Cu/ZrO2 catalyst as well as preparation method and use of Cu/ZrO2 thereof

A catalyst and four-way technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, cyanide reaction preparation, etc., can solve the problem of unsatisfactory catalytic effect of catalyst, difficult control of reduction degree, increase of catalyst cost, etc. Achieve the effects of low raw material prices, easy control of reduction degree, and short preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

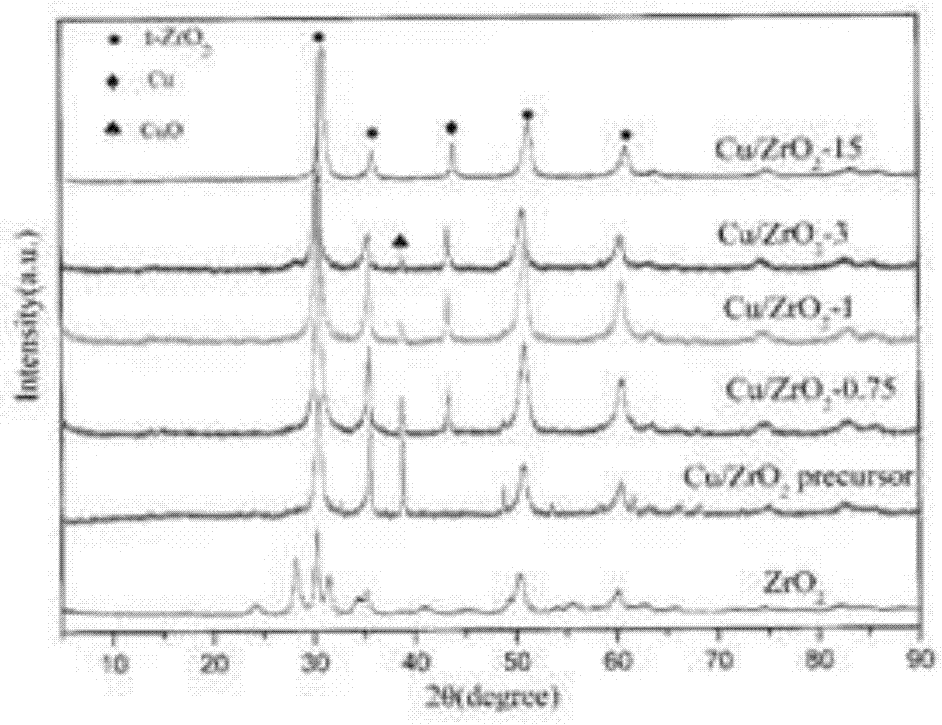

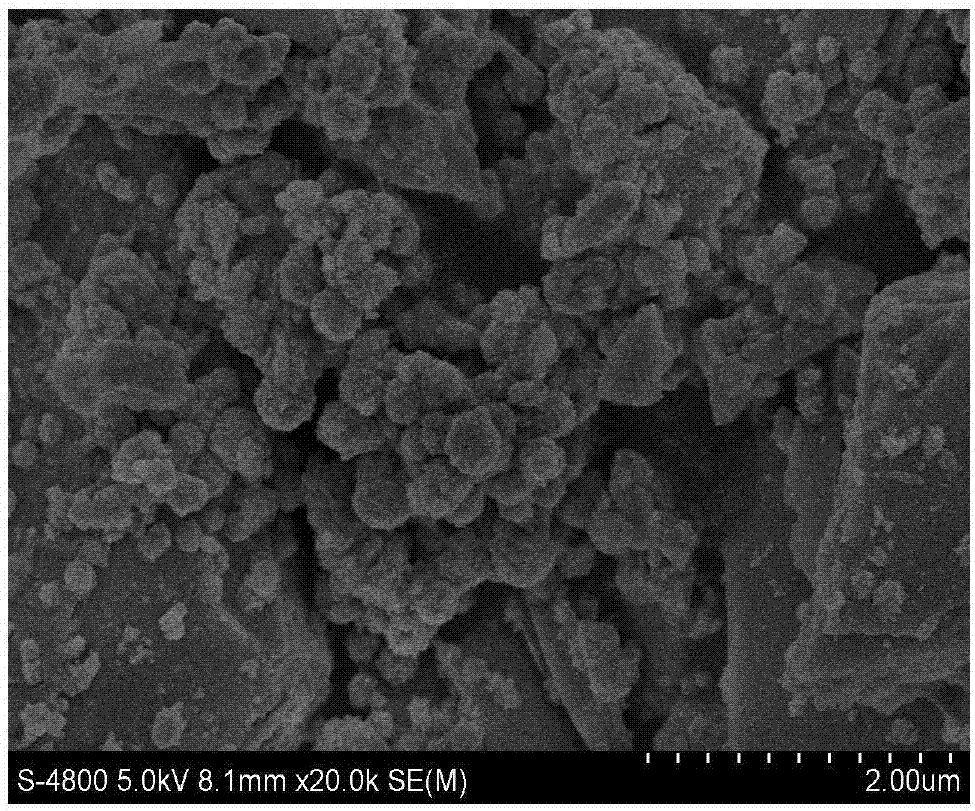

[0022] A Cu / ZrO 2 Catalyst, Cu particles are spherical, with a diameter of 1-4 μm, loaded on sheet-like tetragonal ZrO 2 on the carrier.

[0023] The three valence states of Cu in the catalyst are Cu 0 、Cu + 、Cu 2+ , the molar ratio is 1:0.20~0.35:0.01~0.06.

[0024] A Cu / ZrO 2 Catalyst preparation method:

[0025] (1) Stir and mix the copper salt solution and the zirconium salt solution at a volume ratio of 1:2, slowly add 0.8-1.0mol / L alkali solution dropwise until the pH value of the mixed solution is 11-12, and let it stand for 4-2 After 6 hours, wash and filter with water, put the filter cake in a constant temperature drying oven at 90-110°C and dry it for 10-12 hours, grind it into powder, heat it up to 550°C at 2°C / min, and roast it for 4 hours. After cooling, CuO / ZrO 2 Precursor solid, pulverized to obtain precursor powder;

