobacco air-curing method

A cigar leaf air-curing technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of large air-curing temperature and humidity range, low degree of homogenization of tobacco leaves, and affecting the quality of tobacco leaves, and achieve air-curing temperature and humidity The range is small, the effect of improving quality and reducing loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: The present invention provides a kind of cigar tobacco leaf drying method, the kind of cigar tobacco leaf selects Yunxue No. 36, the fresh tobacco leaf of wrapper is the first-ripe tobacco leaf without dew, the fresh tobacco leaf of filler is the ripe tobacco leaf without dew, must Tobacco leaves can be collected and air-dried when there are no water droplets on the surface of the tobacco leaves; the cigar fresh tobacco leaves are sparsely weaved, and the air-drying rods are 1.5-meter-long air-drying rods, and 40-60 pieces of tobacco leaves are weaved on each air-drying rod.

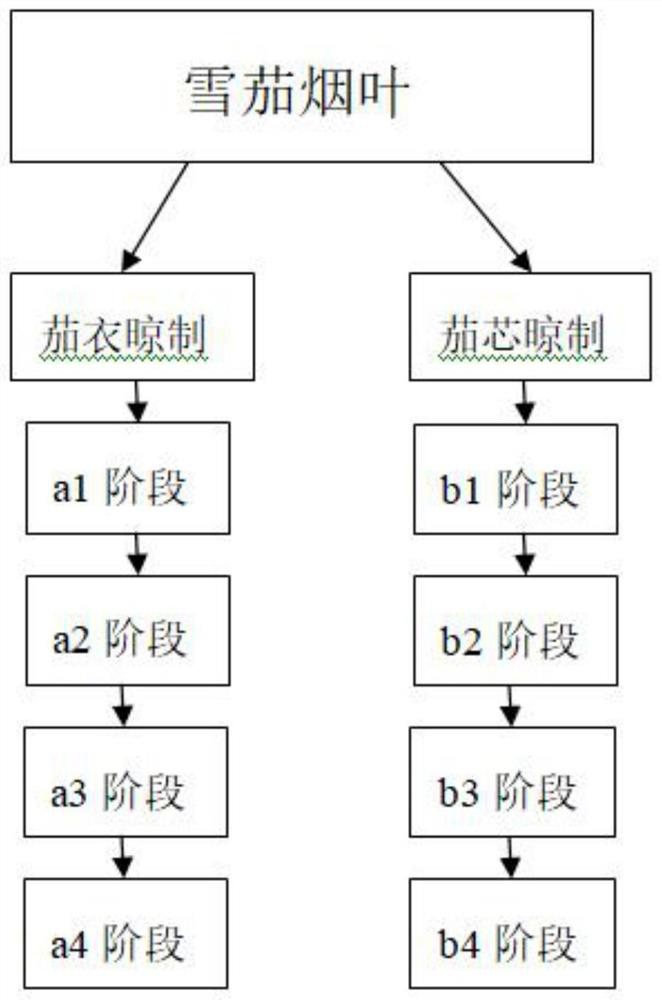

[0031] The cigar air-drying includes wrapper tobacco leaves and filler tobacco leaves. The wrapper tobacco leaves are made by weaving cigar fresh tobacco leaves on the air-drying rods and putting them in the drying room. After air-drying in four stages, they are ventilated. Wrapper tobacco leaves are obtained after the wrapper tobacco leaves are soft and not broken, and then the wrapp...

Embodiment 2

[0034]Embodiment 2: This embodiment provides a kind of cigar leaf natural drying method, and the kind of cigar leaf selects Yunxue No. 36, and the fresh tobacco leaf of the cigar wrapper that is about to gather is worn into pole, and every pole 40-60 tobacco leaves, put Enter the cigar leaf airing room, the temperature is natural temperature, the humidity is controlled by opening and closing the window, and the airing method is carried out in four stages to obtain naturally aired cigar wrapper tobacco leaves. The harvested cigar core fresh tobacco leaves are threaded into rods, with 40-60 tobacco leaves per rod, and placed in the cigar leaf drying room. The temperature is natural temperature, and the humidity is controlled by opening and closing windows. The drying method is carried out in four stages. (The air-curing process of four stages is as shown in Table 1), and the naturally air-cured cigar filler tobacco leaves are obtained.

[0035] stage temperature(℃) ...

Embodiment 3

[0046] Embodiment 3: This embodiment provides a method for drying cigar leaves. The variety of cigar leaves is Yunxue 36, and the fresh cigar leaves are mature tobacco leaves with dew for drying; The rods are air-drying rods of 1.5 meters, and 40-60 tobacco leaves are assembled on each air-drying rod. Compared with that in Example 1, using fresh cigar tobacco leaves as dew-free mature tobacco leaves for air curing, the results are shown in Table 5. The results showed that the fresh cigar tobacco leaves were mature tobacco leaves without dew and without water droplets on the surface of the tobacco leaves for air curing, and the proportion of mildew during the air curing process was low.

[0047] Fresh Tobacco Differences Proportion of mildew during drying (%) dew 45.39 no dew 20.15

[0048] table 5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com