Patents

Literature

31results about How to "Shorten the reduction reaction time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

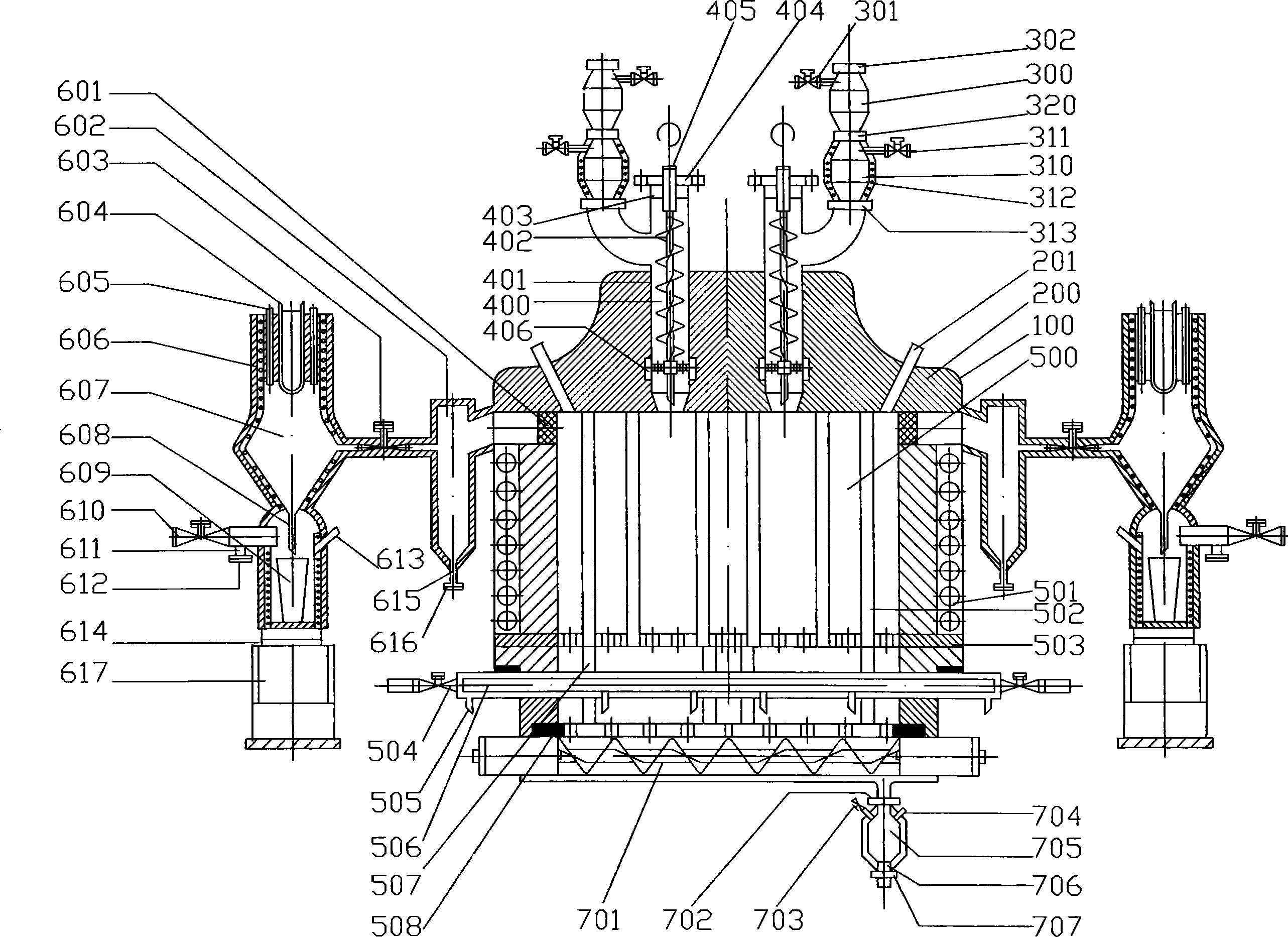

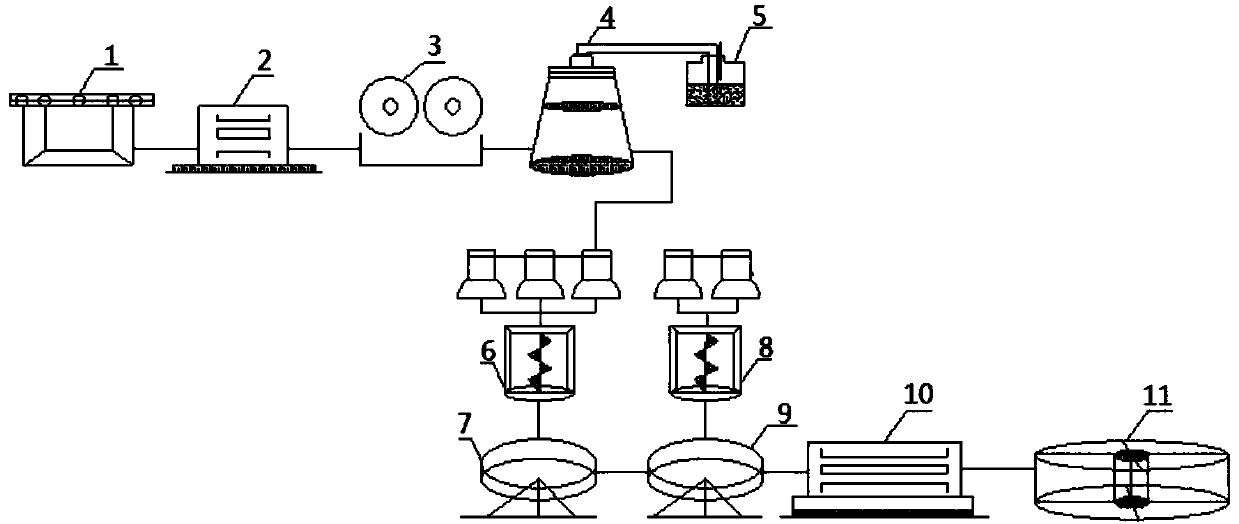

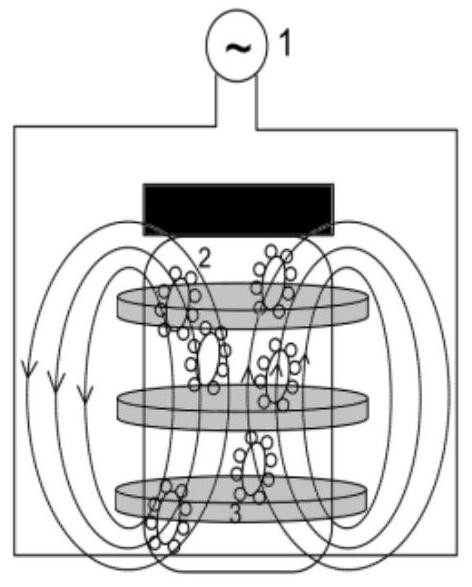

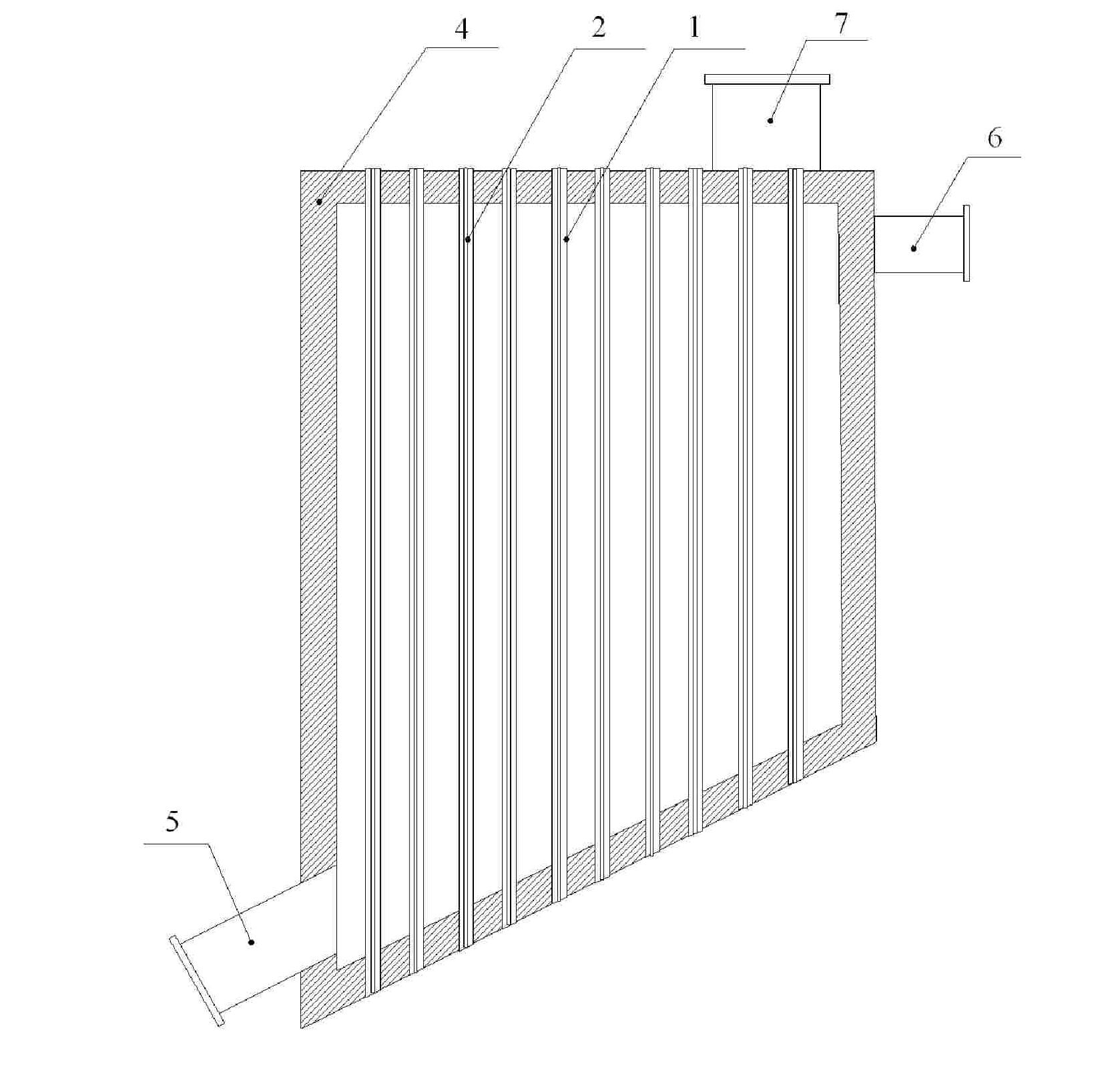

Induction heating continuous magnesium-smelting system and continuous magnesium-smelting technique

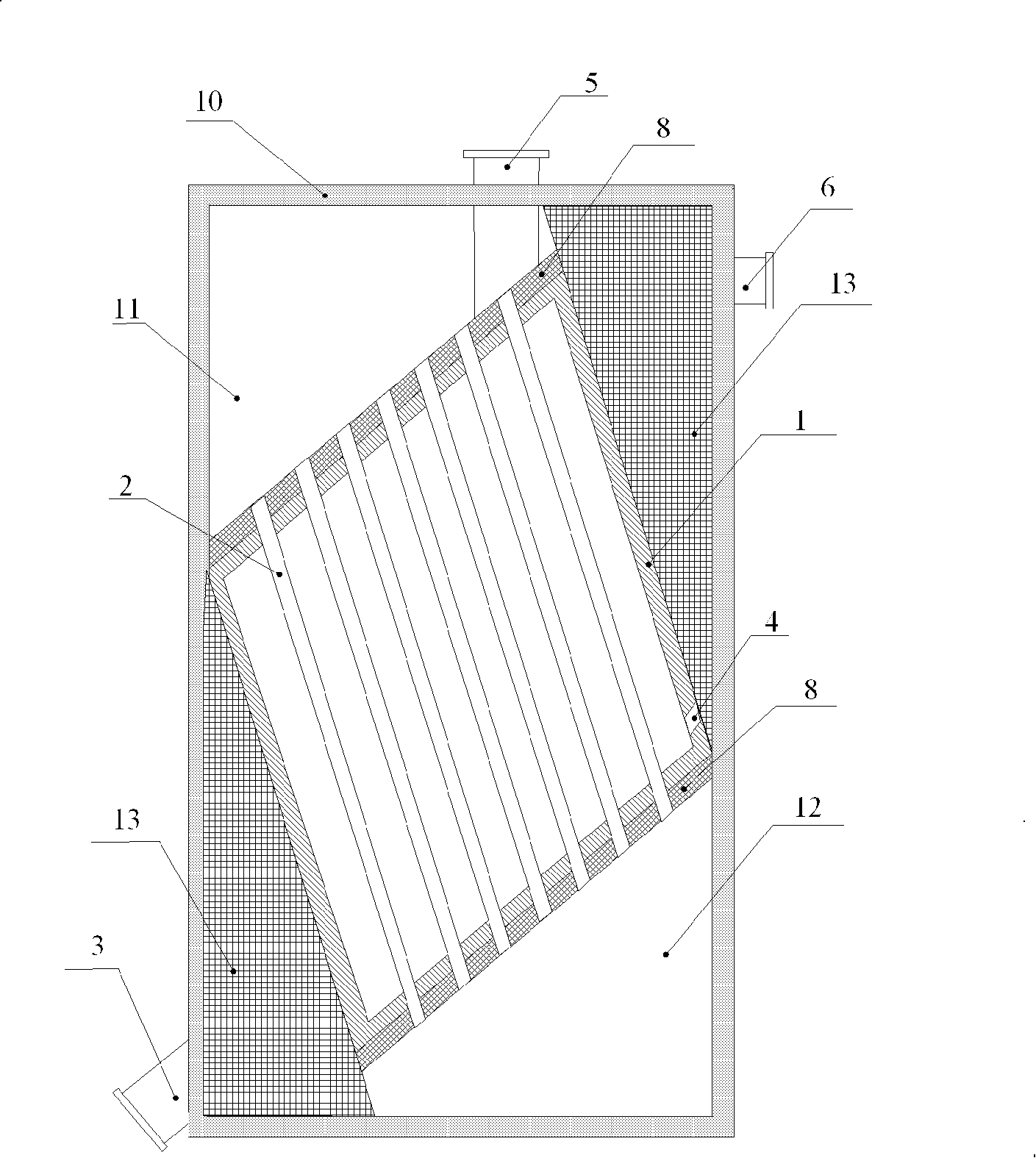

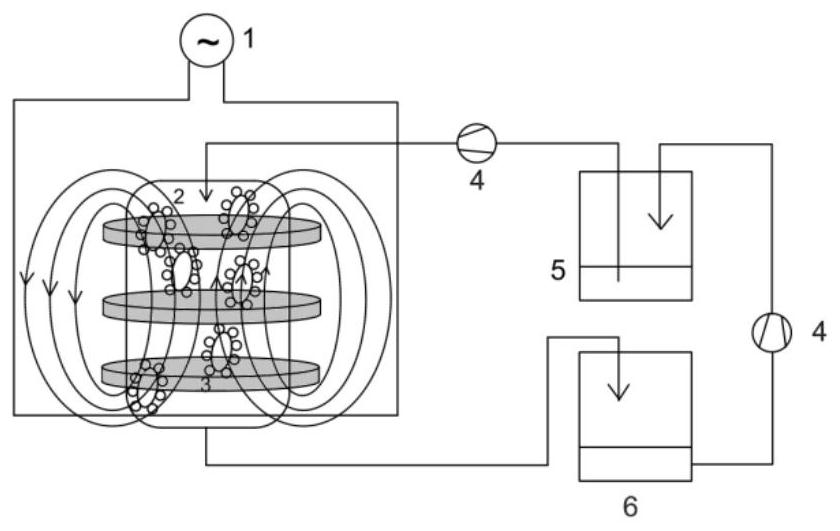

The invention discloses a system of inductive heating continuous magnesium smelting and a continuous magnesium smelting technique. The system comprises a continuous feeding device, an inductive heating reaction chamber, a magnesium steam condensing device and a continuous discharging device; wherein the feeding device consists of a feeding housing and a spiral feeding mechanism, the reaction chamber comprises an inductive heating winding, a heating element, a clapboard with holes and a slag cooling device, the condensing device consists of a mesh clapboard, a dust deposition chamber, the magnesium steam condensing chamber, the continuous discharging device comprises spiral slag discharging mechanism and slag housing. The continuous magnesium smelting technique consists of the processes of the continuous feeding of reacting burden into the reaction chamber, the continuous condensation of the magnesium steam and the discharge of liquid magnesium, and also comprises steps of the continuous feeding of reacting slag into the slag housing and slag discharging. The invention has high heat energy utilization rate, and can realize the low cost continuous production of the metal magnesium.

Owner:CENT SOUTH UNIV

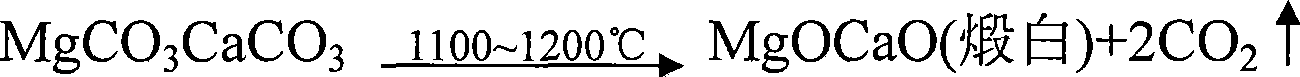

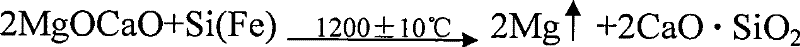

Process for smelting magnesium by microwave heating Pidgeon process

The invention discloses a magnesium reduction process through a micro-wave heating silicothermic method; the process comprises the following steps: 1. dolomite calcinations: the dolomite is heated to 1100 DEG C to 1200 DEG C and becomes calcined dolomite; 2. the calcined dolomite, silicon nitride powder and fluorite powder are weighed, mixed, milled and then pressed into a ball which meets technological requirements; 3. the ball is put into a closed non-metal reduction tank of a micro-wave heating oven to be heated under 1000 DEG C to 1200 DEG C, so that the magnesium compound in the ball reacts with the silicon nitride powder; 4. the vacuum degree of the closed non-metal reduction tank is kept to be 13.3Pa or higher for 4h to 6h; magnesium vapor is condensed in a condenser and becomes crude magnesium; 5. the crude magnesium is heated, melted and refined by solvent, to obtain refined magnesium; 6. acid washing and the like. The method evenly and quickly heats in the principle of micro-wave heating with high heating efficiency, is easy to be controlled, saves production cost, is safe, environment protective and harmless.

Owner:重庆科健冶金材料有限公司

Method for preparing graphene through ball mill aided oxidation and reduction

The invention elates to the technical field of inorganic chemical application, and specifically relates to a method for preparing graphene through ball mill aided oxidation and reduction. The method comprises the following steps: 1, preparing graphite oxide; and 2, preparing a graphene oxide solution through the graphite oxide obtained in step 1, and then refluxing to obtain graphene. With the adoption of the method, the time of subsequent refluxing reduction reaction is reduced, the efficiency of preparing graphene by the oxidation and reduction method is increased, and the reduction degree of graphene oxide is raised.

