Patents

Literature

39results about How to "Increase the speed of the reduction reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing vanadium trioxide

InactiveCN101717117AIncrease the speed of the reduction reactionReduce consumptionVanadium oxidesVanadium(V) oxideAmmonium

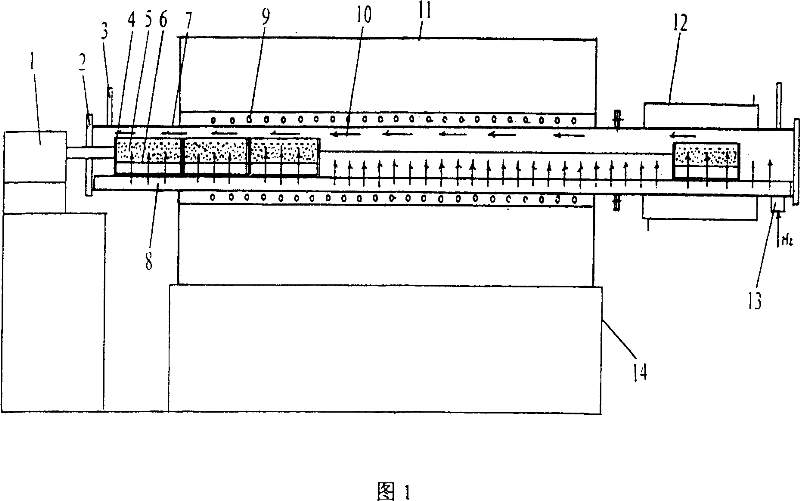

The invention belongs to the chemical field, in particular to a method for producing vanadium trioxide, aiming at improving the reaction speed of the method for producing vanadium trioxide and providing a solution as follows: A. raw material preparation; B. reduction of the prepared raw material by using reducing gas; and C. obtaining vanadium trioxide after reduction. The improvement of the method in the invention is that the used raw material in step A is composed of binder, carbon powder and vanadium-containing material, wherein the vanadium-containing material is ammonium vanadate or vanadium pentoxide. The invention adopts the technologies of carbon-proportioning and pellet preparation aiming at the raw material to enable the raw material to react in a gas-solid bi-phase reducing agent formed by solid carbon powder and reducing gas, thus improving the reduction reaction speed, enhancing recovery rate of the vanadium, and reducing consumption of the reducing gas. The produced pellet has the advantages of improving reaction speed, avoiding and reducing volatilization of vanadium-containing powder material, protecting environment and being beneficial for labor protection.

Owner:SICHUAN CHUANWEI GRP CO LTD +1

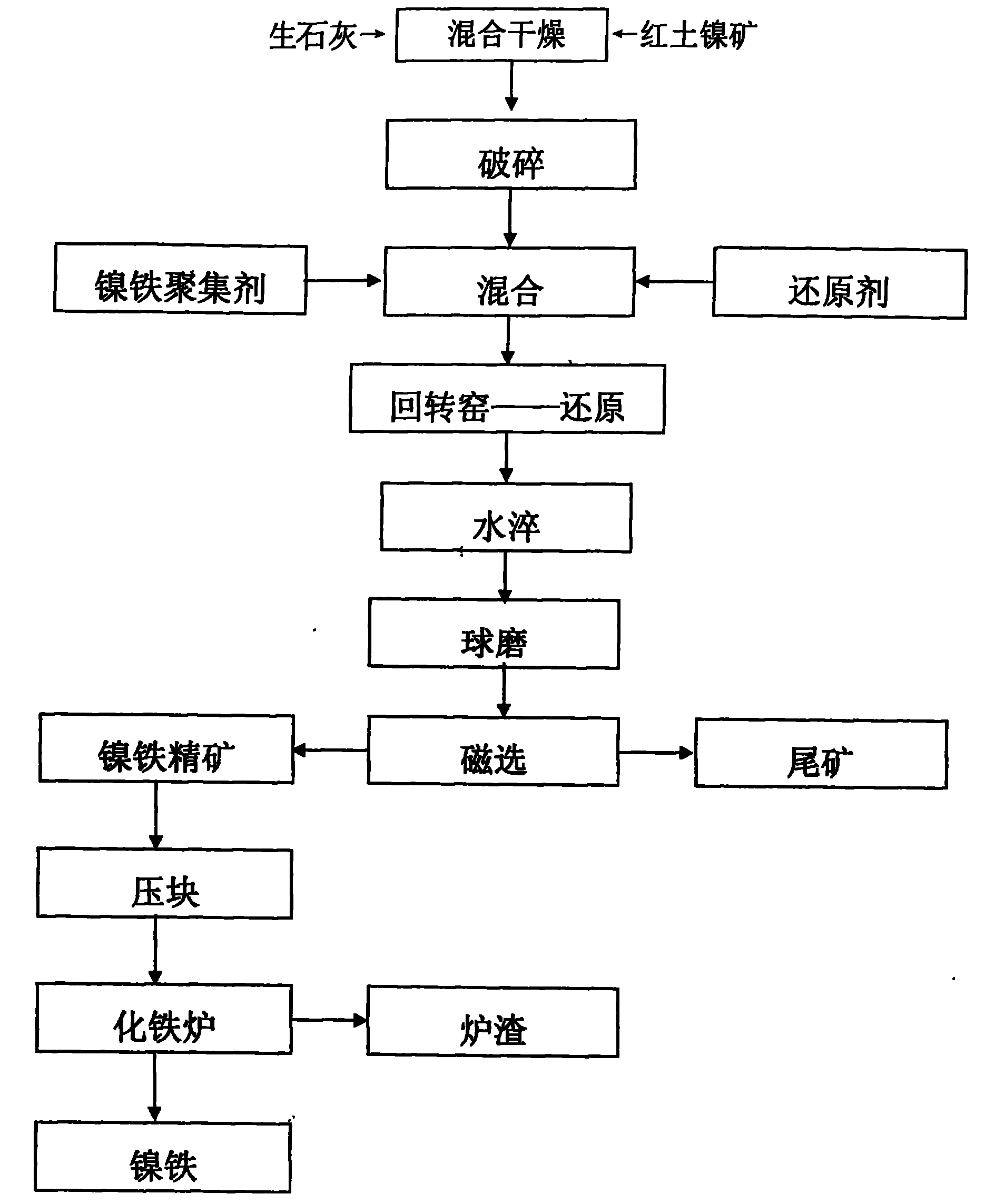

Method for reducing granular ferronickel through laterite-nickel ore in two-stage rotary kiln

The invention relates to a method for reducing granular ferronickel through laterite-nickel ore in a two-stage rotary kiln. The method comprises the steps of adding a drying agent to laterite-nickel ore containing adsorption water, uniformly stirring and mixing, dehydrating and drying; crushing a mixture, adding a reducing agent and a granular ferronickel additive, uniformly mixing, and carrying out reduction roasting in a first stage of rotary kiln; and carrying out smelting reduction on materials subjected to reduction roasting in high temperature in a second stage of rotary kiln, and quenching, cooling, crushing, ball-milling and magnetically separating the materials subjected to reduction roasting to obtain the high-grade granular ferronickel. The method is simple in production, convenient to operate, low in energy consumption, low in cost and high in nickel recovery rate, and the produced ferronickel particle can be directly used as a high-quality raw material for smelting stainless steel. The method is applicable to laterite-nickel ores differing in grade and type.

Owner:毛黎生

Coal gasification method using oxygen-rich air, CO2 flue gas and steam as gasifying agents

InactiveCN101381628AImprove thermal efficiencyIncrease gas calorific valueCombustible gas productionWater vaporCO2 content

The invention relates to a coal gasification method, in particular to a coal gasification method in which oxygen enriched air, CO2 smoke and steam are used as gasification agents. In the method, the CO2 smoke is led out from a combustion gas kiln furnace and pressurized and evenly mixed with the oxygen enriched air according to certain ratio to form the mixed gas richly containing O2 and CO2, wherein the O2 content reaches 30 to 50 percent, and the CO2 content reaches 5 to 25 percent; the mixed gas is mixed with vapor to be used as a coal gasification device; and in the coal gasification device, the gasification agents and coal are subjected to oxidation reduction reaction to generate coal gas in which CO and H2 are main combustible components. In the invention, the coal gasification reaction process is completed, and CO2 in the smoke exhausted by the kiln furnace is used as a reactive substance and is reduced to CO, thereby increasing the CO content in the coal gas, improving the calorific power of the coal gas, lowering the consumption of the gasified coal, reducing the emission of CO2 in the smoke exhausted by the combustion gas kiln furnace and achieving the effective composition of energy conservation and emission reduction.

Owner:唐山科源环保技术装备有限公司

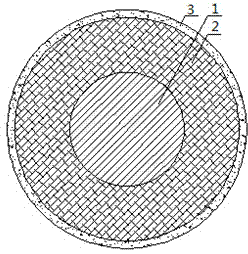

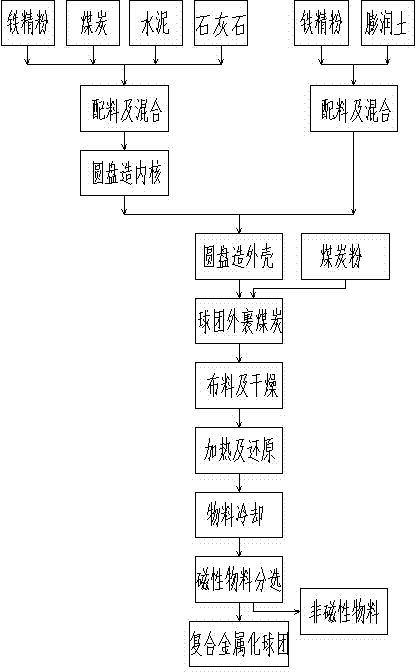

Self-fluxing composite metallized pellet and production process thereof

InactiveCN104745809AIncrease the atmosphere concentration and reduction reaction speedIncrease the speed of the reduction reactionProcess efficiency improvementCoalEnergy consumption

The invention relates to the technical field of metallurgy and mineral engineering, and discloses a self-refluxing composite metallized pellet and a production process thereof. The self-refluxing composite metallized pellet comprises an inner core and an outer shell, wherein the inner core is formed by mixing iron ore concentrate, limestone, coal powder and cement in a proportion of 330:(300-350):(80-120):(6-9); the outer shell is formed by mixing iron core concentrate and bentonite in a mass ratio of 1320:(22-25), the grain size of the inner core is 20-25mm, and the thickness of the outer shell is 5-10mm. The production process for the self-refluxing composite metallized pellet comprises the following steps: preparing the inner core and packaging the outer shell to form a composite metallized pellet; packaging the composite metallized pellet with a reducing layer, distributing and drying the composite metallized pellet, reducing and roasting the composite metallized pellet, cooling and sorting the high-temperature reduced composite metallized pellet. According to the self-refluxing composite metallized pellet and the production process thereof disclosed by the invention, limestone is mixed into the inner core, and CO2 generated by heating and decomposing the limestone in a reducing process of the composite metallized pellet is used as an oxygen producer to participate in gasification reaction of the coal, so that CO concentration inside the pellet is increased, the reducing speed of the pellet is increased, and the energy consumption is reduced.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

