A preparation method for grafting cationic antibacterial coating on the surface of aromatic polymer material

A technology of aromatic polymers and polymer materials, which is applied in the preparation field of grafted cationic antibacterial coatings on the surface of aromatic polymer materials, which can solve the problems of unsuitable aromatic polymer materials, reduced protein retention rate, and enlarged membrane pore size. , to achieve the effects of easy continuous production, reduced reagent consumption, and reduced separation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

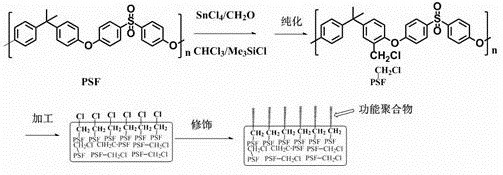

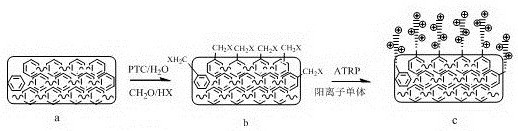

Method used

Image

Examples

example 1

[0040] 1) Put 1 (1cm*1cm) square centimeter phenolphthalein type polyaryletherketone (PEK-C) plate into the reactor, add 2.1g paraformaldehyde, 0.16 g catalyst 1,16-bissulfonic acid betaine, 30 mL of concentrated hydrochloric acid was reacted at 80°C for 8 h to obtain a PEK-C film grafted with chloromethyl groups on the surface. The prepared chloromethylated PEK-C membrane was repeatedly washed with deionized water.

[0041] 2) ATRP grafting reaction on the surface: 0.0067 g of copper bromide powder, 0.0094 g of 2,2-bipyridyl, 1.21 g of methacryloyloxyethyltrimethylammonium chloride and PEK grafted with chloromethyl -Put the C plate into the polymerization reactor, then add 4 ml of methanol and deionized water in a volume ratio of 1:1 into a 50 ml polymerization tube, keep blowing nitrogen for 30 minutes, then add 0.0049 g of vitamin C to the In the polymerization tube, the reaction was stirred at 70 °C for 6 h. After the reaction, the membrane was washed three times with dei...

Embodiment 2

[0043] 1) Put 1 (1*1) square centimeter bisphenol A polysulfone (PSF) membrane into a reaction tube, add 1.5 g paraformaldehyde, 0.25 g catalyst 2-butylpyridinesulfobetaine, 40 mL concentrated hydrochloric acid. The reaction temperature was 70℃, and the reaction time was 4 h, and the PSF membrane with chloromethyl groups grafted on the surface was obtained. The prepared chloromethylated PSF membrane was washed repeatedly with deionized water.

[0044] 2) The above surface chloromethylated PSF film, 0.0072g cuprous bromide powder, 0.0200 g 2,2-bipyridine and 3.0 g N,N-dimethyl-N-(ethoxyylmethyl)-N -[2'-(Methacryloyloxy)ethyl]ammonium chloride and PSF membrane grafted with chloromethyl group were placed in a 50 ml polymerization tube, and high-purity nitrogen gas was passed into the polymerization tube, and the nitrogen gas was kept blowing for 30 min Afterwards, 5 mL of ethanol was added. The polymerization tube was sealed, and the reaction was stirred at 70 °C for 4 h. Afte...

example 3

[0046] 1) Put 1 (1cm*1cm) square centimeter biphenyl polyimide (BP-PI, prepared by biphenyl dianhydride and 4,4-diaminodiphenyl ether) film into the reactor, add 2.1g polymer Formaldehyde, 0.16 g catalyst methylimidazole sulfobetaine, and 35 mL concentrated hydrochloric acid were reacted at 90 °C for 6 h to obtain a BP-PI film grafted with chloromethyl groups on the surface. The prepared chloromethylated polyBP-PI membrane was washed repeatedly with deionized water.

[0047] 2) ATRP grafting reaction on the surface: 0.0041 g of cuprous chloride powder, 0.0130 g of 2,2-bipyridyl, 2.5 g of methacryloyloxyethyltrimethylammonium chloride and grafted chloromethyl Put the BP-PI membrane into a 50 ml polymerization reactor, keep blowing nitrogen for 30 min, and then add 4 ml of anaerobic methanol and deionized water in a volume ratio of 1:1 to the polymerization tube, at a temperature of 60 The reaction was stirred and reacted at ℃ for 4 hours. After the reaction, the membrane was w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com