Owner:宋鹏

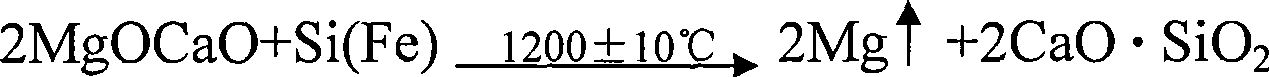

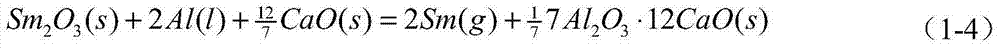

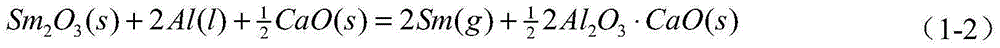

Method for continuously preparing metal samarium through direct thermal reduction

The invention discloses a method for continuously preparing metal samarium through direct thermal reduction, and belongs to the technical field of nonferrous metallurgy. The preparation method comprises the following steps: Sm2O3, Al, CaO or MgO are mixed, wherein a reducing agent is Al, and can be replaced by an Si-Fe alloy with 75 mass% of Ca or Si; the batching and the pelletizing are performed; and then, the high-temperature reduction reaction is performed for pellets in flowing inert gas or nitrogen atmosphere; and finally, high-temperature samarium steam carried out by flowing inert carrier gases or nitrogen in a high-temperature reduction furnace is condensed to obtain the metal samarium. The method adopts the relative-vacuum manner, cancels a vacuum system and a vacuum reduction tank, realizes the continuous preparation of the metal samarium, shortens the reduction period, and improves the preparation efficiency; the recovery rate of the metal samarium can reach above 97%; as the energy consumption is obviously reduced, the method is a novel energy-saving green process for preparing the metal samarium with low cost; and the method is simple in operation, is simpler in equipment, is low in requirement, and reduces the equipment investment and the operation cost.

Owner:NORTHEASTERN UNIV

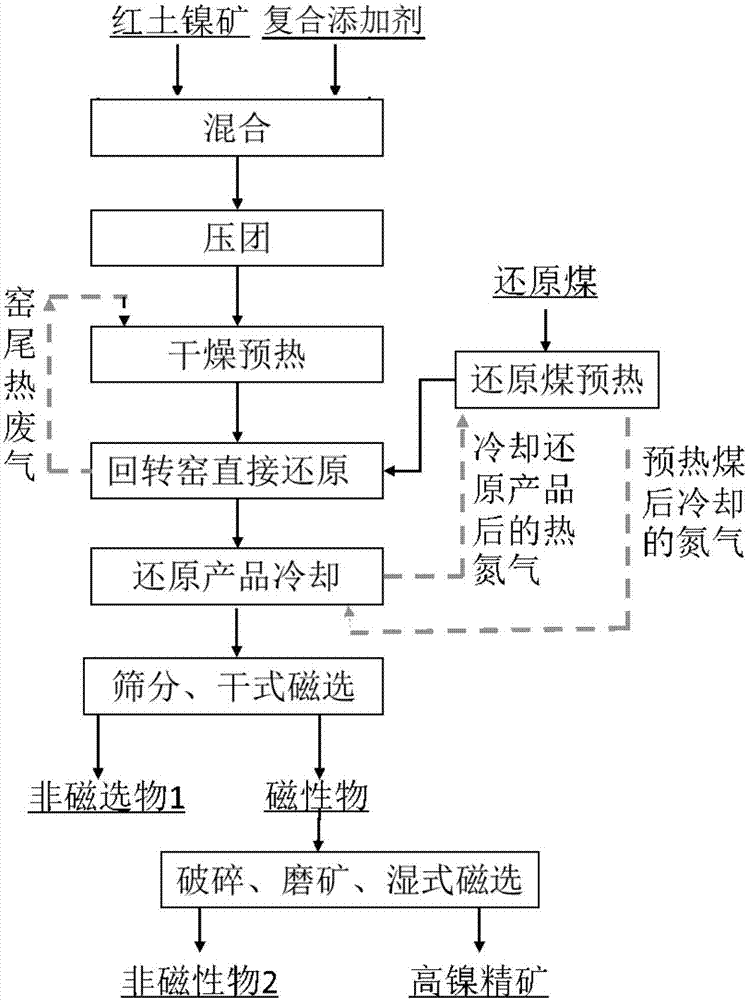

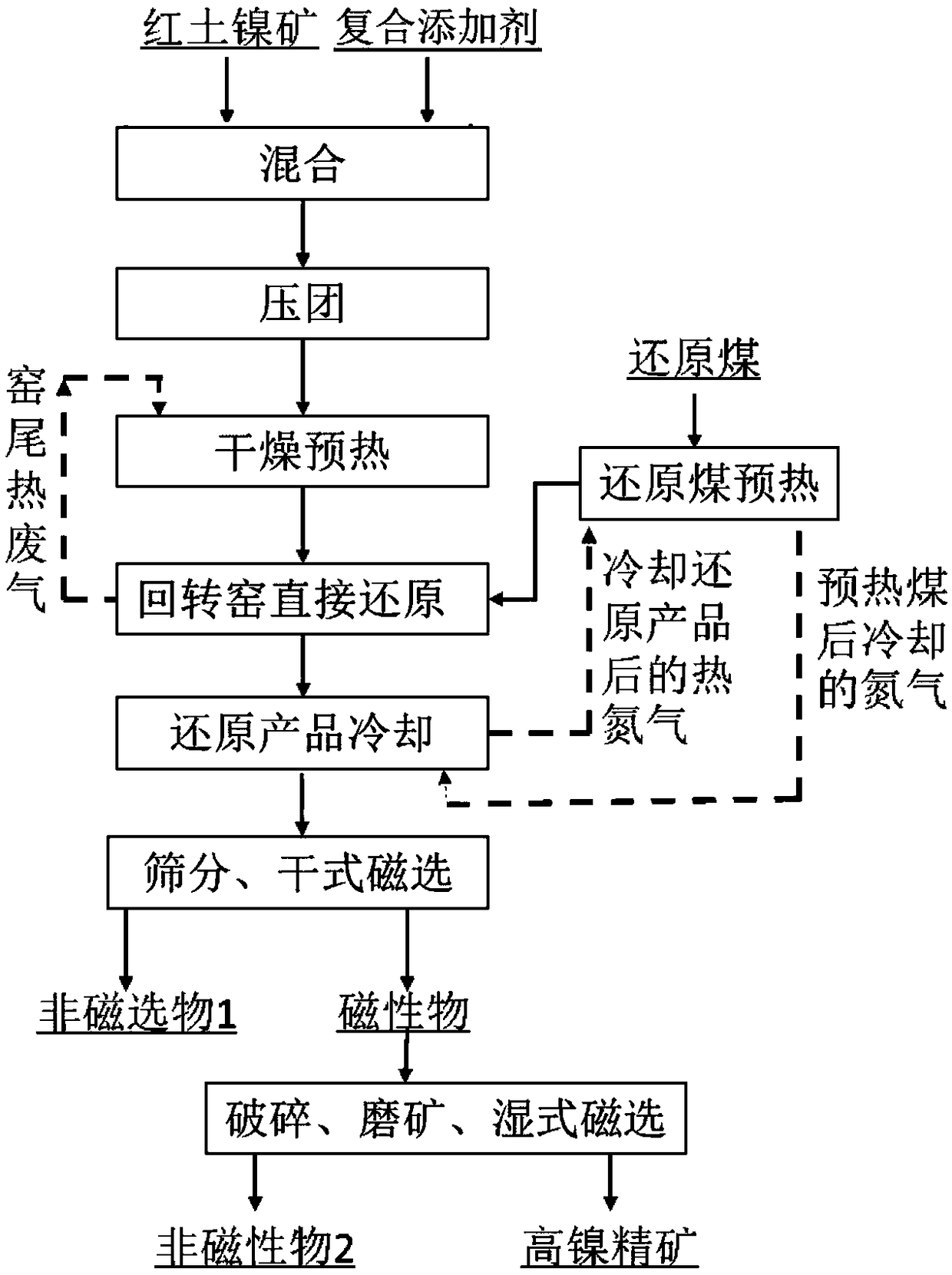

Rapid reduction process of rotary kiln for laterite nickel ore

The invention discloses a rapid reduction process of a rotary kiln for laterite nickel ore. The rapid reduction process of the rotary kiln for the laterite nickel ore includes the following steps that laterite nickel ore and a composite adding agent are mixed and then are pressed into block masses, and the composite adding agent comprises pulverized coal and limestone; the block masses are dried and pre-heated, and then enter the rotary kiln, reduction coal is added in, and reduction is performed under the reduction atmosphere so that reduced products can be obtained; the reduced products are cooled, screened and magnetically separated so that magnetic products can be obtained; and the magnetic products are crushed, subjected to ore grinding and magnetically separated, and high-nickel concentrate is obtained. According to the rapid reduction process of the rotary kiln for the laterite nickel ore, the low grade laterite nickel ore serves as raw materials, three manners that fuel is matched in the block masses, the block masses are preheated in a vertical furnace and coal is fed through hot air are developed to guarantee that the laterite nickel ore block masses are contained in the kiln while being hot, high temperature rapid reduction of the whole kiln is achieved, and therefore the rotary kiln temperature is lowered, the reduction time is shortened, and the high-nickel concentrate is effectively manufactured from the low grade laterite nickel ore.

Owner:CENT SOUTH UNIV

Method for preparing 3-hydrazinobenzoic acid hydrochloride

InactiveCN101337910AShorten the reduction reaction timeReduce manufacturing costHydrazine preparationMeta-toluidineBenzene

The invention relates to a method for preparing 3-methyl phenyl hydrazine hydrochloride, which comprises the following steps: (1) meta-toluidine is used as starting material, and benzene diazonium chloride is prepared through diazo reaction; (2) benzene diazonium chloride obtained from the step (1) is utilized to further prepare reduction products through the reduction reaction under the action of a reducing agent; (3) the reduction products obtained from the step (2) undergoes the hydrolysis reaction under the action of hydrochloric acid to generate 3-methyl phenyl hydrazine hydrochloride, more particularly, sodium metabisulfite is used as the reducing agent in the reduction reaction in the step (2), and the reaction is performed under the condition that the temperature is 15 to 25 DEG C and the pH value is 7 to 9. The method has higher yield, and can shorten the production period and reduce the manufacture cost at the same time.