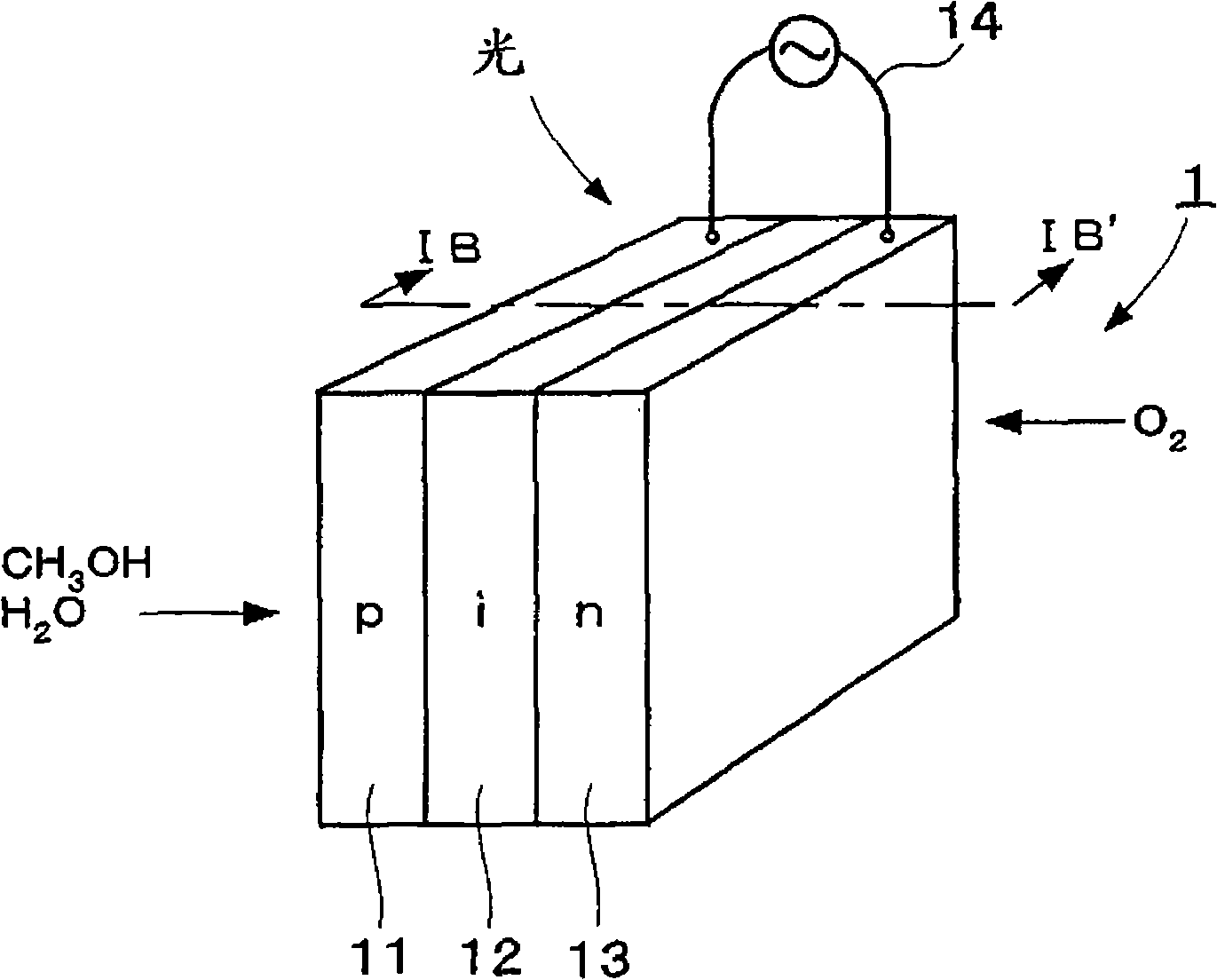

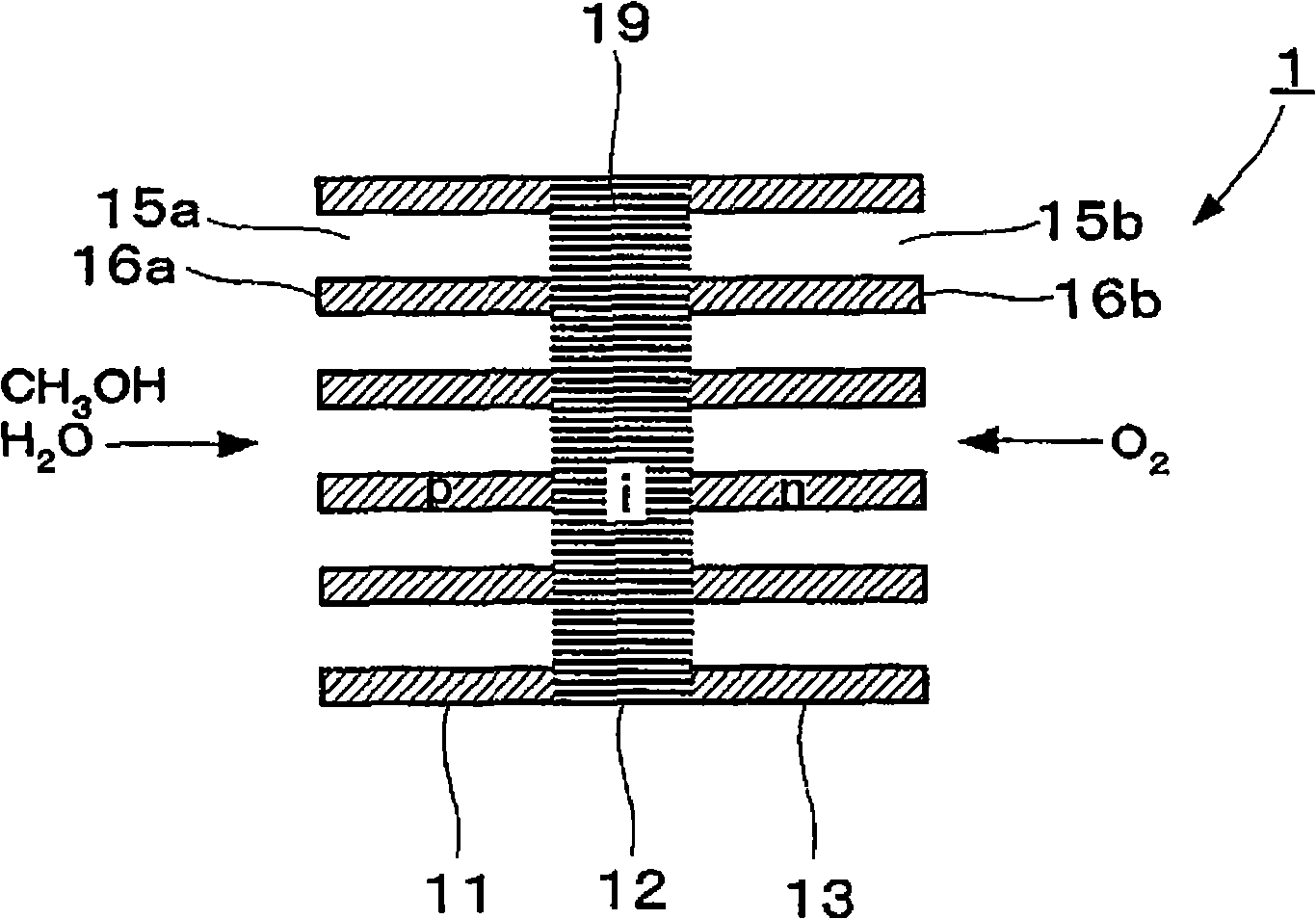

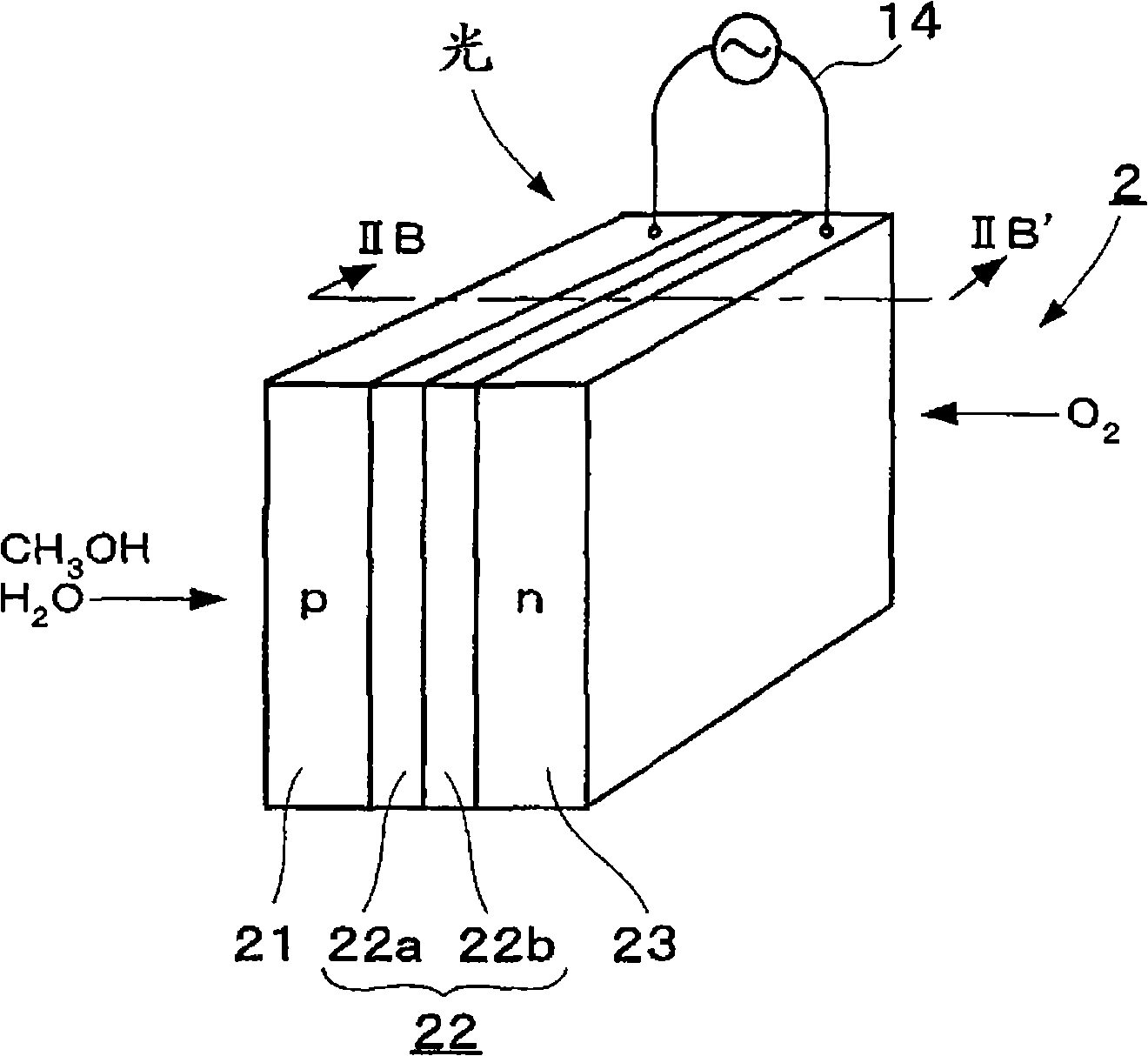

Fuel battery unit cell, fuel battery unit cell array, fuel battery module, and fuel battery system

InactiveCN101278428ACatalytic activationIncrease the speed of oxidation reactionElectrolyte holding meansFuel cells groupingPtru catalystFuel cells

This invention provides a fuel battery unit cell, which can realize a size reduction and a cost reduction, a fuel battery unit cell array, a fuel battery module, and a fuel battery system. The fuel battery unit cell has a pin structure comprising a fuel electrode (11) formed of a p-type semiconductor, an oxygen electrode (13) formed of an n-type semiconductor, and an intermediate layer (12) interposed between the fuel electrode (11) and the oxygen electrode (13) and formed of an authentic semiconductor. The fuel electrode (11) and the oxygen electrode (13) are porous and permeable to a fluid. A metal-base catalyst layer is provided on the inner surface of pores in the porous part. The intermediate layer (12) is porous and permeable to a hydrogen ion produced in the fuel electrode (11) and is impermeable to electrons. A hydrogen-containing fuel is supplied on the surface of the fuel electrode (11), and an oxygen-containing oxidizing fluid is supplied on the surface of the oxygen electrode (13). Connecting terminals electrically connected respectively to the fuel electrode (11) and the oxygen electrode (13) are provided.

Owner:MICRO SILITRON INC

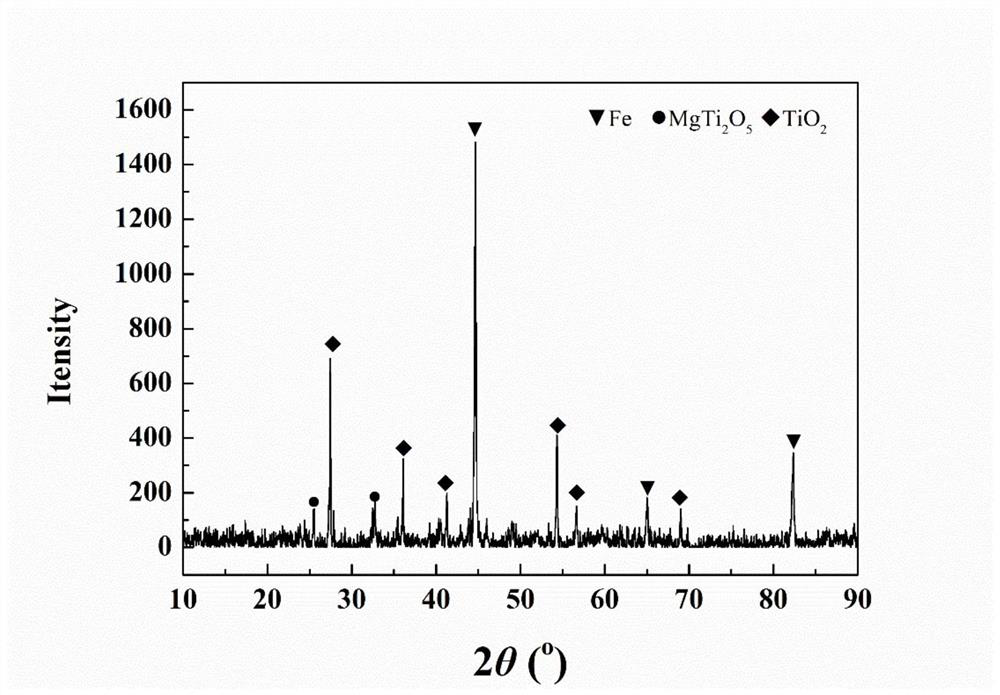

Metallurgical reduction production method for titanium containing slag

InactiveCN106755658ARealize quenching and temperingIncrease the specific surface area for chemical reactionsCement productionRecycling and recovery technologiesAlkalinityMolten state

The invention provides a metallurgical melting reduction production method for titanium containing slag and belongs to the field of non-blast furnace ironmaking and resource comprehensive utilization. The metallurgical melting reduction production method comprises the steps that (1) vanadium containing slag or vanadium-titanium containing steel slag is added into a melting reaction device, reducing agents are sprayed into the melting reaction device while iron containing materials and / or vanadium-titanium containing materials are sprayed into the melting reaction device with oxidizing gas, reaction mixed slag is obtained, heated to be in a molten state and monitored in real time, and the situations that the reaction slag temperature is within the set range, and the reaction slag alkalinity CaO / SiO2 ratio is 0.6-2.0 are ensured at the same time through adjustment and control, so that the reaction slag is fully mixed, and reduced and oxidized slag is obtained; and (2) separating and recycling are conducted. According to the metallurgical melting reduction production method for the titanium containing slag, the recycling rate of metallic iron is 92%-96%; heat compensation is not needed or a small quantity of heat compensation is needed; the operability is high; the production cost is low; no solid waste is produced in the whole process; the reaction conditions are mild; energy saving and emission reduction are achieved; and the metallurgical melting reduction production method is an environment-friendly metallurgical process.

