Method for increasing heating speed of material in metal vacuum smelting reduction still and reduction still

A technology of vacuum smelting and heating speed, applied in the field of reduction kettle, can solve the problems of limited production capacity, long heat transfer time, low thermal conductivity, etc., and achieve the effects of improving production capacity, high heat utilization rate, and increasing heat conduction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

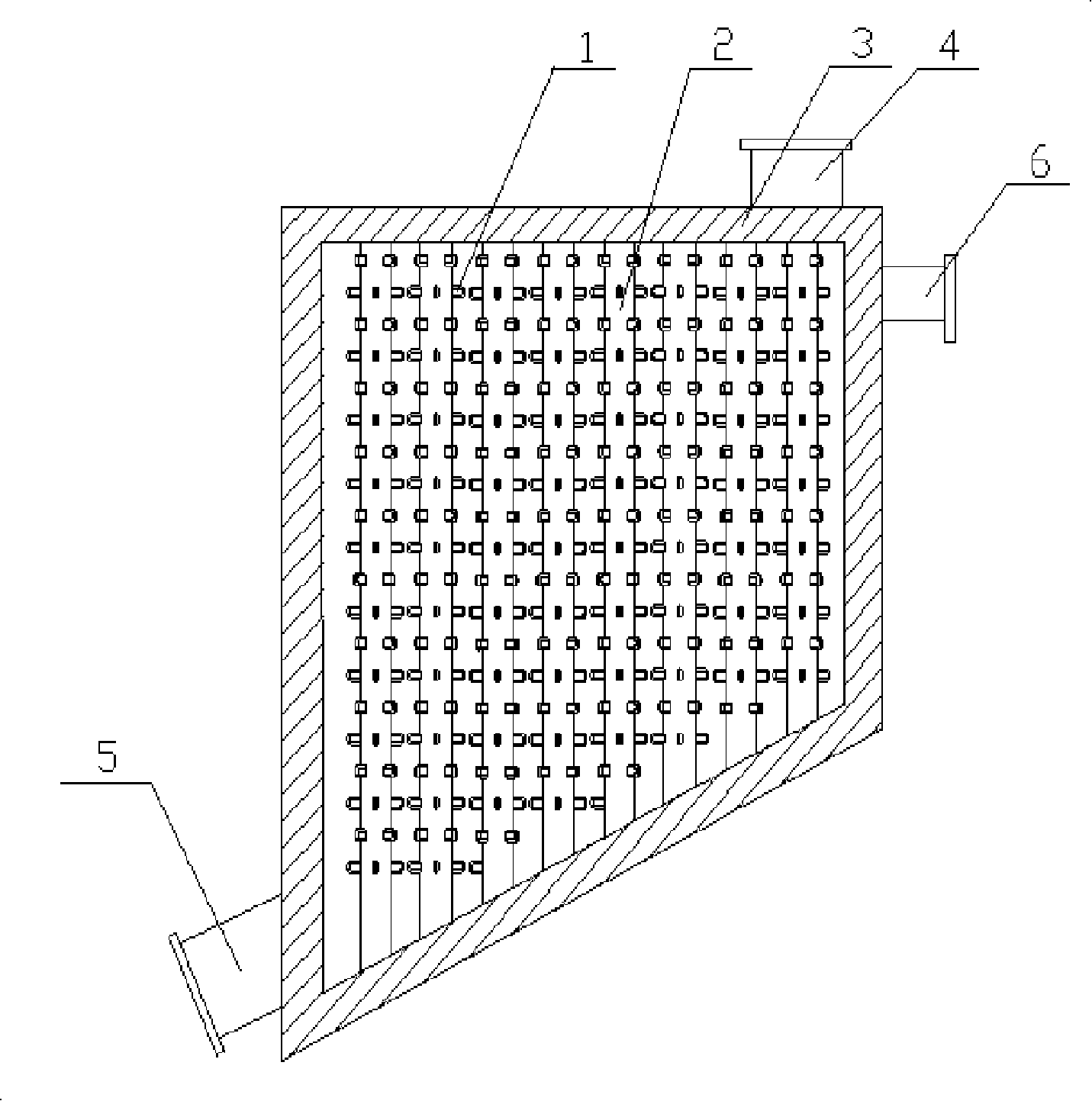

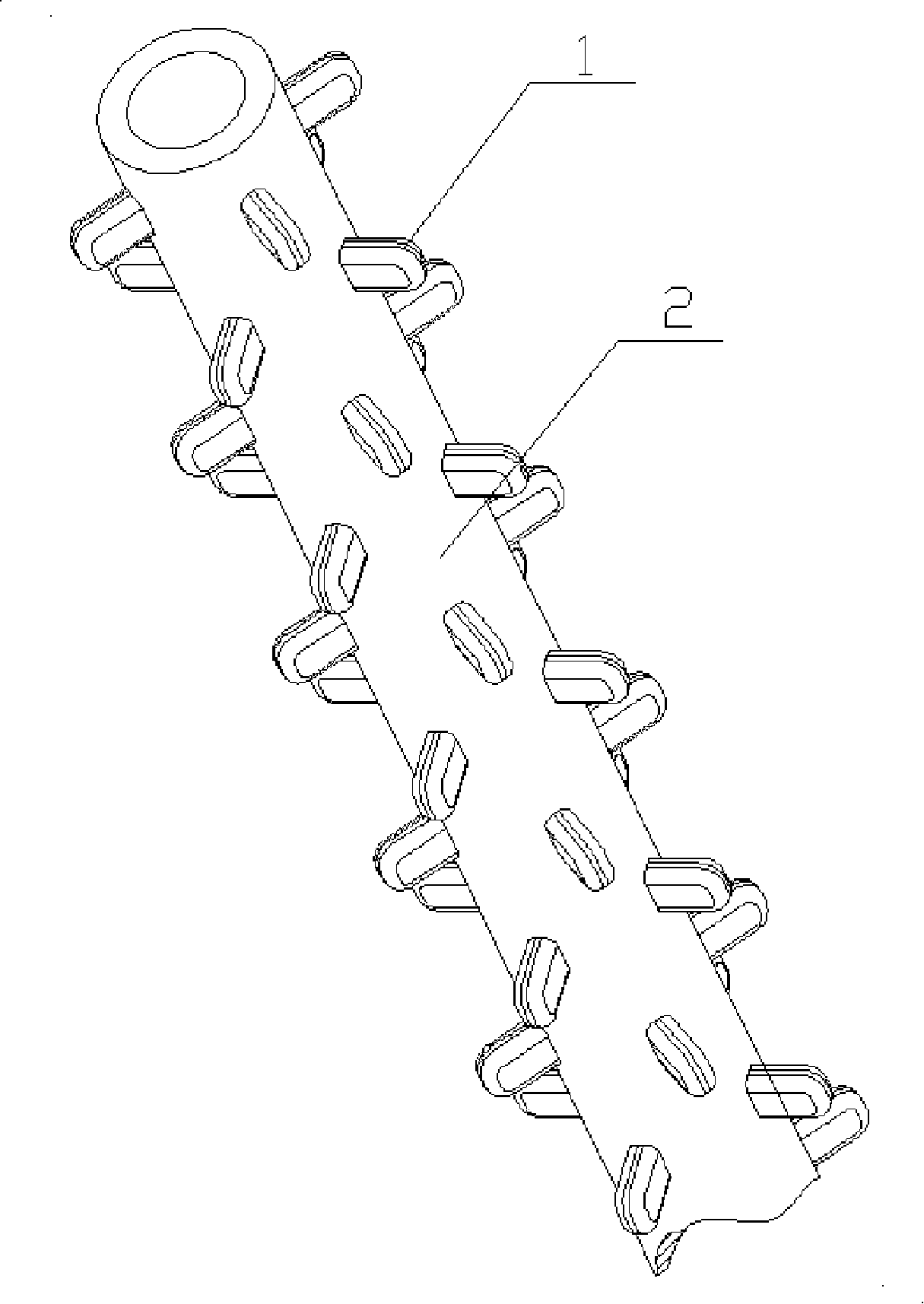