Owner:太仓市华联化工实业有限公司

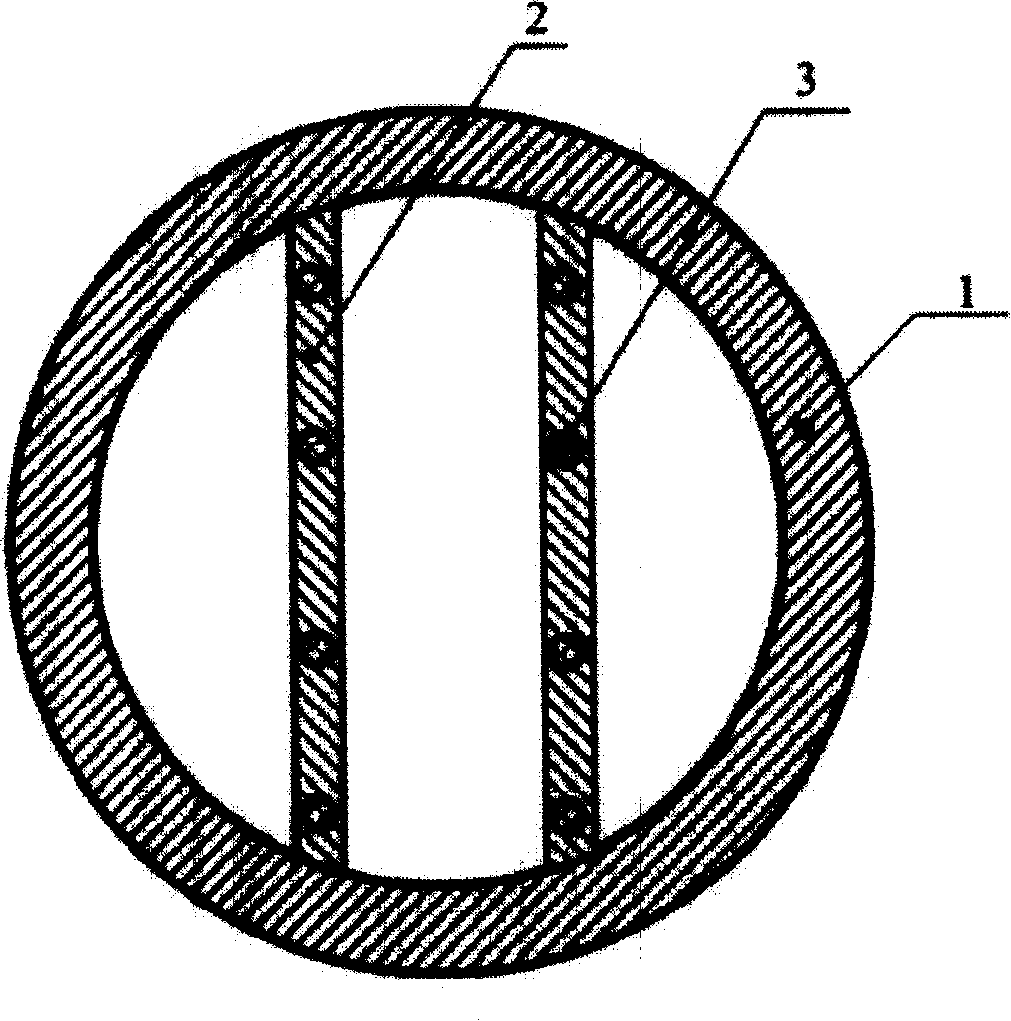

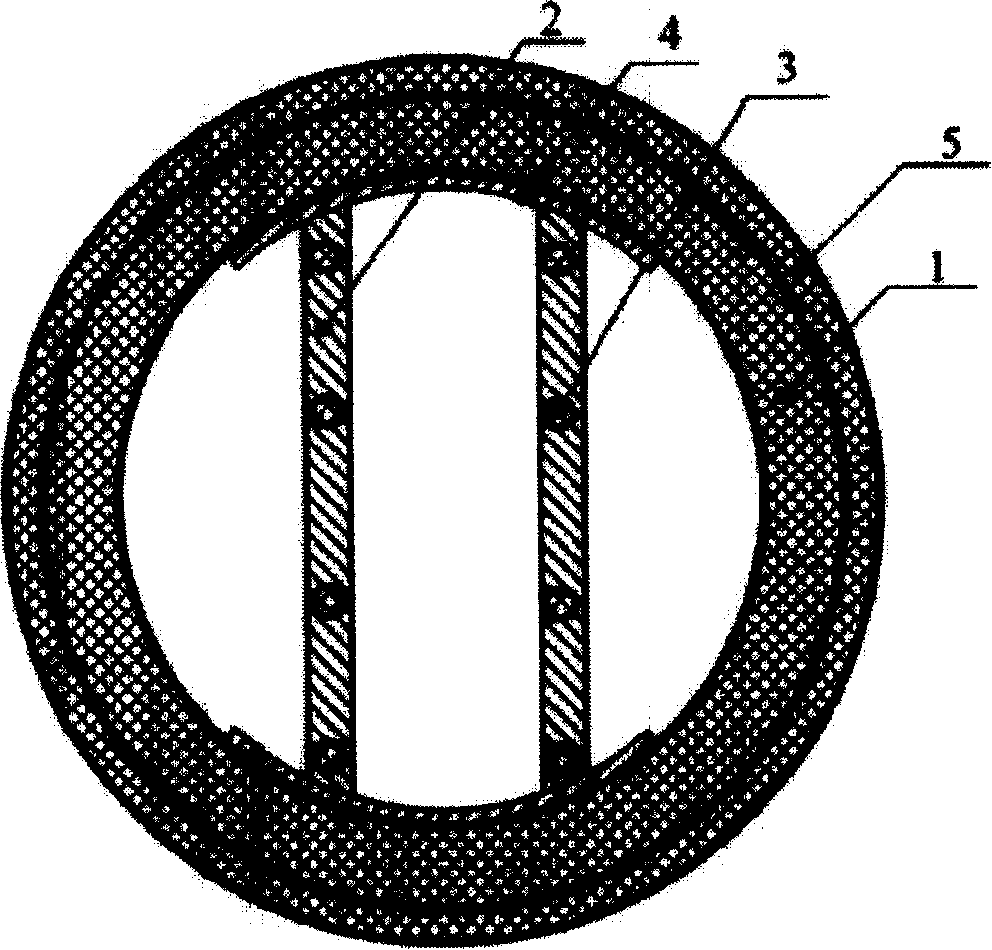

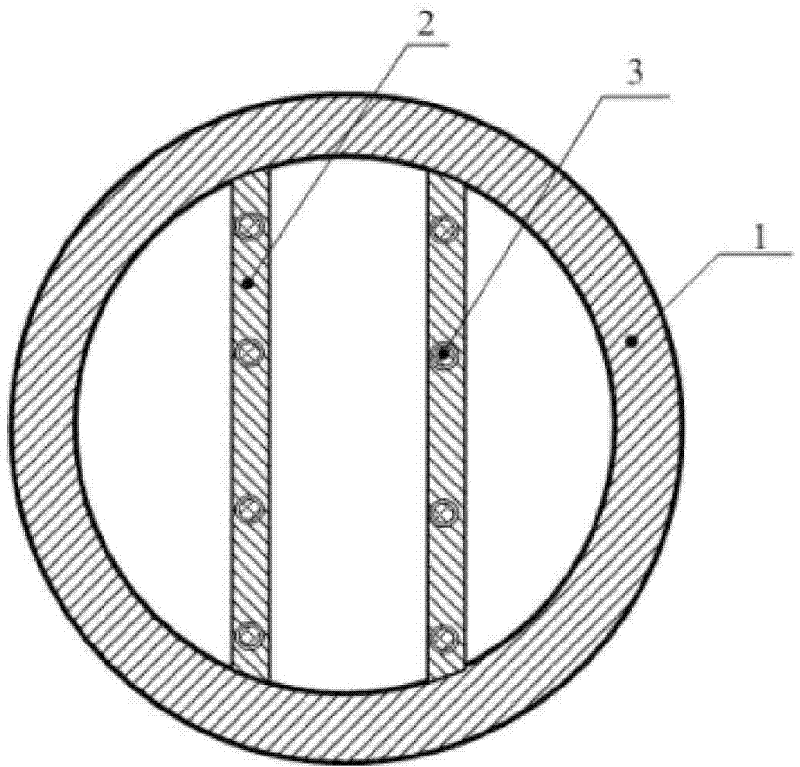

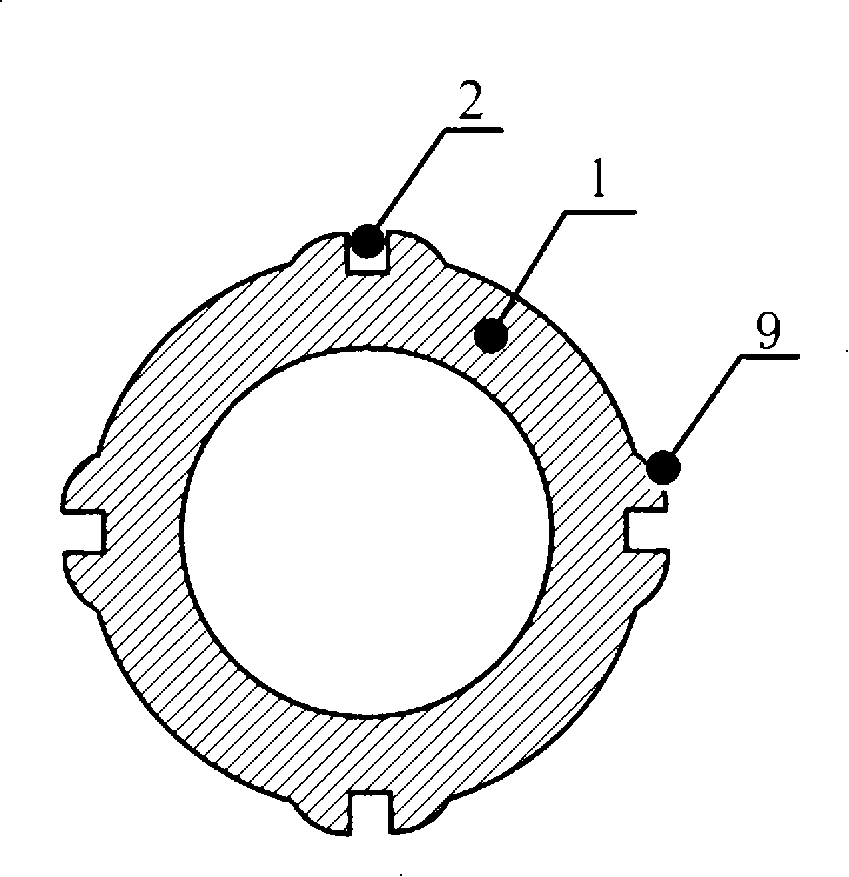

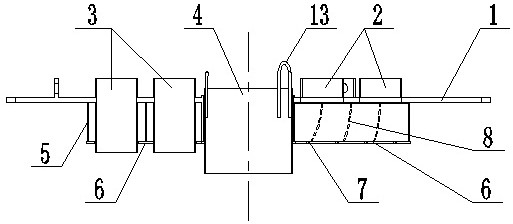

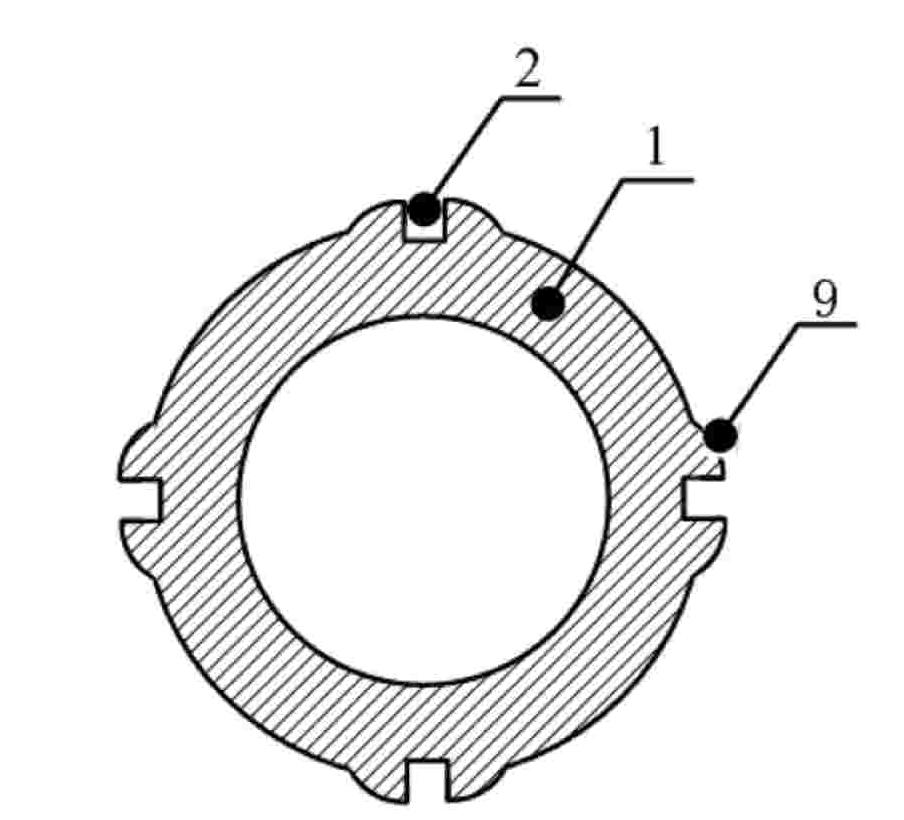

Electric heating method for reduction pot and reduction pot used for the same

The invention discloses an electric heating method for a reducing pot and the reducing pot used by the method, wherein, a heat conductor is arranged inside a pot body of the reducing pot; an electrical bar is embedded into the heat conductor; heat generated after the electrical bar is electrified is conducted through the heat conductor, and reducing materials in the reducing pot are heated. The reducing pot (1) takes the structure of a cylinder, wherein, a charging hole is arranged on one end of the reducing pot; the other end of the reducing pot is closed or provided with a slag notch; the heat conductor (2) is arranged inside the reducing pot (1); the heat conductor (2) and the inner wall of the reducing pot (1) are integrated into a whole or the heat conductor (2) is a movable structure which is closely embedded and sleeved into the reducing pot (1); shape and set mode of the heat conductor (2) are random; the electrical bar (3) is embedded into the heat conductor (2). The invention can be used for auxiliary heating of the prior heating method and also can be completely used for electric heating, and has the advantages of great reduction of reaction time of reducing materials, improvement of production rate per unit time, reduction of production cost and capability of reducing environmental pollution.

