Microwave irradiation pressurized sintering equipment and use method thereof

A pressure sintering and microwave irradiation technology, applied in the field of powder metallurgy, can solve the problems of reducing the mechanical and physical properties of materials, effectively reducing the sintering temperature, and uneven performance of sintered bodies, so as to achieve good industrial application prospects and shorten sintering process. The effect of low time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment, the present invention is further described, not limitation to its protection scope:

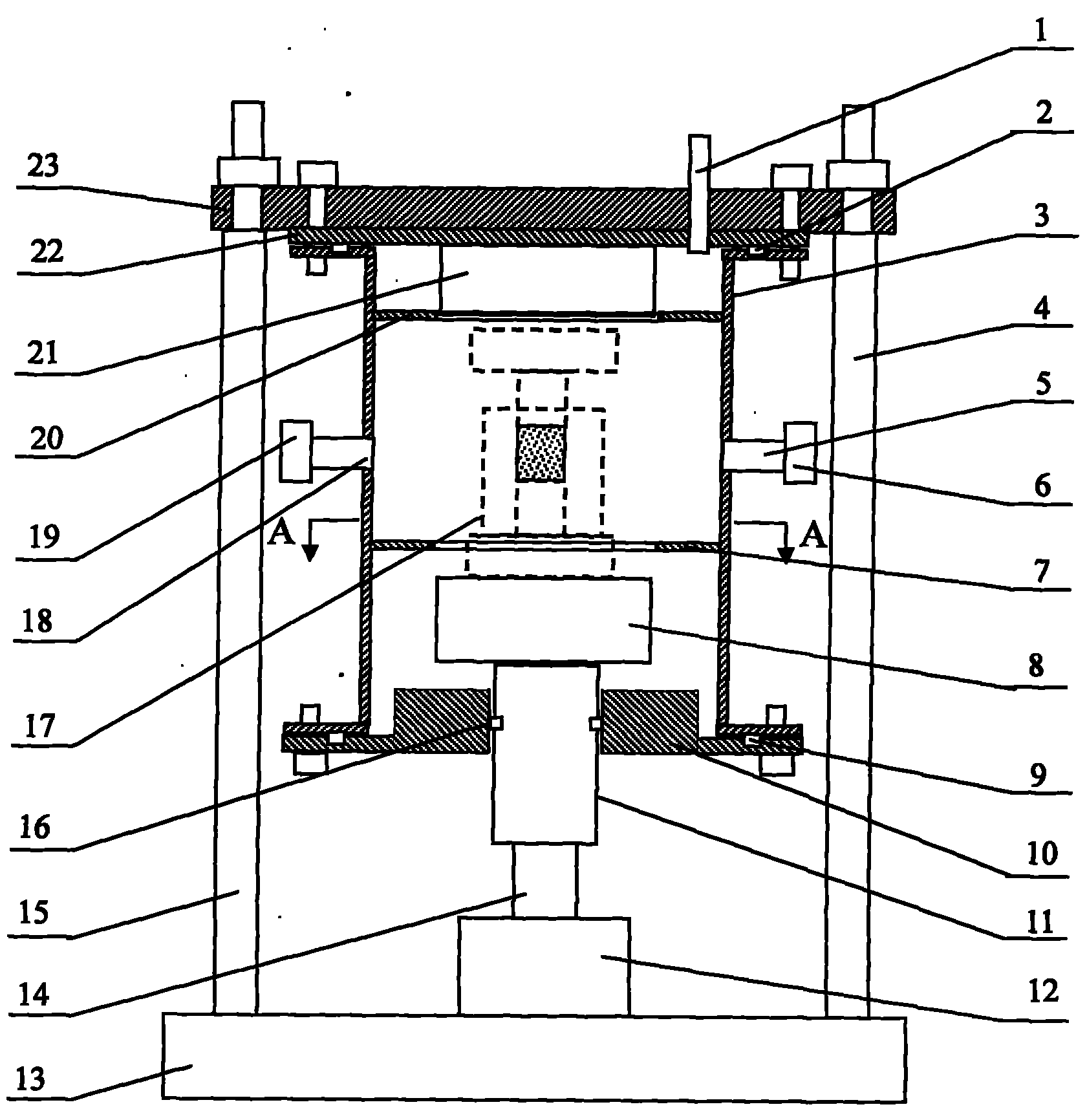

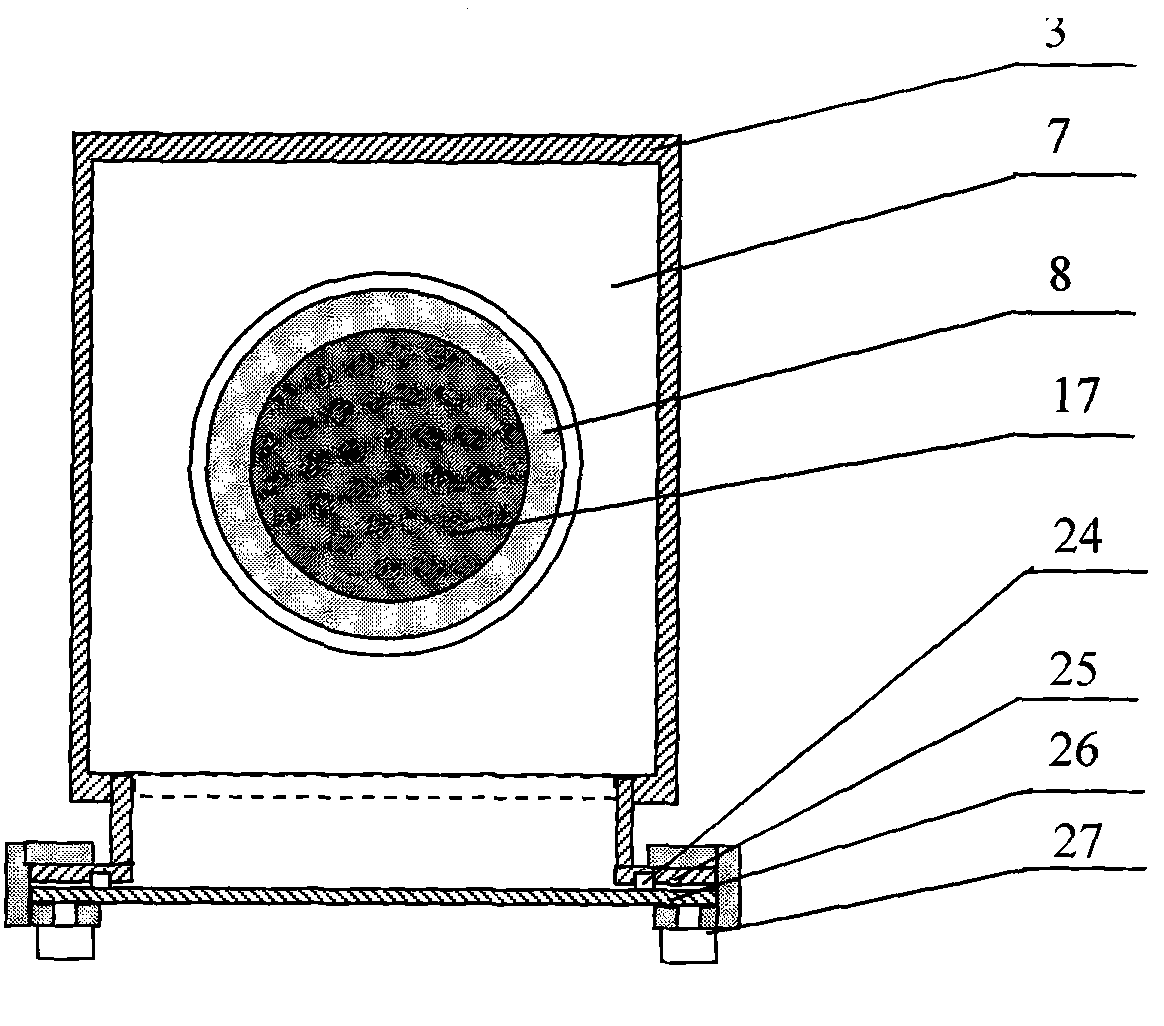

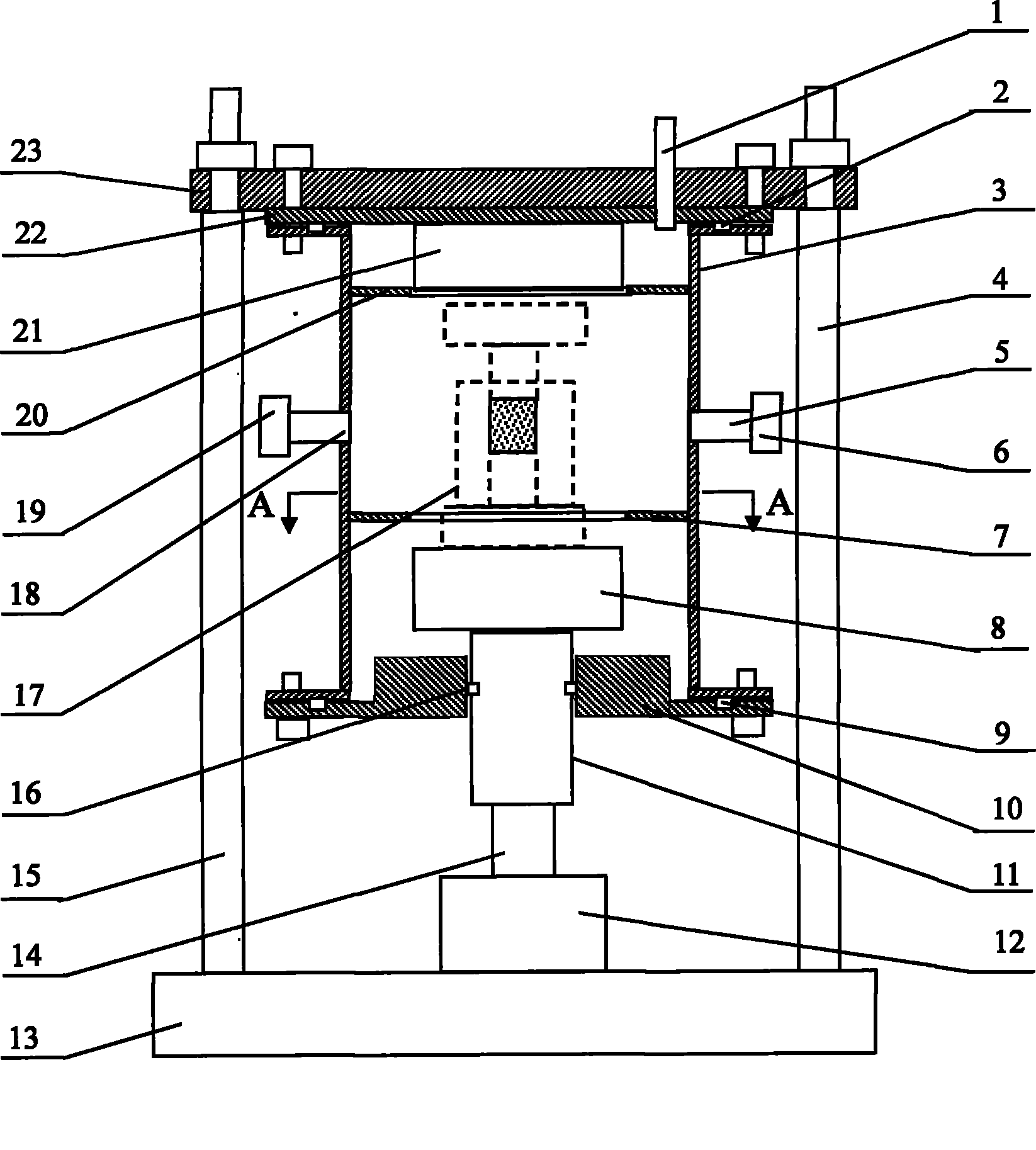

[0024] A microwave irradiation pressure sintering equipment and its use method, its structure is as follows figure 1 and figure 2 As shown: the lower ends of the two columns 4, 15 are respectively symmetrically fixed on the base 13, and the upper ends of the two columns 4, 15 are fixedly connected with the two ends of the beam 23; the upper cover 22 of the microwave oven is fixed on the lower plane of the beam 23, An upper pressure head 21 is fixedly installed at the center of the inner wall of the upper lid 22 of the microwave oven, and a microwave upper reflector 20 and a microwave lower reflector 7 are respectively fixed on the upper and lower parts of the inner wall of the side plate 3 of the microwave oven. The right side of the side plate 3 of the microwave oven is embedded with The first waveguide 5, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com