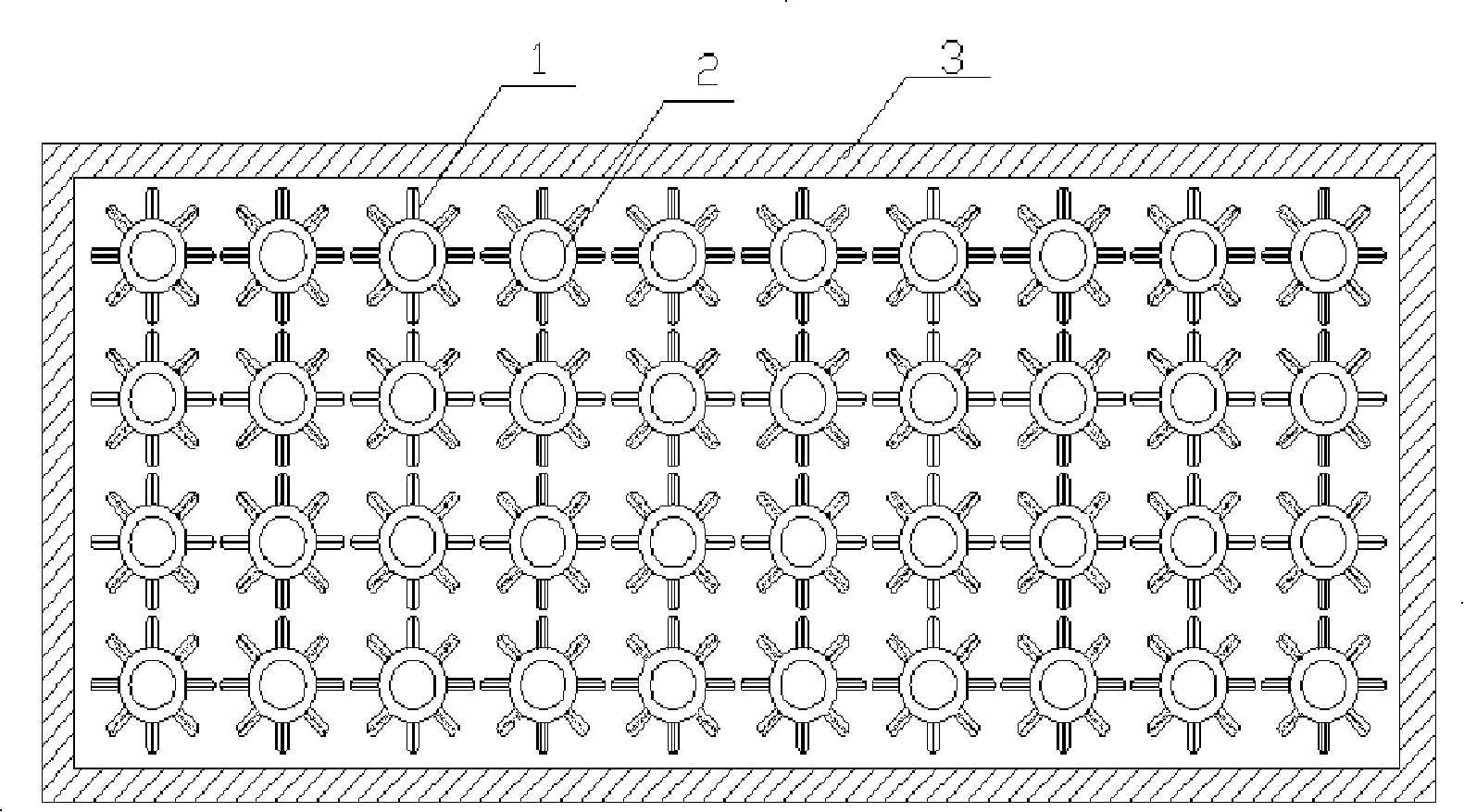

[0019] Example. A method to increase the heating rate of materials in the metal vacuum smelting reduction kettle, such as figure 1 As shown, the reduction kettle used for metal vacuum smelting is placed in the reduction furnace 8, and a group of radiation tubes arranged in an array and running through the reduction kettle are arranged in the reduction kettle, and the two ends of the radiation tubes are connected to the combustion chamber 9 in the reduction furnace. . The radiant tube 2 can be arranged vertically or horizontally. Such as figure 2 As shown, a heat conductor is installed on the radiant tube or the wall of the kettle to increase the contact area between the radiant tube and the reduced material in the reduction kettle, reduce the heat conduction distance between the radiant tube and the reduced material, and increase the heating rate of the reduced material. The shape, quantity and arrangement of the heat conductor 1 are arbitrary, such as figure 2 As shown,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com