Owner:GUIZHOU SHIJI TIANYUAN MINING IND

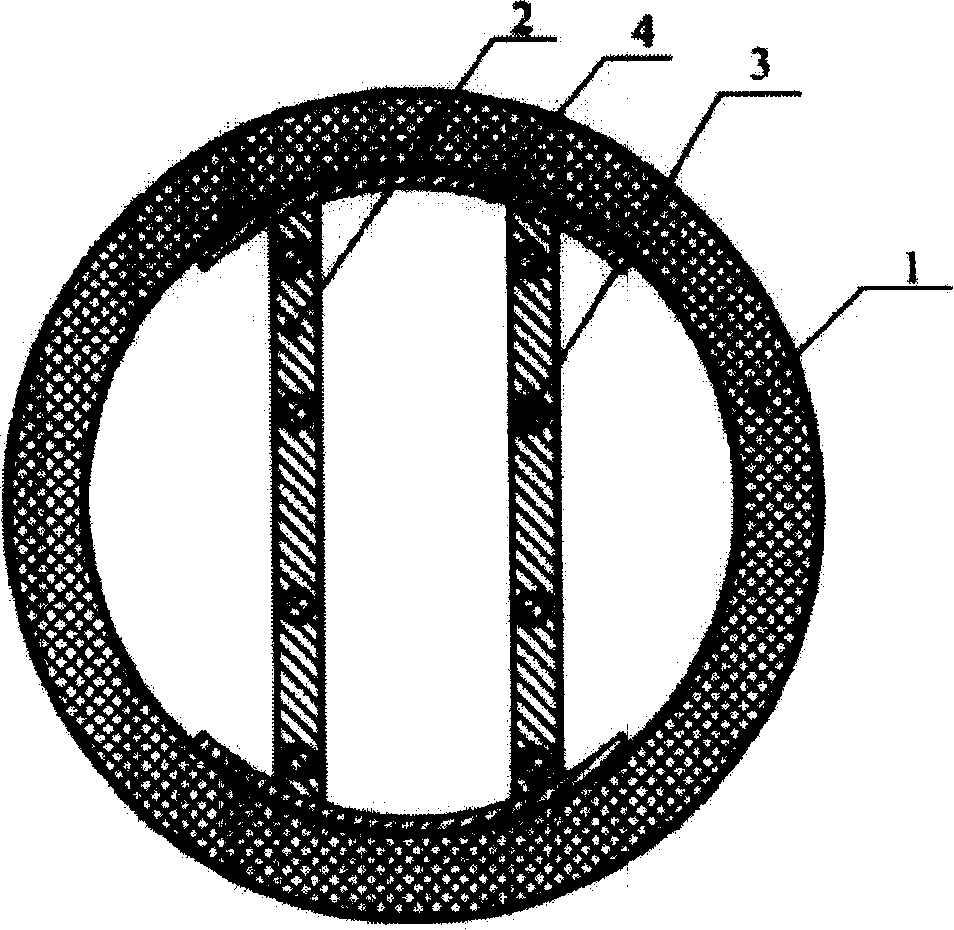

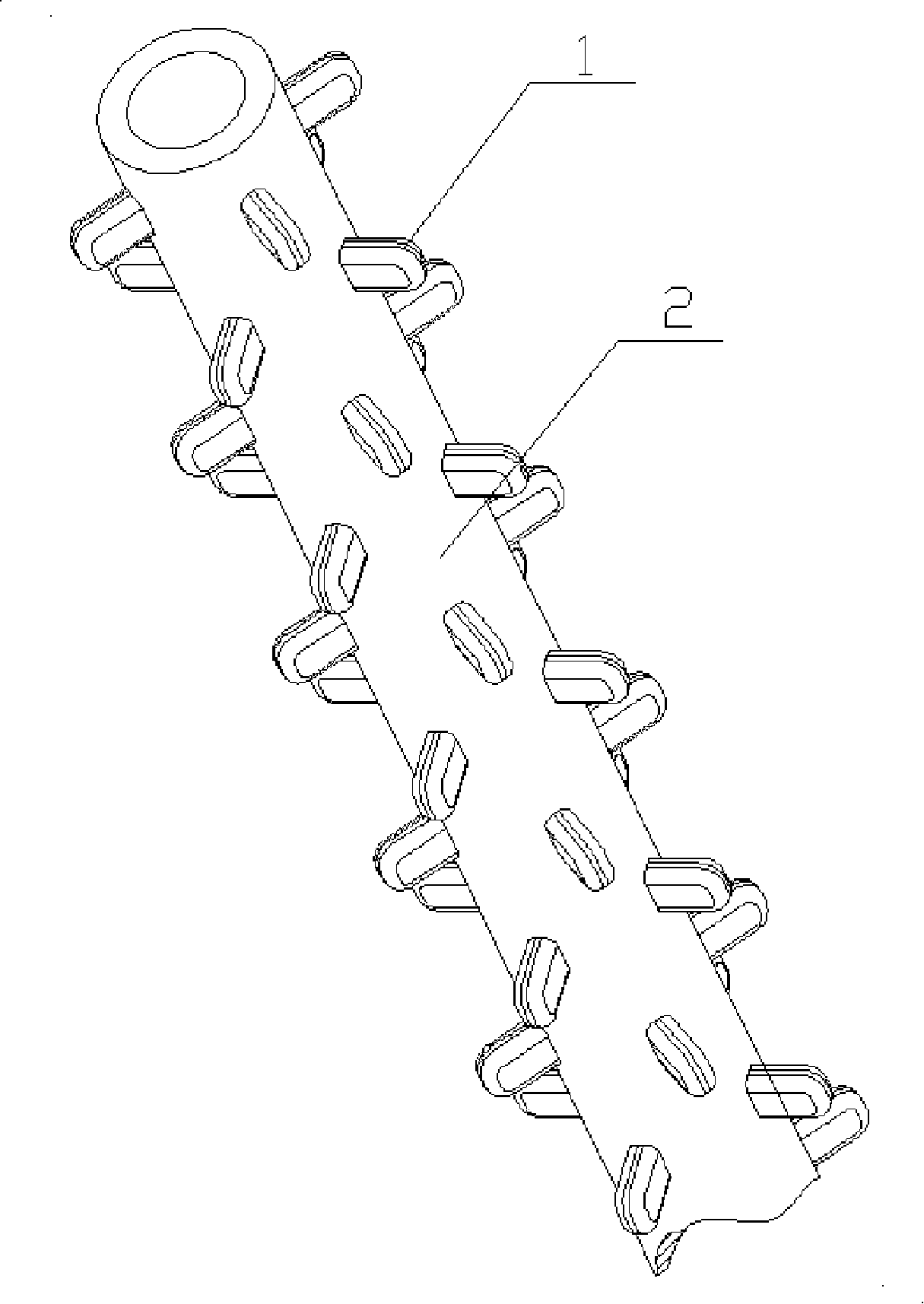

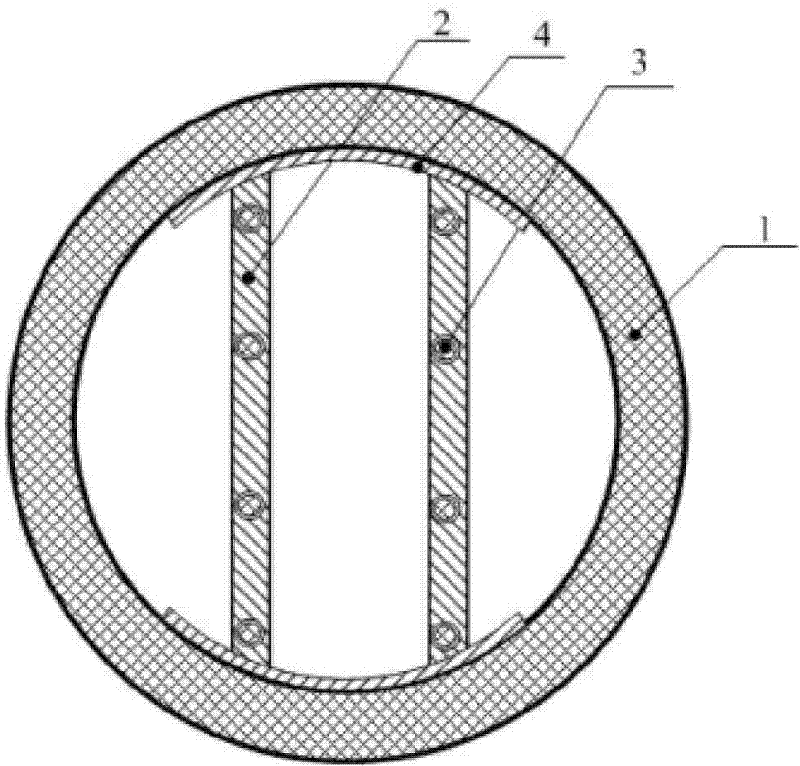

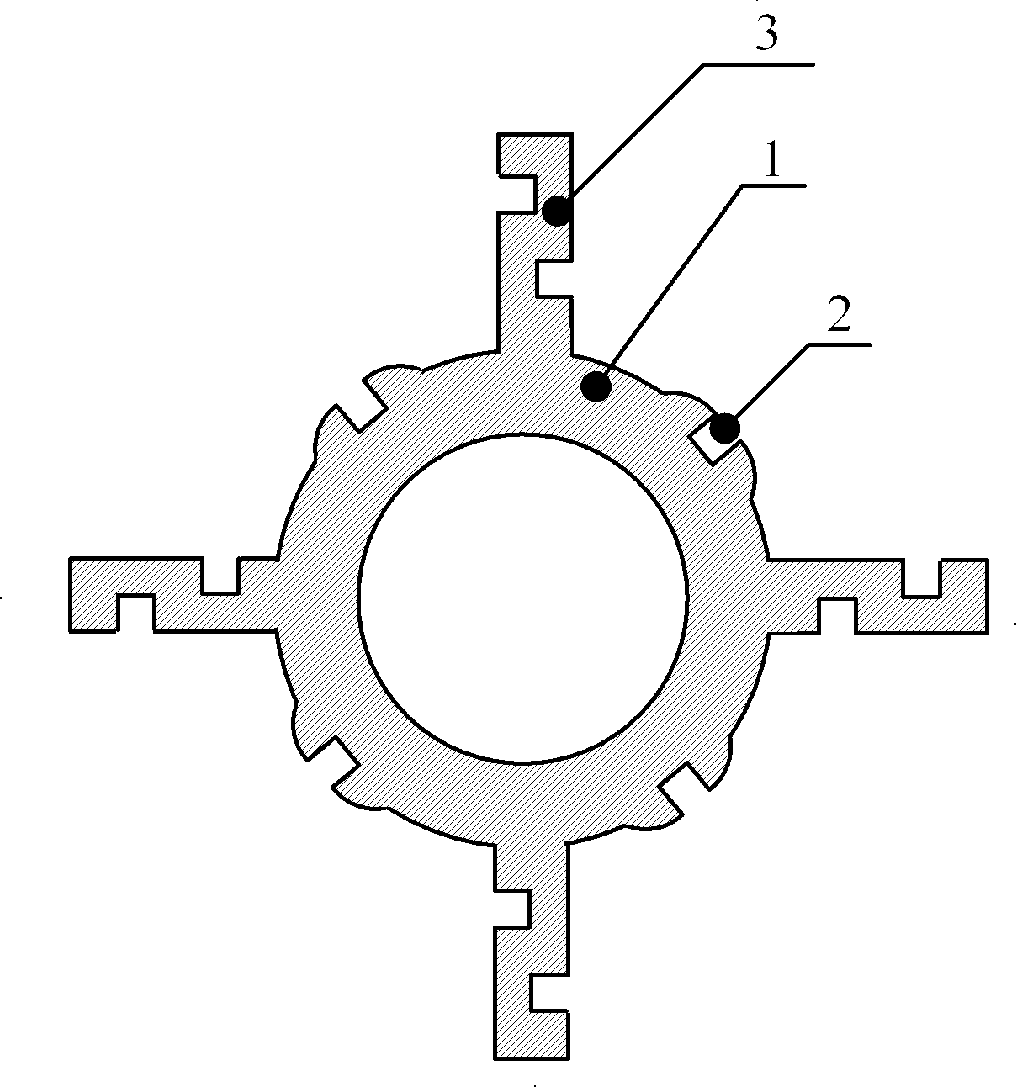

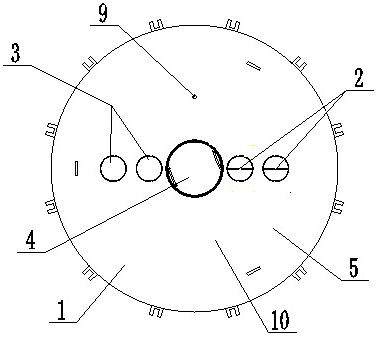

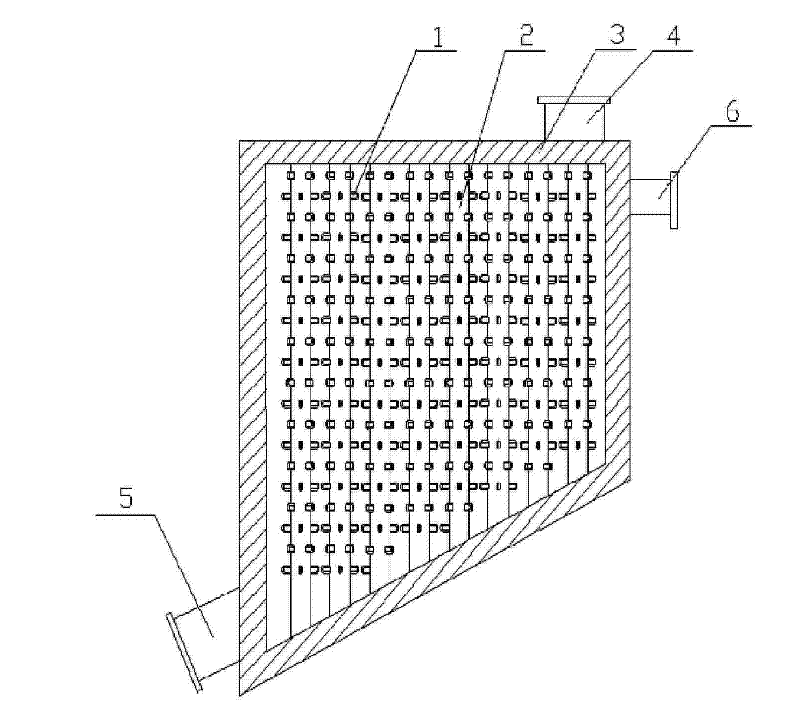

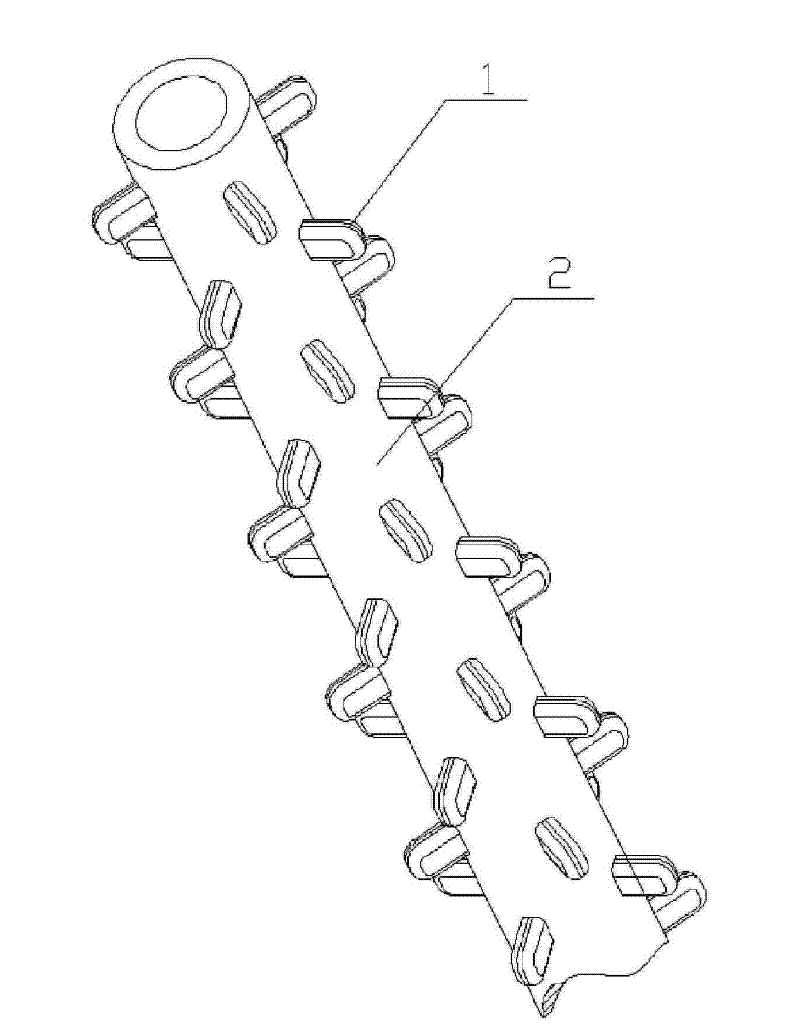

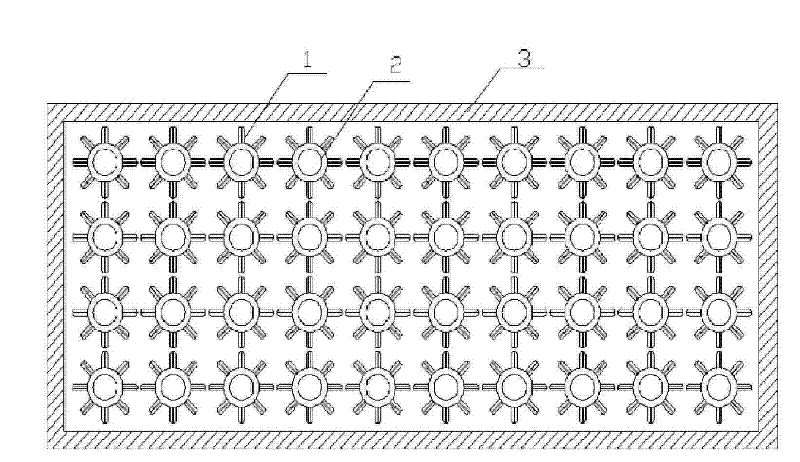

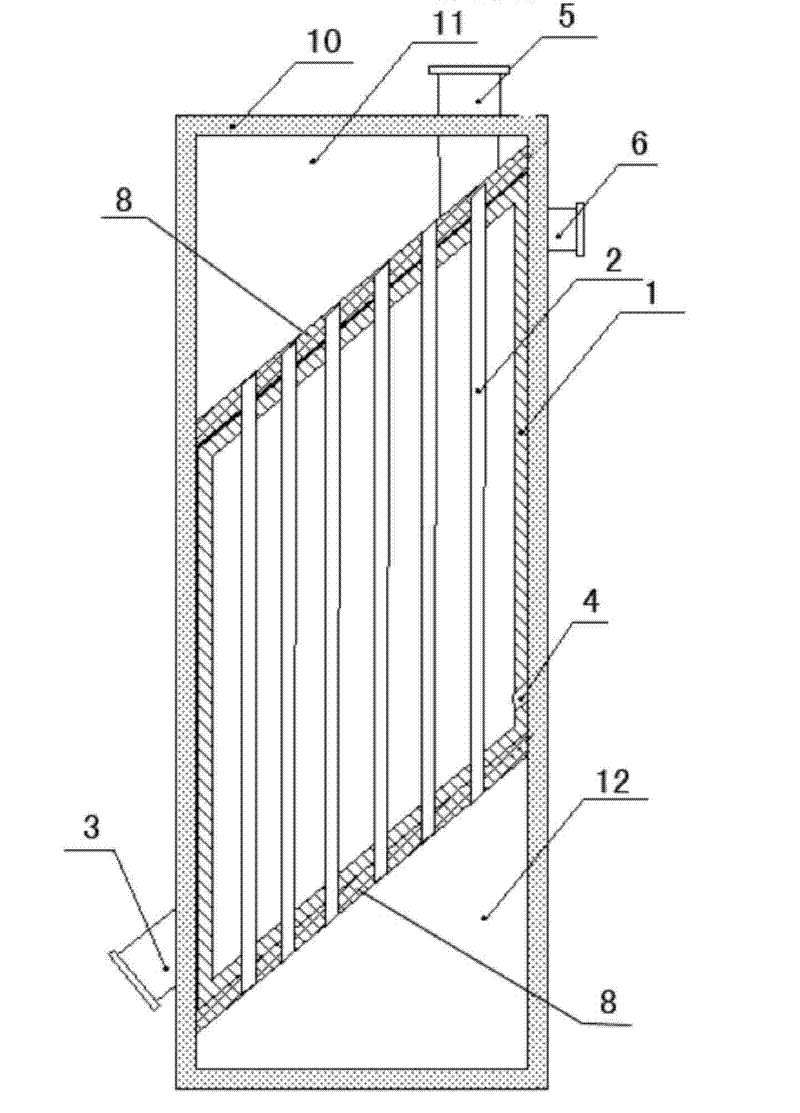

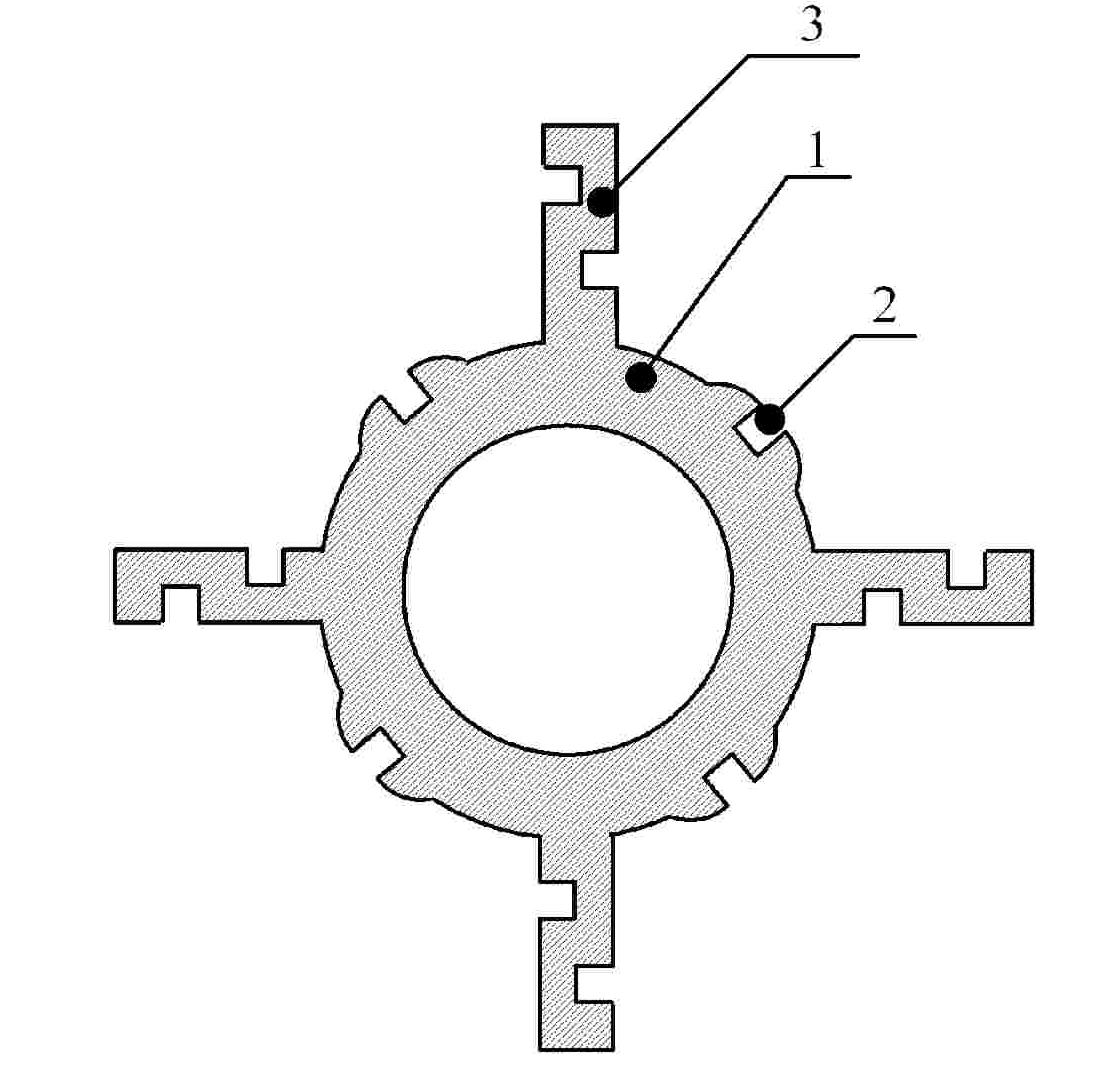

Method for increasing heating speed of material in metal vacuum smelting reduction still and reduction still

InactiveCN101210285AIncrease heat conduction areaFast heatingProcess efficiency improvementMetalUtilization rate

The invention discloses a method for improving material heating speed in a reduction kettle for vacuum metal smelting, which comprises the following steps of: arranging heat conductors (1) on the wall of a reduction kettle for vacuum metal smelting or on a radiation pipe (2) penetrating in the reduction kettle, thus increasing the contact area between the radiation pipe and a reduction material in the reduction kettle, reducing the heat conduction distance between the radiation pipe and the reduction material and improving the heating speed of the reduction material. By arranging the plurality of heat conductors on the kettle wall and on the radiation pipe connected with the reduction kettle, the invention can increase the contact heat conduction area between the radiation pipe and the reduction material in the reduction kettle for vacuum metal smelting, shorten the heat conduction distance from the reduction material and improve the heating speed of the reduction material, thus improving heat utilization rate, achieving energy saving effect, reducing reduction reaction time and improving the production capacity.

Owner:GUIZHOU SHIJI TIANYUAN MINING IND

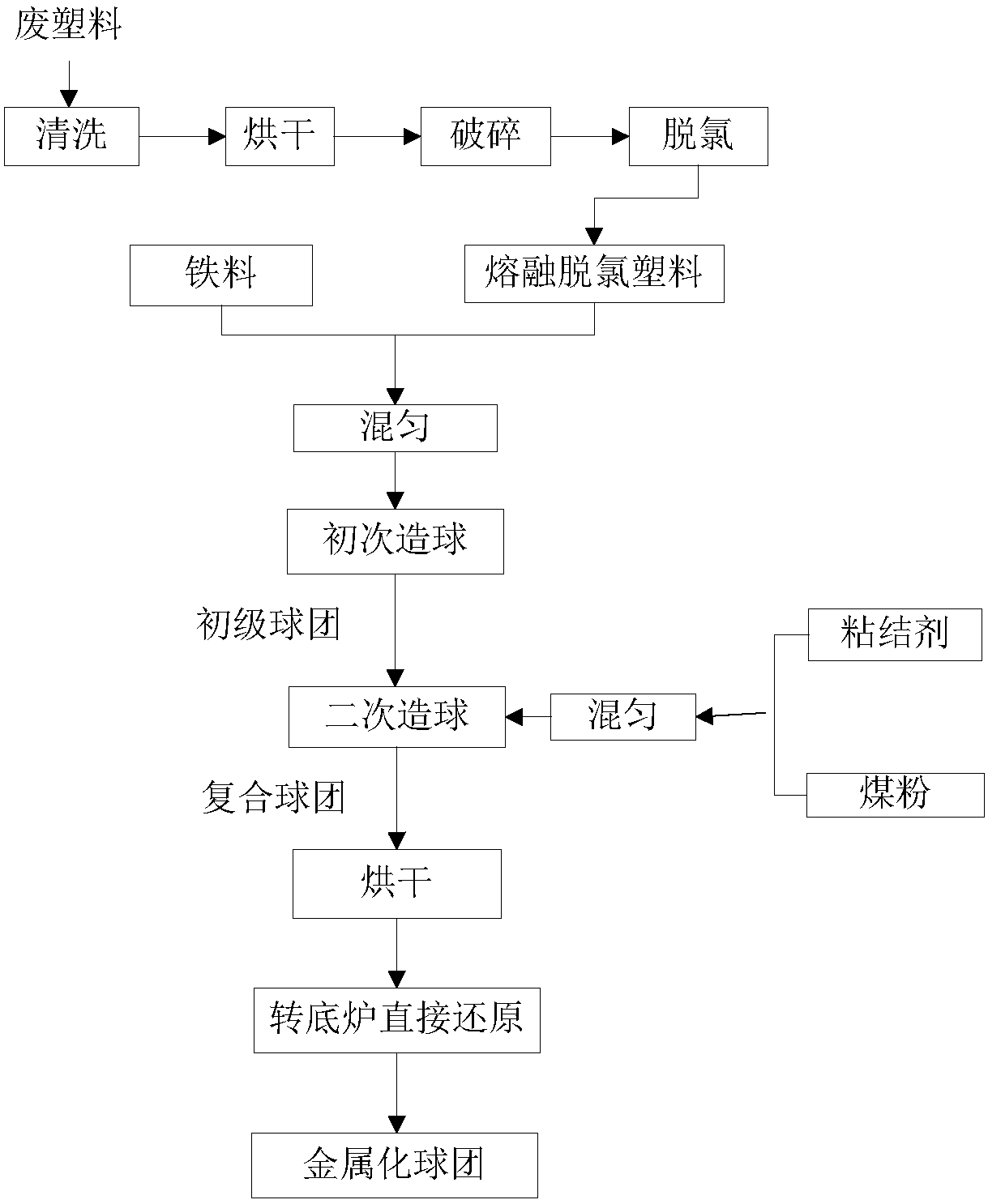

Carbon-containing pellet reducing system and method

The invention discloses a carbon-containing pellet reducing system and method. The carbon-containing pellet reducing system comprises a dechlorination device, a first material mixer, a first pelletizer, a second pelletizer, a pellet drying machine and a rotary hearth furnace, wherein a thermal dechlorination plastic outlet of the dechlorination device is connected with a thermal dechlorination plastic inlet of the first material mixer; a first mixture outlet of the first material mixer is connected with a first mixture inlet of the first pelletizer; a primary pellet outlet of the first pelletizer is connected with a primary pellet inlet of the second pelletizer; a compound pellet outlet of the second pelletizer is connected with a compound pellet inlet of the pellet drying machine; a dry pellet outlet of the pellet drying machine is connected with a dry pellet inlet of the rotary hearth furnace. According to the carbon-containing pellet reducing system and the method which are disclosed by the invention, waste plastic is fully used, the porosity of compound pellets is increased, generation of harmful substances is avoided, the use amount of coal ash is reduced, and the energy consumption of the rotary hearth furnace is reduced.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

