Pulverized coal fired boiler hearth provided with variable-section combustor area and adapting to flexible peak shaving

A pulverized coal boiler and burner technology, applied in the combustion chamber, combustion method, combustion equipment, etc., can solve the problems of low temperature level and ambient temperature, fuel oil or natural gas consumption, low heat transfer intensity of water wall, etc., and achieve low load Improved combustion stability, reduced burner elevation, and flexible peak shaving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

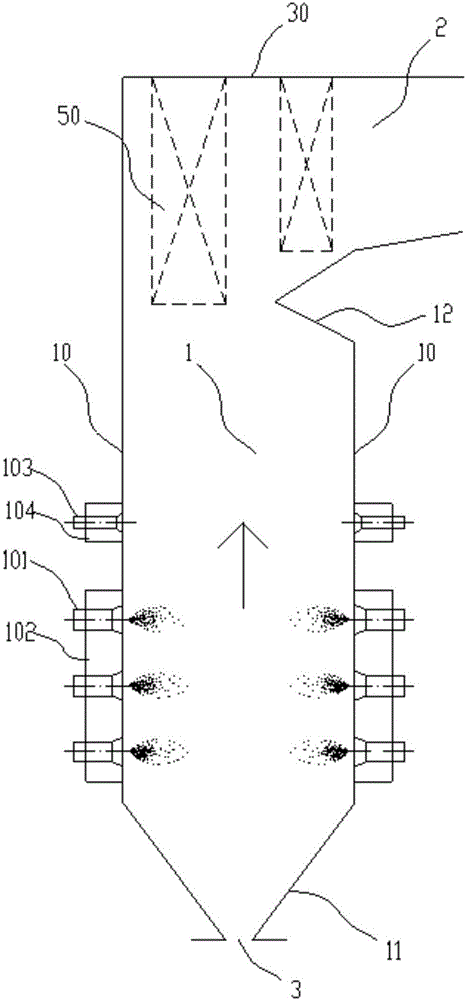

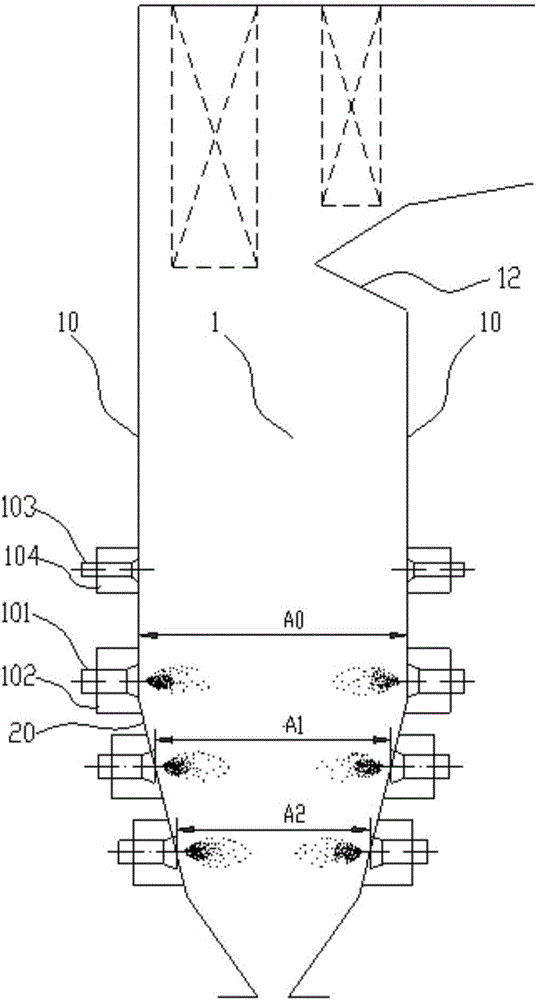

[0040] refer to image 3 As shown in Fig. 1, a pulverized-coal boiler furnace with variable burner area adapting to flexible peak regulation, the furnace cross-sectional area of different burner layers is not exactly the same, and the furnace cross-sectional area of the burner area gradually expands along the flue gas flow direction (ie A2 image 3 As shown in the hearth of the П-type pulverized coal furnace, a first-level slope section is set in the burner area of the furnace. The slope section is directly connected to the cold ash hopper, and the front and rear walls of the slope section are arranged symmetrically. The inclination angle between the slope section and the flue gas flow direction (vertical upward direction in the figure) is in the range of 5° to 35°. The burners include 2 layers of burners arranged in the variable section furnace, and 1 layer of upper layer burners (downstream burners) above. A layer of overfired air is arranged downstream of the flue gas ...

Embodiment 2

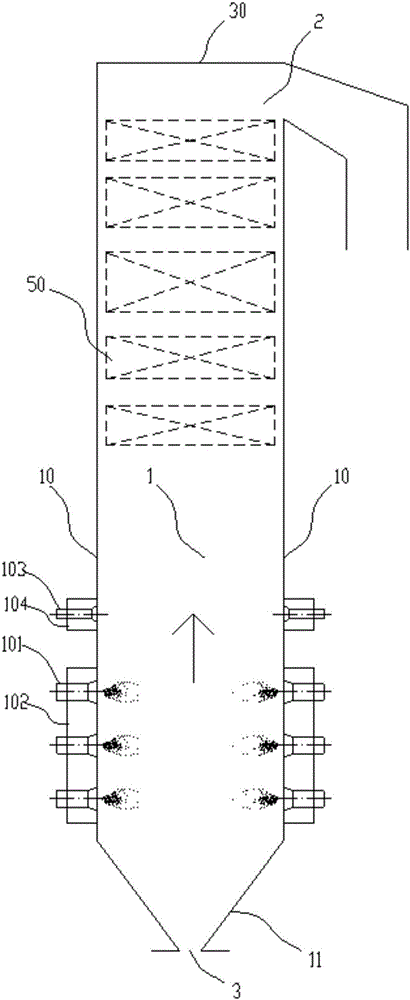

[0042] refer to Figure 4 As shown, this embodiment is basically the same as Embodiment 1, and the difference is that two grades of slope sections are set in the burner area of the furnace to form a furnace with a variable cross-sectional area, the vertical section transition between the slope section and the cold ash hopper, and the slope section between each slope section The two-layer burner of the variable-section furnace is installed on the water-cooled wall of the vertical section, and there is an upper layer of burner (downstream burner) on it.

Embodiment 3

[0044] refer to Figure 5 As shown, this embodiment is basically the same as Embodiment 1, and the difference is that a grade 1 slope section is set in the burner area of the furnace to form a furnace with a variable cross-sectional area (that is, A1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com