Owner:NORTHEASTERN UNIV

Technique for alloying steel making directly from tungsten ore

InactiveCN101050506AIncrease the speed of the reduction reactionReduce contact areaProcess efficiency improvementSteelmakingReduction rate

This invention discloses a process for direct alloying steelmaking from tungsten ore. The tungsten ore pellet is composed of: tungsten ore 80-85.5%, reducer 13-16.5%, catalyst 1-2%, and binder 0.5-1.5%. The process comprises: pulverizing tungsten ore, reducer and catalyst, grinding into 200 mesh powder, mixing uniformly, adding binder, and pressing into tungsten ore pellet, loading into an electric oven, melting, and performing solid-state reduction until the reduction rate is higher than 90%. The tungsten recovery rate is higher than 95%. The process solves the problems of low reduction speed and rate, low tungsten recovery rate, and large slag amount faced by direct alloying of tungsten ore in an electric oven. The process is a single-step process, and has lowered investment and energy consumption.

Owner:CENT IRON & STEEL RES INST

Method for metallurgic smelting reduction recovery of titanium-contained mixed slag

InactiveCN106755657AIncrease the speed of the reduction reactionAchieve settlementRecycling and recovery technologiesProcess efficiency improvementMolten stateSlag

The invention discloses a method for metallurgic smelting reduction recovery of titanium-contained mixed slag, and belongs to the field of non-blast furnace iron refining and resource comprehensive utilization. The method comprises the following steps: 1) molten-state vanadium-contained slag and molten-state steel slag are added in an insulation device or a smelting reaction device capable of flowing out slag liquid, and are mixed to form reaction mixed slag; the reaction mixed slag is monitored in real time; the following conditions are synchronously guaranteed through control: (a) the temperature of the reaction mixed slag is in a set range; (b) the reaction mixed slag realizes full stirring; and (c) in the reaction mixed slag, the mass concentration of FeO is not more than 1.0%; in the reaction mixed slag, when the mass concentration of FeO is not more than 1.0%, the operation in the step 1 is stopped, and the slag after reduction oxidation is obtained; and 2) the separation and the recovery are performed. The recovery rate of metal ion in the method is 92-96%; the whole process needs no or low heat compensation; the operability is high; the production cost is low; no solid waste is generated in the whole process; the reaction conditions are mild; the energy conservation and the emission reduction are realized; and the method is a green metallurgy process.

Owner:NORTHEASTERN UNIV LIAONING

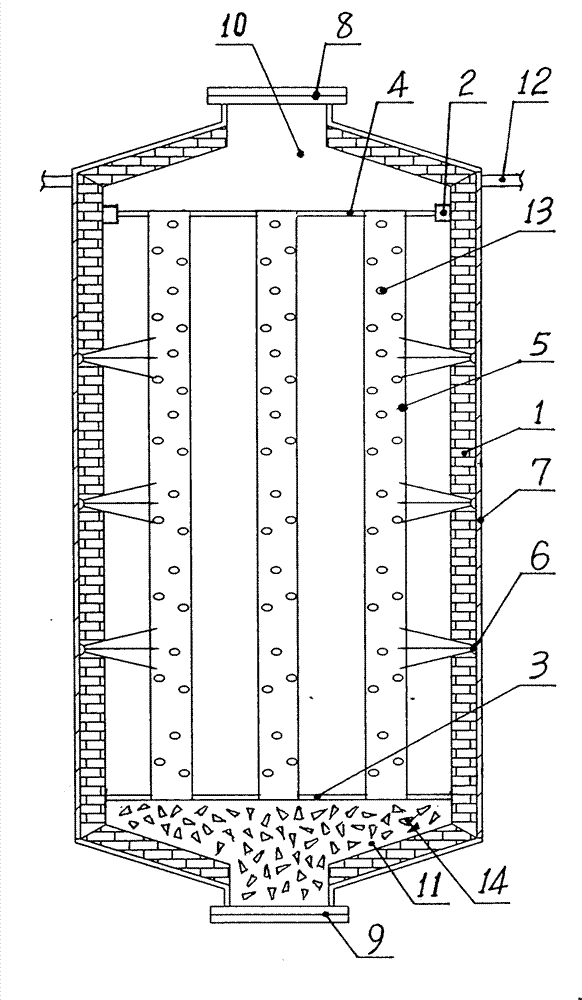

Magnesium smelting technique by microwave heating

The invention discloses a magnesium smelting technique by microwave heating and relates to the field of magnesium smelting techniques. The upper end of the round wall of a furnace body is connected with an expander by bricklaying through a refractory material, and the lower end of the round wall of the furnace body is fixed with a tray; the expander is movably connected with a support in a sliding manner; the lower end of a microporous ceramic tube is fixed with the tray while the upper end of the microporous ceramic tube is fixed with the support; the furnace body is fixed with a microwave generator and a shell; the shell is fixed with an upper flange and a lower flange; a gaseous magnesium collecting chamber is formed by the wall of the furnace body above the support, an upper convergent section of the shell and the inner side of the upper flange; a gaseous magnesium outlet tube is penetrated from the gaseous magnesium collecting chamber and then is fixed with the furnace body and the shell; a slag chamber is formed by the wall of the furnace body below the tray, a lower convergent section of the shell and the inner side of the lower flange; a magnesium ball is put in the microporous ceramic tube; slag is put in the slag chamber; the power of the microwave generator is 1-500KW, the frequency of the microwave generator is 300-3000MHz, the temperature of the microwave generator is 1200-1350 DEG C, and the smelting time is 15-60 minutes; the magnesium ball is acquired by roasting dolomite to acquire magnesium oxide and calcium oxide and then mixing silicon iron and fluorite with magnesium oxide and calcium oxide. The magnesium smelting technique by microwave heating is used for smelting magnesium, which is a microwave new energy heating technology.

Owner:于洪喜

Method for metallurgic smelting reduction recovery of rare earth-contained mixed slag

InactiveCN106755659AIncrease throughputReduce consumptionCement productionRecycling and recovery technologiesMolten stateNiobium

The invention relates to a method for metallurgic smelting reduction recovery of rare earth-contained mixed slag, and belongs to the field of non-blast furnace iron refining and resource comprehensive utilization. The method comprises the following steps: molten-state rare earth-contained blast furnace slag and molten-state steel slag are mixed to form reaction mixed slag; the temperature of the reaction mixed slag is controlled in a set temperature range; the full mixing is realized; the mass concentration of FeO is not more than 1.0%; and the reaction mixed slag is separated and recovered according to differences of reaction devices. The rare earth and calcium components, the niobium component, the phosphorus component and the like in the mixed slag are efficiently recovered; cold-state materials containing niobium, rare earth and iron can be treated to achieve high-efficiency resource comprehensive utilization; the method is short in reaction time, high in metal recovery rate, low in production cost, high in raw material adaptability, high in treatment quantity, environment-friendly and high in economic benefit, and can effectively solve the high-efficiency recycling problems of metallurgic resources and heat energy.

Owner:NORTHEASTERN UNIV

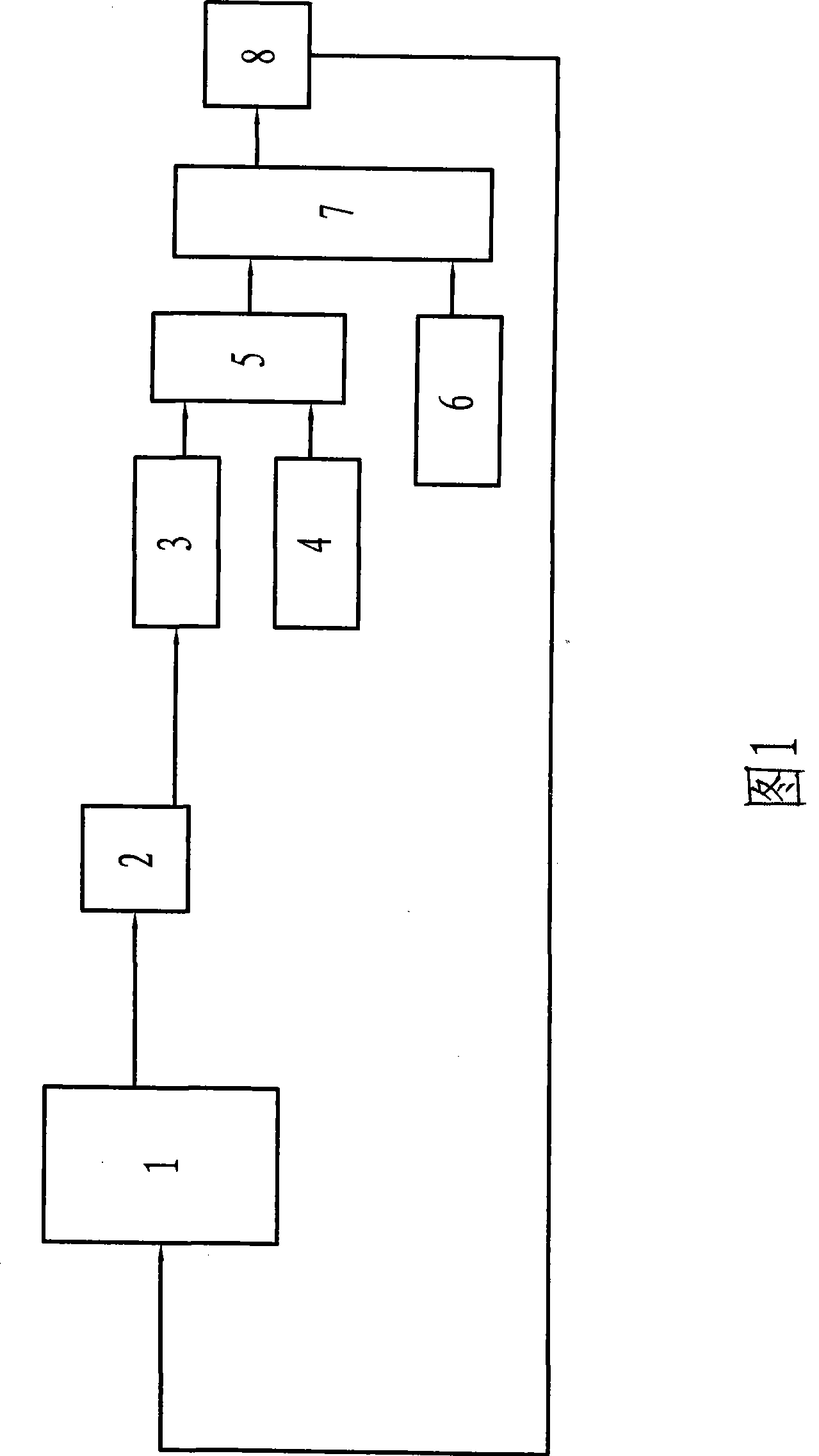

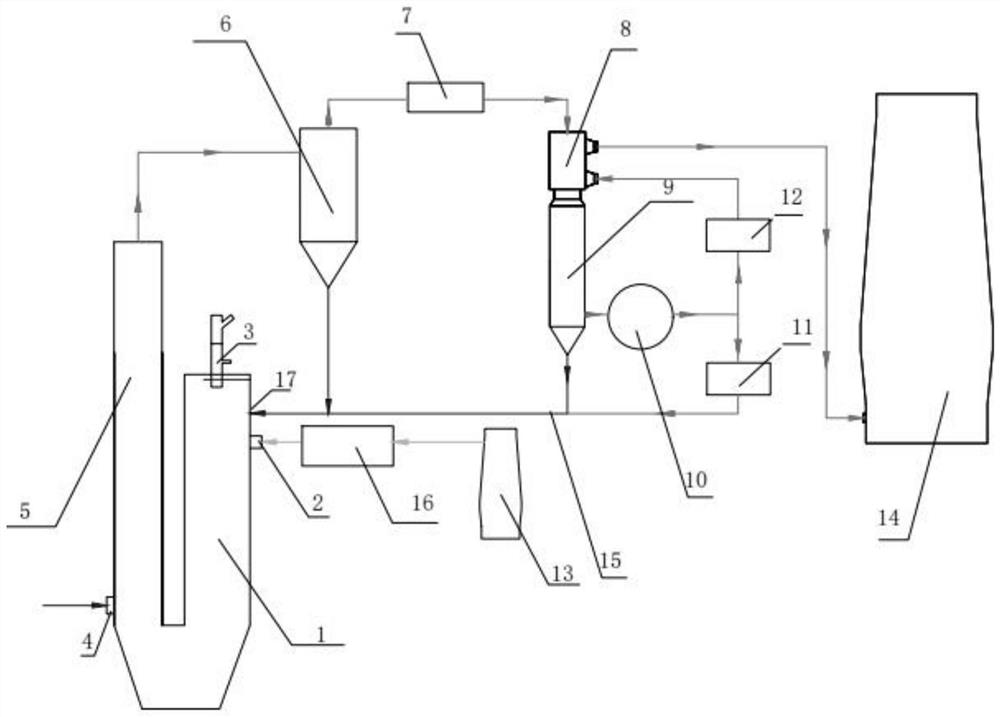

System for preparing hydrogen-rich coal gas and applying hydrogen-rich coal gas to blast furnace injection and working process