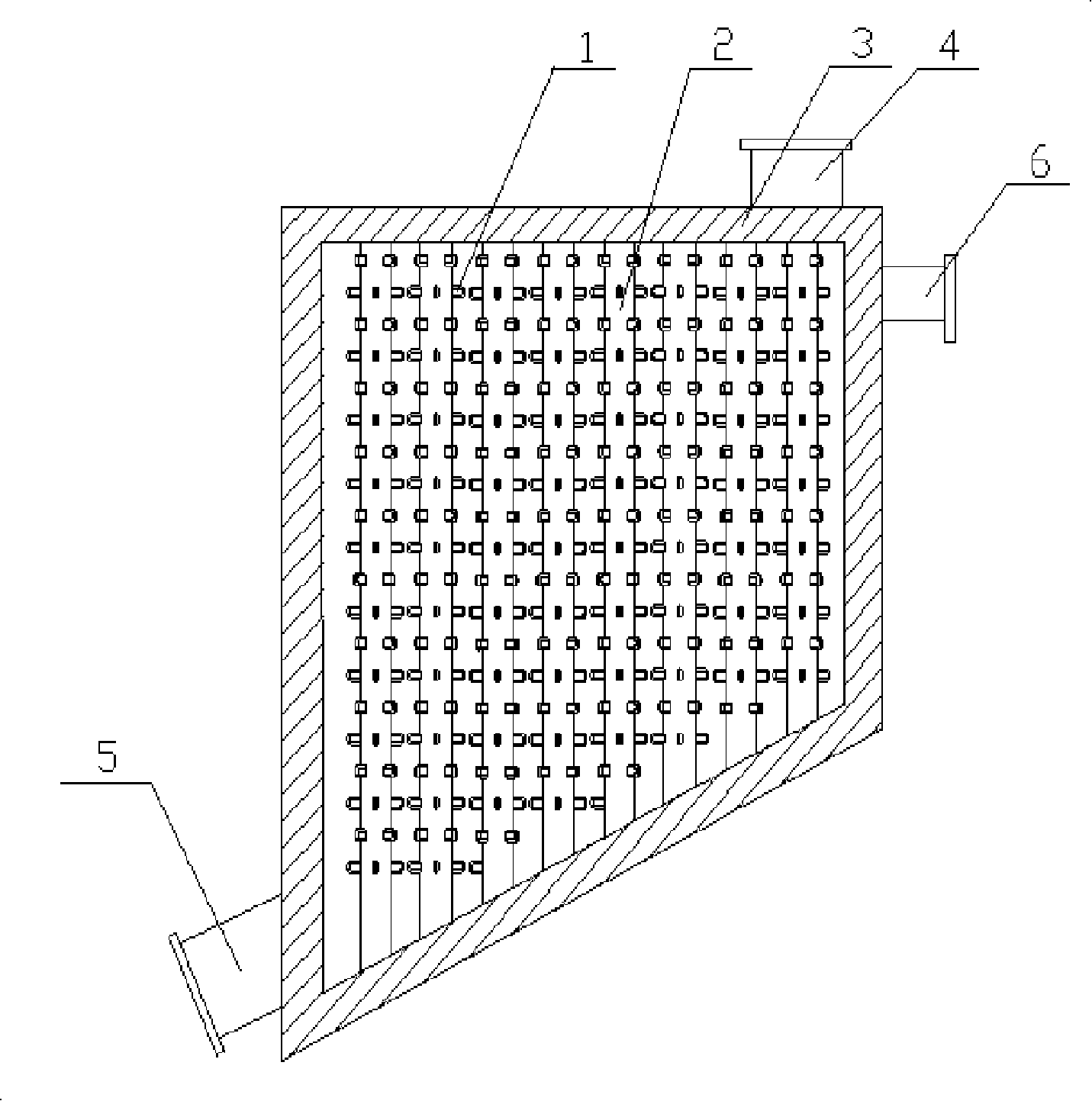

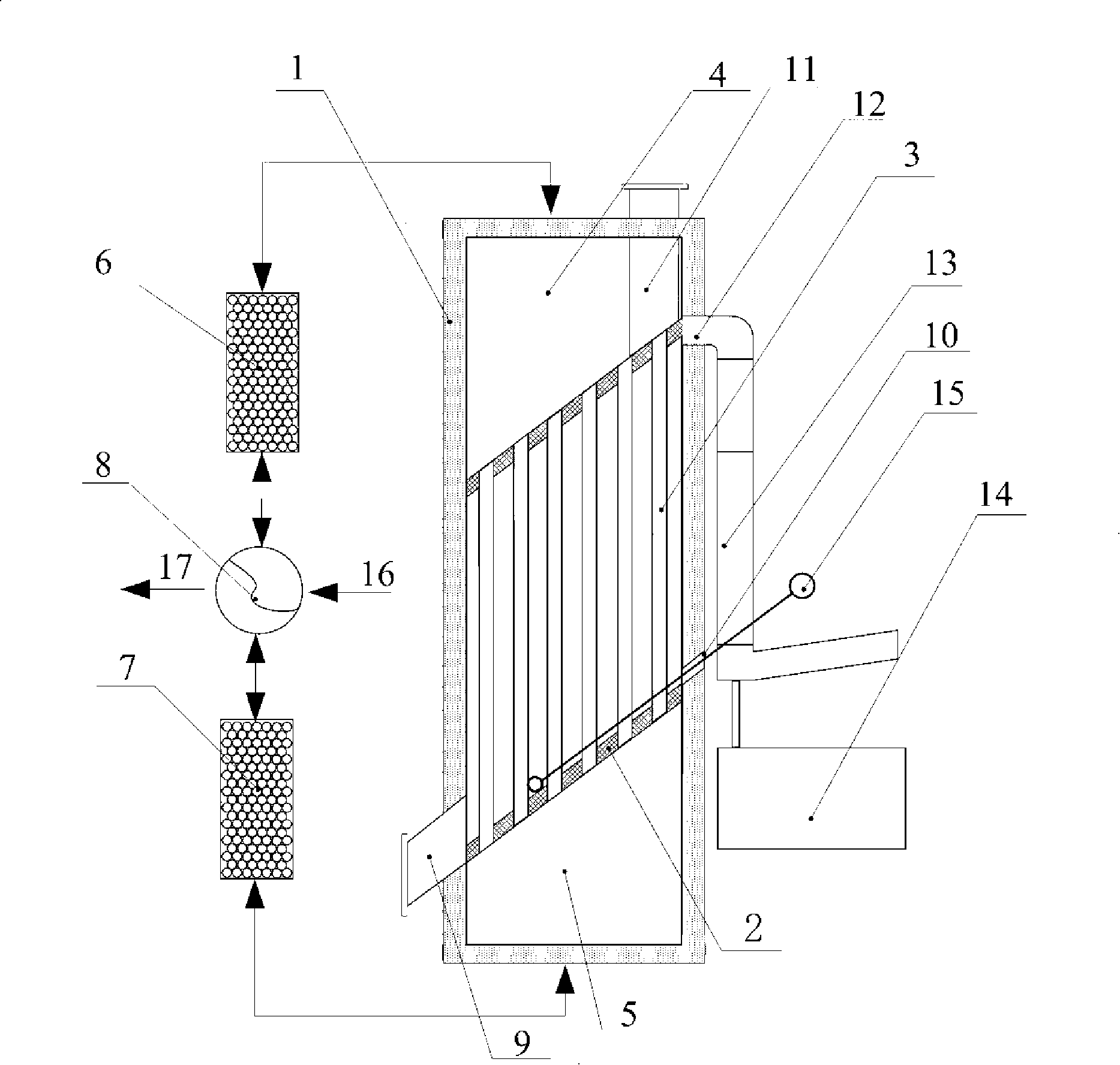

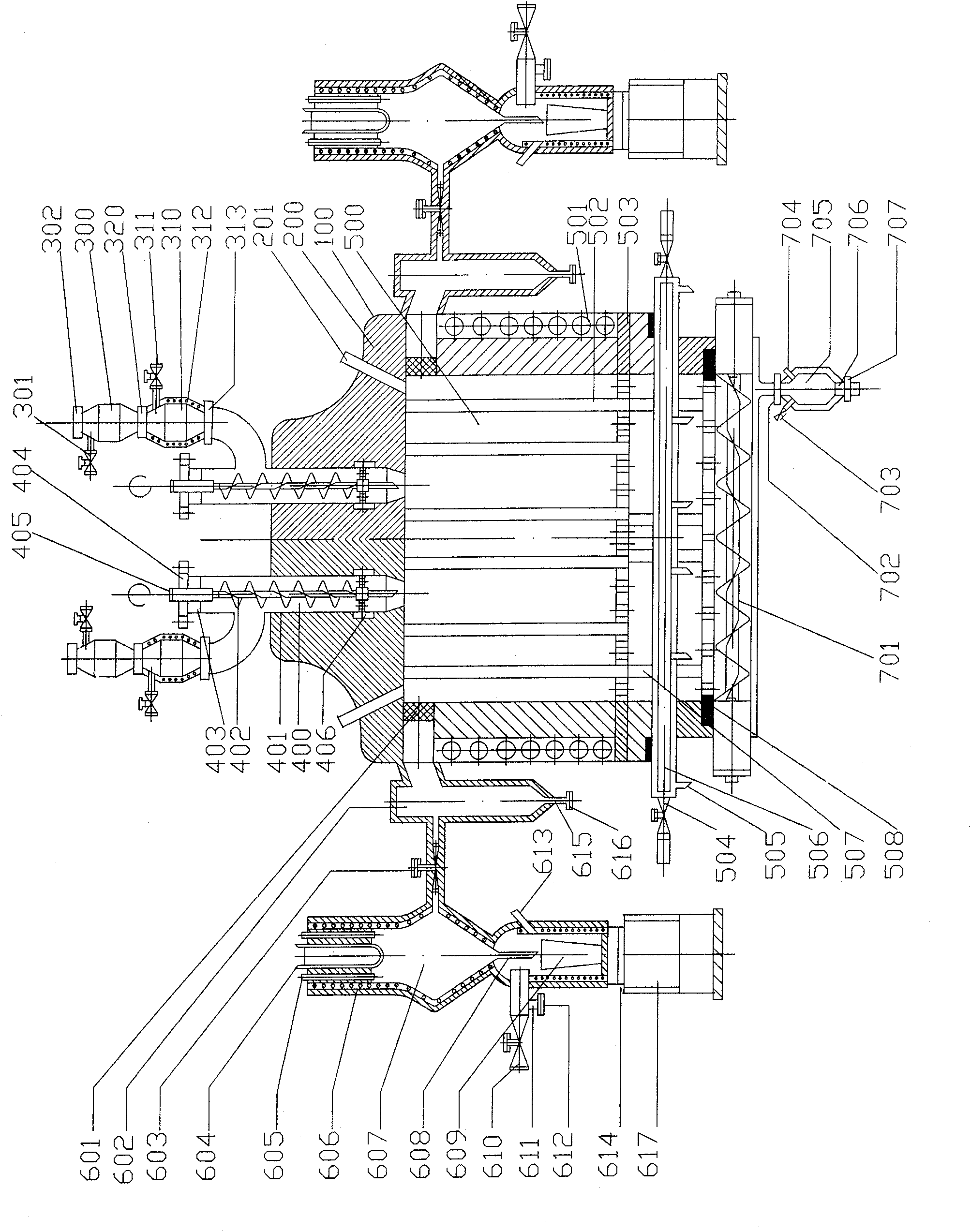

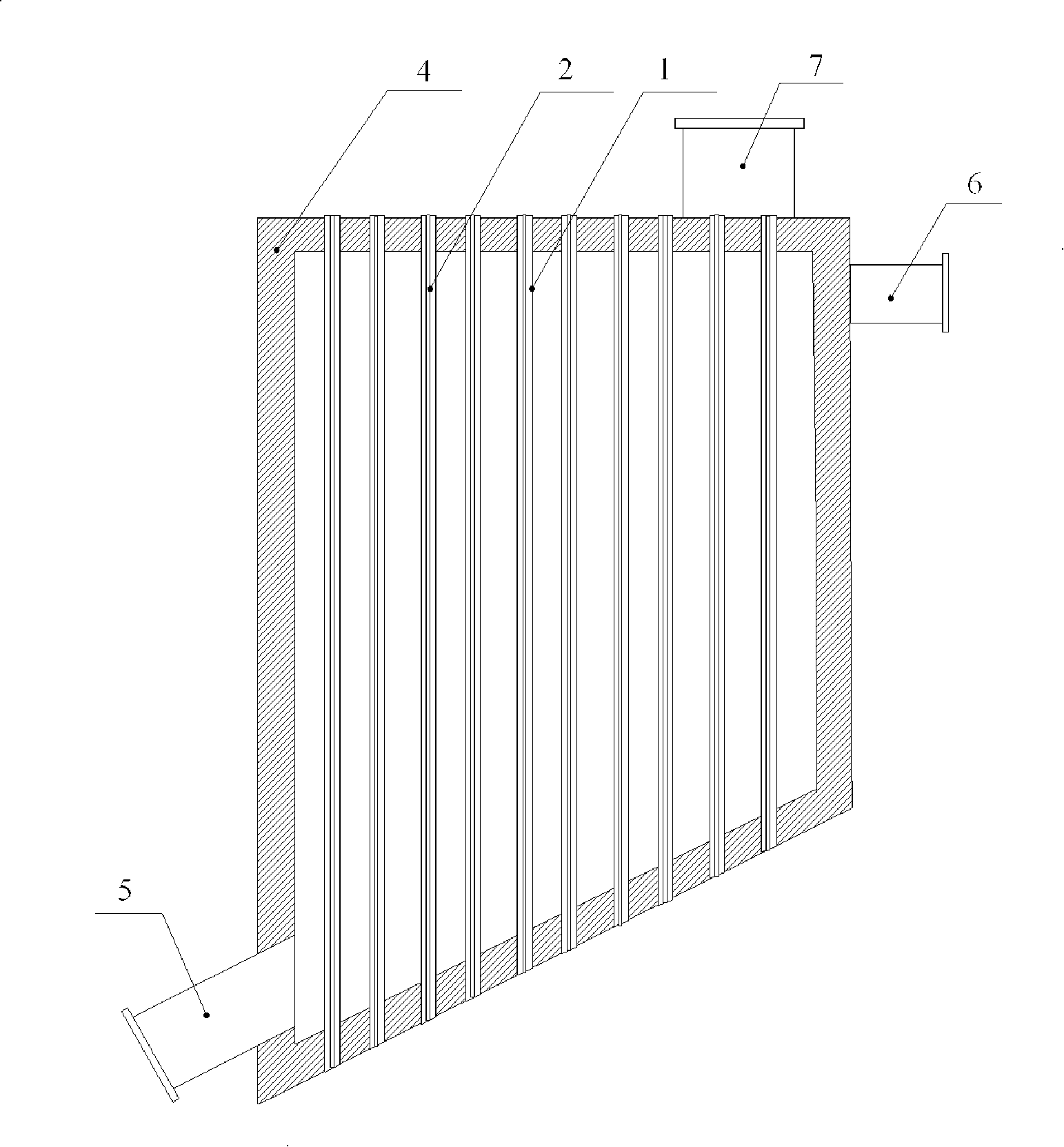

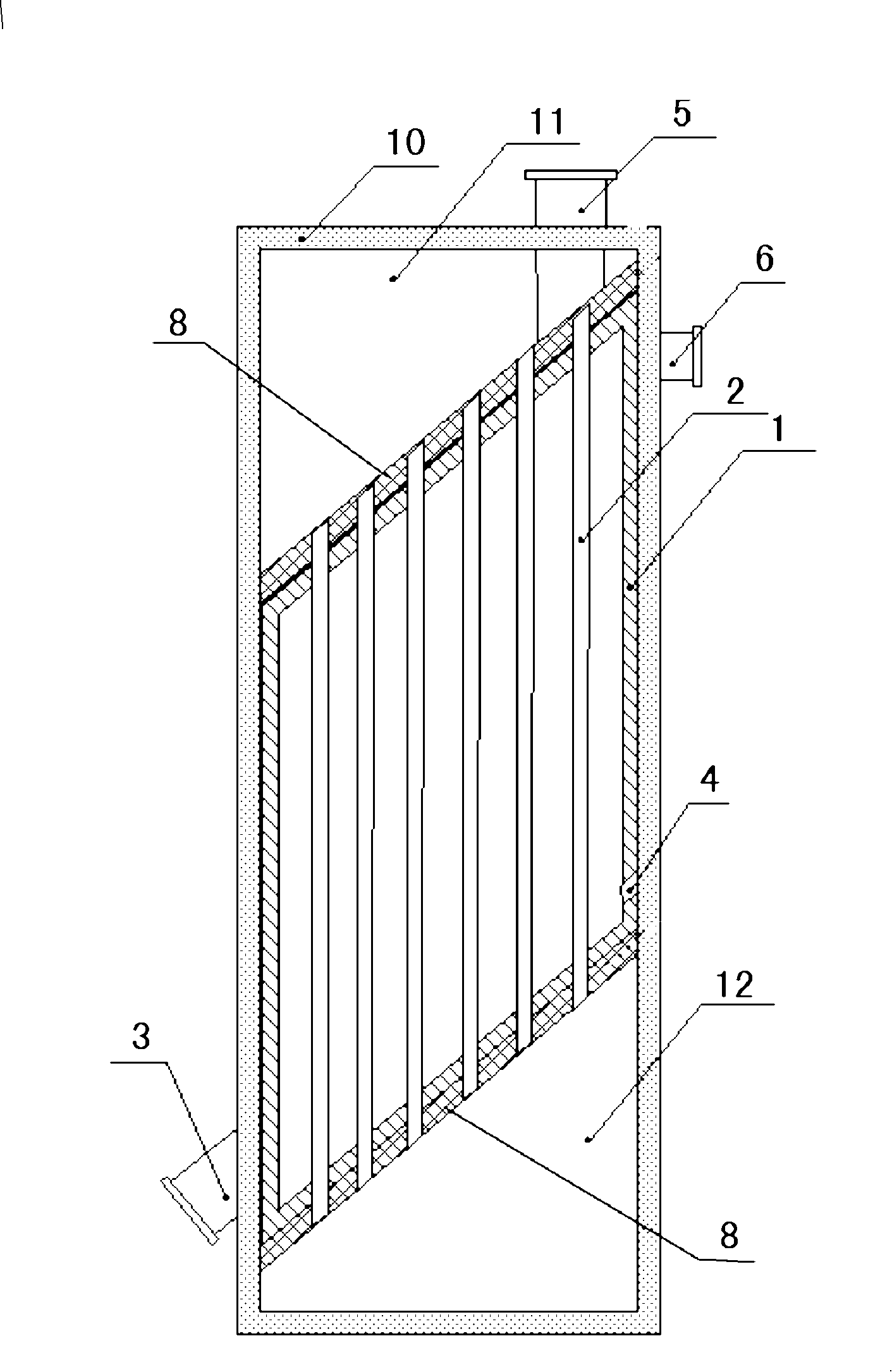

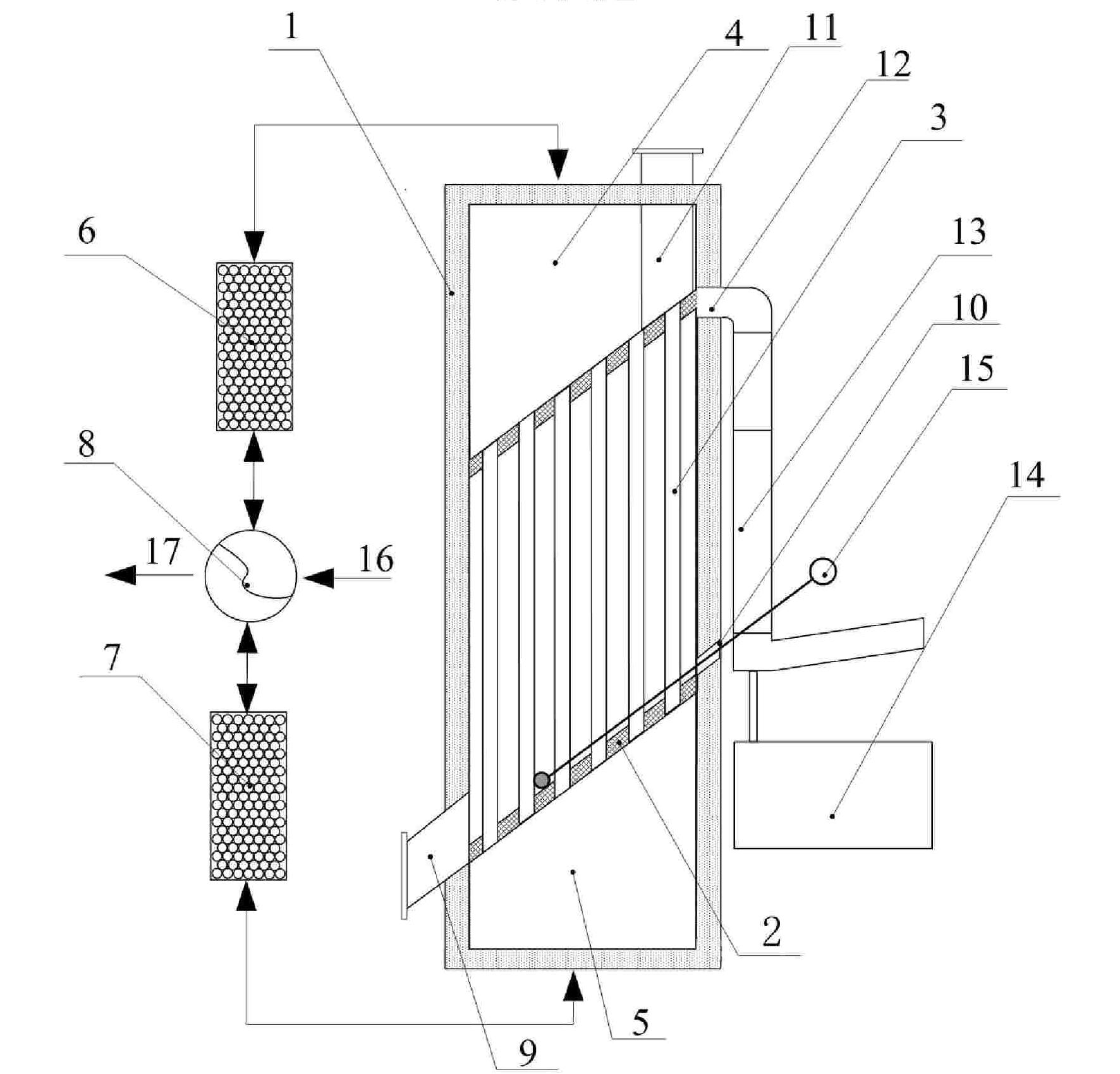

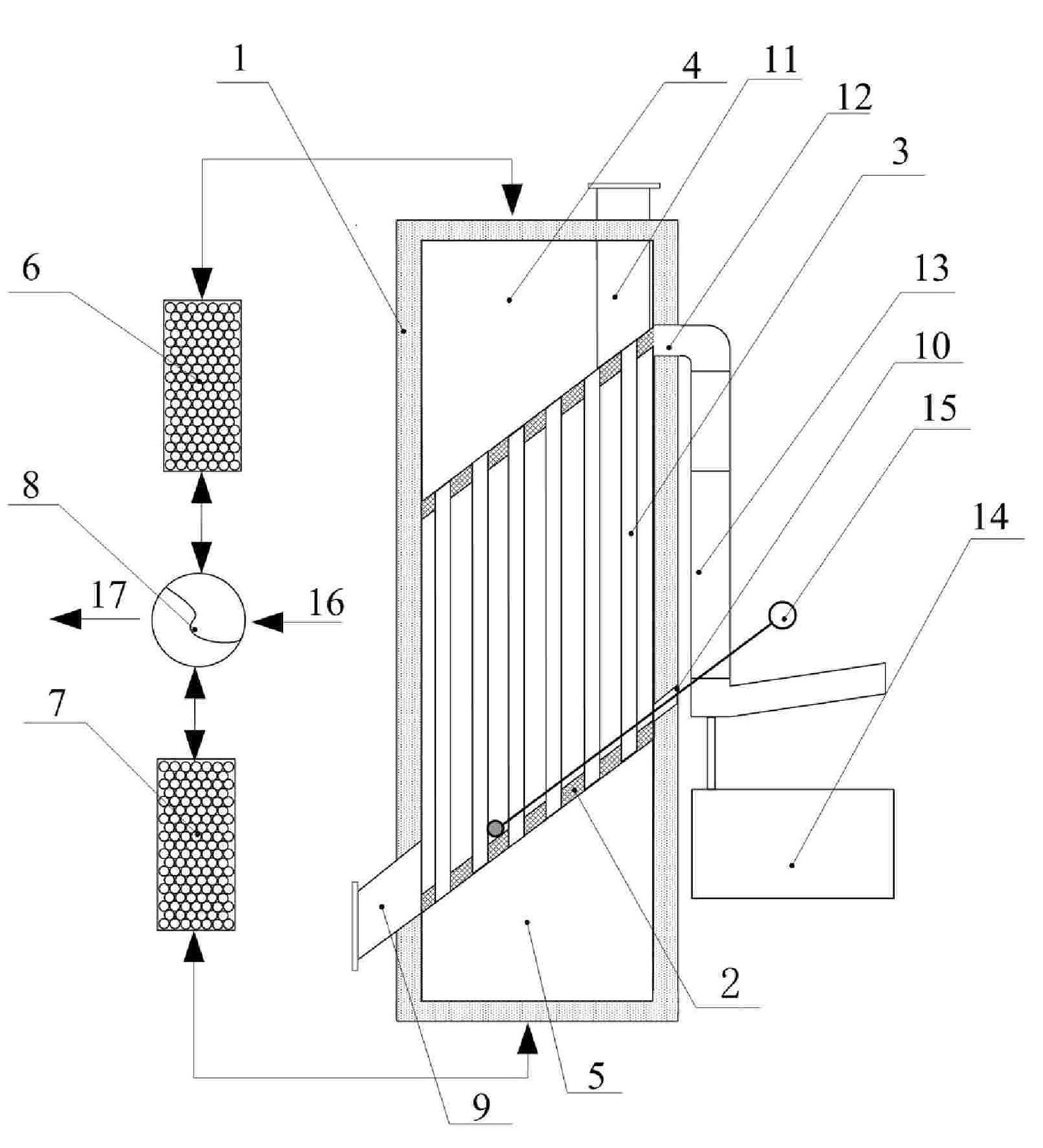

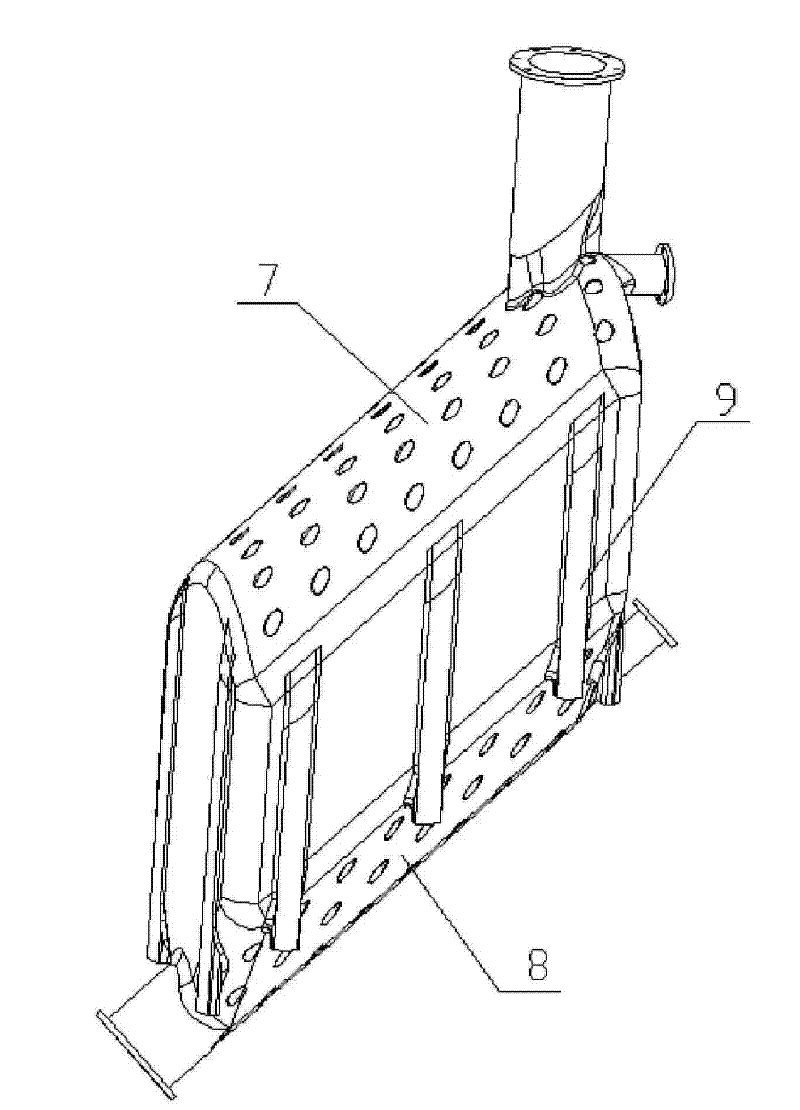

Vacuum metal smelting heat accumulation reducing furnace system

The invention discloses a vacuum regenerative and reduction furnace system for metal smelting, which comprises a reduction furnace (1), a reduction kettle (2), a regenerative burning system and a liquid-state metal collection system. The reduction kettle with a bevel bottom structure is provided with a radiation pipe (3) penetrating in the reduction kettle and is arranged at the middle section of the reduction furnace to divide the reduction furnace into an upper or a left combustion chamber (4) and a lower or a right combustion chamber (5), and the two combustion chambers are communicated with each other through the radiation pipe (3), so that the hot smoke in the combustion chambers can pass through the radiation pipe (3). The two combustion chambers are respectively connected with each other a regenerative combustion system, which is used for storing the heat of smoke discharged from the reduction furnace after heating materials through the radiation pipe and for controlling the alternate combustion of the combustion chambers and the flow direction of the high-temperature gas in the radiation pipe. A reduction material in the reduction kettle produces a metal vapor after reduction reaction, and the metal vapor is collected by the liquid-state metal collection system and is directly cast or conveyed to a refining furnace. The invention has the advantages of high heat utilization rate, good power saving effect, complete combustion and short reduction reaction time.

Owner:GUIZHOU SHIJI TIANYUAN MINING IND

Process for smelting magnesium by microwave heating Pidgeon process

The invention discloses a magnesium reduction process through a micro-wave heating silicothermic method; the process comprises the following steps: 1. dolomite calcinations: the dolomite is heated to 1100 DEG C to 1200 DEG C and becomes calcined dolomite; 2. the calcined dolomite, silicon nitride powder and fluorite powder are weighed, mixed, milled and then pressed into a ball which meets technological requirements; 3. the ball is put into a closed non-metal reduction tank of a micro-wave heating oven to be heated under 1000 DEG C to 1200 DEG C, so that the magnesium compound in the ball reacts with the silicon nitride powder; 4. the vacuum degree of the closed non-metal reduction tank is kept to be 13.3Pa or higher for 4h to 6h; magnesium vapor is condensed in a condenser and becomes crude magnesium; 5. the crude magnesium is heated, melted and refined by solvent, to obtain refined magnesium; 6. acid washing and the like. The method evenly and quickly heats in the principle of micro-wave heating with high heating efficiency, is easy to be controlled, saves production cost, is safe, environment protective and harmless.

