System device for adding rare earth into continuous casting tundish and adding method

The invention relates to a continuous casting tundish and system device technology, which is applied in the field of rare earth adding system device and adding method in continuous casting tundish, which can solve the problem that the lubricating and heat transfer functions of mold powder cannot be fully exerted, and the melting performance of mold powder can be changed. Problems such as the difficulty of on-site layout of wire feeding equipment, to achieve the effect of shortening alloying time, improving dynamic conditions, and light equipment

Inactive Publication Date: 2010-08-25

INNER MONGOLIA UNIV OF SCI & TECH

View PDF5 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The above addition methods have problems such as low yield of rare earth and other elements distributed in the steel, poor uniformity, long processing cycle, and difficulty in site layout of feeding equipment, which affects site operation.

Due to their special properties, rare earth elements are often used to feed rare earth wires into the steel in the crystallizer. If the rare earth wire diameter and wire feeding speed are well controlled, the uniformity of rare earth distribution in the billet can be improved, but because the rare earth stays in the steel The time is short, and it is difficult to remove the rare earth inclusions generated. In addition, the rare earth oxidation products generated enter the molten layer of mold slag, which changes the melting performance of the mold slag, makes the lubrication and heat transfer function of the mold slag unable to fully play, and causes the slab quality deterioration

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

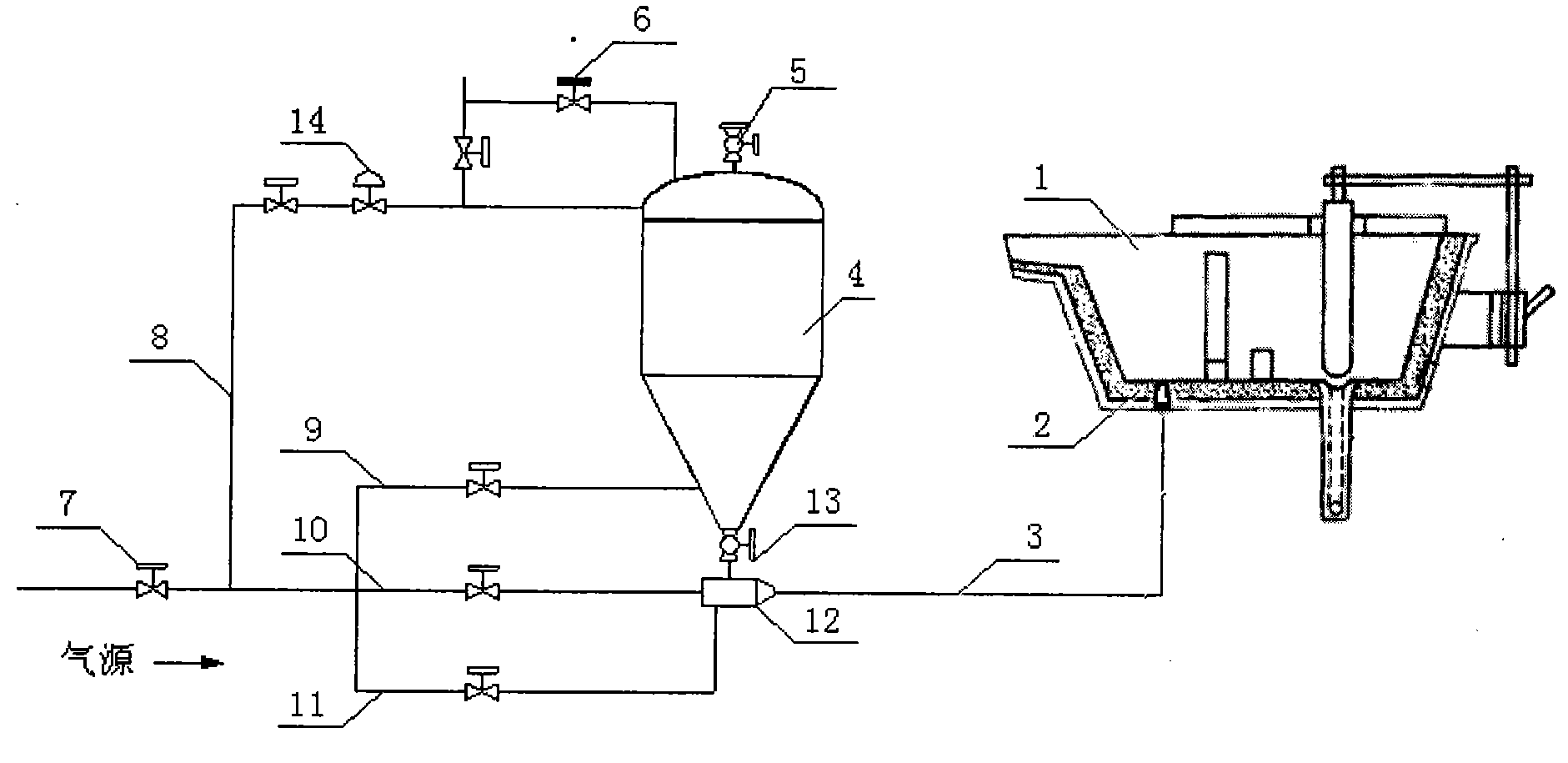

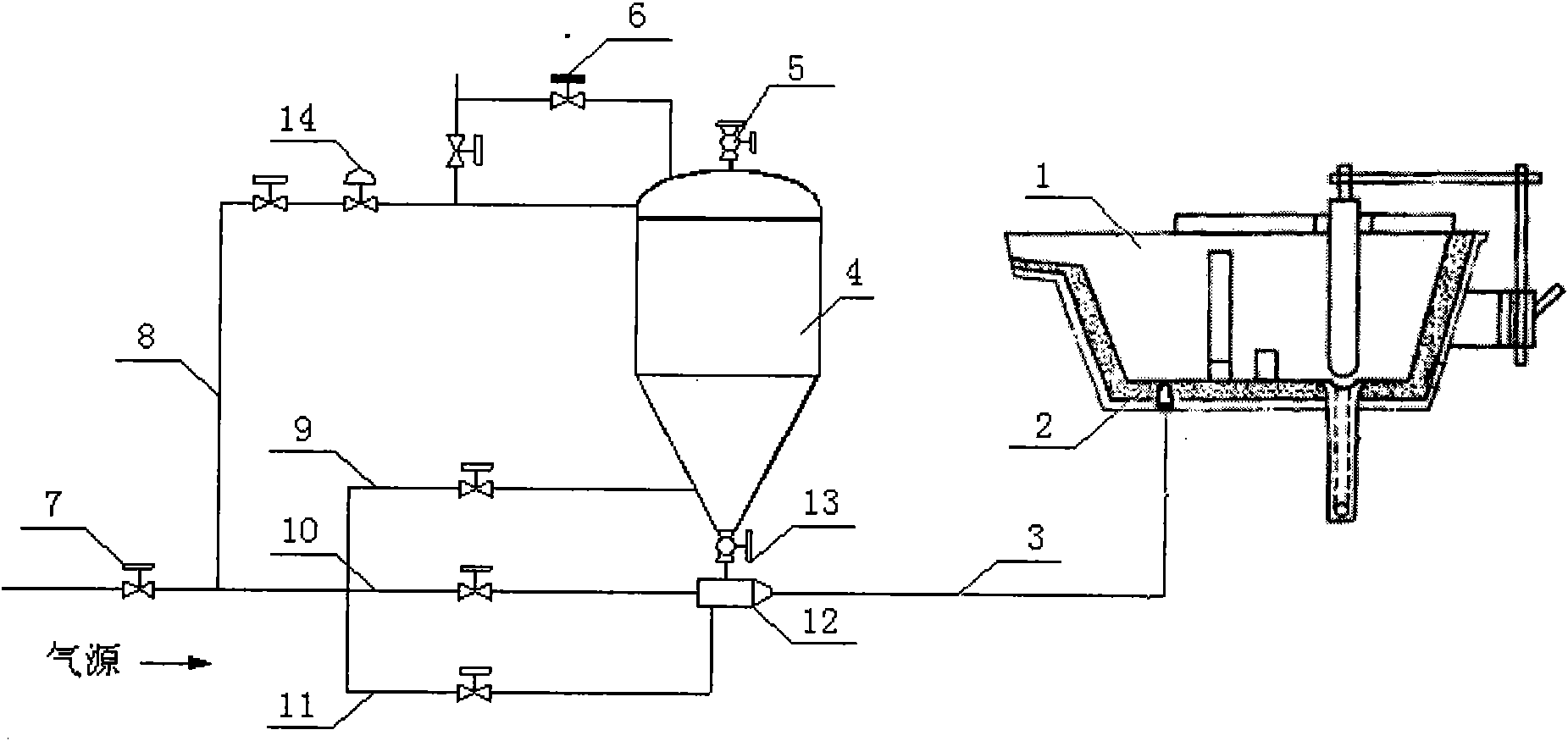