PendingCN113005250AReduce lossesHigh calorific valueBlast furnace componentsEnergy inputDust abatementChemistry

The invention discloses a system for preparing hydrogen-rich coal gas and applying the hydrogen-rich coal gas to blast furnace injection and a working process. The system comprises a two-stage furnace, a gasifying agent injection system, a high-temperature material pneumatic conveying system, a coal gas injection system, a gas-solid separation device, a coal gas heat exchanger, a waste heat boiler, a dust removal device and a two-stage coal gas pressurizing machine. According to the system, hydrogen-rich coal gas preparation, coal gas injection system and blast furnace ironmaking coupling linkage operation are achieved, and the working processes of hot charging and hot conveying of high-temperature coke breeze and conveying of high-temperature coal gas into a furnace are realized; according to the preparation process, the high-calorific-value hydrogen-rich coal gas can be obtained, the coal type adaptability is good, the carbon conversion rate is high, and the coal energy utilization rate is effectively increased; in addition, the hydrogen-rich coal gas is safely injected into the blast furnace for reduction smelting, the proportion of H2 in the blast furnace reducing atmosphere is increased, the reduction reaction speed in the furnace can be increased, the direct reduction reaction of carbon is reduced, the coke consumption is reduced, and the smelting cost is reduced; and meanwhile, the carbon dioxide emission of the blast furnace is greatly reduced.

Owner:河北燕钢科技有限公司

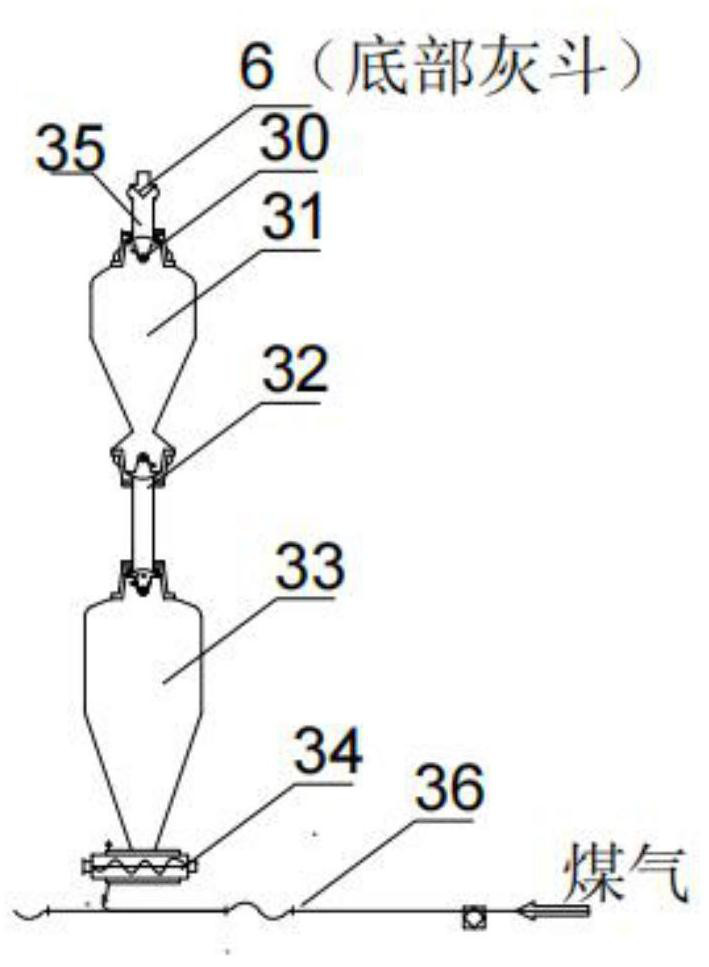

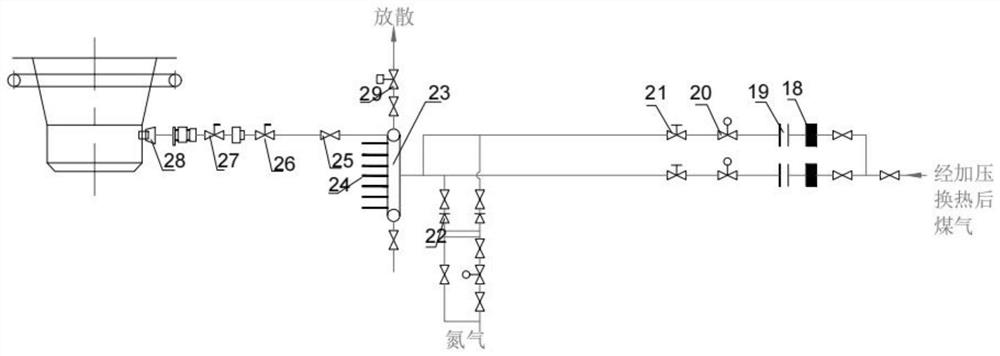

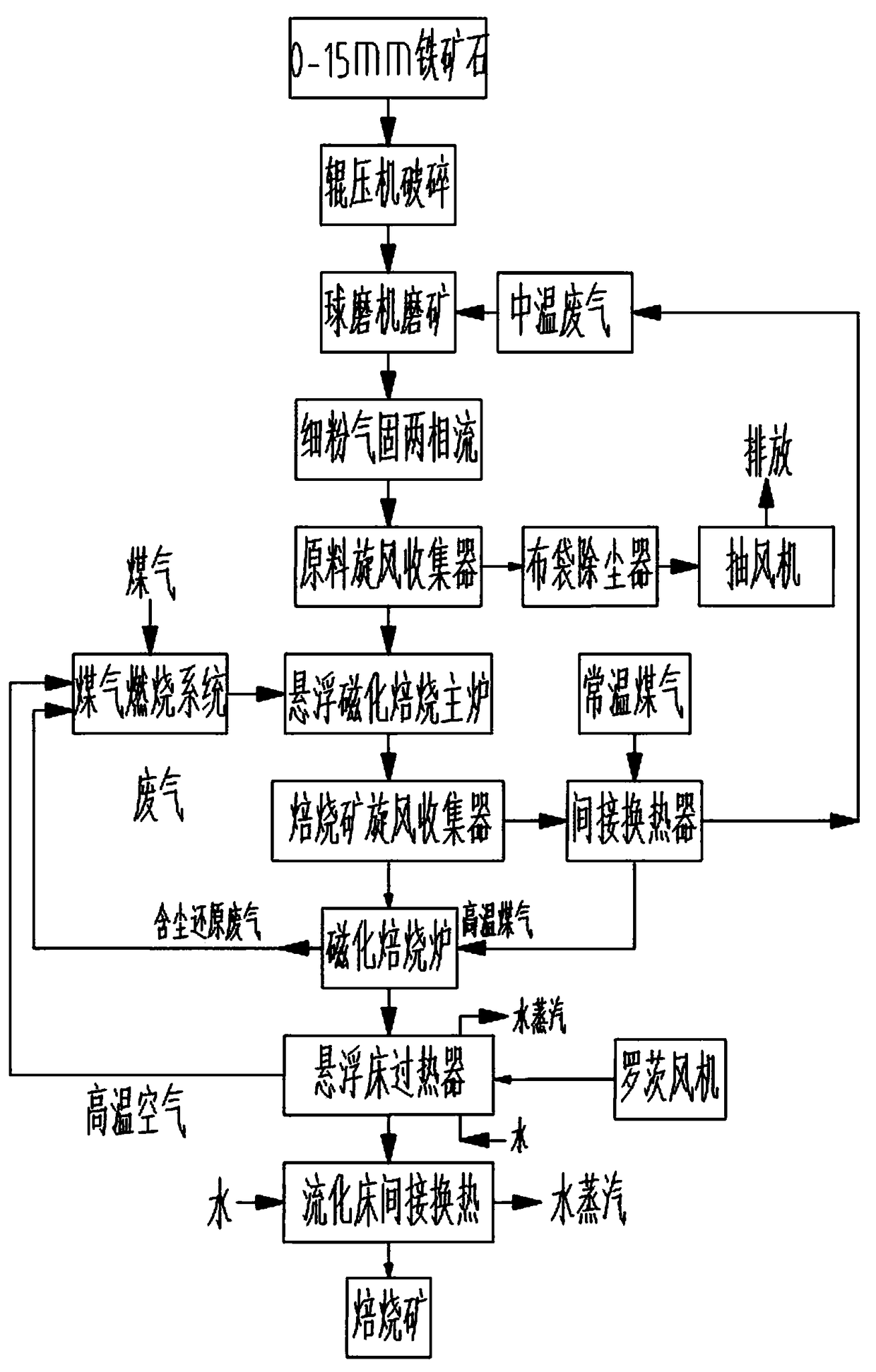

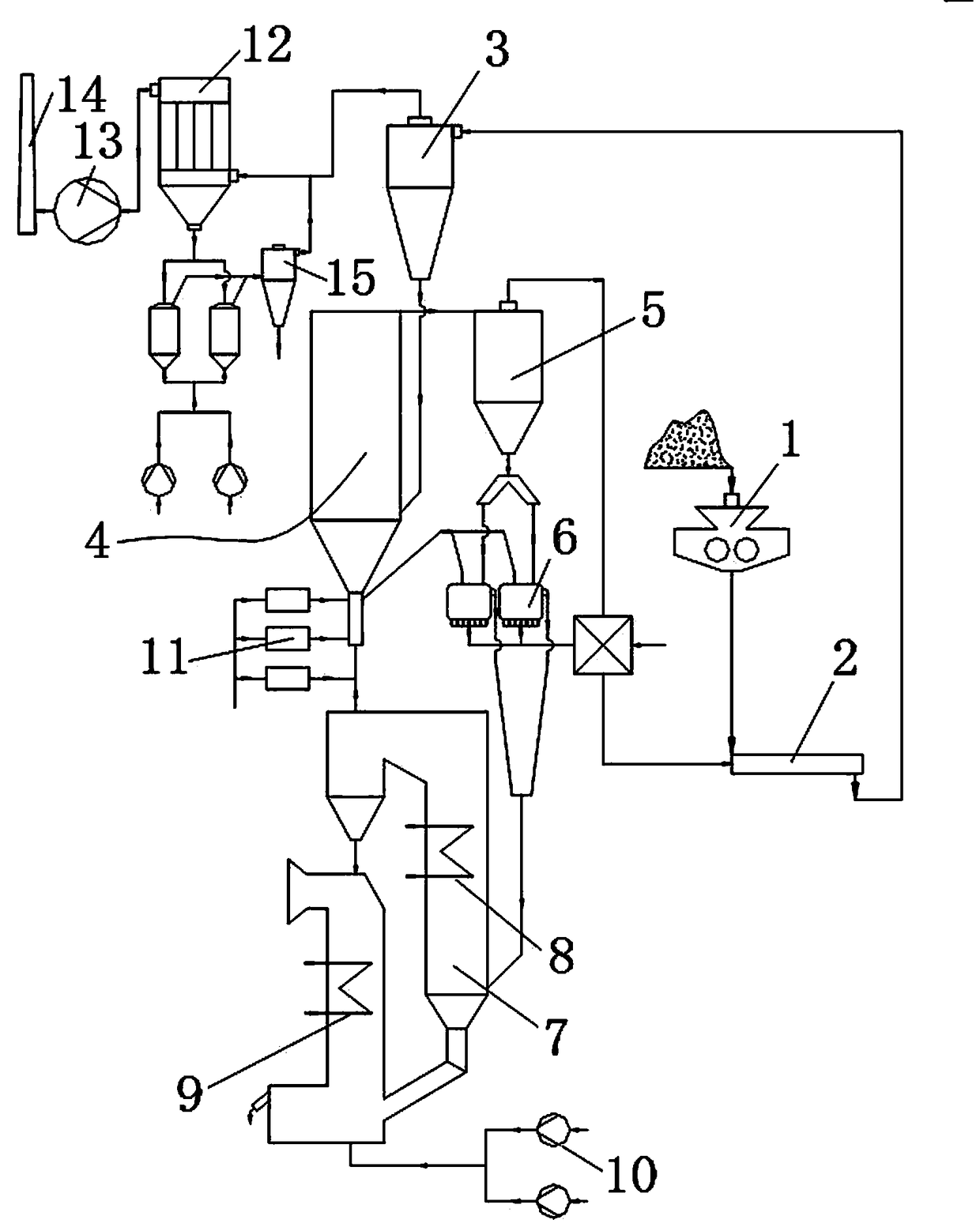

Refractory iron ore dry grinding-suspension roasting integration technology and device

