Method for improving rotating bending fatigue performance of locomotive axle steel

A bending fatigue and wheel axle technology is applied in the field of metal material surface nanometerization, which can solve the problems of difficulty in meeting the requirements of fatigue performance, high surface roughness value of materials, and limited range of refinement, and achieves improved surface finish and simple realization form. , the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

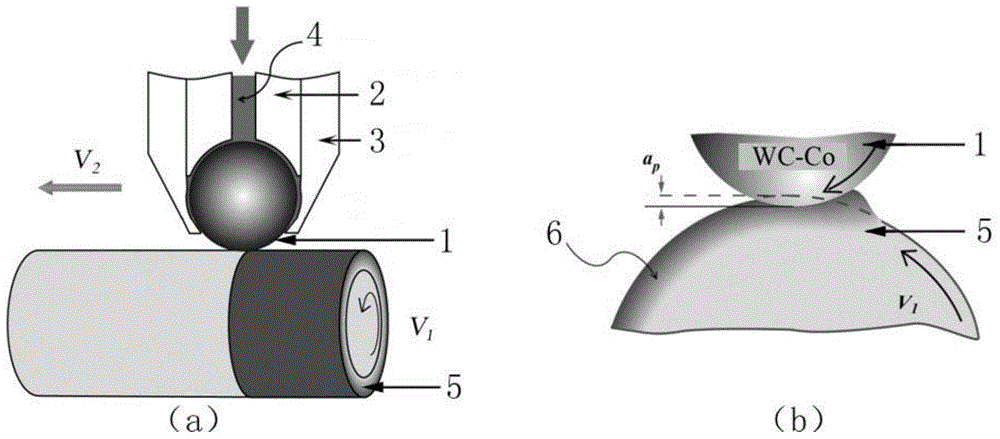

Embodiment 1

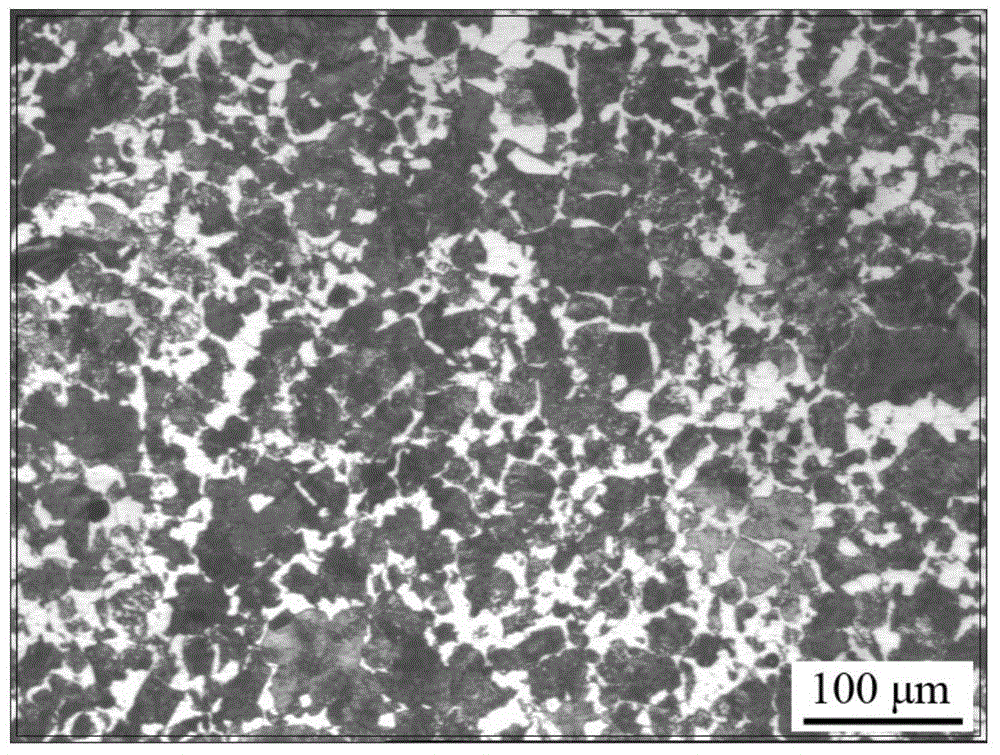

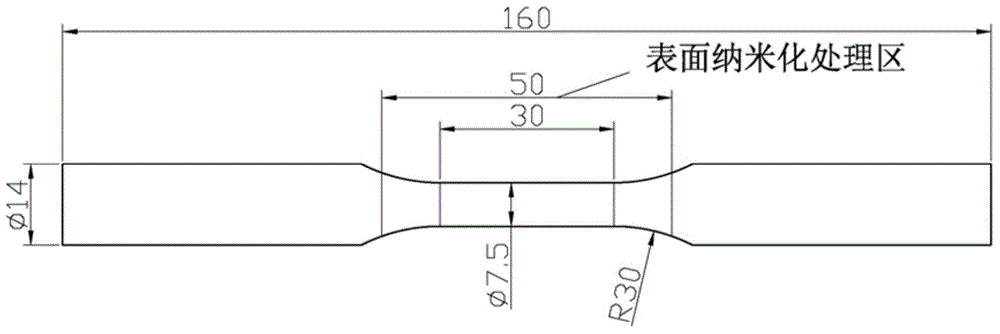

[0036] The locomotive axle steel is a medium-carbon alloy steel of the brand LZ50, and its chemical composition is (wt.%): C0.47%, Si0.17%, Mn0.6%, S0.03%, P0.03%, Cr0.03 %, Ni0.03%, Cu0.25%, Al0.02%, Fe balance. The initial delivery state of LZ50 steel is twice normalized + once tempered. The microstructure of LZ50 steel supply state is as follows: figure 2 As shown, it can be seen from the figure that the microstructure of LZ50 steel is mainly composed of ferrite and pearlite. The dimensions of LZ50 steel standard rotating bending fatigue specimens are as follows: image 3 shown. The surface nano-processing method of the present invention is used to process the fatigue sample of the locomotive wheel axle LZ50 medium carbon alloy steel. The WC-Co hard alloy ball diameter of the processing cutter head is 8mm, and the cooling lubricating liquid is selected CastrolCN008 / 04 type. image 3 shown. The selection of surface nano-treatment process parameters is as follows:

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com