Method for recovering silver from waste circuit board

A technology of waste circuit boards and circuit boards, which is applied in the field of resource recycling, can solve the problems of cumbersome process, complicated process, and low product purity, and achieve the effects of simplifying the process, improving extraction efficiency, and shortening the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] 1.1 Recycling

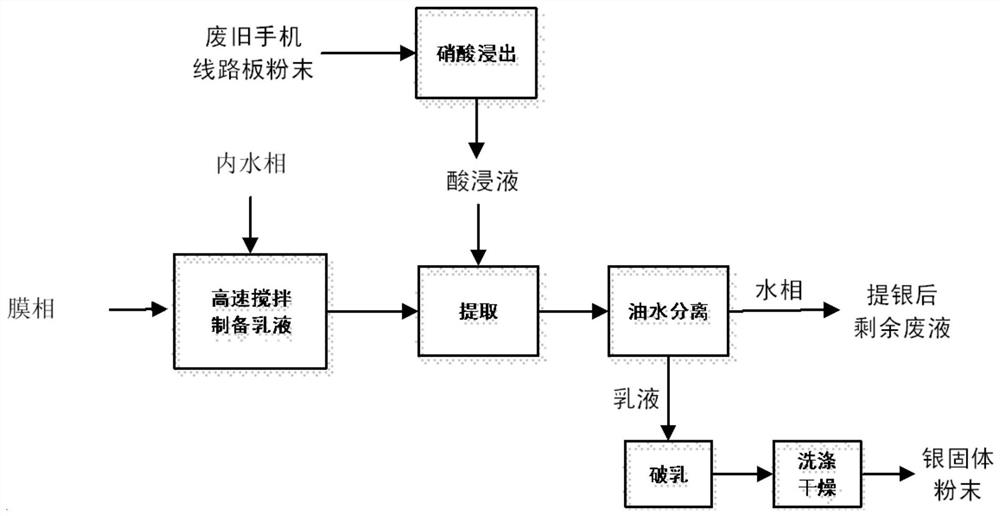

[0095] S1. Waste mobile phone circuit boards are disassembled, crushed, sorted, ground and dried to obtain 100 mesh metal-containing powders.

[0096] S2. Mix the metal-containing powder and nitric acid solution (concentration: 5.5M) with a solid-to-liquid ratio of 1g: 10mL, and carry out the impregnation reaction in a constant temperature magnetic stirring water bath. The control temperature is 60°C, and the magnetic stirring speed is 350r / min. It is 3.5h. After that, it is filtered to obtain pickling solution.

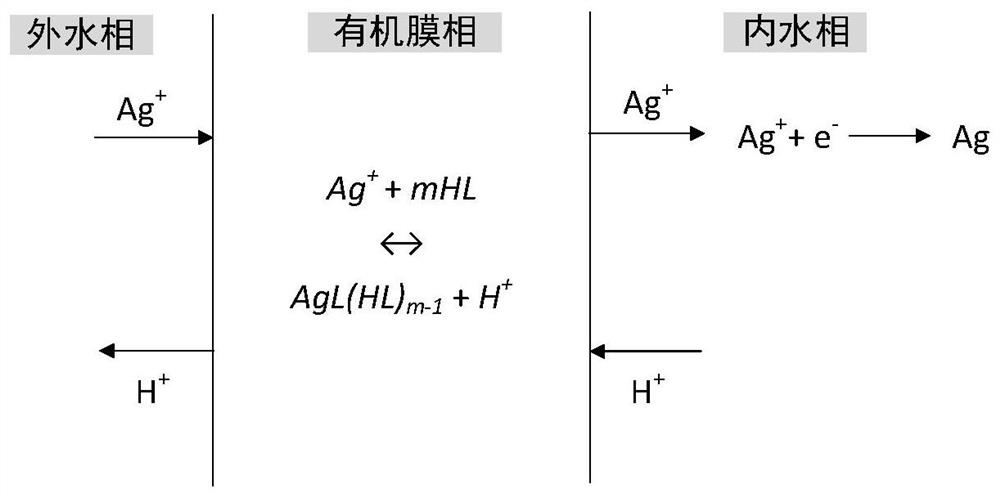

[0097] S3. Membrane phase: Span 80 emulsifier 5%, silver extraction carrier Cyanex 302 0.4%, liquid paraffin 3%, kerosene as solvent. Inner water phase: 5% aqueous solution of vitamin C.

[0098] The membrane phase and the inner water phase were mixed at a volume ratio of 1:1, and emulsified at a stirring speed of 3500 r / min for 10 min to obtain an emulsion.

[0099] Mix the emulsion and pickling liquid in a volume ratio of 1:3, and extract...

Embodiment 2

[0109] 1.1 Recycling

[0110] S1. Waste mobile phone circuit boards are disassembled, crushed, sorted, ground and dried to obtain 100 mesh metal-containing powders.

[0111] S2. Mix the metal-containing powder and nitric acid solution (concentration: 5.5M) with a solid-to-liquid ratio of 1g: 10mL, and carry out the impregnation reaction in a constant temperature magnetic stirring water bath. The control temperature is 60°C, and the magnetic stirring speed is 350r / min. It is 3.5h. After that, it is filtered to obtain pickling solution.

[0112] S3. Membrane phase: Span 80 emulsifier 10%, silver extraction carrier Cyanex 302 0.4%, liquid paraffin 3%, kerosene as solvent. Inner water phase: 5% aqueous solution of vitamin C.

[0113] The membrane phase and the inner water phase were mixed at a volume ratio of 1:1, and emulsified at a stirring speed of 3500 r / min for 10 min to obtain an emulsion.

[0114] Mix the emulsion and pickling liquid in a volume ratio of 1:3, and extrac...

Embodiment 3

[0122] 1.1 Recycling

[0123] S1. Waste mobile phone circuit boards are disassembled, crushed, sorted, ground and dried to obtain 100 mesh metal-containing powders.

[0124] S2. Mix the metal-containing powder and nitric acid solution (concentration: 5.5M) with a solid-to-liquid ratio of 1g: 10mL, and carry out the impregnation reaction in a constant temperature magnetic stirring water bath. The control temperature is 60°C, and the magnetic stirring speed is 350r / min. It is 3.5h. After that, it is filtered to obtain pickling solution.

[0125] S3. Membrane phase: Span 80 emulsifier 15%, silver extraction carrier Cyanex 302 0.4%, liquid paraffin 3%, kerosene as solvent. Inner water phase: 5% aqueous solution of vitamin C.

[0126] The membrane phase and the inner water phase were mixed at a volume ratio of 1:1, and emulsified at a stirring speed of 3500 r / min for 10 min to obtain an emulsion.

[0127] Mix the emulsion and pickling liquid in a volume ratio of 1:3, and extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com