ActiveCN108823400AReduce power consumptionReduce energy consumptionHuman health protectionGrain treatmentsSuperheaterBall mill

The invention provides a refractory iron ore dry grinding-suspension roasting integration technology and device. The refractory iron ore dry grinding-suspension roasting integration technology comprises the following steps of: breaking powder iron ores by a roller press, carrying out ore grinding by a dry-type ball grinder or the roller press, fluidifying to generate fine powder gas-solid two phase flow, then introducing the fine powder gas-solid two phase flow to a raw material cyclone collector for gas-solid separation in a suspension magnetic roasting technology, introducing middle-temperature flue gas discharged by the suspension magnetic roasting technology to a dry-type ore grinding technology for fluidifying, separating to obtain iron ore powder, carrying out oxidizing roasting on iron ore powder in a suspension magnetizing roasting main furnace, preheating coal gas to 450-500 DEG C by using burnt gas discharged by the oxidizing roasting in the suspension magnetizing roasting main furnace, entering a magnetizing roasting furnace so as to carry out iron ore reducing roasting, carrying out indirect heat exchanger cooling on roasted ore produced after reducing coasting to obtain roasting ore with the relatively high magnetism by using a suspended bed supercharger and a fluidized bed. The refractory iron ore dry grinding-suspension roasting integration technology has short technological process, does not consume water, consumes little coal gas, is low in cost, reduces the carbon emission, improves environments and improves economic benefits.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Catalyzer used in pidgeon's magnesium reduction process and the magnesium reduction process adopting the catalyzer

ActiveCN101112688AImprove recovery rateEasily damagedPhysical/chemical process catalystsFerrosiliconMagnesium fluoride

The invention relates to a pidgeon method magnesium deoxidization catalyst and the magnesium deoxidization method by adopting the catalyst. The catalyst consists of the magnesium fluoride, molybdenum oxide and calcium chloride which are matched according to the mol ratio of 1:( 0.01- 0.5) : ( 0.5- 1.5). The magnesium deoxidization method includes the steps that: 1) the preparation of the catalyst: after uniformly mixed according to the mol ratio, the magnesium fluoride, molybdenum oxide and calcium chloride are heated and melted under the temperature ranging from 850 DEG C to 950 DEG C and are poured, cooled and crushed, less than 200 grids; 2) the calcining-white, ferrosilicon and the catalyst are mixed according to the weight ratio of 100:(19- 21):(2- 5), pressed into bulks and arranged in a deoxidization tank for high-temperature vacuum deoxidization. The process conditions of the vacuum deoxidization are the same as the conditions of the pidgeon method. By adopting the invention, the deoxidization time can be shortened by 3 hours through 5 hours, and the deoxidization efficiency of the magnesium can be improved by 2 percent through 8 percent.

Owner:WUTAI YUNHAI MAGNESIUM IND

Method for producing vanadium trioxide

InactiveCN101717117BReduce consumptionIncrease the speed of the reduction reactionVanadium oxidesSolid carbonReaction speed

The invention belongs to the chemical field, in particular to a method for producing vanadium trioxide, aiming at improving the reaction speed of the method for producing vanadium trioxide and providing a solution as follows: A. raw material preparation; B. reduction of the prepared raw material by using reducing gas; and C. obtaining vanadium trioxide after reduction. The improvement of the method in the invention is that the used raw material in step A is composed of binder, carbon powder and vanadium-containing material, wherein the vanadium-containing material is ammonium vanadate or vanadium pentoxide. The invention adopts the technologies of carbon-proportioning and pellet preparation aiming at the raw material to enable the raw material to react in a gas-solid bi-phase reducing agent formed by solid carbon powder and reducing gas, thus improving the reduction reaction speed, enhancing recovery rate of the vanadium, and reducing consumption of the reducing gas. The produced pellet has the advantages of improving reaction speed, avoiding and reducing volatilization of vanadium-containing powder material, protecting environment and being beneficial for labor protection.

Owner:SICHUAN CHUANWEI GRP CO LTD +1

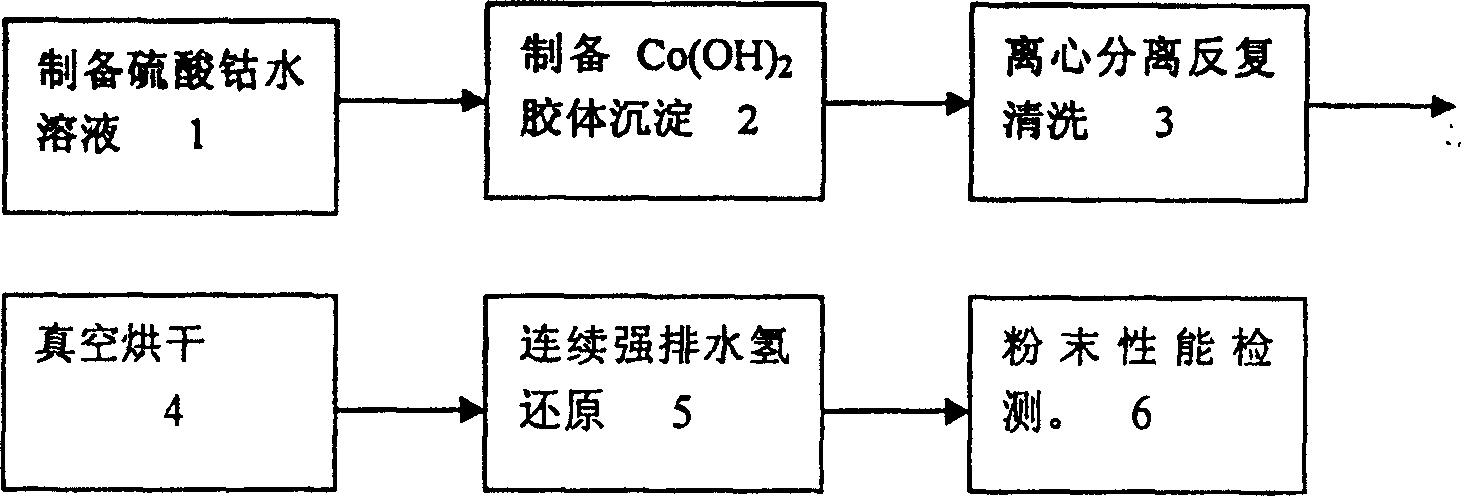

Precipitation reduction method of preparing nano-cobalt powder

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing sponge iron from sulfate cinder

The invention relates to the field of metallurgy of non-ferrous metals, and concretely provides a method for preparing sponge iron from sulfate cinder. The method uses sulfate cinder as a raw material, soft coal as a reducing agent and CaCO3 as a desulfurizer, and adopts a concentric tube filling mode for charging or a pellet mixing mode for charging, wherein the charging mass ratio of the sulfate cinder to the soft coal to the CaCO3 is 100:(34-35):(6-7). The method comprises the following steps of: roasting at 1100 DEG C to 1200 DEG C for 3.5 hours to 4.0 hours, quenching under a shielding gas atmosphere to obtain roasted ore, and obtaining sponge iron by performing magnetic separation on the roasted ore, wherein in the sponge iron, the total iron content is greater than or equal to 93.41%, the degree of metallization is greater than or equal to 96.38%, the content of impurity except S is less than or equal to 0.016%, and the content of SiO2 plus Al2O3 is less than or equal to 5.32%, which all reach the national standards. According to the invention, the sponge iron is directly produced from sulfate cinder without the processes of sintering and iron making, thus saving energy and having a wide range of sources of raw materials.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Cu/ZrO2 catalyst as well as preparation method and use of Cu/ZrO2 thereof

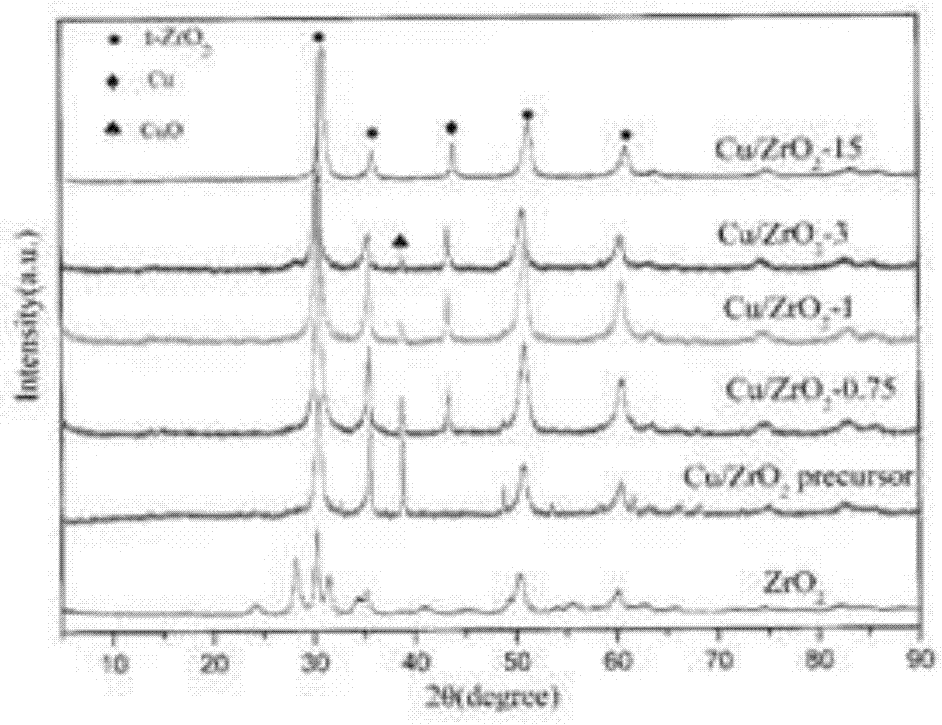

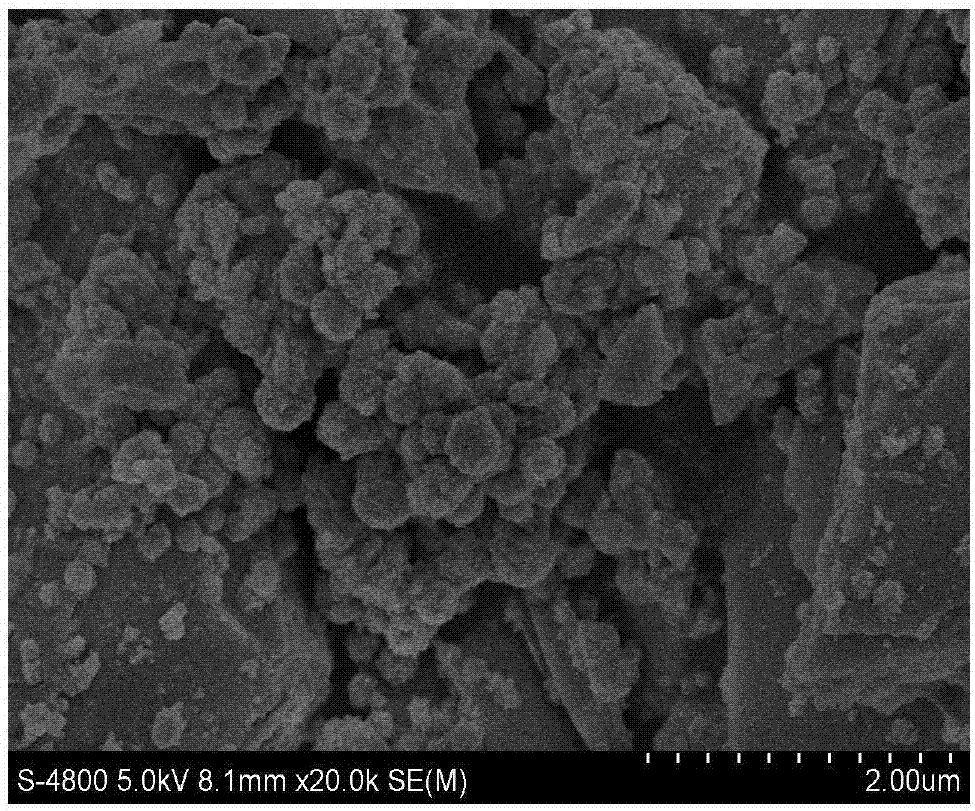

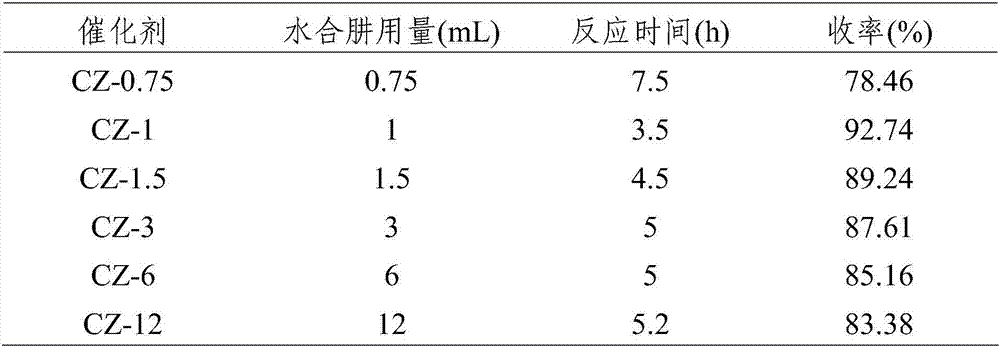

InactiveCN107442120AShort recovery timeThe degree of reduction is easy to controlOrganic compound preparationCatalyst activation/preparationIminodiacetic acidEnergy consumption

The invention provides a Cu / ZrO2 catalyst as well as a preparation method and use of the Cu / ZrO2 thereof. According to the preparation method, a Cu / ZrO2 precursor is reduced in alkaline and medium temperature environments by virtue of hydrazine hydrate, the alkaline environment is beneficial to the reducibility of hydrazine hydrate, and the medium temperature environment is beneficial to the acceleration of reduction reaction. By controlling the use amount and reduction time of hydrazine hydrate, the reduction degree of the catalyst is controlled; and by adding ice water, the reduction reaction can be rapidly terminated. According to the preparation method, the Cu / ZrO2 catalyst is prepared in the alkaline and medium temperature environments by virtue of hydrazine hydrate, Cu in the catalyst has three valence states including Cu<0>, Cu<+> and Cu<2+> in a molar ratio of 1 to (0.20-0.35) to (0.01-0.06), and the performance of the catalyst is excellent. The preparation method has the beneficial effects that the time is short, the energy consumption is low, and the reduction degree of the catalyst can be effectively controlled; and the yield of iminodiacetic acid salt prepared from diethanol amine through the catalysis Cu / ZrO2 exceeds 98%, the shortest reaction time is 2.3h, and the Cu / ZrO2 catalyst has good industrial application prospects.

