Stirring device

A stirring device and stirring shaft technology, which is applied to clay stirring devices, cement stirring devices, mixers with rotating stirring devices, etc., can solve problems such as poor mixing uniformity, achieve uniform water injection, increase rotation speed, and shorten mixing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

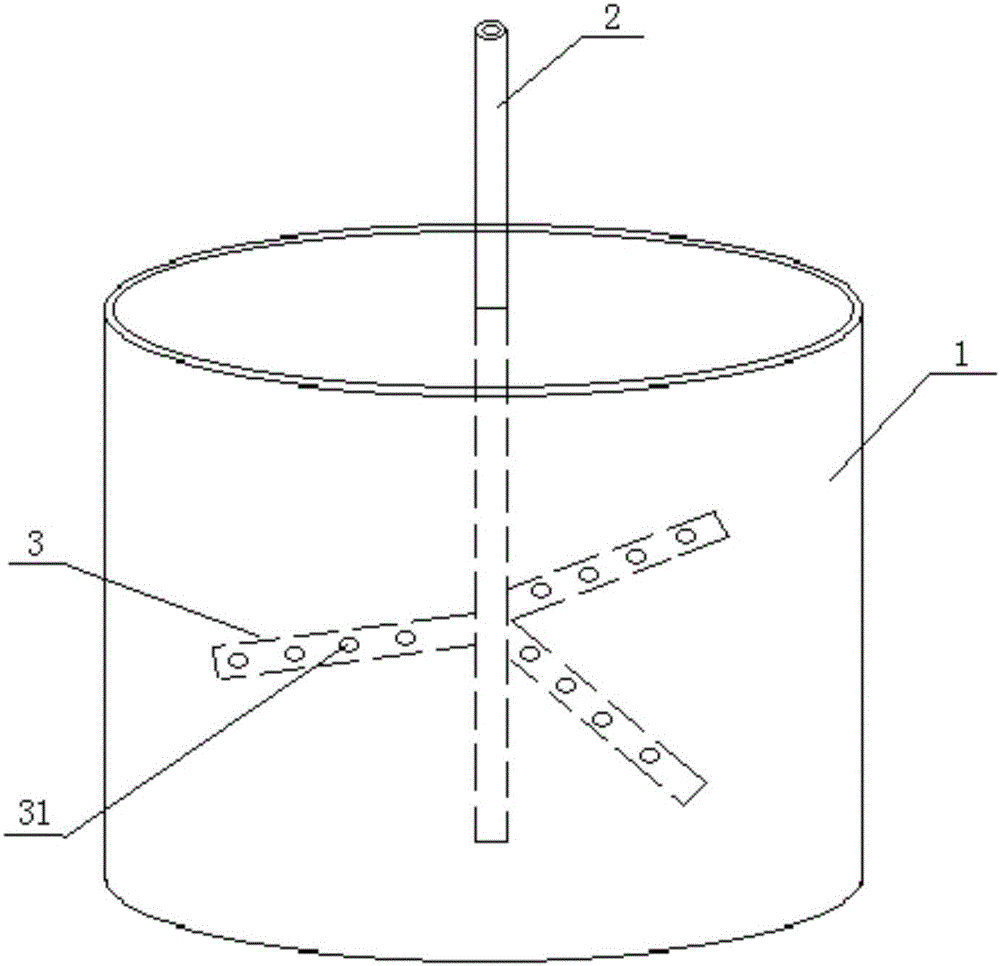

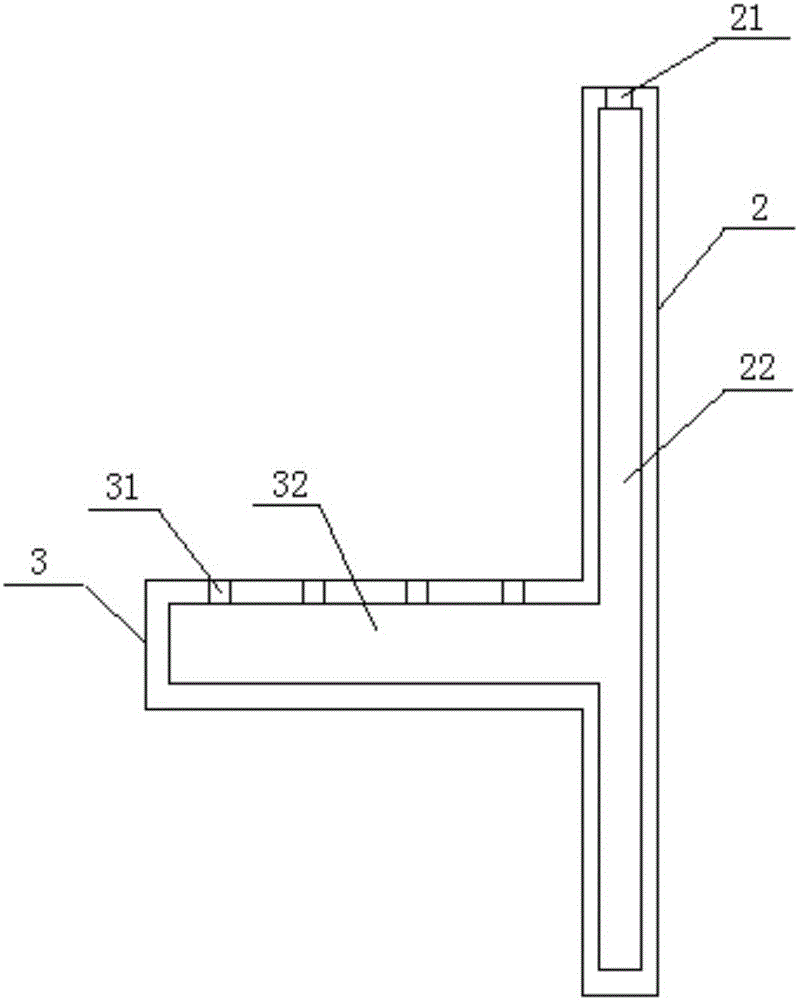

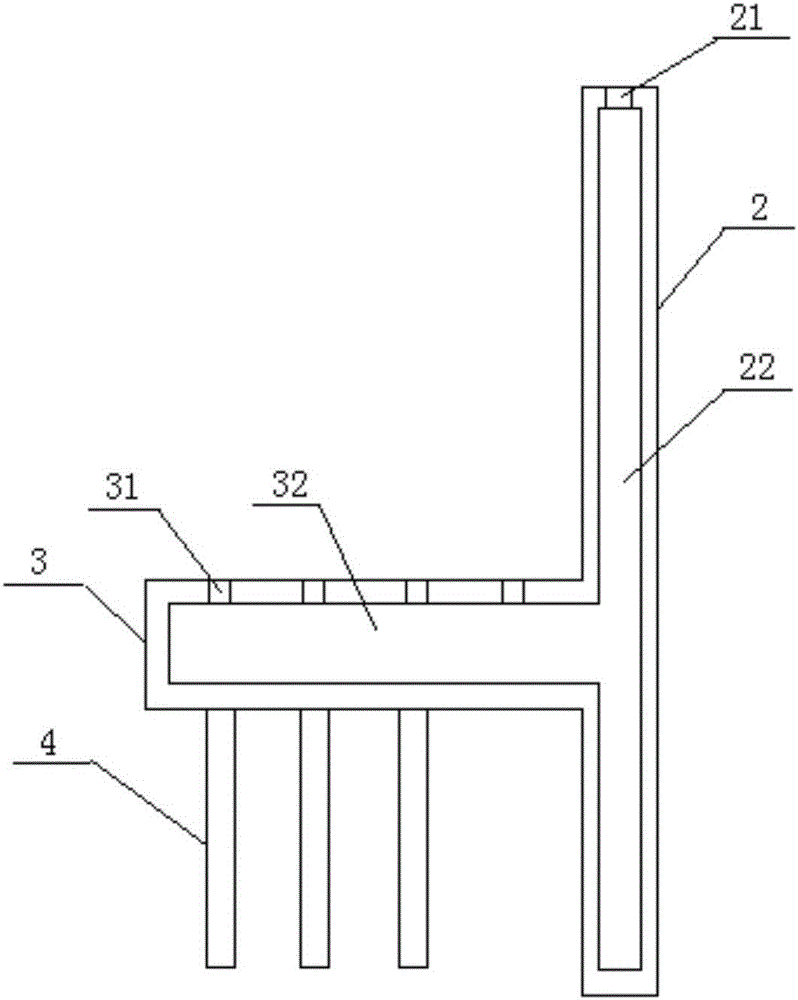

[0031] refer to figure 1 , is a structural schematic diagram of an embodiment of a stirring device, which includes a box 1 with an open upper end, a stirring shaft 2 and a stirring paddle 3 . figure 2 A cross-sectional view showing the stirring shaft and paddle, as figure 2 As shown, the stirring shaft 2 is connected to the stirring paddle 3, the stirring shaft 2 includes a first hollow cavity 22, and the wall of the first hollow cavity 22 is provided with a water injection port 21; the stirring paddle 3 includes a second hollow cavity 32, The second hollow body 32 communicates with the first hollow body 22 , and a plurality of first water outlet holes 31 are opened on the wall of the second hollow body 32 .

[0032] When stirring, fluid substances such as water are injected from the water injection port 21 , flow through the first hollow cavity 22 , flow into the second hollow cavity 32 , and then flow out from the plurality of first water outlet holes 31 .

[0033] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com