Reduction method of methanol synthesis catalyst

A methanol synthesis and catalyst technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of high system operating costs and waste costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

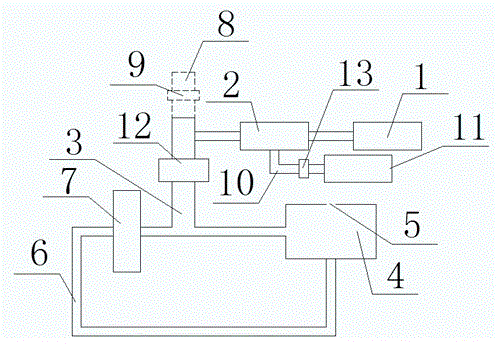

[0017] figure 1 Show the specific embodiment of the reduction method of a kind of methanol synthesis catalyst of the present invention: the reduction method of this methanol synthesis catalyst comprises the following steps:

[0018] (1) Transport hydrogen from the gas storage tank 1 of the hydrogen drainage and irrigation vehicle to the hydrogen pressure reducing valve group 2 of the hydrogen drainage and irrigation vehicle for decompression;

[0019] (2) The hydrogen after decompression treatment is transported to the syngas compressor 4 through the hydrogen supply main pipe 3 to boost the pressure;

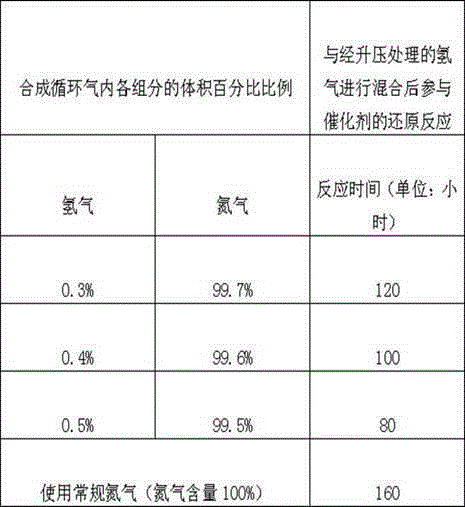

[0020] (3) Transport the synthesis cycle gas containing hydrogen and nitrogen to the nitrogen inlet 5 of the synthesis gas compressor 4 to mix with the boosted hydrogen. The volume percentage ratio of each component in the synthesis cycle gas is: hydrogen: 0.3 -0.5%, nitrogen 99.5-99.7%.

[0021] (4) The mixed gas is transported to the catalyst bed layer of the methanol synthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com