Owner:XIANGTAN UNIV

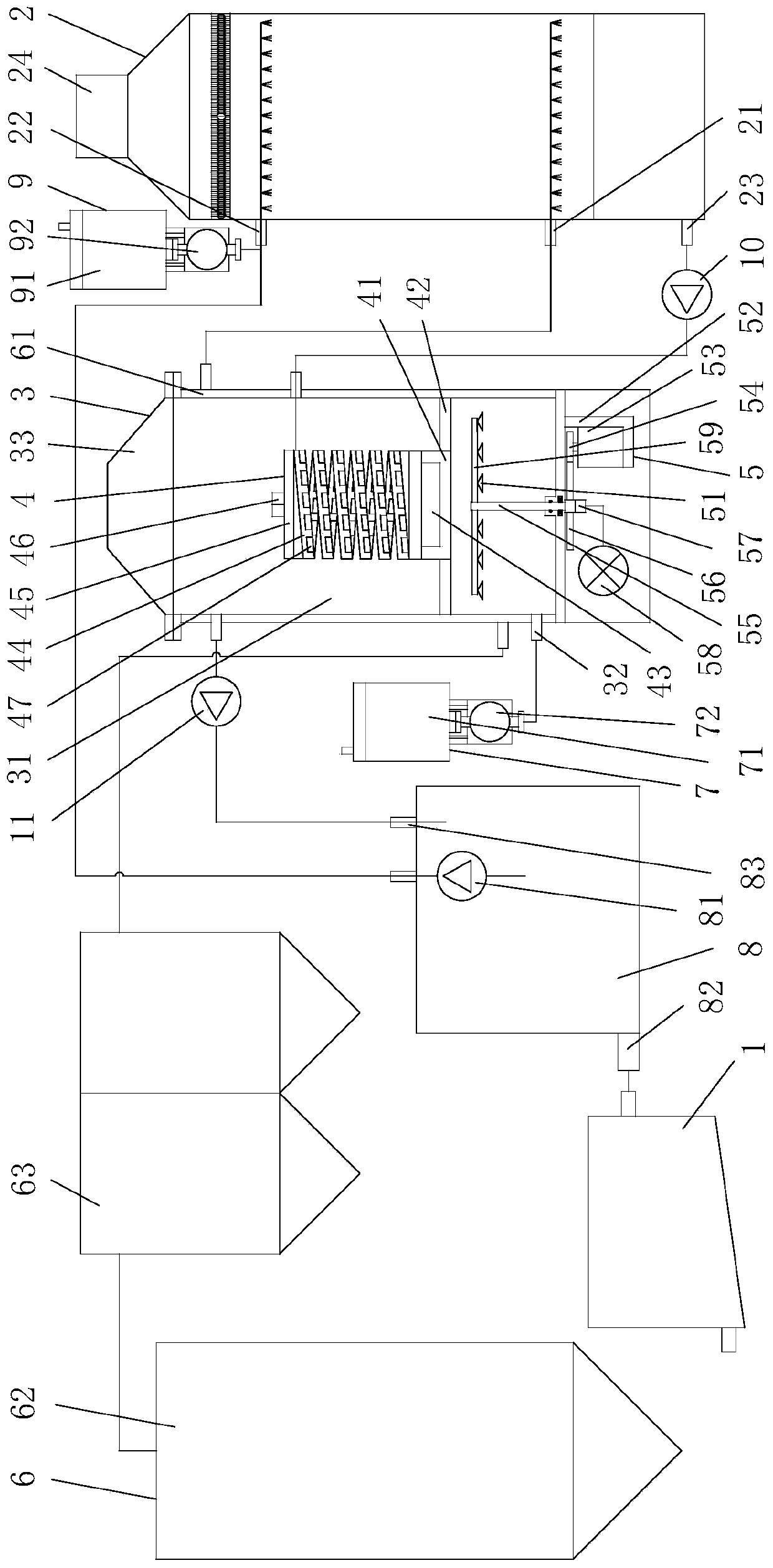

Desulfurization waste liquid treatment and reuse system and method

The invention relates to a desulfurization waste liquid treatment and reuse system. The desulfurization waste liquid treatment and reuse system includes a desulfurizing tower, a filter pressing device, a reduction tower, a desulfurization waste liquid distributing device, an aeration device, a heating device, a flocculant charging device, a sedimentation basin, a desulfurization waste liquid waterpump and a reduction liquid water pump, wherein the desulfurizing tower is provided with a flue gas inlet, a desulfurizing agent inlet, a desulfurization waste liquid outlet and an exhaust port, a tower body of the reduction tower is provided with a flocculant inlet, the desulfurization waste liquid distributing device is arranged in the tower body, the aeration device is provided with an aeration nozzle group located on the lower side of the desulfurization waste liquid distributing device, the sedimentation basin is provided with a reduction liquid cleaning water pump, an inlet of the desulfurization waste liquid water pump communicates with the desulfurization waste liquid outlet, and an inlet of the reduction liquid water pump communicates with an inner cavity of the reduction tower;and a waste residue outlet of the sedimentation basin communicates with the filter pressing device, an outlet of the desulfurization waste liquid water pump communicates with the desulfurization wasteliquid distributing device, an outlet of the reduction liquid water pump communicates with a reduction liquid inlet of the sedimentation basin, and an outlet of the reduction liquid cleaning water pump communicates with the desulfurizing agent inlet. According to the desulfurization waste liquid treatment and reuse system, treatment and reuse of desulfurization waste liquid are convenient, the amount of a desulfurizing agent is small, and the desulfurization effect is good.

Owner:台州临港热电有限公司

Method for producing powdered rock phosphate pellets by using low-grade powdered rock phosphate

ActiveCN112591723AReduce utilizationTake advantage ofRaw phosphate material treatmentSocial benefitsO-Phosphoric Acid

The invention discloses a method for producing powdered rock phosphate pellets from low-grade powdered rock phosphate, and the method comprises the following steps: screening, proportioning, mixing, briquetting, drying and cooling; the proportioning procedure comprises the following steps: adding 1-10 parts by mass of phosphoric acid, 0.5-2 parts by mass of silicon phosphate, 5-10 parts by mass ofcarbonaceous reducing agent, 5-10 parts by mass of silica powder and 1-5 parts by mass of rice hull ash into every 100 parts by mass of powdered rock phosphate. The method is simple in process, easily available in raw materials, high in pellet strength and thermal stability and high in utilization rate of low-grade ground phosphate rock, has better economic and social benefits, and is easy to popularize and use.

Owner:云南省宣威东升化工有限公司

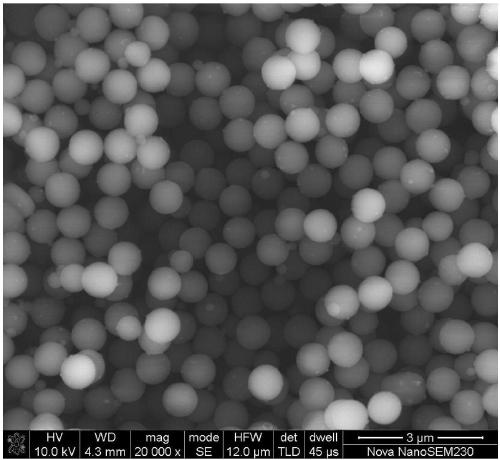

Process for preparing nano silicon carbide by sol-gel method

The invention provides a process for preparing nano silicon carbide by a sol-gel method, and relates to the technical field of preparation of the silicon carbide. The method comprises the following steps of S1, preparing silica by the sol-gel method; S2, homogeneously mixing the silica prepared in step S1 with a homogenizing agent, a carbon source and a combustion-supporting reducing agent; S3, conducting high-temperature reduction; S4, conducting dispersed grading. The process prepares the silica by the sol-gel method, and the prepared silica is well dispersed; the monodisperse silica, the homogenizing agent, the carbon source and the combustion-supporting reducing agent are homogeneously mixed, the high-temperature reduction is conducted, the prepared silica has good dispersibility and the problems of agglomeration and the like in the preparation process of the nano silicon carbide are solved. A reaction energy is activated by the combustion-supporting reducing agent, a reaction energy barrier is lowered, thereby lowering the reduction temperature of the silica, and convenience is provided for the prevention of the growth of high-temperature silicon carbide particles. Since the carbon source is uniformly mixed with the monodisperse silica, the reaction process is reduced, thereby contributing to an increase in a reduction reaction rate.

Owner:LANXI ZHIDE ADVANCED MATERIALS CO LTD

Method of microwave selective reduction roasting-dilute acid leaching nickel oxide ore

InactiveCN101323909BReduce consumptionHigh chemical activityProcess efficiency improvementLateriteCobalt

The invention relates to a microwave selective reduction roasting-dilute acid method for lixiviating nickel oxide ore. The nickel oxide ore, such as limonite type lateritic ore containing nickel, is mixed with a reducing agent containing carbon, such as nano carbon powder, active carbon, xylanthrax, soft coal and / or anthracitic coal, and then heated under the microwave irradiation of 2450MHz or 916MHz. As material containing carbon has excellent microwave absorption capability, microwave is used for rapidly heating the material so as to realize rapid warming of reactants, quicken the reduction of valuable elements in the ore, such as nickel and cobalt and control the reduction degree of iron so as to realize the selective reduction roasting of the ore. Selective lixiviating of nickel and cobalt is carried out on reduzate after roasting in the dilute acid solution so as to realize the effective extraction of nickel and cobalt. The method of the invention has short roasting time, low consumption of reducing agent and low energy consumption. The consumption of reagents is low during lixiviating and lixiviated residue is suitable for being used for iron making as raw material so that no damage to environment occurs.