Owner:重庆科健冶金材料有限公司

Induction heating continuous magnesium-smelting system and continuous magnesium-smelting technique

The invention discloses a set of induction heating continuous magnesium smelting device and continuous magnesium smelting process. The device includes a continuous feeding device, an induction heating reaction chamber, a magnesium steam condensing device and a continuous slagging device; wherein, the feeding device is composed of a silo and a screw feeding mechanism, and the reaction chamber is composed of an induction heating coil, a heating element, a belt The baffle plate of the hole and the slag cooling device are composed. The condensing device is composed of a baffle plate with a mesh structure, a dust settling chamber, and a magnesium steam condensing chamber. The continuous slag discharge device includes a spiral slag pushing mechanism and a slag bin. The continuous magnesium smelting process includes the continuous push of the reaction charge into the reaction chamber, the continuous condensation of magnesium vapor, and the discharge of liquid magnesium, as well as the continuous entry of reaction slag into the slag bin and slag discharge. The invention has high thermal energy utilization rate and can realize continuous production of metal magnesium at low cost.

Owner:CENT SOUTH UNIV

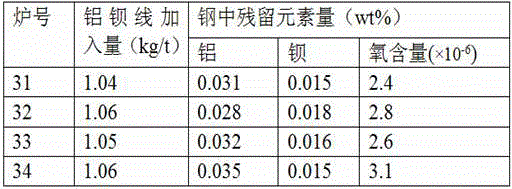

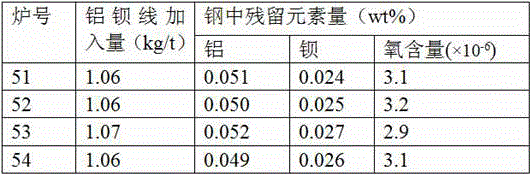

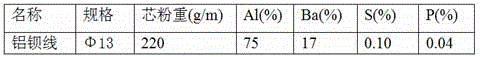

A kind of aluminum-barium wire and its production process

Owner:河南鹏钰集团有限公司

Electric heating method for reduction pot and reduction pot used for the same

The invention discloses an electric heating method for a reducing pot and the reducing pot used by the method, wherein, a heat conductor is arranged inside a pot body of the reducing pot; an electrical bar is embedded into the heat conductor; heat generated after the electrical bar is electrified is conducted through the heat conductor, and reducing materials in the reducing pot are heated. The reducing pot (1) takes the structure of a cylinder, wherein, a charging hole is arranged on one end of the reducing pot; the other end of the reducing pot is closed or provided with a slag notch; the heat conductor (2) is arranged inside the reducing pot (1); the heat conductor (2) and the inner wall of the reducing pot (1) are integrated into a whole or the heat conductor (2) is a movable structure which is closely embedded and sleeved into the reducing pot (1); shape and set mode of the heat conductor (2) are random; the electrical bar (3) is embedded into the heat conductor (2). The invention can be used for auxiliary heating of the prior heating method and also can be completely used for electric heating, and has the advantages of great reduction of reaction time of reducing materials, improvement of production rate per unit time, reduction of production cost and capability of reducing environmental pollution.