The invention relates to a system device for adding rare earth into a continuous casting tundish and an adding method, belonging to the field of ferrous metallurgy. In the invention, a powder spraying tube is arranged between a tundish and a powder spraying pot, one end of the powder spraying tube is connected with a powder spraying pot, the other end is arranged at the slit of a slit-type air brick arranged at the lower part of the tundish, and argon is adopted to spray rare earth powder to the slit of the air brick by the powder spraying tube and then enters the tundish. In the invention, high-pressure powder airflow is utilized to intensively stir molten steel, thus shortening alloying time, greatly improving dynamical condition of metallurgy reaction, promoting homogenized degree of rare earth elements in steel, improving yield of alloy, having strong reproducibility and accurate sprayed elements, and controlling the components of smelt steel within a narrow range. The invention also solves the problem of environmental pollution, and has the advantages of saved investment, portable equipment, easy operation and the like.

Description

Continuous casting tundish rare earth adding system device and adding method technical field The invention relates to a continuous casting tundish rare earth adding system device and adding method, belonging to the field of iron and steel metallurgy. Background technique The molten steel that has been refined outside the furnace is required not to be re-polluted during the continuous casting process. During the flow of the molten steel in the tundish, inclusions should be promoted to float up to further purify the molten steel. For this reason, the tundish adopts a heating device, air blowing, and wire feeding. And other functions constitute the tundish metallurgical technology. Tundish metallurgical technology is the key to improving the cleanliness of continuous casting slabs and ensuring excellent quality of slabs. With the development of continuous casting technology, the research on tundish metallurgy technology has become a key research topic for metallurgists. At...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B22D11/116C21C7/04

Inventor 董方周建安蔡国君

Owner INNER MONGOLIA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com