Owner:NORTHEASTERN UNIV LIAONING

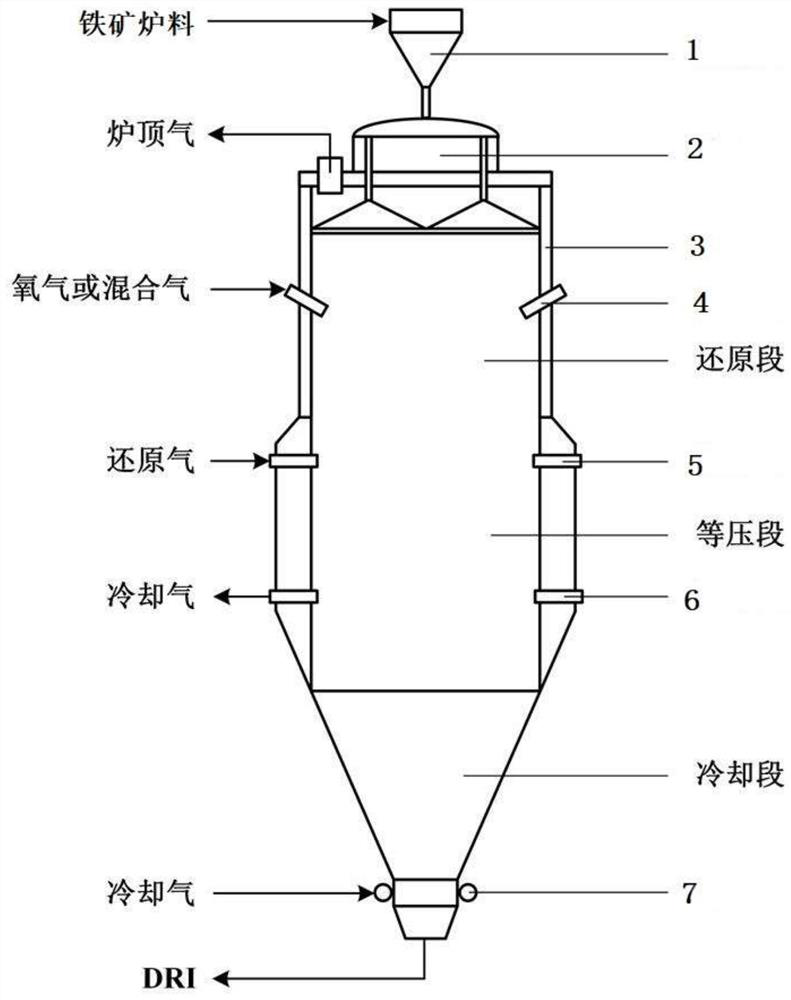

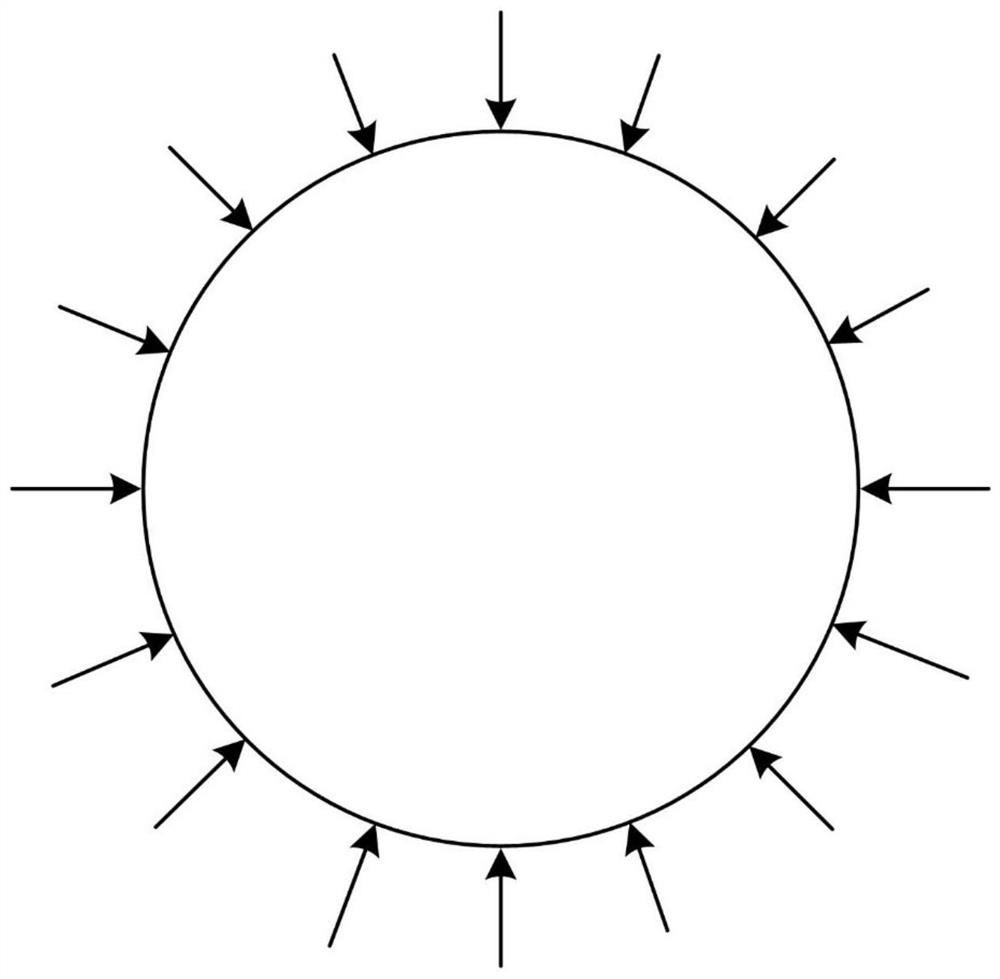

Method for preparing direct reduced iron by feeding hydrogen into reduction shaft furnace

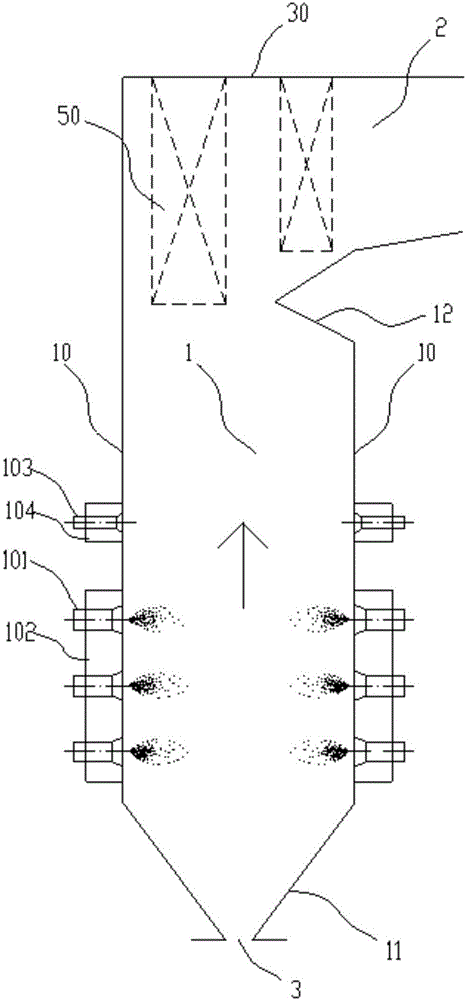

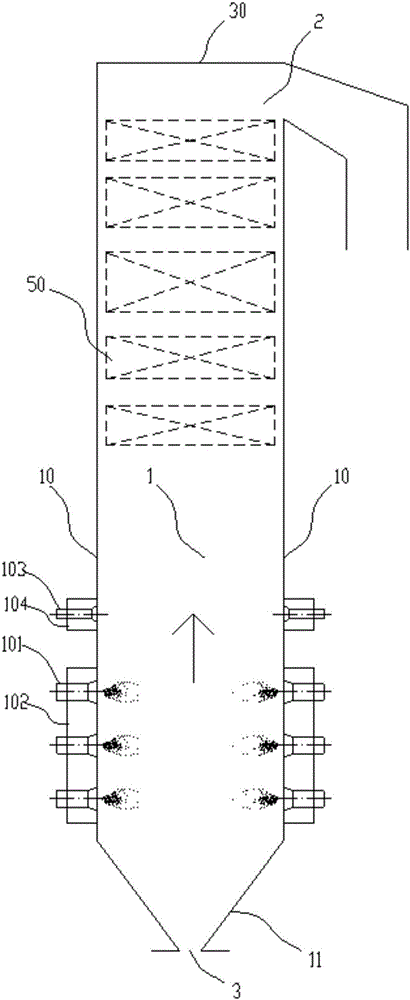

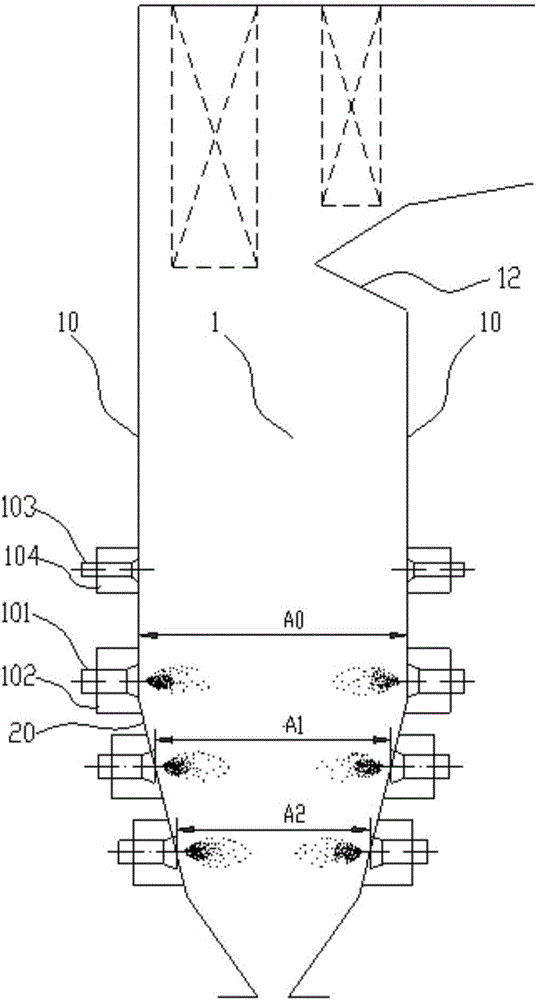

ActiveCN113930568AFast supplemental heatingIncrease the speed of the reduction reactionShaft furnaceGas emission reductionCombustionProcess engineering

The invention provides a method for preparing direct reduced iron by feeding hydrogen into a reduction shaft furnace. Combustion injection blowing devices are uniformly arranged around a furnace body of a reduction section of the shaft furnace. The method comprises the following steps that S1, a furnace charge containing iron is fed into the shaft furnace, and meanwhile, hot reducing gas is continuously fed into the reduction section of the shaft furnace to reduce the furnace charge containing iron, wherein hydrogen in the hot reducing gas accounts for 80% or above of the reducing gas; and S2, in the reduction process of the furnace charge containing iron, according to the temperature of the furnace charge containing iron in the reduction section of the shaft furnace, the combustion injection blowing devices inject oxygen into the reduction section of the shaft furnace. The problem that in a high-purity hydrogen shaft furnace direct reduction technology, due to the fact that the furnace charge temperature can be rapidly reduced through hydrogen reduction heat absorption, the production efficiency is reduced is solved.