Owner:GUIZHOU SHIJI TIANYUAN MINING IND

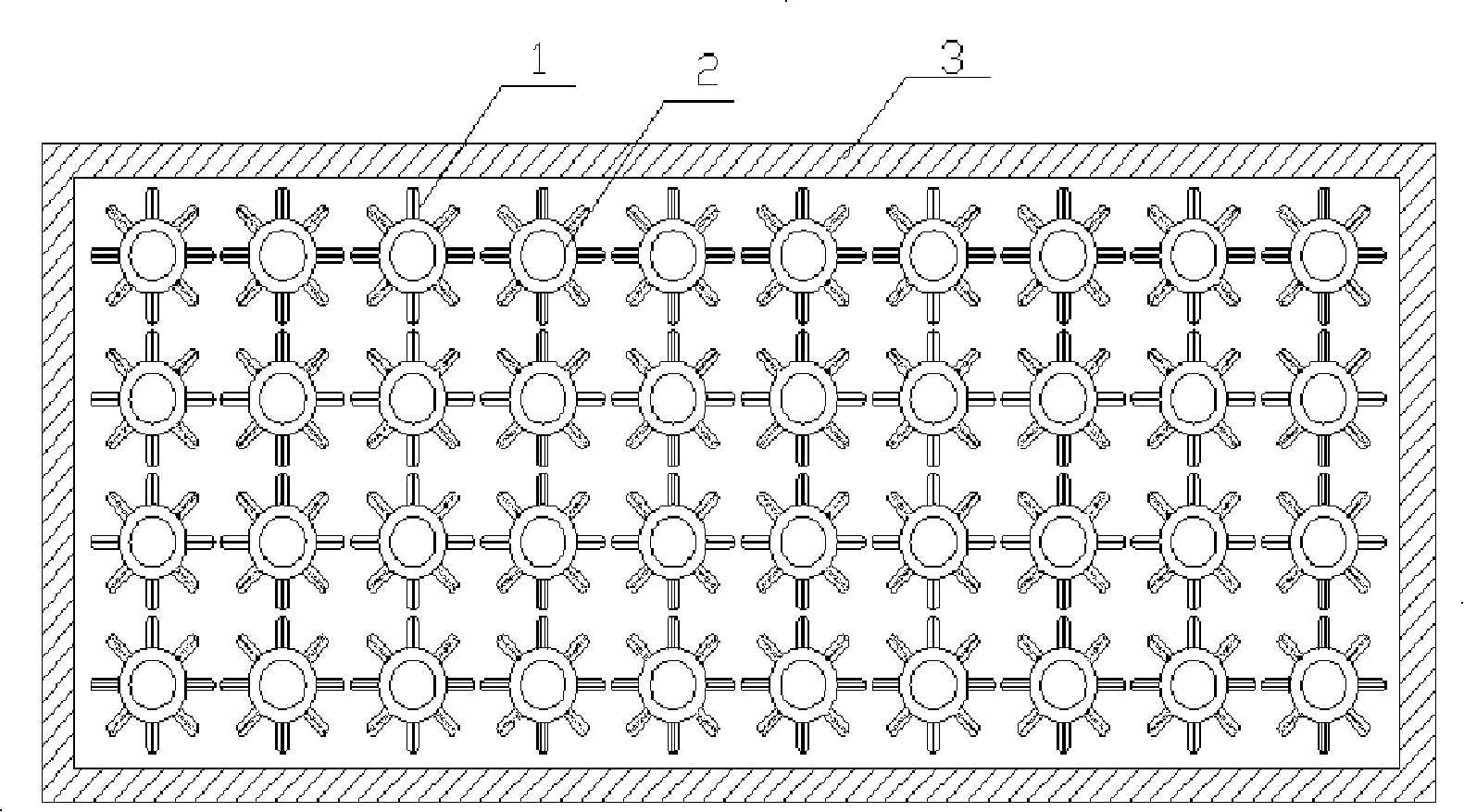

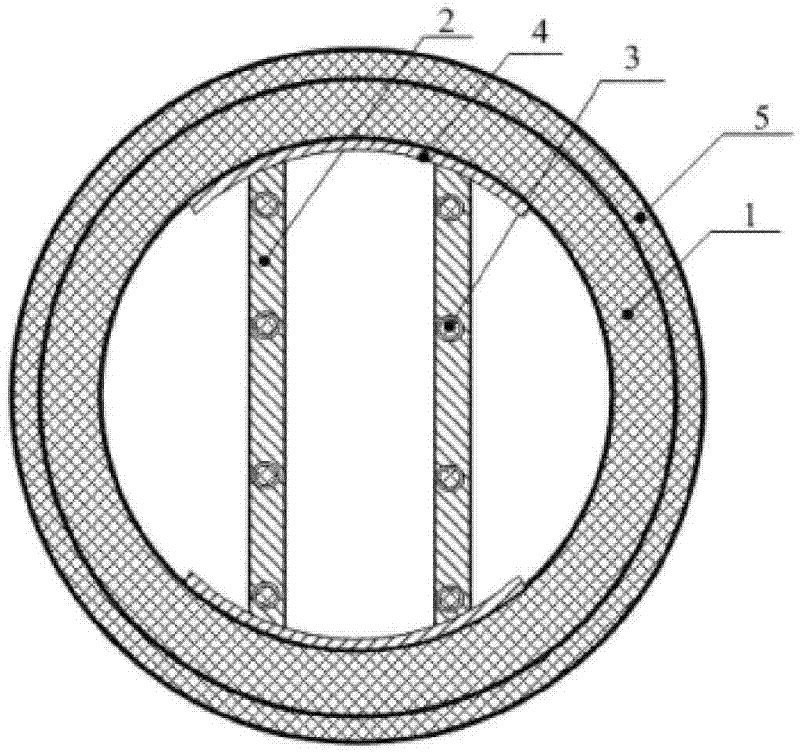

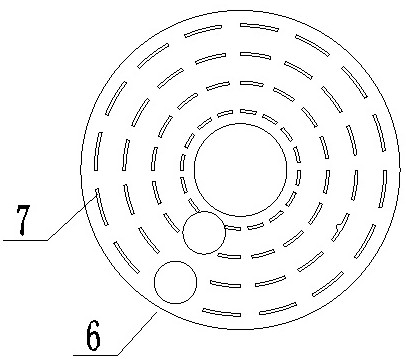

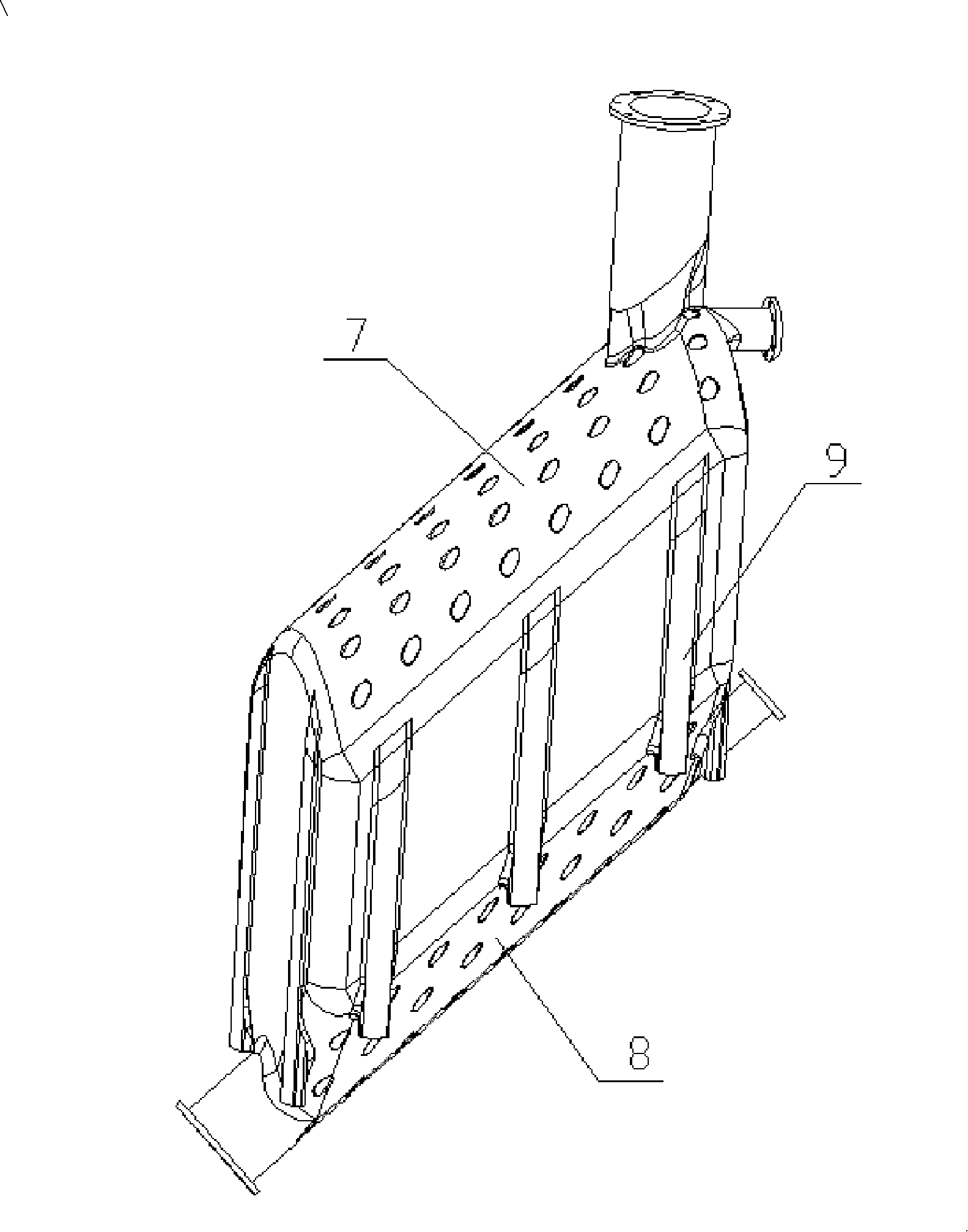

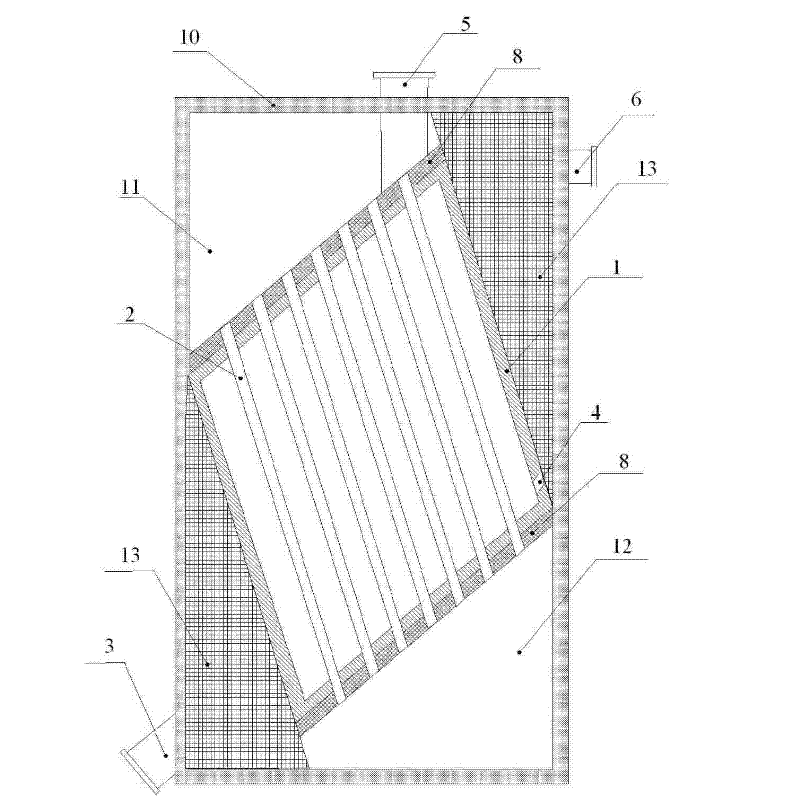

Method for eliminating local partial pressure in vacuum smelting reduction still and used reduction still

The invention discloses a method for eliminating local differential pressure in a vacuum smelting reduction kettle, which comprises the following steps of: arranging a metal vapor vacuum pumping hole or a crystallizer interface on the reduction kettle; and disposing a metal vapor guide channel in the reduction kettle, so that the metal vapor can escape into a metal collector or the crystallizer along the guide channel. The reduction kettle (4) adopted by the method has a rectangular or round box body with a bevel bottom structure and has a bottom inclined by an angle of 30 to 60 DEG. The metal vapor vacuum pumping hole (6) is provided on the kettle body on the highest point side on the top of the reduction kettle, an air guide groove (2) pointing to the metal vapor vacuum pumping hole is provided on the inner wall of the reduction kettle, a radiation pipe (1) with the air guide groove and penetrating in the kettle is vertically or horizontally arranged in the reduction kettle, or an air guide groove is provided on a heat conductor arranged on the radiation pipe. The invention can effectively eliminate local differential pressure in the vacuum smelting reduction kettle to successfully guide the metal vapor produced by reduction reaction, thus holding the pressure environment in the reduction kettle and ensuring the smooth execution of the reduction reaction.

Owner:GUIZHOU SHIJI TIANYUAN MINING IND

A method for the continuous preparation of samarium metal by direct thermal reduction

A method for continuously preparing samarium metal by direct thermal reduction, belonging to the technical field of non-ferrous metal metallurgy. The preparation method of the present invention specifically includes: mixing Sm2O3, Al, CaO or MgO, where the reducing agent is Al, which can be replaced by Ca or a Si-Fe alloy with a Si mass content of 75%. After batching, the pellets are pelletized. The high-temperature reduction reaction is carried out in a flowing inert gas or nitrogen atmosphere, and finally the high-temperature samarium vapor carried out by the flowing inert carrier gas or nitrogen in the high-temperature reduction furnace is condensed to obtain samarium metal. The method of the present invention adopts "relative vacuum" means, cancels the vacuum system and the vacuum reduction tank, realizes the continuous production of samarium metal, shortens the reduction cycle, improves production efficiency, and the recovery rate of samarium metal can reach more than 97%; it can It is a new, energy-saving and green process for preparing samarium metal at low cost, with significantly lower consumption. It is also simple to operate, has simpler equipment and lower requirements, reducing equipment investment and operating costs.

Owner:NORTHEASTERN UNIV LIAONING

Air cooling device for large cover of titanium sponge I-type reactor

PendingCN114592134AImprove air cooling efficiencyIncrease the feeding speedProcess efficiency improvementEngineeringTitanium

The invention relates to an air cooling device for a large cover of a titanium sponge I-type reactor, which comprises a cover plate, air cooling areas are distributed on the left side and the right side of the cover plate, one air cooling area is provided with an air inlet, the other air cooling area is provided with an air outlet, the middle part of the cover plate is provided with a feed port, an air distribution plate is arranged below the cover plate through a connecting plate, and the air distribution plate is provided with an air outlet. The air inlet and the air outlet penetrate through the air distribution plate, the air inlet is located above the air distribution plate, air distribution plate outlets are evenly formed in the air distribution plate, a guide plate is vertically arranged between the upper side of the air distribution plate and the cover plate on the lower side of the air inlet, and a temperature measuring opening is formed in the bottom of the cover plate. The device can monitor and reduce the surface temperature of the large cover, avoids high-temperature deformation, improves the feeding speed, shortens the reduction reaction time, and is high in safety coefficient.

Owner:河南龙佰智能装备制造有限公司

Reduction kettle

InactiveCN101221016ARaise the reaction temperatureReduce manufacturing costMuffle furnacesRetort furnacesVacuum pumpingSlag

The invention discloses a reduction kettle, comprising a kettle body (1) which appears as a box or cylinder structure. The bottom or top part of the kettle body is arranged in an inclined form. Radiation pipes (2) arranged to be parallel with both the front and back side walls of the reduction kettle or in a horizontal array form run through the kettle body. A slag draining port (3) is arranged on the side kettle body of the lowest point of the kettle bottom part, and an assistant slag draining port (4) is arranged on the kettle body, namely on a position where the highest point of the kettle bottom is opposite to the slag draining port. A charging inlet (5) is arranged on the highest point of the top part of the kettle body, and a metal steam vacuum adsorbing port (6) is arranged on the side kettle body of the highest point of the kettle body top. The invention can reduce reduction action time, enhance manufacturing capability, and also can reduce energy cost. The invention prolongs the service life of reduction kettle. The design of the invention leads slag draining to be easier and can enhance slag draining efficiency and reduce heat energy loss. The collection of the metal steam becomes convenient and the purity of the products is high.

Owner:GUIZHOU SHIJI TIANYUAN MINING IND

Vacuum metal smelting heat accumulation reducing furnace system

The invention discloses a vacuum regenerative and reduction furnace system for metal smelting, which comprises a reduction furnace (1), a reduction kettle (2), a regenerative burning system and a liquid-state metal collection system. The reduction kettle with a bevel bottom structure is provided with a radiation pipe (3) penetrating in the reduction kettle and is arranged at the middle section ofthe reduction furnace to divide the reduction furnace into an upper or a left combustion chamber (4) and a lower or a right combustion chamber (5), and the two combustion chambers are communicated with each other through the radiation pipe (3), so that the hot smoke in the combustion chambers can pass through the radiation pipe (3). The two combustion chambers are respectively connected with eachother a regenerative combustion system, which is used for storing the heat of smoke discharged from the reduction furnace after heating materials through the radiation pipe and for controlling the alternate combustion of the combustion chambers and the flow direction of the high-temperature gas in the radiation pipe. A reduction material in the reduction kettle produces a metal vapor after reduction reaction, and the metal vapor is collected by the liquid-state metal collection system and is directly cast or conveyed to a refining furnace. The invention has the advantages of high heat utilization rate, good power saving effect, complete combustion and short reduction reaction time.

Owner:GUIZHOU SHIJI TIANYUAN MINING IND

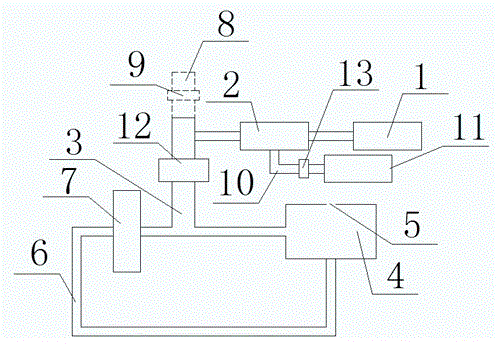

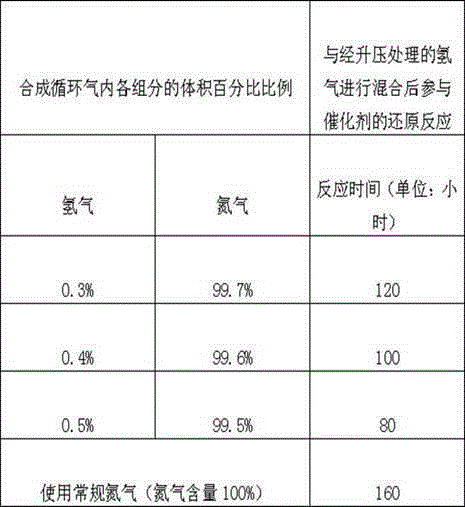

Reduction method of methanol synthesis catalyst

InactiveCN104857997AIncrease the speed of the reduction reactionSpeed up the reduction reaction timeCatalyst activation/preparationReaction timingChemistry

The invention discloses a reduction method of methanol synthesis catalyst. The reduction method comprises the following steps: conveying hydrogen from a gas storage tank of a hydrogen drainage and irrigation vehicle to a hydrogen depressurizing valve of the hydrogen drainage and irrigation vehicle to depressurize; conveying hydrogen after the depressurizing treatment to a synthesis gas compressor through a general hydrogen supplementing pipe to boost; conveying the synthesis circular gas containing hydrogen and nitrogen to a nitrogen inlet of the synthesis gas compressor so as to mix with the hydrogen after the boosting treatment, wherein the volume percent of every component in the synthesis circular gas is: 0.3-0.5% of hydrogen and 99.5-99.7% of nitrogen; conveying the mixed gas to a catalyst bed layer of a methanol synthesis reactor through a gas conveying pipe to participate in the reduction reaction. By adopting the technical scheme of the invention, the reduction reaction speed is accelerated, the reaction time is saved, and working efficiency is improved; the system is completely and stably ran without a series of assistant systems and the gas required by reduction is supplied, and thus cost is saved.

Owner:LINHUAN COKING

Method for preparing 2-hydrazinobenzoic acid hydrochloride

InactiveCN101337909AShorten the reduction reaction timeReduce manufacturing costHydrazine preparationBenzeneSodium metabisulfite

The invention relates to a method for preparing 2-carboxyl phenyl hydrazine, which comprises the following steps: (1) 2-aminobenzoic acid is used as starting material, and benzene diazonium chloride is prepared through diazo reaction; (2) benzene diazonium chloride obtained from the step (1) is utilized to further prepare reduction products through the reduction reaction under the action of a reducing agent; (3) the reduction products obtained from the step (2) undergoes the hydrolysis reaction under the action of hydrochloric acid to generate 2-carboxyl phenyl hydrazine, more particularly, sodium metabisulfite is used as the reducing agent in the reduction reaction in the step (2), and the reaction is performed under the condition that the temperature is 15 to 25 DEG C and the pH value is 7 to 9. The method has higher yield, and can shorten the production period and reduce the manufacture cost at the same time.