[0026] (2) Weigh the 10.0gCuO / ZrO 2 The precursor powder was added to 100 mL of 1mol / L NaOH solution, stirred mechanically and heated to...

Embodiment 2~6

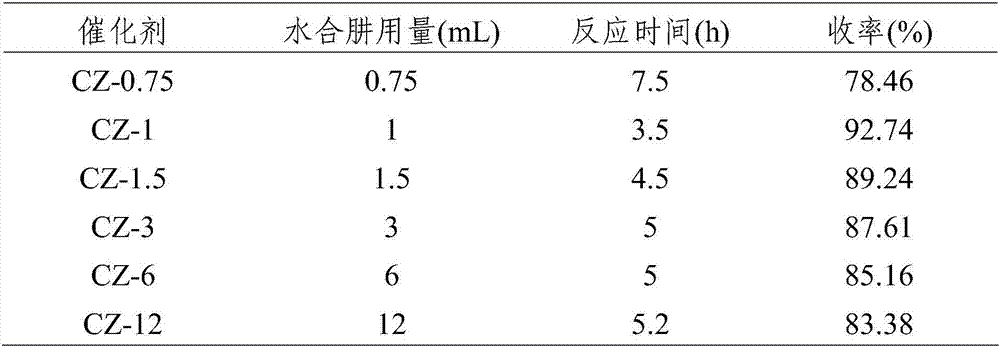

[0029] According to the method of embodiment 1, adopt identical preparation method and take the CuO / ZrO of identical weight 2 Precursor powder, just change the amount of hydrazine hydrate to 1mL, 1.5mL, 3mL, 6mL, 12mL respectively, and the prepared catalysts are marked as CZ-1, CZ-1.5, CZ-3, CZ-6, CZ-12. Evaluate using the implementation plan. The catalyst performance evaluation results are shown in Table 1.

[0030] The diethanolamine catalyzed reaction reaction performance result of each catalyst of table 1

[0031]

Embodiment 7

[0033] Weigh the 10.0gCuO / ZrO 2Add the precursor powder to 100mL of 1mol / L NaOH solution, stir mechanically and heat up to 50°C in a water bath, slowly add 1mL of hydrazine hydrate with a mass fraction of 80%, react for 20min, quickly add 200mL of ice water to cool, wash and filter , The filter cake was vacuum-dried at 40° C. for 12 h to prepare the T-20 catalyst. Evaluate using the implementation plan. The performance evaluation results of the catalysts are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com