Owner:NORTHEASTERN UNIV

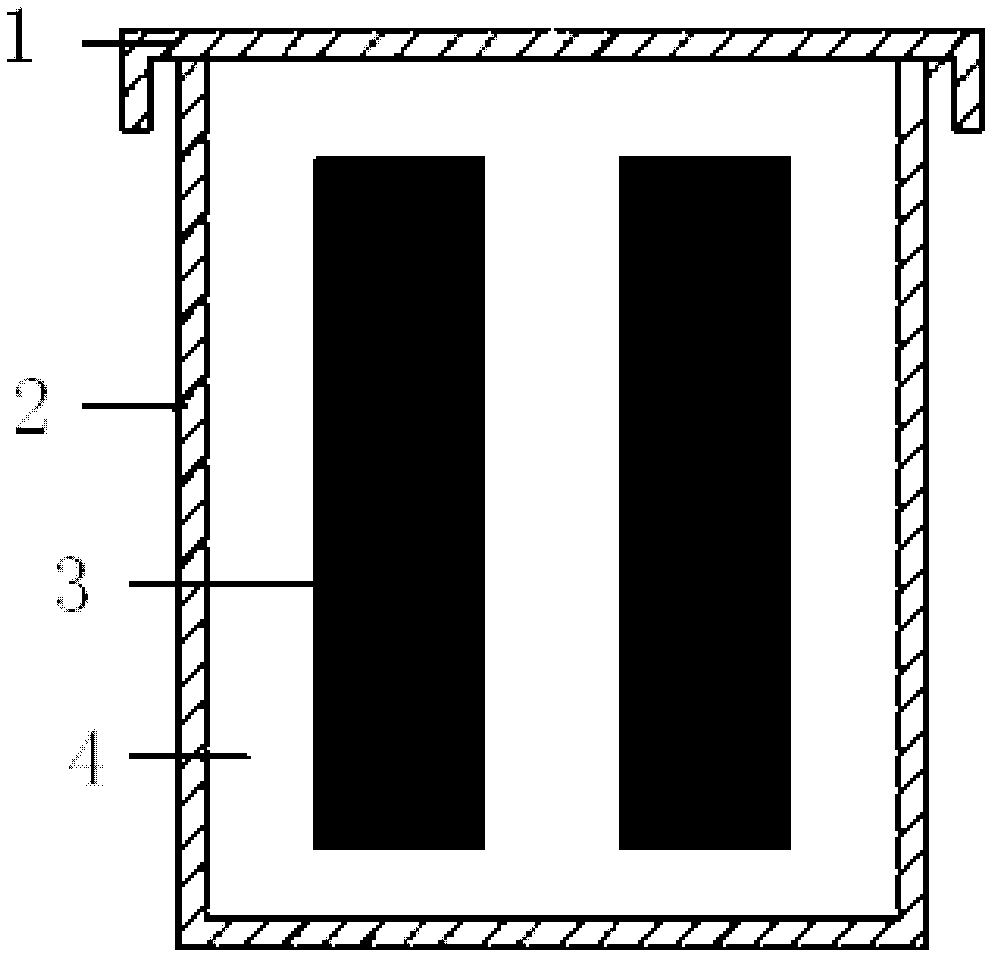

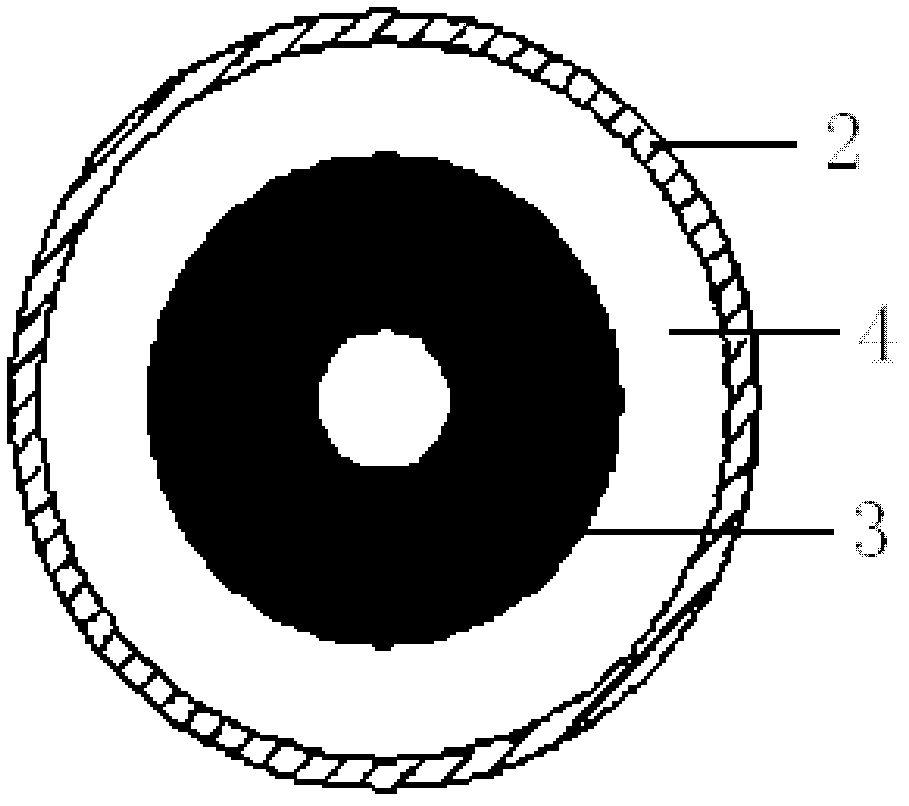

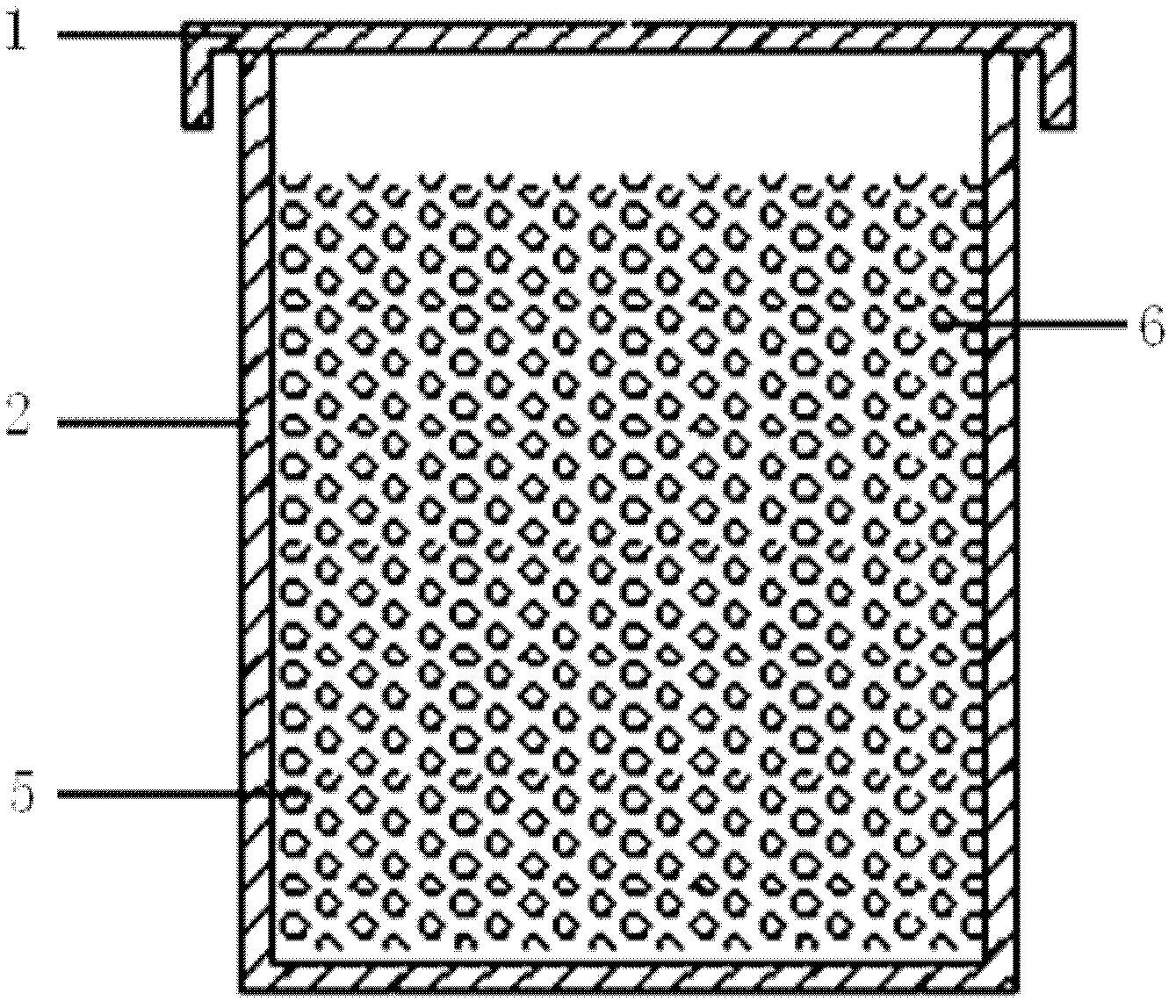

Ventilated forced drainage type nano tungsten powder reducing furnace for industrial use

InactiveCN100357050CEasy dischargeIncrease partial pressureMaintainance of heating chambersFurnace typesPositive pressureWater cooling

Owner:UNIV OF SCI & TECH BEIJING

Pulverized coal fired boiler hearth provided with variable-section combustor area and adapting to flexible peak shaving

ActiveCN106765061AReduce depthLower the elevationIndirect carbon-dioxide mitigationCombustion chambersCombustorFlue gas

The invention discloses a pulverized coal fired boiler hearth provided with a variable-section combustor area and adapting to flexible peak shaving and belongs to the field of boilers. The heath section area of different combustor layers is not completely the same, the hearth section in the combustor area is gradually enlarged in the flue gas flowing direction, and the specific value of the section area of a section-variable segment of the hearth and the section area of the part, corresponding to a downstream combustor of the hearth, of the hearth ranges from 0.75 to 0.95. The pulverized coal fired boiler solves the above problem existing in a conventional pulverized coal fired boiler hearth type, especially, the single-mill stable combustion capability is achieved, single-mill stable combustion can be achieved on the boiler, and the 20% BMCR oil-feeding-free stable combustion capability is achieved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Preparation method of dihydroartemisinin

The invention relates to the technical field of organic medicine synthesis, particularly to a preparation method of dihydroartemisinin. According to the invention, sodium borohydride is used as a strong reducing agent to quickly and effectively reduce artemisinin, and a suspension chemical reaction system is established by increasing the stirring speed in a mixing process, so that the heat of thereduction reaction can be quickly dissipated, the reduction reaction speed is increased, the generation of byproducts is effectively inhibited, and the yield and the purity of the product are improved; the preparation method provided by the invention is simple and convenient, saves a large amount of solvents, electricity and heat, shortens the production period and reduces the production cost; andaccording to the embodiments, by adopting the preparation method provided by the invention, the yield of dihydroartemisinin can be up to 110%, and is significantly increased compared with the traditional preparation process, and the preparation method is suitable for large-scale production.

Owner:恩施硒禾生物科技有限公司

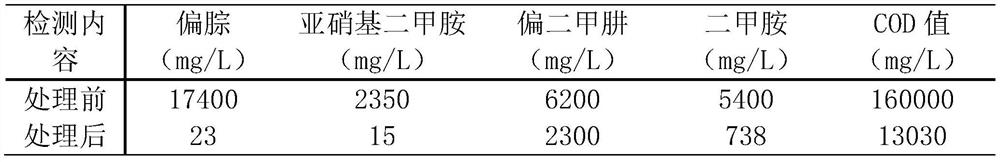

Catalyst, device and method for catalytic reduction treatment of aerospace propellant production sewage

PendingCN114602468AImprove reducibilityIncrease reaction rateCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsChemical platingPtru catalyst

The invention discloses a catalyst, device and method for catalytic reduction treatment of aerospace propellant production sewage, the catalyst comprises an iron base material with an oxidation film removed from the surface and metal copper particles deposited on the surface of the iron base material based on chemical plating, and the iron base material and the metal copper particles on the surface of the iron base material are subjected to surface modification and are partially in an oxidation state. The device comprises a filter bed reactor, a catalyst filled in the filter bed reactor, a water pump for lifting sewage to the filter bed reactor, and a circulating water pump for circularly lifting the sewage in the filter bed reactor. According to the method, the aerospace propellant production sewage is subjected to reduction treatment by using the device. The iron-copper composite catalytic reduction system is formed through chemical plating and oxidation modification, the contact area is large, the adhesive force is high, the copper consumption is small, equipment is simple, operation and management are convenient, other energy consumption is avoided except for power consumption of a water pump, the catalytic activity is higher, the reduction reaction rate is high, and secondary pollution is avoided; the method is very suitable for treatment of aerospace propellant production sewage.

Owner:中国人民解放军63605部队

Process for producing nickel iron in rotary kiln-blast furnace by using laterite nickle mine

Owner:毛耐文

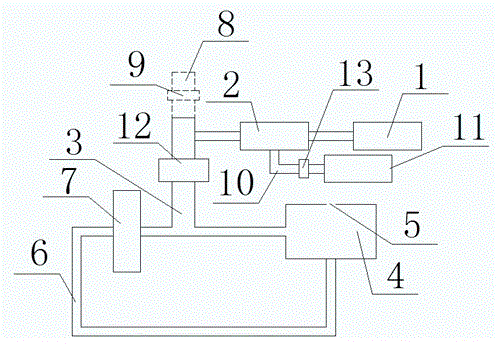

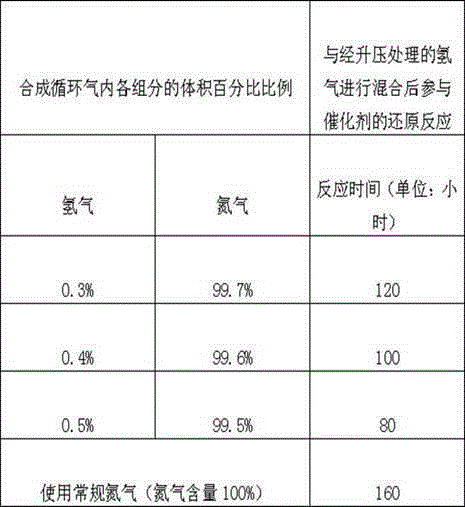

Reduction method of methanol synthesis catalyst

InactiveCN104857997AIncrease the speed of the reduction reactionSpeed up the reduction reaction timeCatalyst activation/preparationReaction timingChemistry

The invention discloses a reduction method of methanol synthesis catalyst. The reduction method comprises the following steps: conveying hydrogen from a gas storage tank of a hydrogen drainage and irrigation vehicle to a hydrogen depressurizing valve of the hydrogen drainage and irrigation vehicle to depressurize; conveying hydrogen after the depressurizing treatment to a synthesis gas compressor through a general hydrogen supplementing pipe to boost; conveying the synthesis circular gas containing hydrogen and nitrogen to a nitrogen inlet of the synthesis gas compressor so as to mix with the hydrogen after the boosting treatment, wherein the volume percent of every component in the synthesis circular gas is: 0.3-0.5% of hydrogen and 99.5-99.7% of nitrogen; conveying the mixed gas to a catalyst bed layer of a methanol synthesis reactor through a gas conveying pipe to participate in the reduction reaction. By adopting the technical scheme of the invention, the reduction reaction speed is accelerated, the reaction time is saved, and working efficiency is improved; the system is completely and stably ran without a series of assistant systems and the gas required by reduction is supplied, and thus cost is saved.

Owner:LINHUAN COKING

High-activity reduction agent for smelting iron alloy by electric oven

The invention discloses a highly active reducing agent for smelting ferroalloys in an electric furnace. It first selects one or more of coke powder, bituminous coal, and anthracite, and prepares a mixture of fixed carbon not less than 78%, ash content not greater than 16%, and hair content not less than 10%; then the mixture is processed into a particle size For powders smaller than 1mm, add 5-8% catalyst and 2-3% binder according to the weight of the powder, mix well, and press into spherical objects with a block diameter of 20-30mm to obtain finished products. This reducing agent not only gathers the advantages of a single carbonaceous reducing agent, but also reduces the cost of obtaining the reducing agent. In practice, the reducing agent of the present invention has the characteristics of high reaction activity, increased oxide reduction amount, accelerated reduction reaction speed, increased output, reduced power consumption and reduced total production cost. The reducing agent of the present invention is especially suitable for smelting ferroalloys of silicon series, manganese series and chromium series in large and medium-sized electric furnaces.

Owner:陈航

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com