Owner:太仓市华联化工实业有限公司

Preparation process for 4-trifluoromethoxy

InactiveCN102531951AShorten the reduction reaction timeReduce manufacturing costHydrazine preparationProcarbazine HydrochlorideChloride

The invention relates to a preparation process for 4-trifluoromethoxy. The preparation process comprises the followings steps of: (1) undergoing a nitridation reaction on o-toluidine serving as a starting raw material to obtain benzene diazonium chloride; (2) further undergoing a reduction reaction on the benzene diazonium chloride obtained in the step (1) under the action of a reducing agent to obtain a reduction product; and (3) undergoing a hydrolysis reaction on the reduction production obtained in the step (2) under the action of hydrochloric acid to generate 2-procarbazine hydrochloride, wherein particularly, in the step (2), the reduction reaction is undergone by taking sodium pyrosulfite as a reducing agent under the condition that the temperature is 15-25 DEG C and the pH is 7-9. A method disclosed by the invention has high yield, production period can be shortened, and production cost is lowered simultaneously.

Owner:陆士昌

Rapid reduction process of laterite nickel ore rotary kiln

Owner:CENT SOUTH UNIV

Method for increasing heating speed of material in metal vacuum smelting reduction still and reduction still

InactiveCN101210285BIncrease heat conduction areaFast heatingProcess efficiency improvementThermodynamicsEngineering

The invention discloses a method for improving material heating speed in a reduction kettle for vacuum metal smelting, which comprises the following steps of: arranging heat conductors (1) on the wall of a reduction kettle for vacuum metal smelting or on a radiation pipe (2) penetrating in the reduction kettle, thus increasing the contact area between the radiation pipe and a reduction material in the reduction kettle, reducing the heat conduction distance between the radiation pipe and the reduction material and improving the heating speed of the reduction material. By arranging the plurality of heat conductors on the kettle wall and on the radiation pipe connected with the reduction kettle, the invention can increase the contact heat conduction area between the radiation pipe and the reduction material in the reduction kettle for vacuum metal smelting, shorten the heat conduction distance from the reduction material and improve the heating speed of the reduction material, thus improving heat utilization rate, achieving energy saving effect, reducing reduction reaction time and improving the production capacity.

Owner:GUIZHOU SHIJI TIANYUAN MINING IND

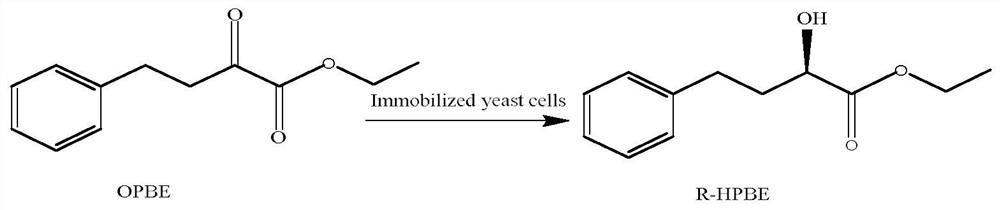

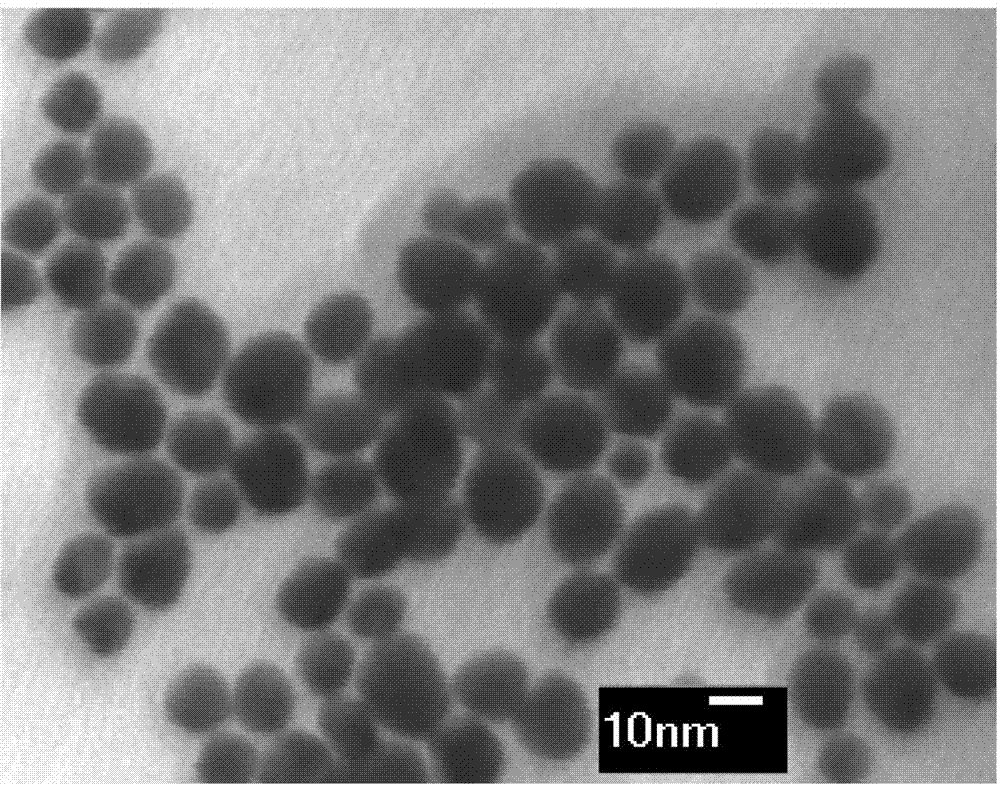

Magnetic immobilization of yeast cells and its application in the preparation of ethyl (r)-2-hydroxy-4-phenylbutyrate

ActiveCN111218441BImprove stabilityEnhanced mass transferMaterial nanotechnologyFerroso-ferric oxidesMother cellsPhenyl group

The invention discloses a magnetically immobilized yeast cell and its application in the preparation of (R)-2-hydroxy-4-phenylbutyrate ethyl ester. The magnetically immobilized yeast cell is made of lysine-modified magnetic nano The particles are mixed with the yeast cell solution, fixed in a shaker at 20°C-40°C, 130-170r / min for 2-6h, after the reaction, magnetically separated, the precipitate is washed with deionized water, and freeze-dried to obtain magnetically immobilized yeast cell. The immobilization method of the invention effectively improves the stability of the yeast cells and enhances the tolerance of the cells to the substrate solution. Under the action of an external magnetic field, the magnetically immobilized cells are easier to separate from the reaction system, which is beneficial to the separation and extraction of products and simplifies the process flow. Appropriate magnetic field frequency and magnetic field strength in the alternating magnetic field reactor can effectively enhance the mass transfer process of the reaction system, significantly shorten the reduction reaction time, and then improve the biotransformation efficiency.

Owner:ZHEJIANG UNIV OF TECH

a reduction kettle

InactiveCN101221016BRaise the reaction temperatureReduce manufacturing costMuffle furnacesRetort furnacesThermal energyVacuum pumping

Owner:GUIZHOU SHIJI TIANYUAN MINING IND

Method for eliminating local partial pressure in vacuum smelting reduction still and used reduction still

Owner:GUIZHOU SHIJI TIANYUAN MINING IND

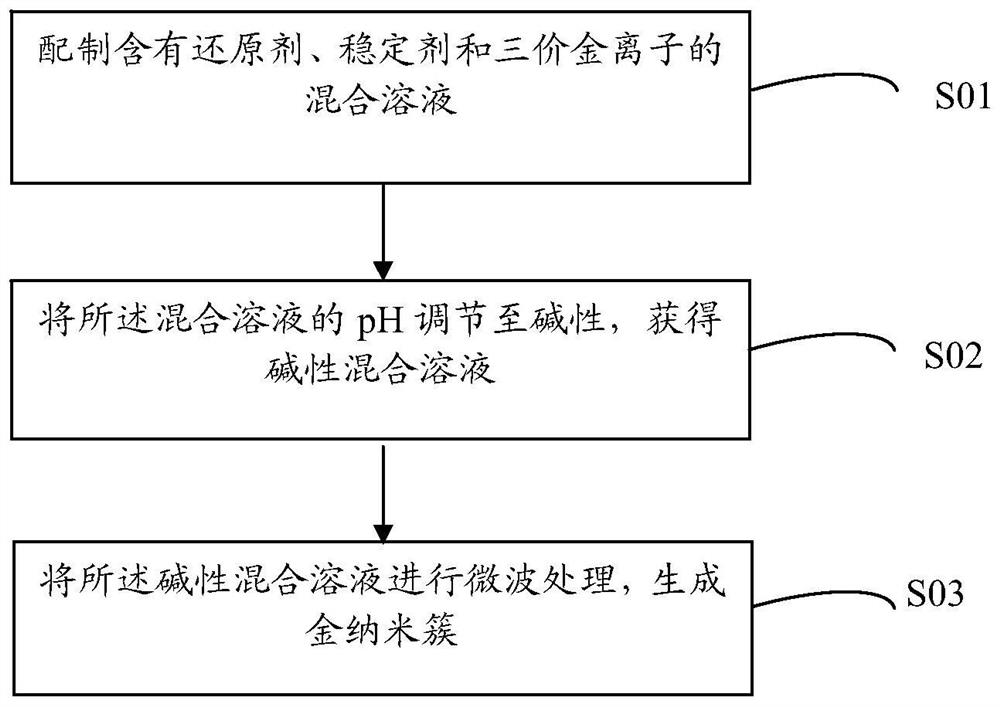

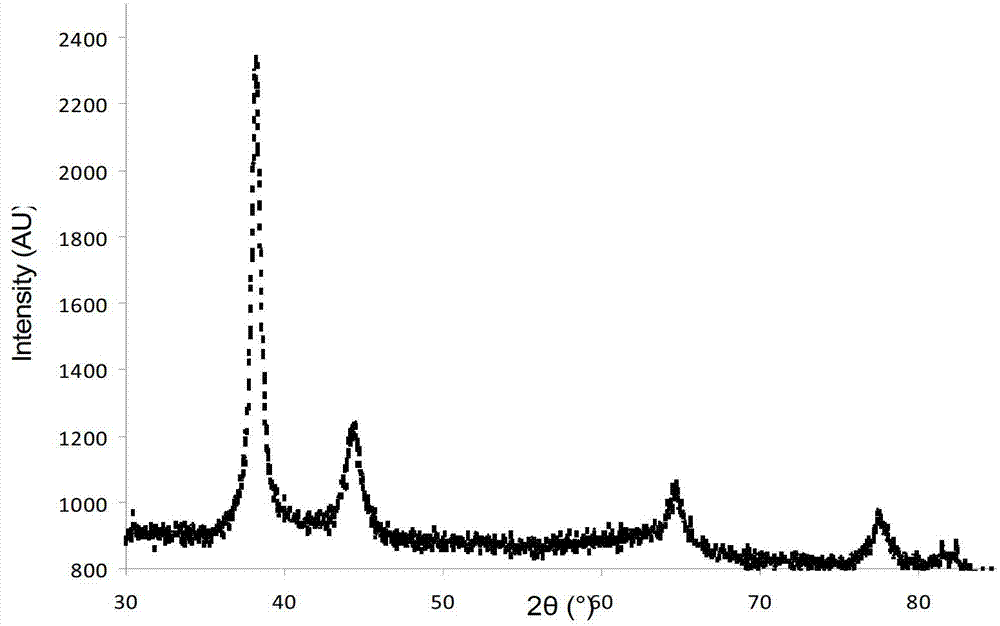

Preparation method of gold nano-clusters

PendingCN112170859AAvoid reunionEvenly heatedMaterial nanotechnologyTransportation and packagingReducing agentAnalytical chemistry

The invention provides a preparation method of gold nano-clusters. The preparation method of the gold nano-clusters comprises the following steps that a mixed solution containing a reducing agent, a stabilizing agent and trivalent gold ions is prepared; the pH value of the mixed solution is adjusted to be alkaline to obtain an alkaline mixed solution; and the alkaline mixed solution is subjected to microwave treatment to generate the gold nano-clusters. According to the preparation method of the gold nano-clusters, microwave treatment is carried out on the alkaline mixed solution, the reduction efficiency and the synthesis efficiency of the alkaline mixed solution can be effectively improved, and the reduction reaction time is remarkably shortened. In addition, the microwave treatment canalso play a synergistic effect with the stabilizing agent so that the consistency of the generated gold nano-cluster products can be better controlled, and the gold nano-clusters are effectively prevented from being agglomerated. Furthermore, the alkaline mixed solution can be uniformly heated through microwave treatment, and the method is suitable for synthesis of the gold nano-clusters with large sample amount.

Owner:SHENZHEN TECH UNIV

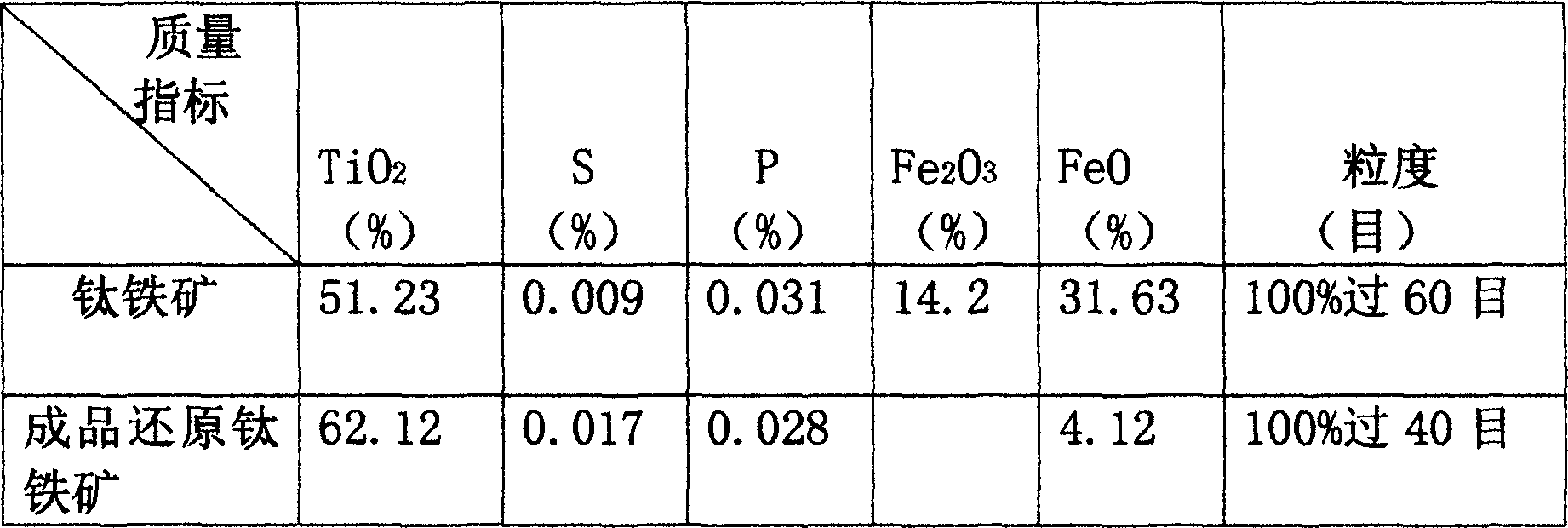

Technology for producing and reducing ilmenite using rotary kiln

Owner:广西粤桥新材料科技有限公司 +1

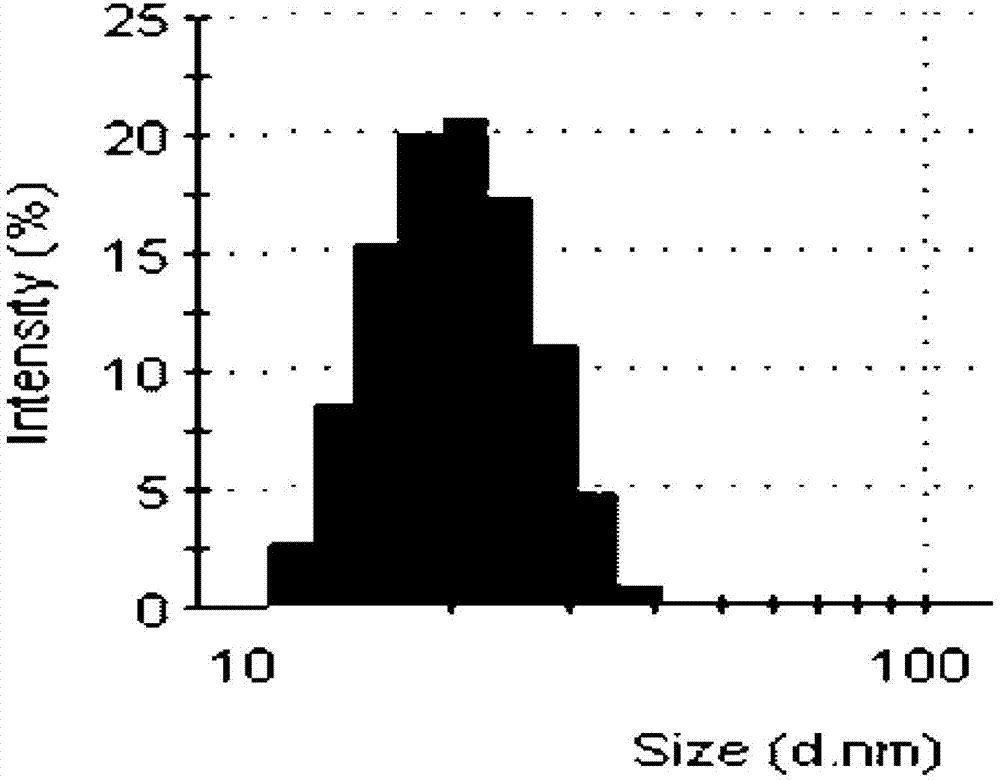

Environmentally-friendly synthetic method for metal nanoparticle

ActiveCN103071808BUniform particle sizeShorten the reduction reaction timeNanotechnologyDipotassium phosphateNutrient solution

The invention discloses an environmentally-friendly synthetic method for the metal nanoparticle, and belongs to the field of the nanometer material. The existing ingredients in a microorganism nutrient solution are used as reducing agent, stabilizing agent and morphological control agent to synthetize metal nanometer material in one step. The environmentally-friendly synthetic method for the metal nanoparticle comprises the following steps of: (1) blending a reducing stable morphology control agent solution, and meanwhile, adding sodium chloride or dipotassium phosphate; (2) regulating the pH (potential of hydrogen) value of the solution to 2-13; (3) adding the soluble metal salt water solution of the metal nanoparticle while stirring the solution; and (4) at the temperature of 15-50DEG C, reacting for 5 seconds to 24 hours to obtain the metal nanoparticle. The environmentally-friendly synthetic method for the metal nanoparticle, which is disclosed by the invention, has the moderate reaction condition, short synthesis time and low production cost, the particle diameter of the obtained metal nanoparticle is 1-100nm, the particle diameter of the nanometer material is relatively even, and the morphology of the generated metal nanoparticle can be controlled. Compared with the biosynthesis method, the environmentally-friendly synthetic method for the metal nanoparticle is simpler, efficient and environmentally-friendly.

Owner:上海穗杉实业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com