Precipitation reduction method of preparing nano-cobalt powder

A nano-cobalt and precipitate technology, which is applied in the field of nano-metal powder preparation, can solve the problems of not meeting the demand for quantity and quality, small production scale and low grade of cobalt powder, and achieve the prevention of aggregation, recrystallization, growth and particle size distribution. Narrow, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

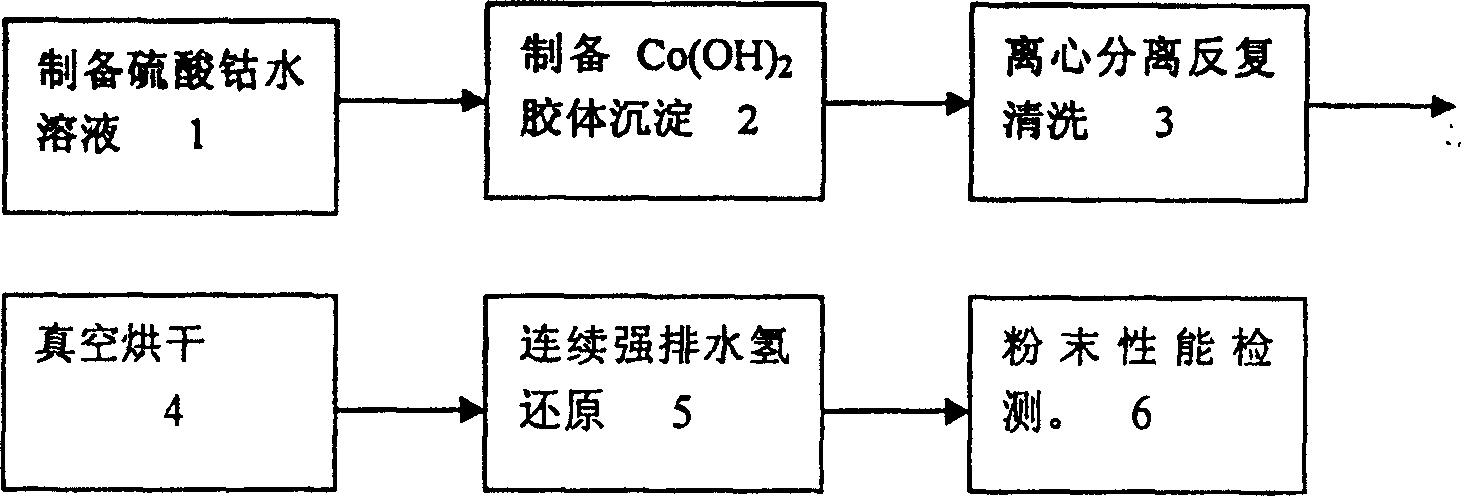

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, when preparing 1kg nanometer cobalt powder, should finish according to the following steps.

[0030] 1. Weigh 4.7682kg (16.969mol) of cobalt sulfate (CoSO 4 ·7H 2 O) powder by 1mol / L concentration, cobalt sulfate (CoSO 4 ·7H2 O) The powder is poured into 16.969kg of deionized water, heated to 60° C., stirred and dissolved to make an aqueous solution of cobalt sulfate.

[0031] 2. Add 1.3572kg (33.938mol) of NaOH powder into the above solution and continue heating and stirring to generate pink Co(OH) 2 colloidal precipitate.

[0032] 3. Pump the pink slurry into a continuous high-speed centrifuge, separate the mother liquor and wash the Co(OH) with deionized water or distilled water repeatedly 2 powdery precipitate, until the acid radicals and Na +1 The ions are cleaned, and finally the cleaning solution is centrifuged out to obtain Co(OH) with a small amount of water. 2 powder block.

[0033] 4. The above Co(OH) 2 Put the powder into a vacuum dryin...

Embodiment 2

[0036] Embodiment 2, should finish according to the following steps when preparing 10kg nanometer cobalt powder

[0037] 1. Weigh 47.682kg (169.69mol) of cobalt sulfate (CoSO4 7H2O) powder, pour it into 169.69kg of deionized water, heat to 80°C and continuously stir and dissolve to make an aqueous solution of cobalt sulfate.

[0038] 2. Weigh 13.572kg (339.38mol) of NaOH powder and add it into the above solution and continue heating and stirring to generate pink Co(OH) 2 colloidal precipitate.

[0039] 3. Exactly the same as 3 in Example 1

[0040] 4. The above Co(OH) 2 Put the powder into a vacuum drying oven, and dry it in a vacuum at 20Pa, 85°C, for 60 minutes to obtain dry Co(OH) 2 powder.

[0041] 5. Dry the Co(OH) 2 The powder is put into the continuous strong drainage type H 2 450°C in reduction furnace, 40 minutes, H 2 Air section flow rate 40ml / cm 2 min, after reduction, it can be made (SAXS) with an average particle size of 44.5nm and a median diameter of d ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com